Patents

Literature

38results about How to "Enhanced pull-out load bearing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

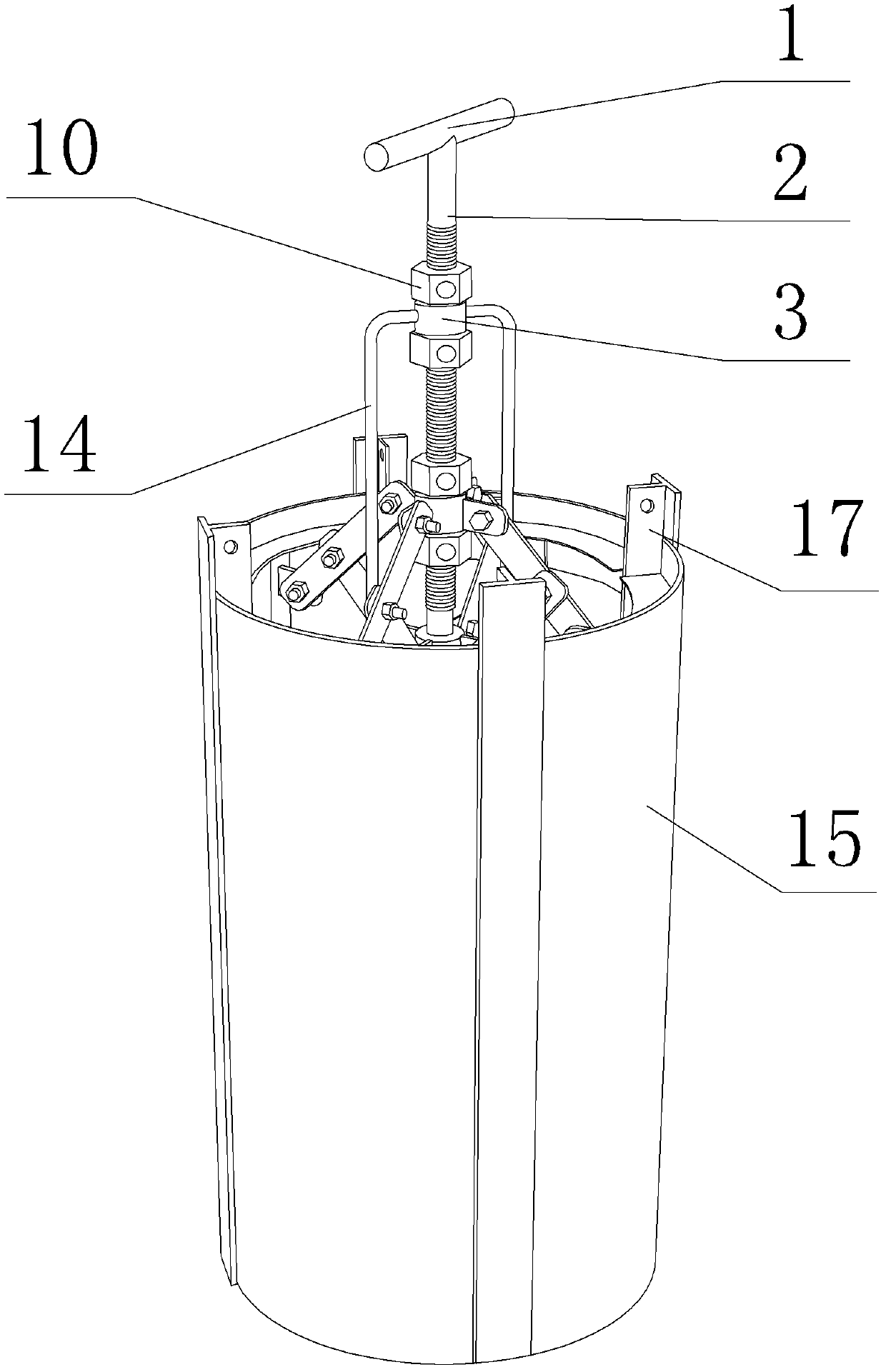

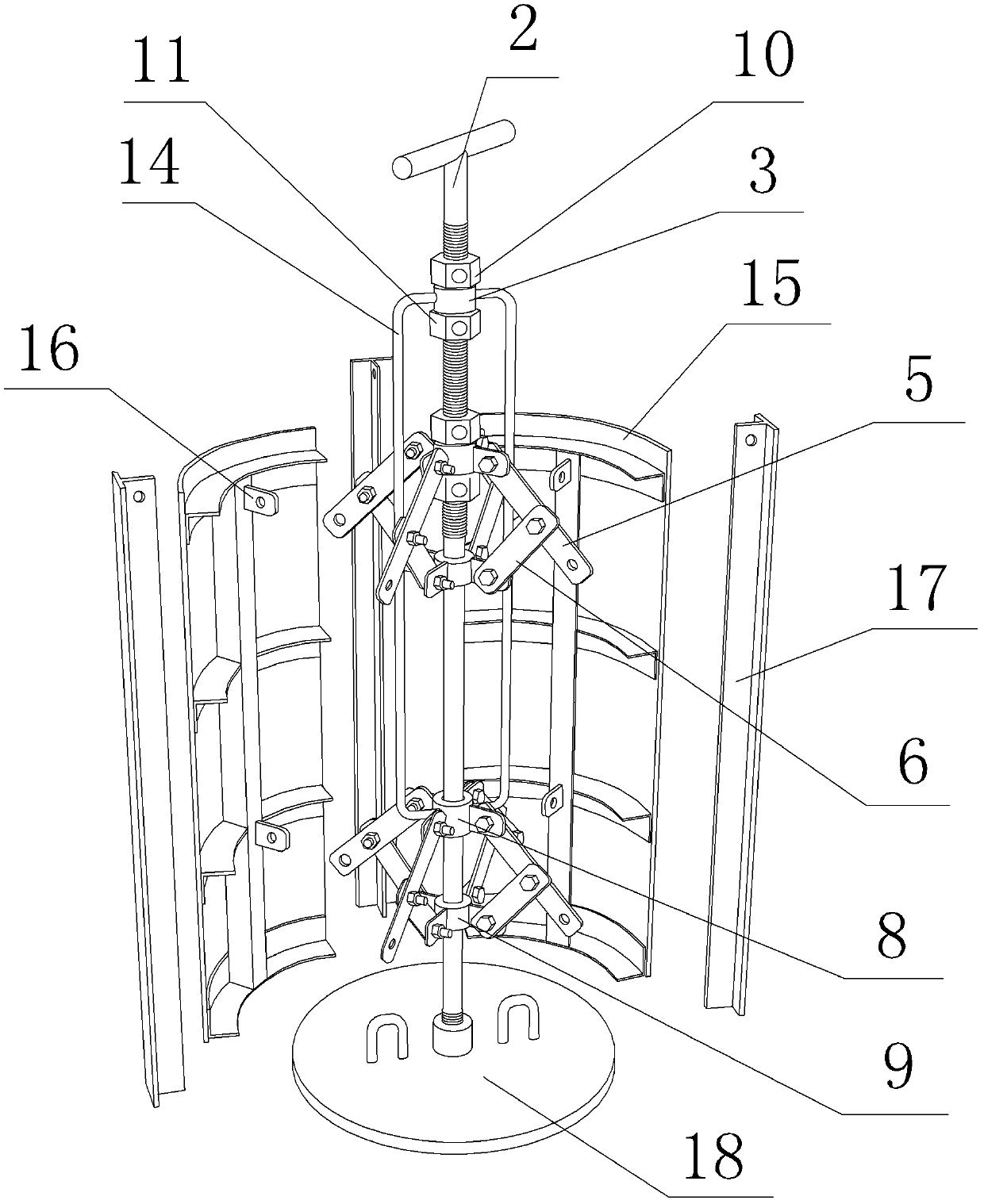

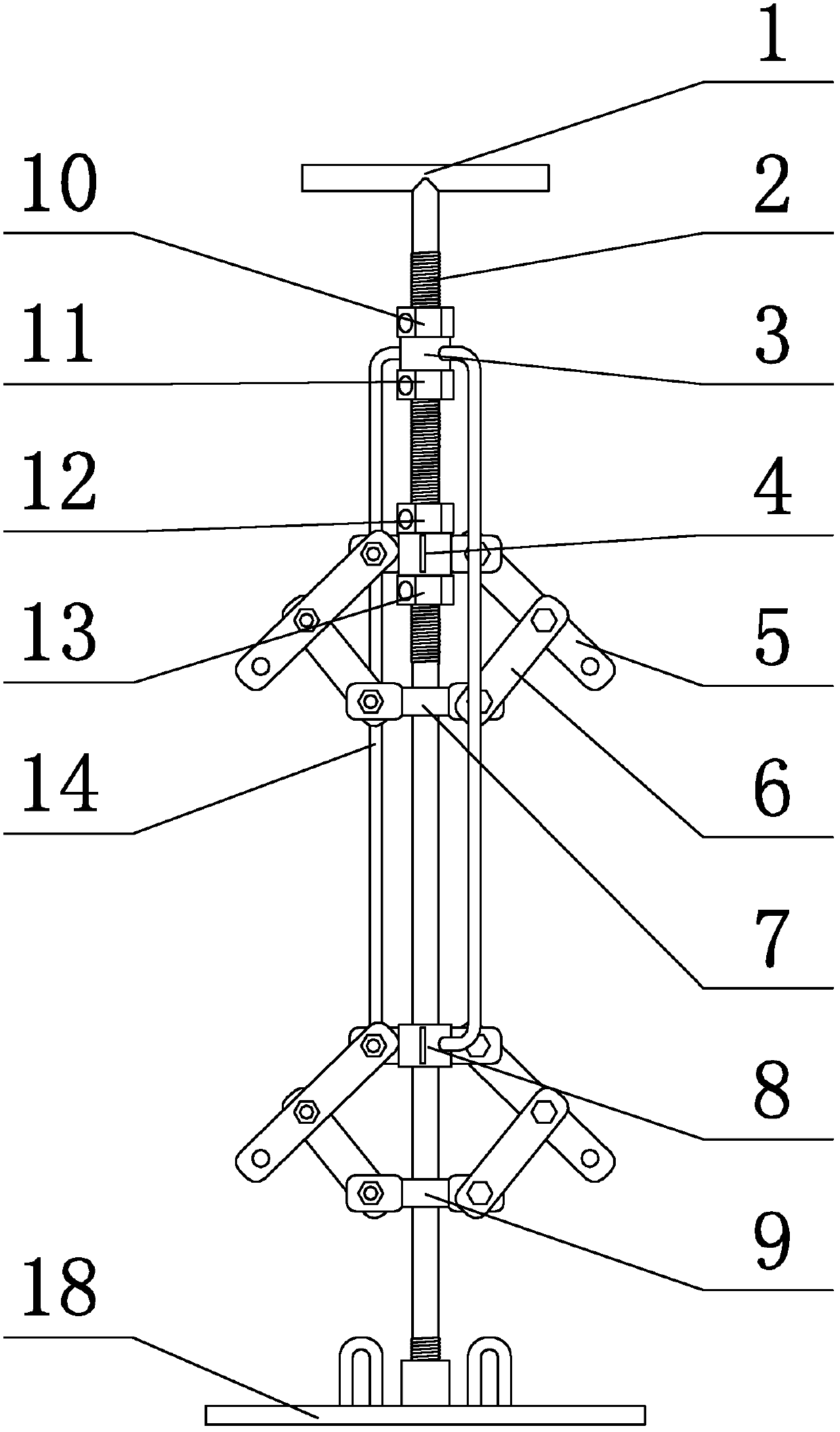

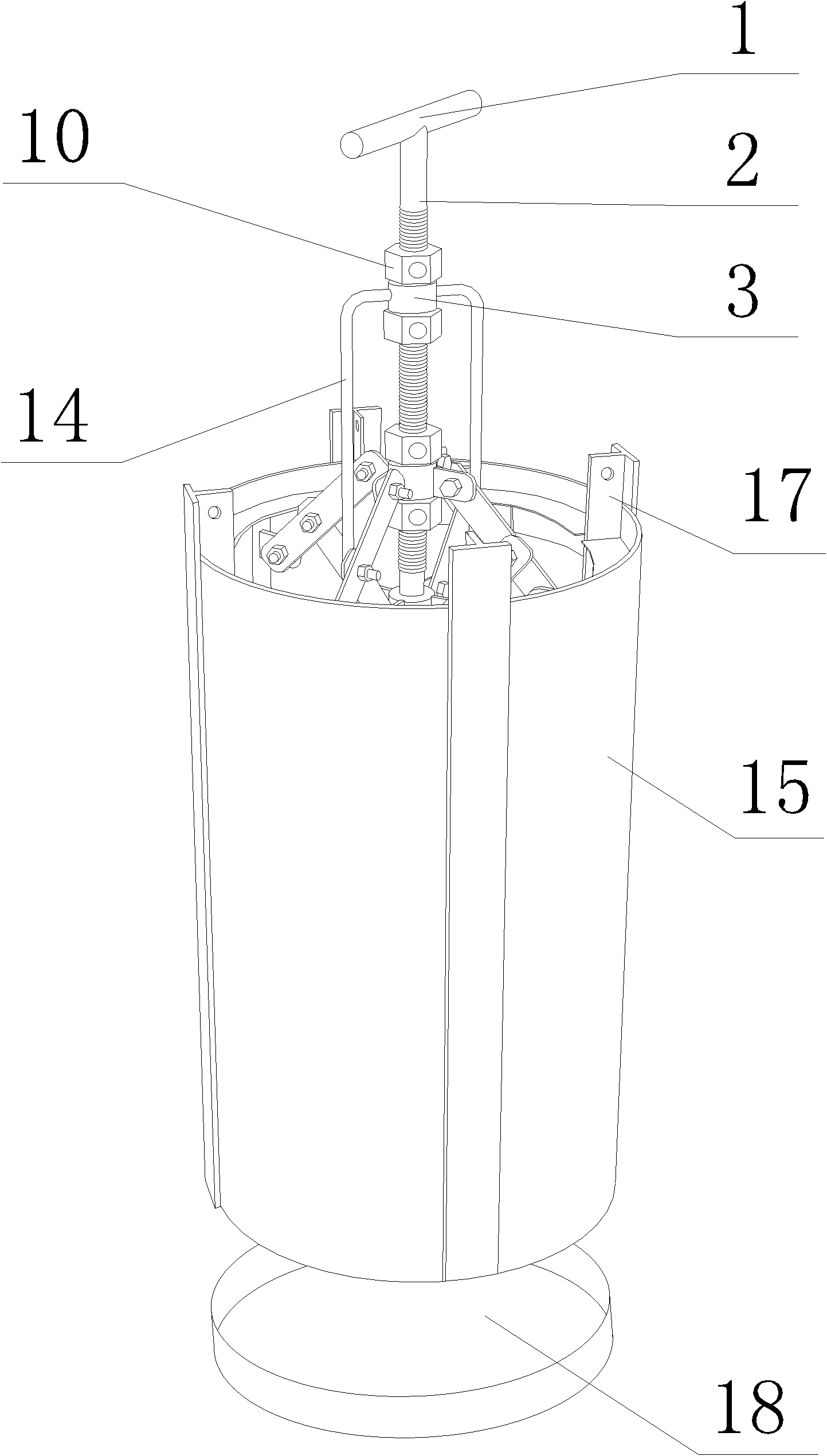

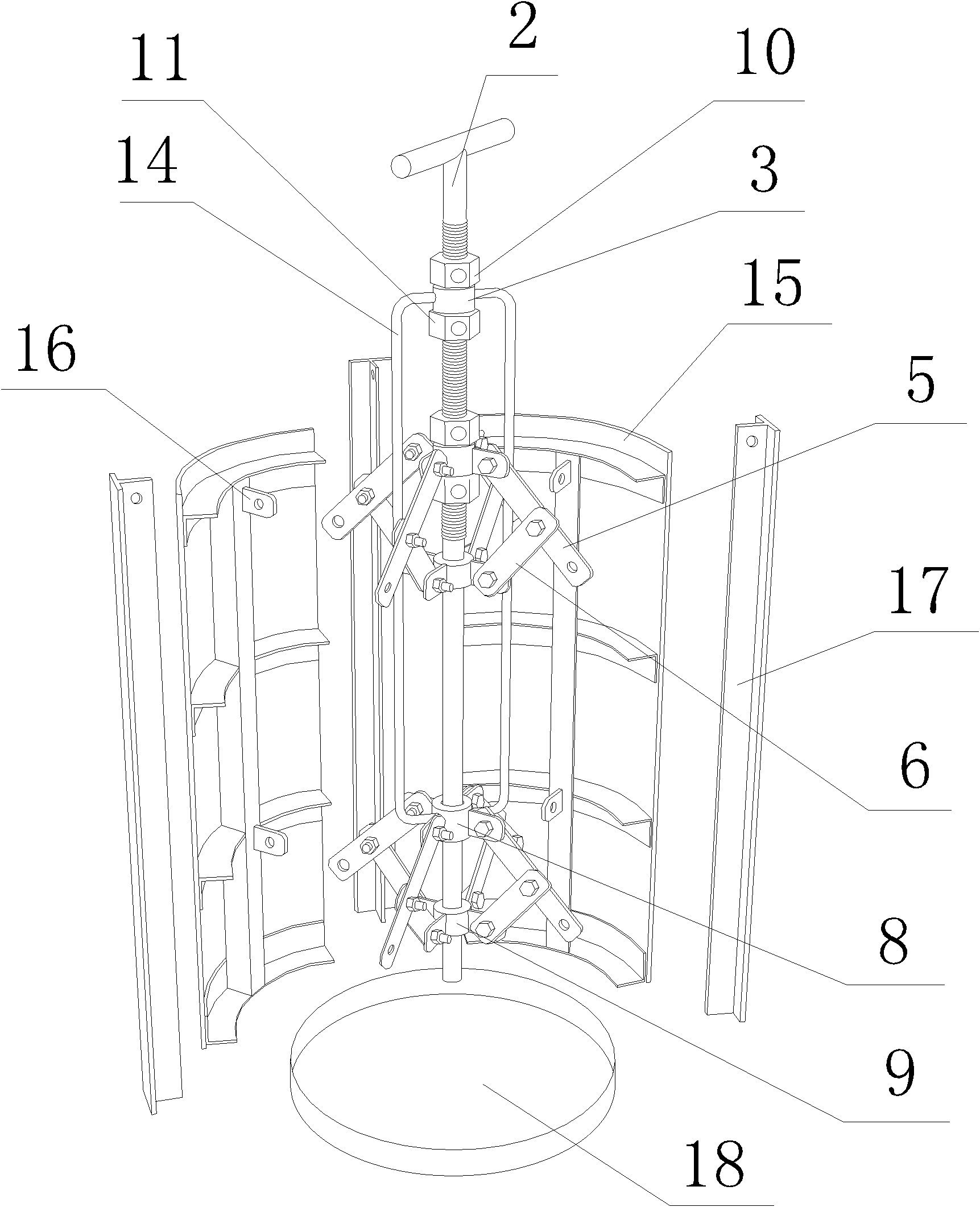

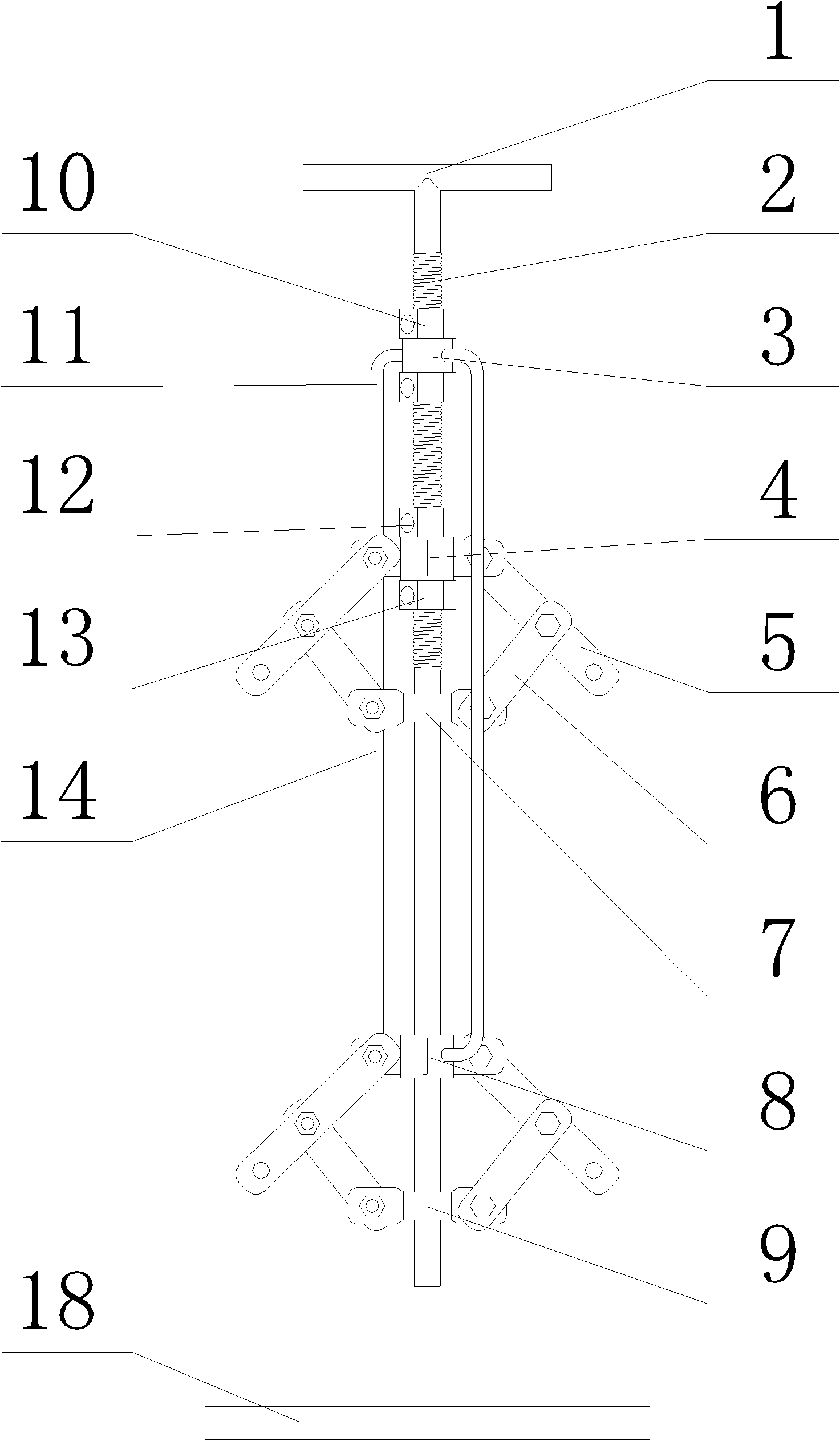

Equipment base pre-reservation round anchor bolt hole die

ActiveCN102433989AFlexible supportFlexible demolitionForms/shuttering/falseworksEngineeringScrew thread

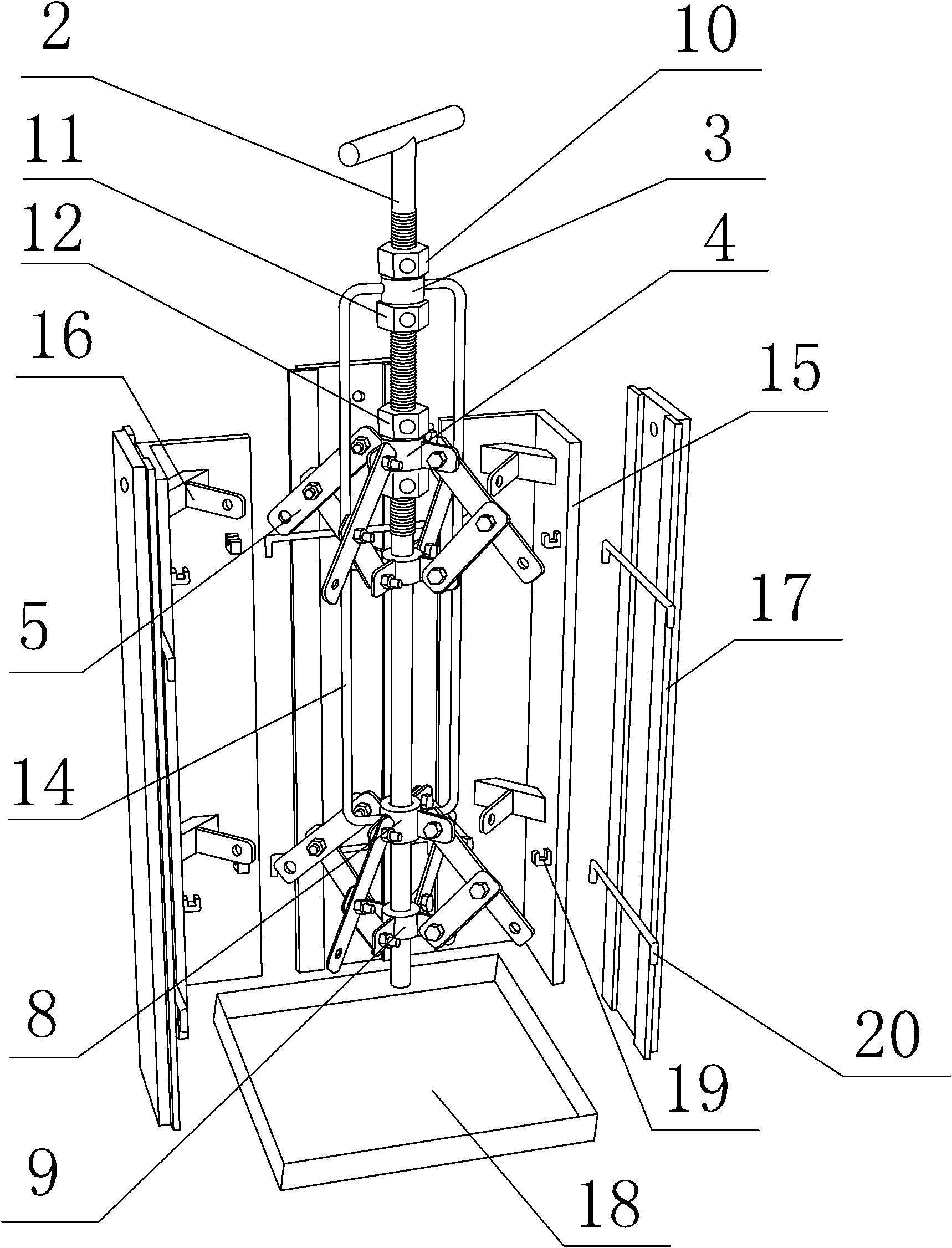

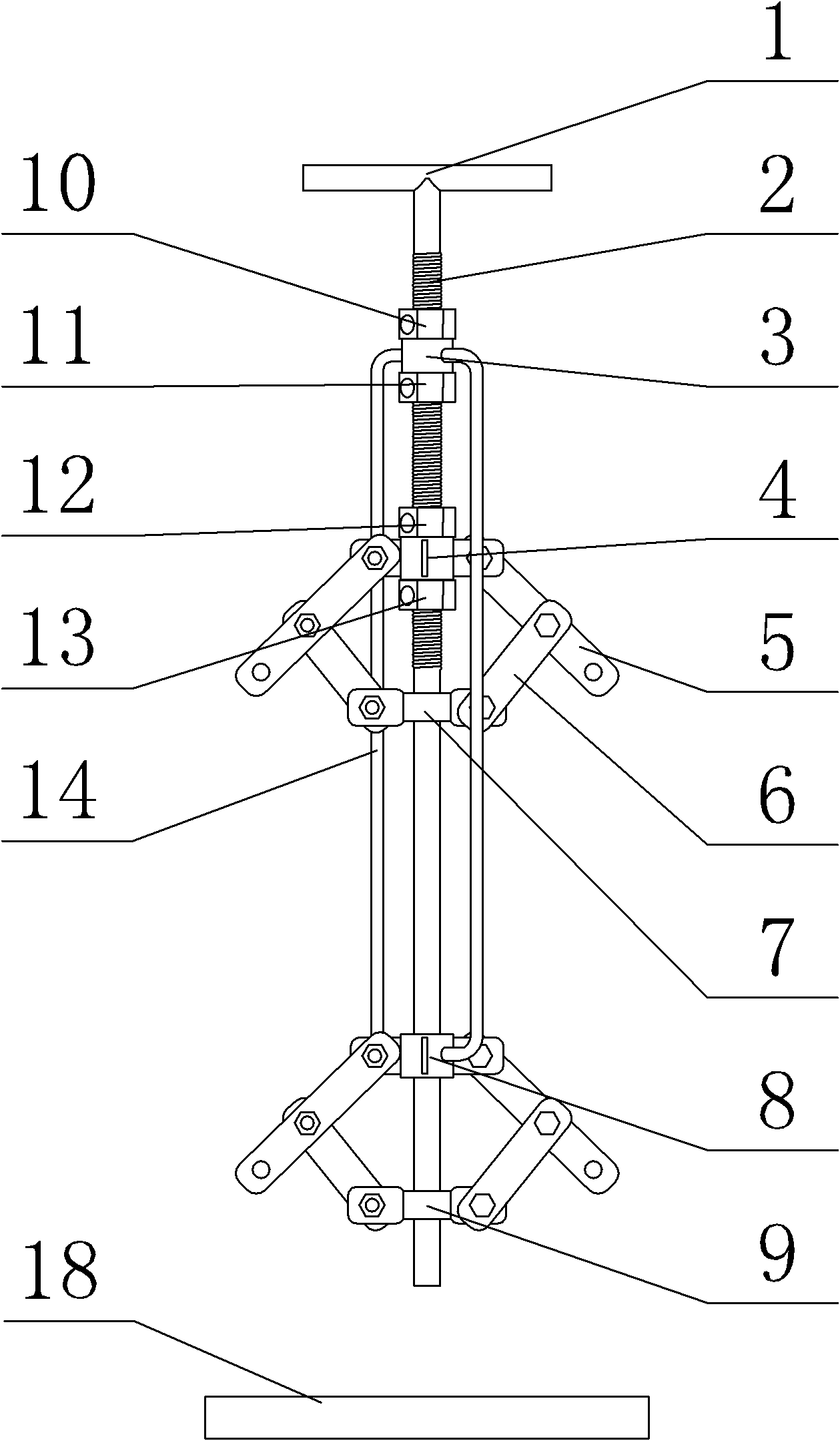

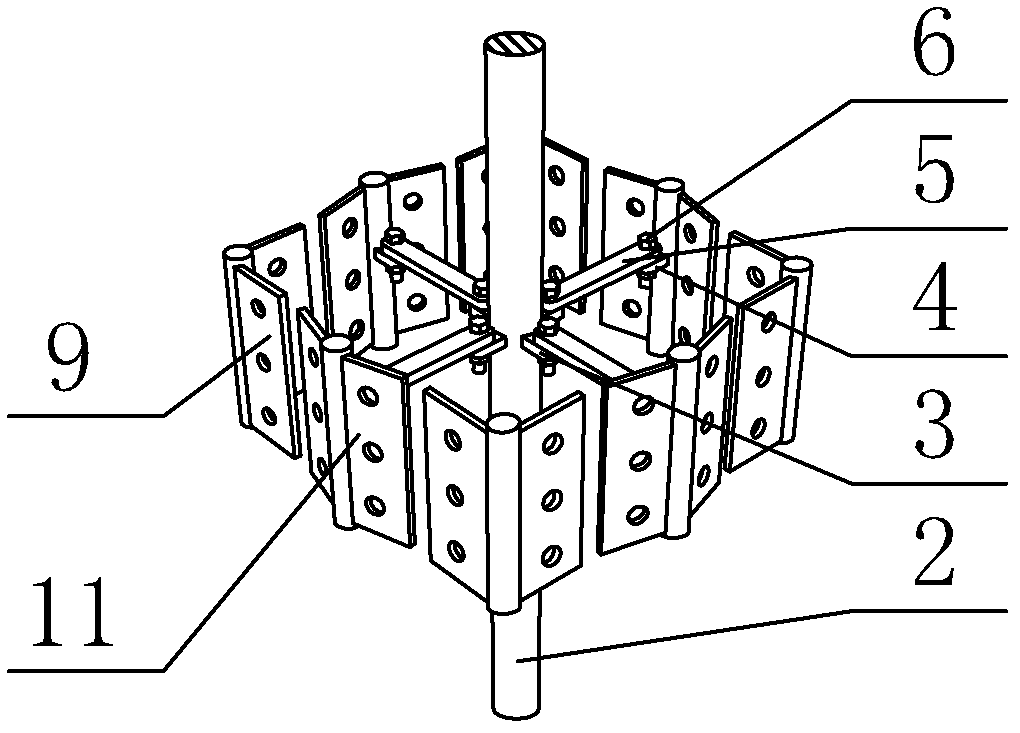

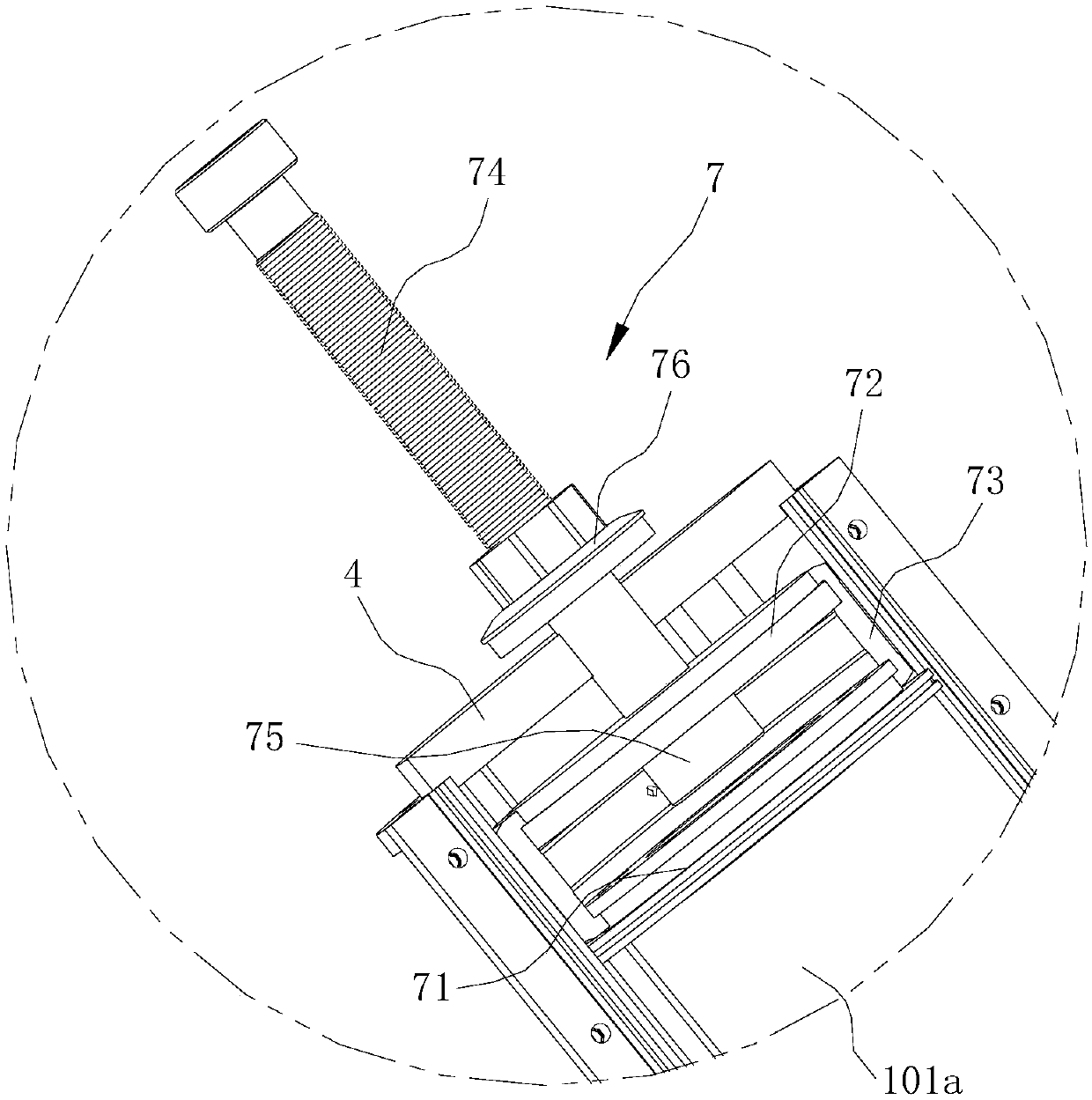

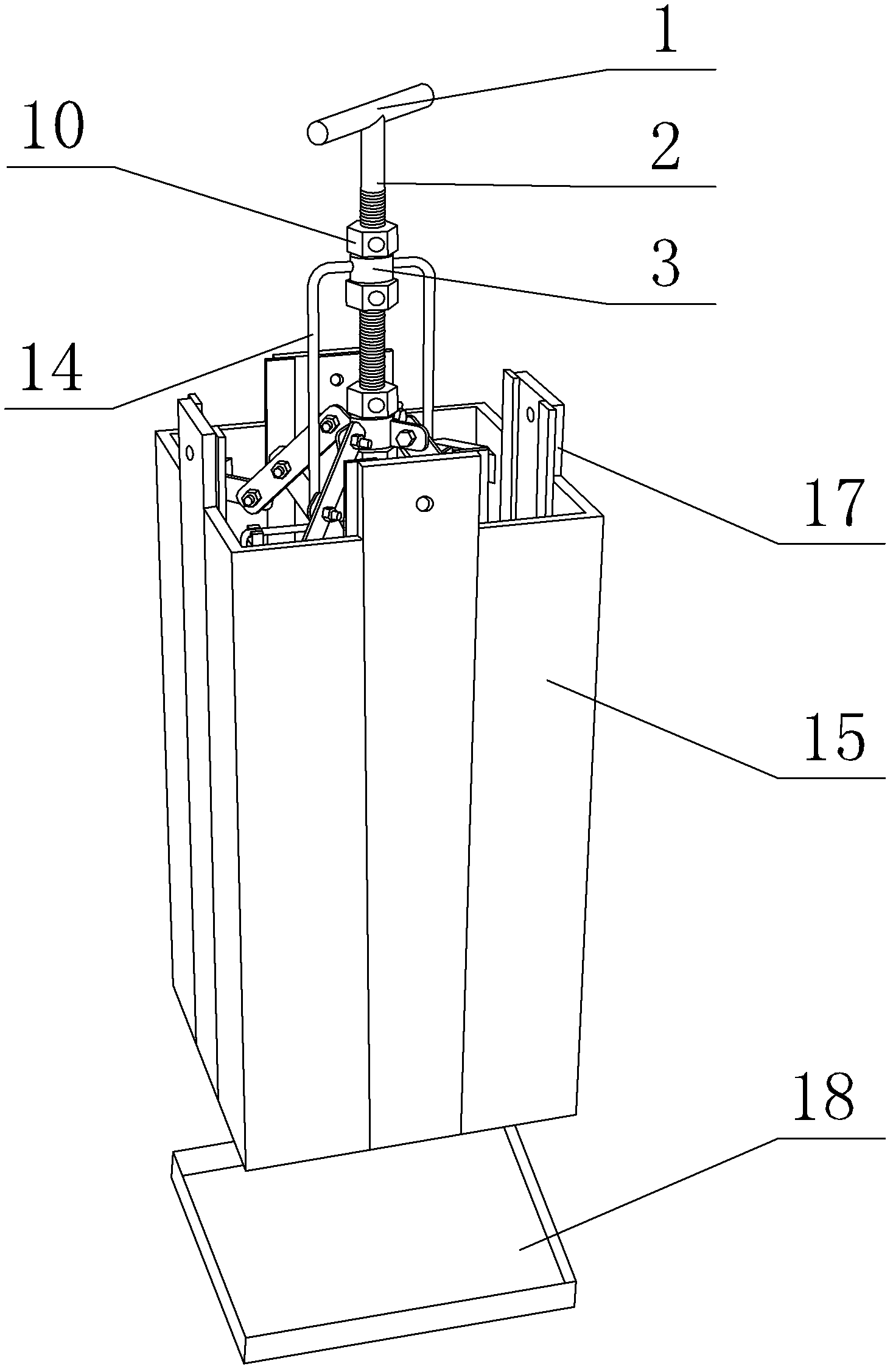

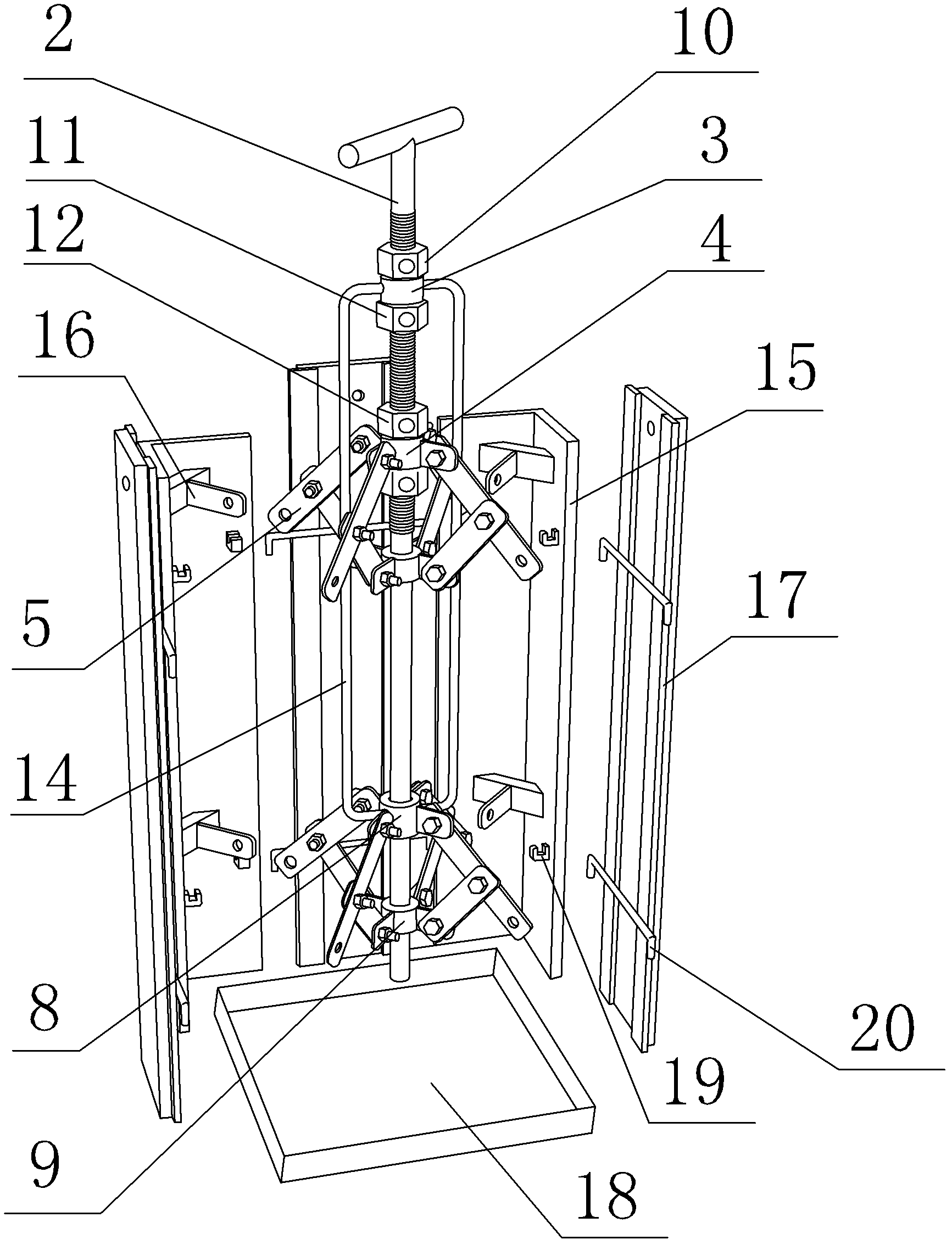

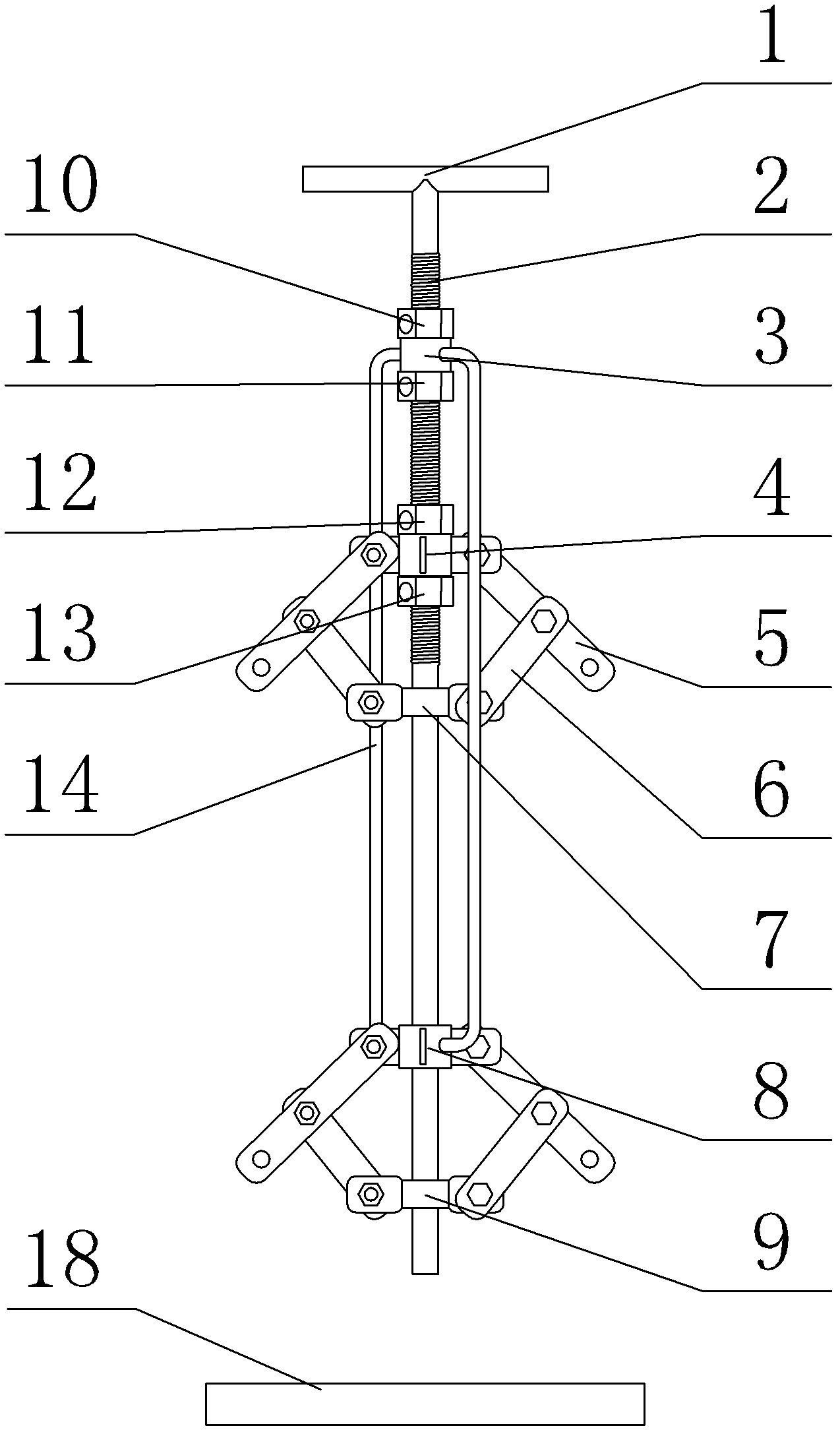

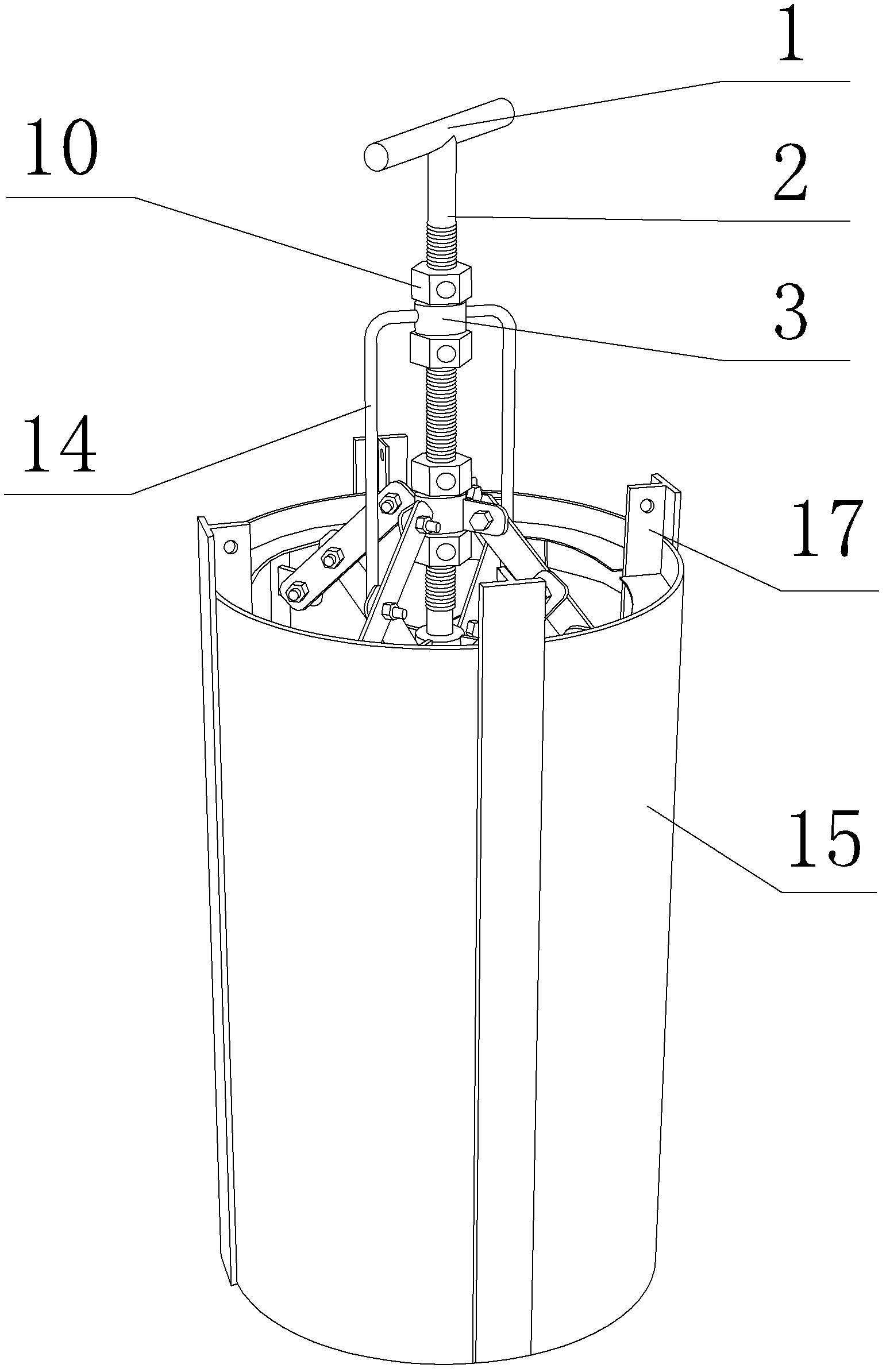

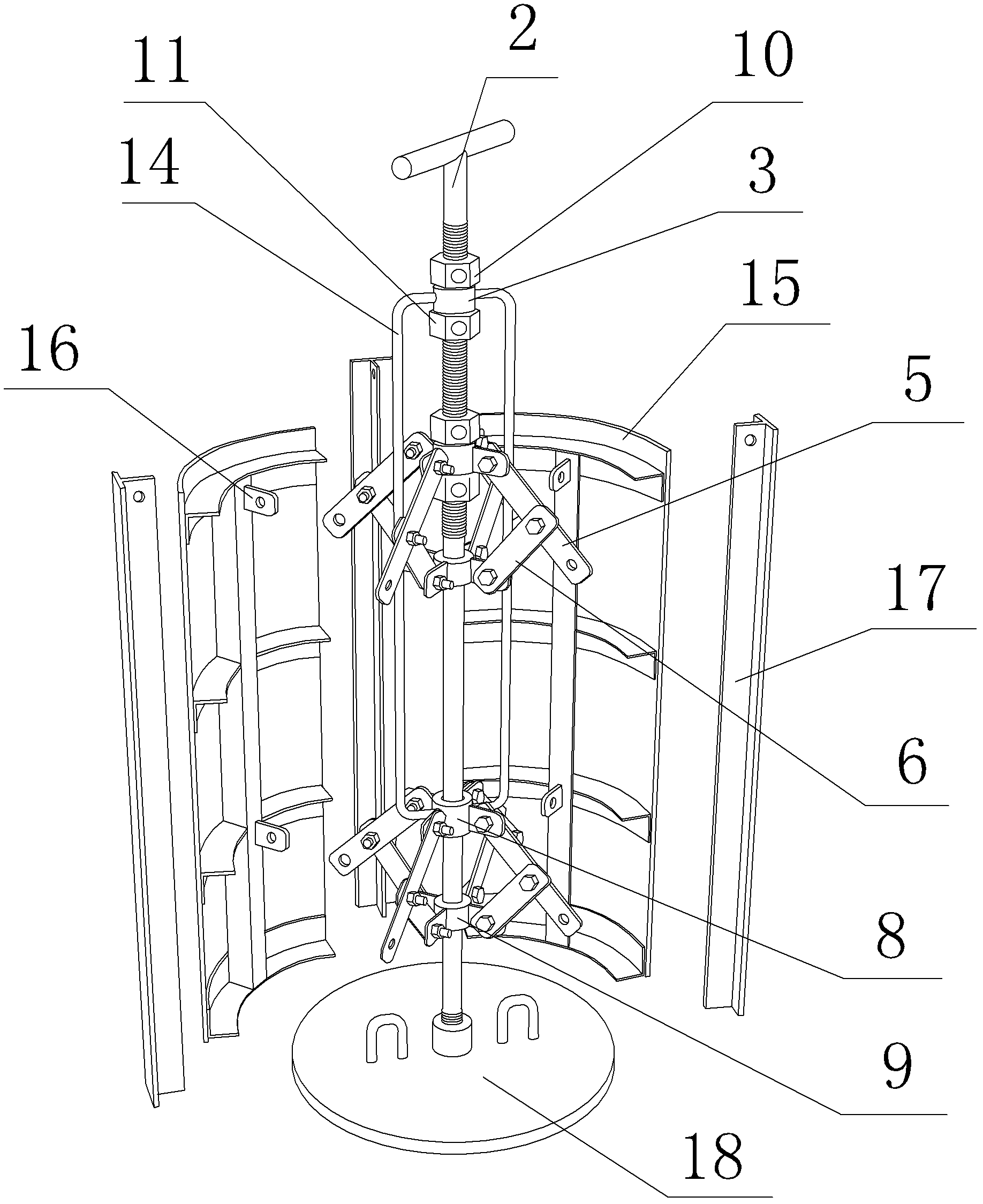

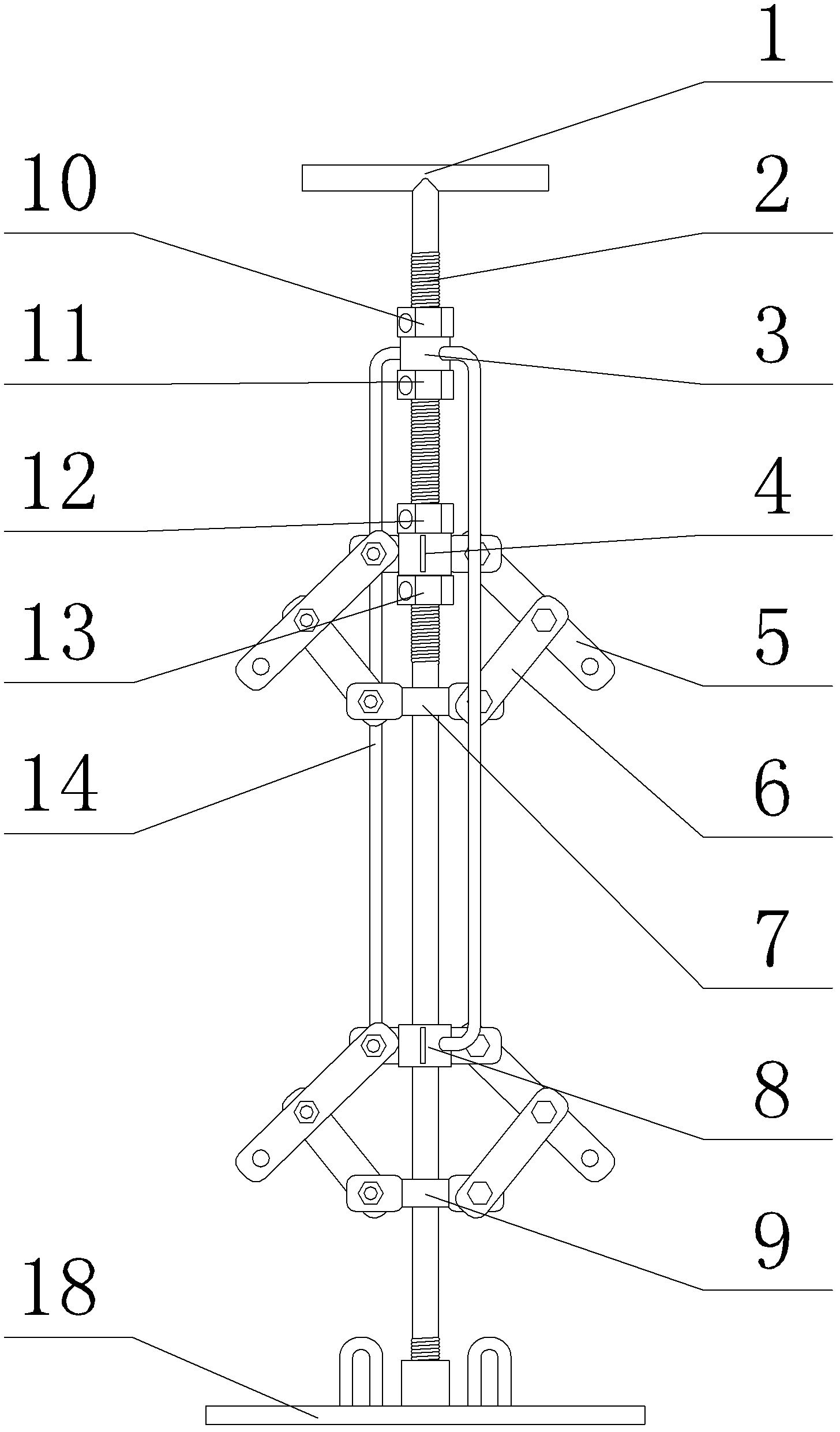

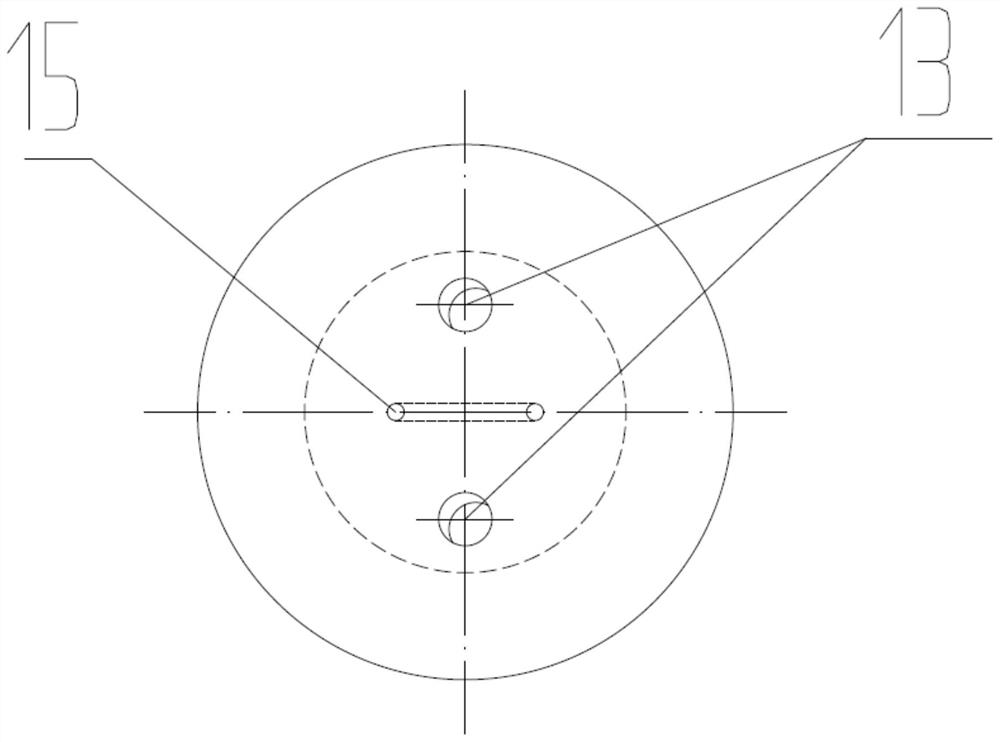

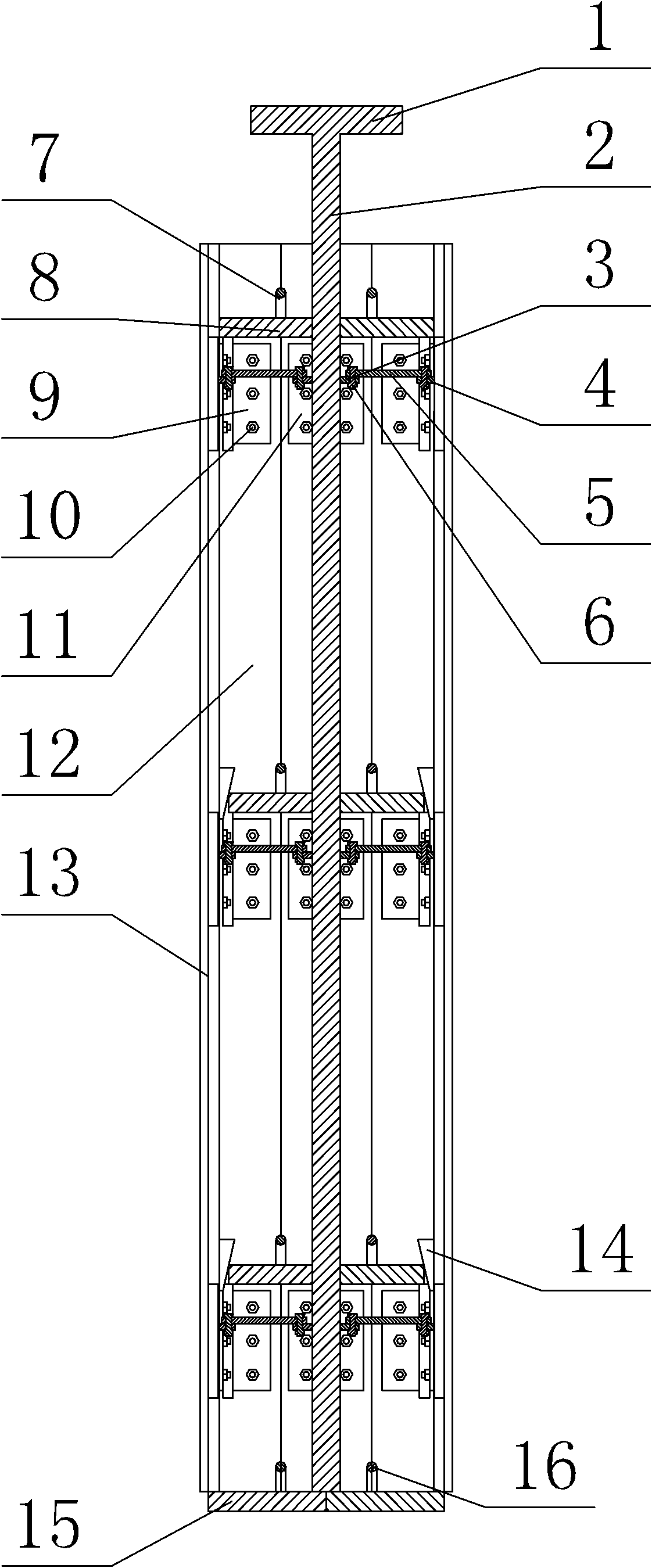

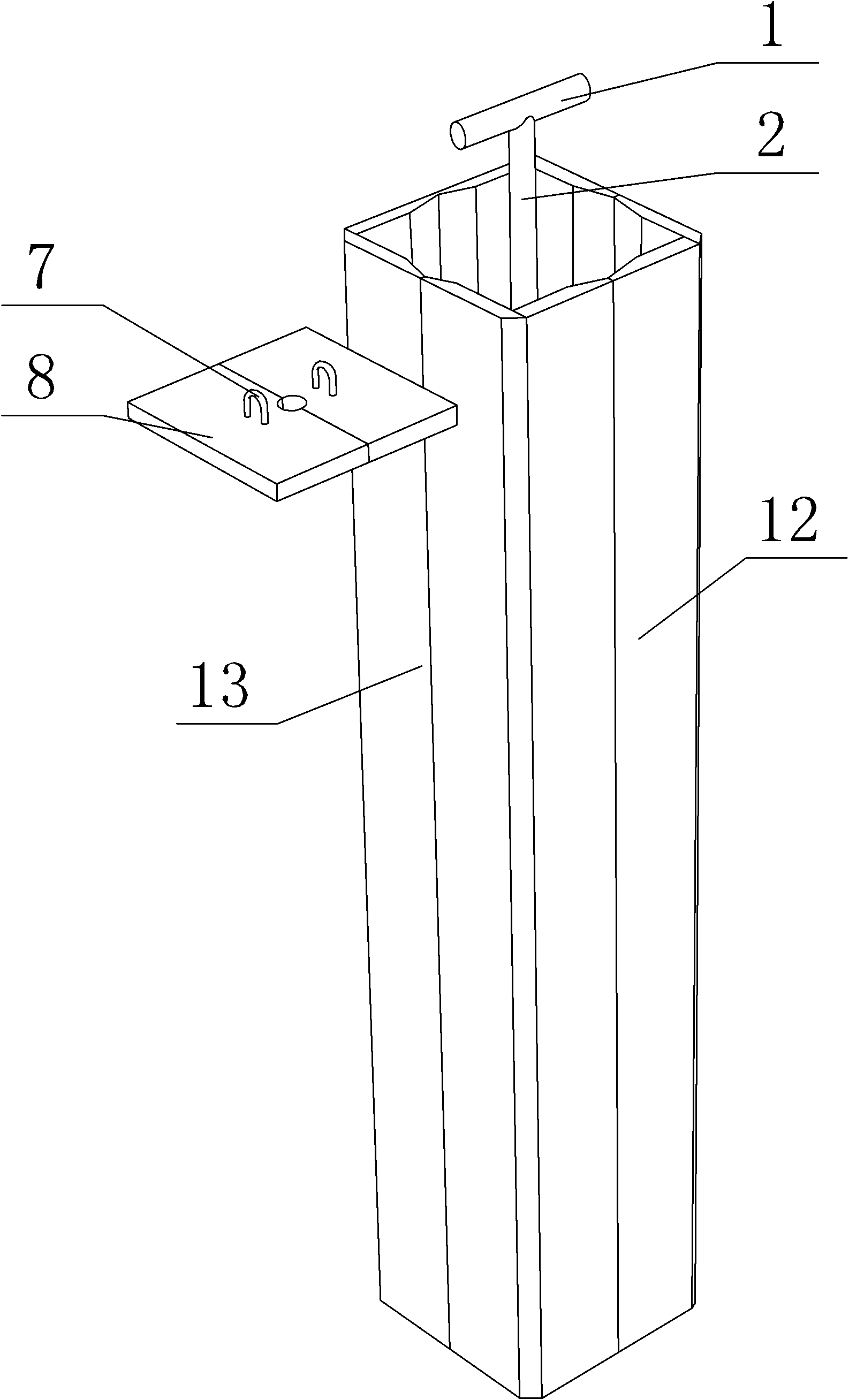

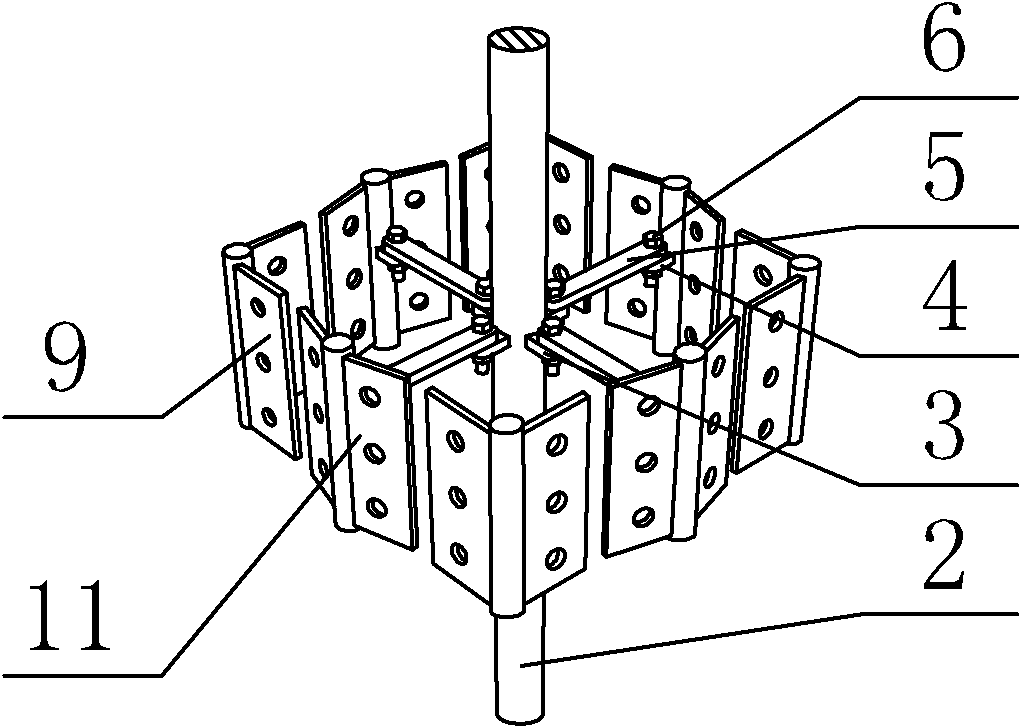

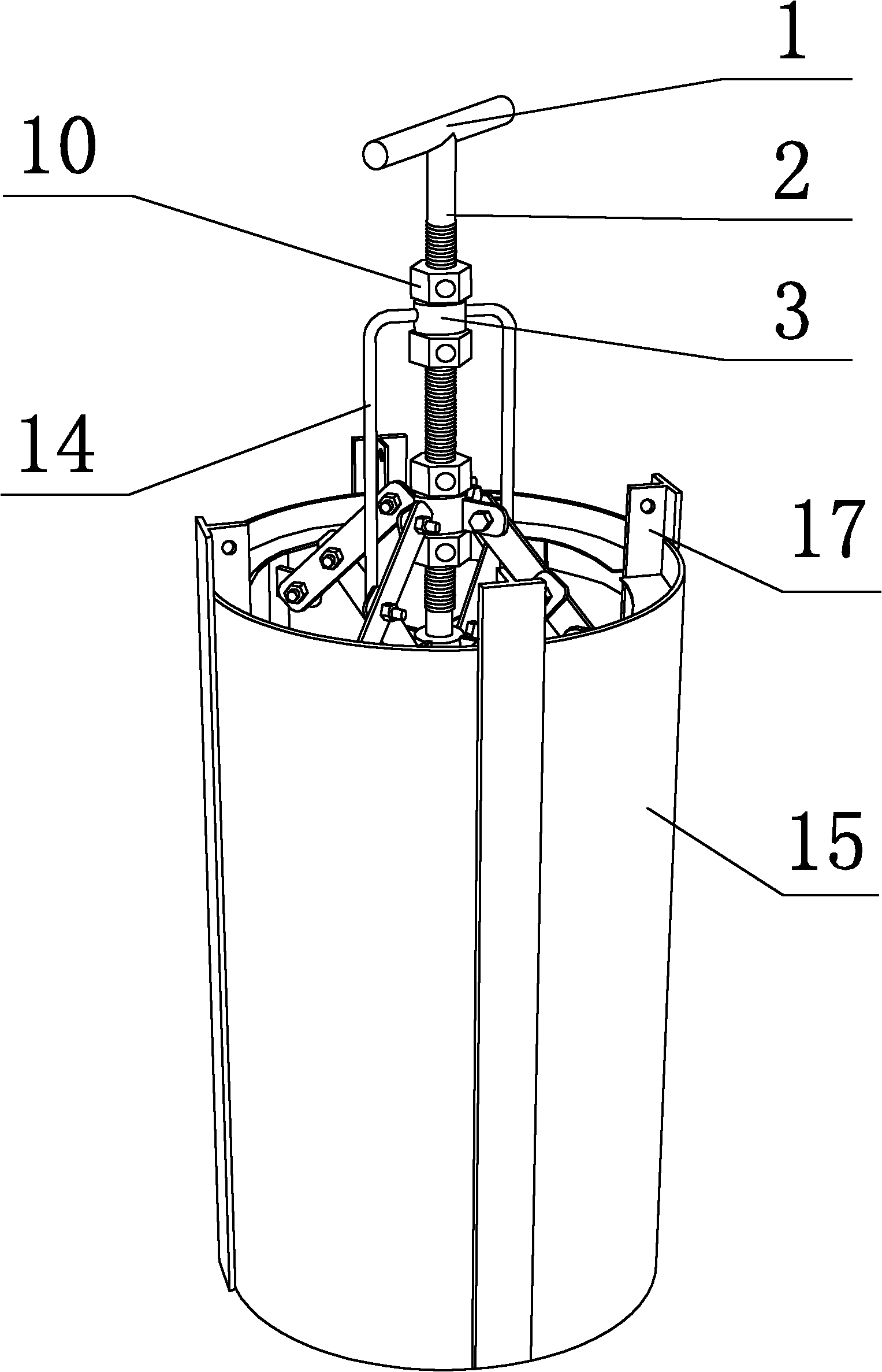

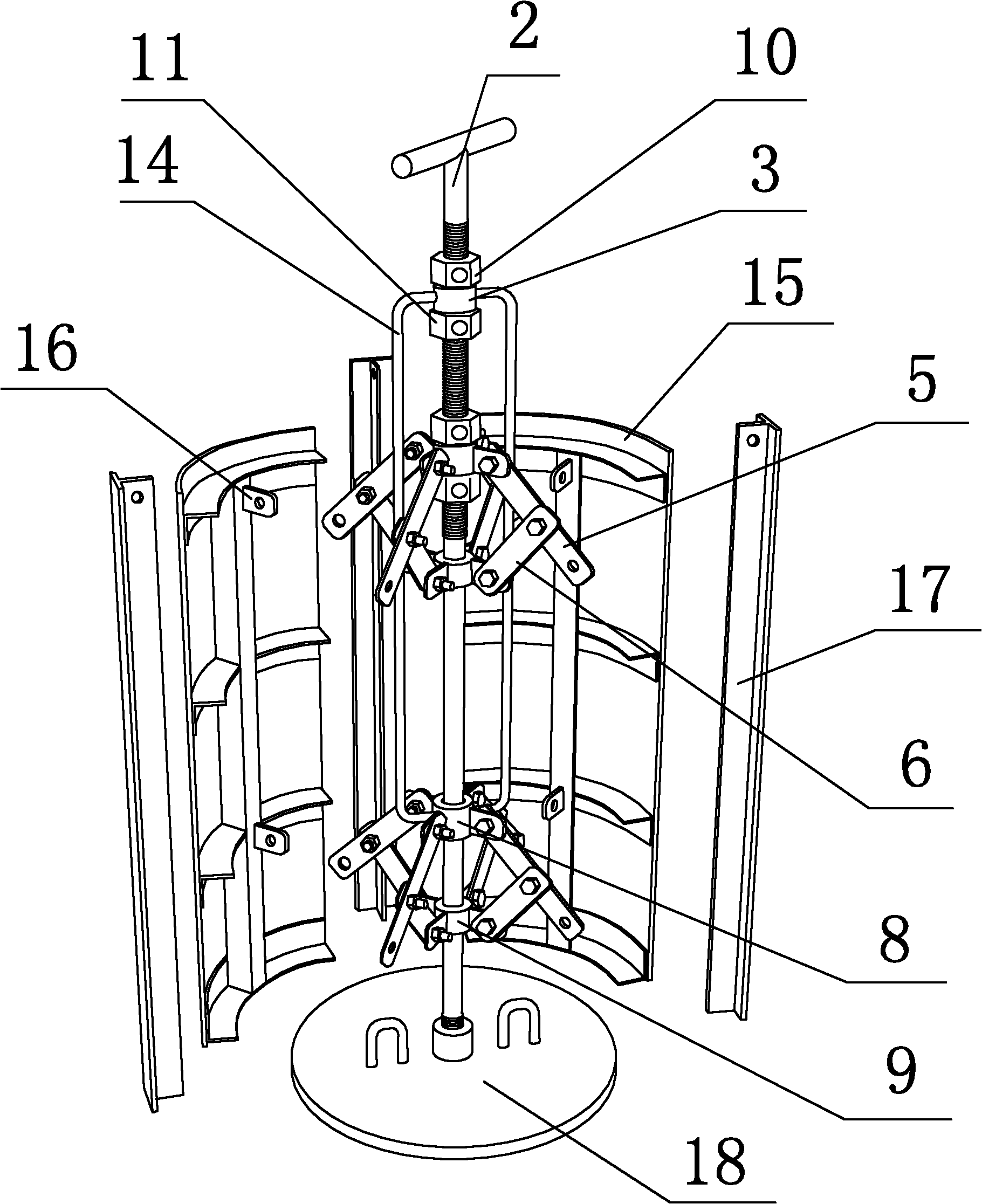

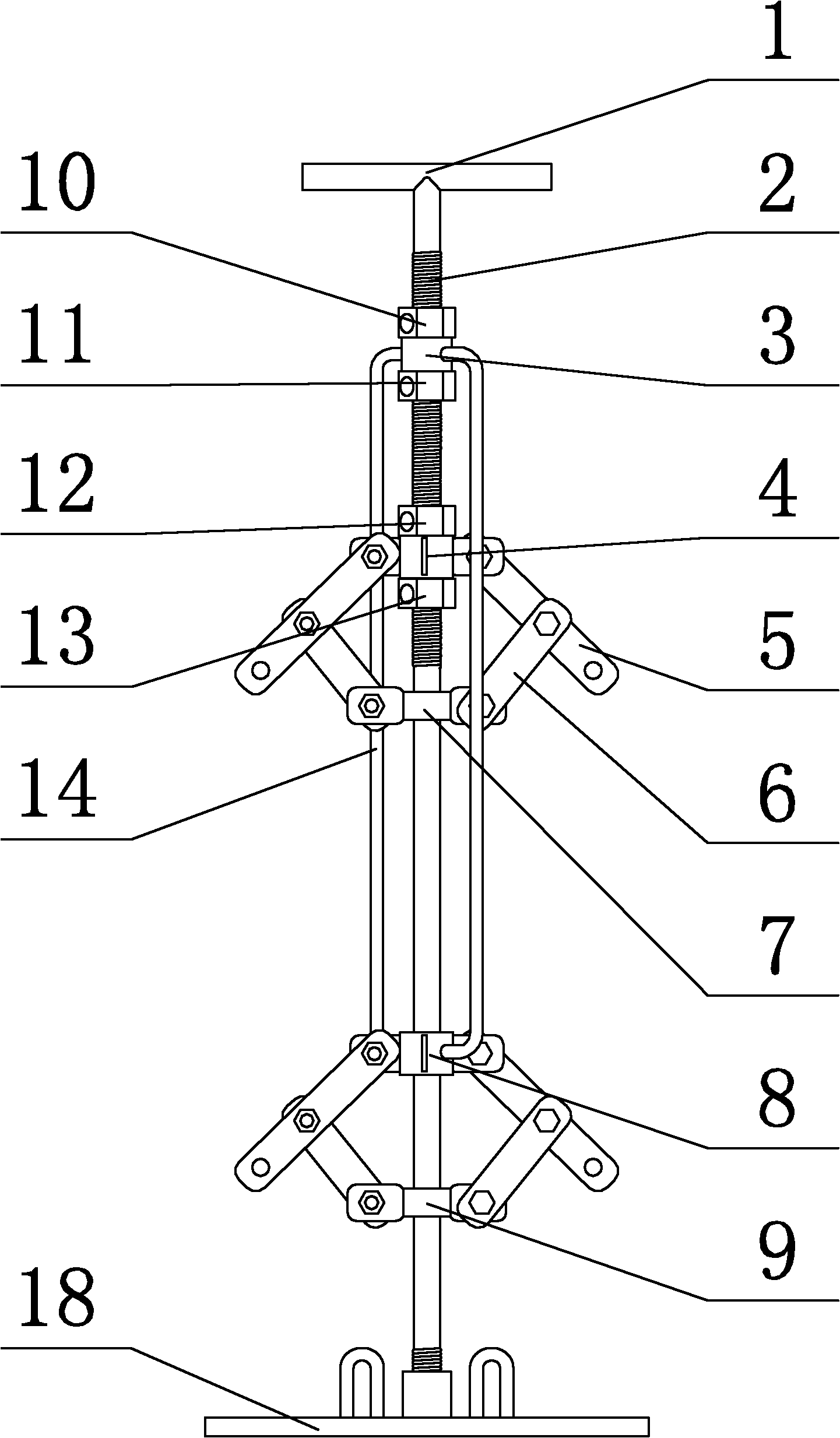

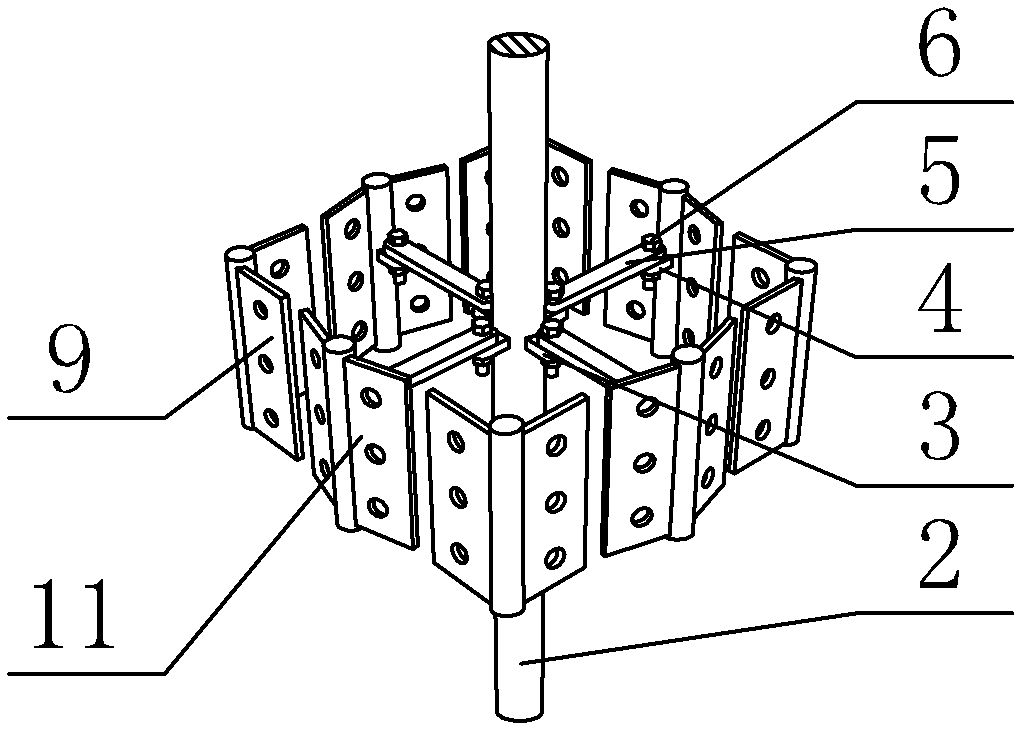

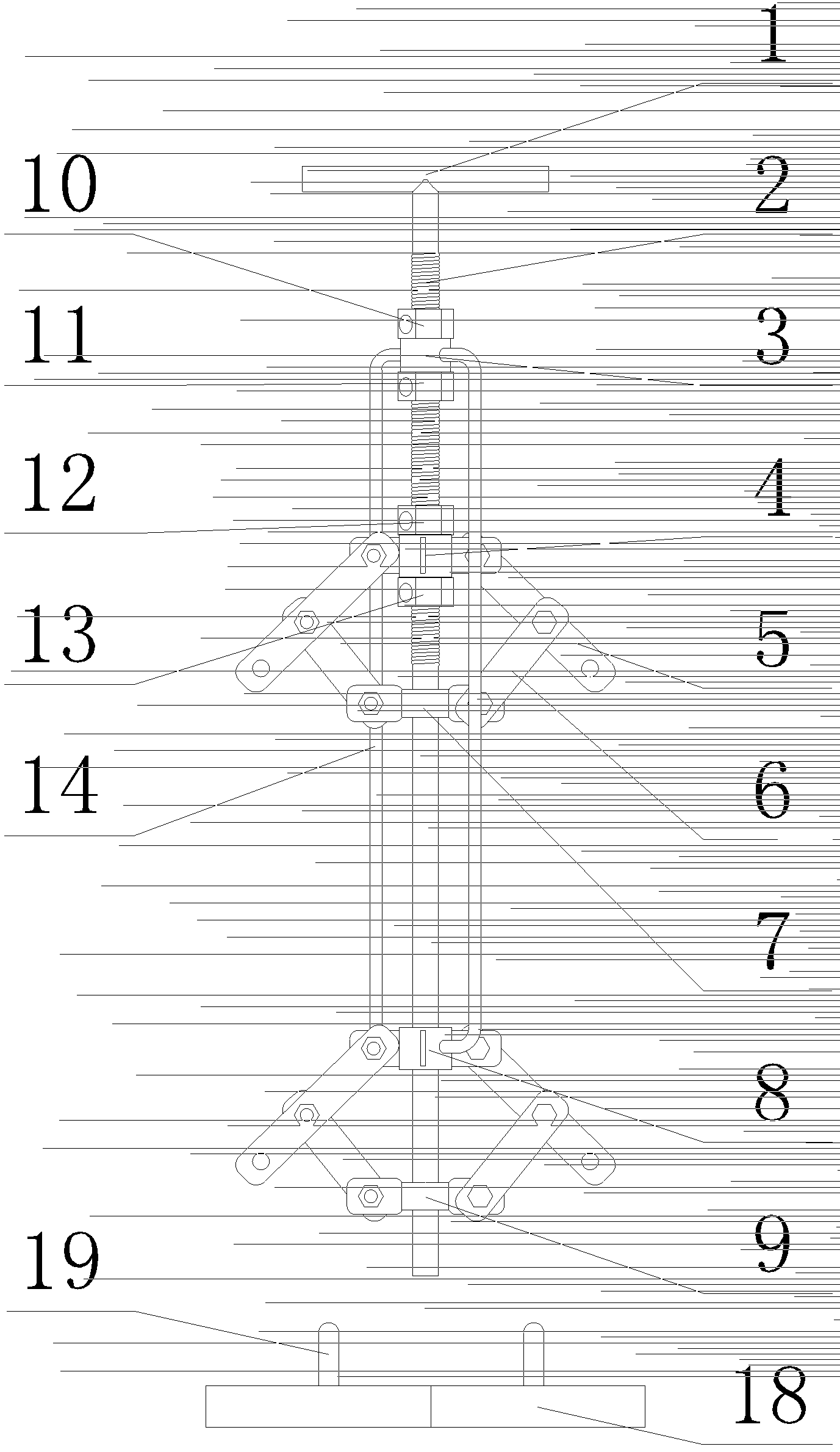

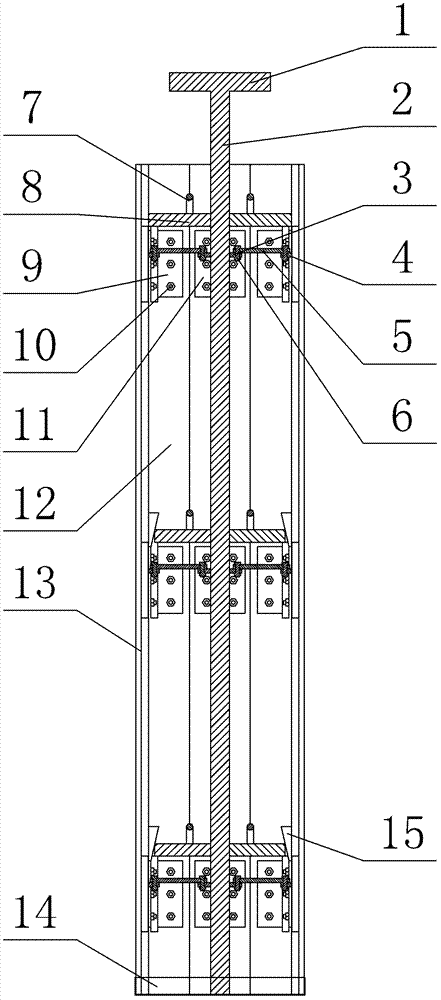

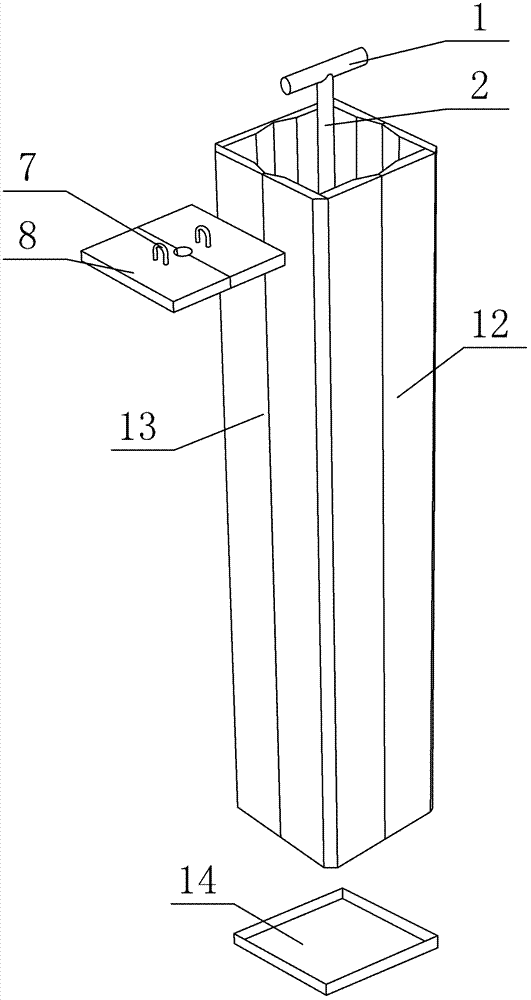

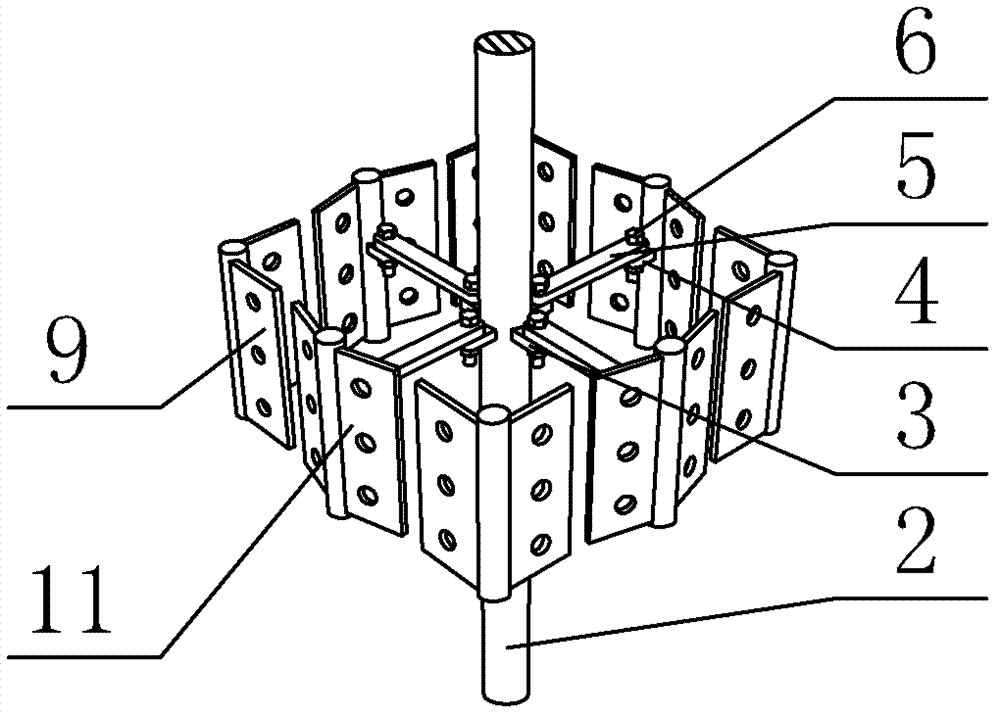

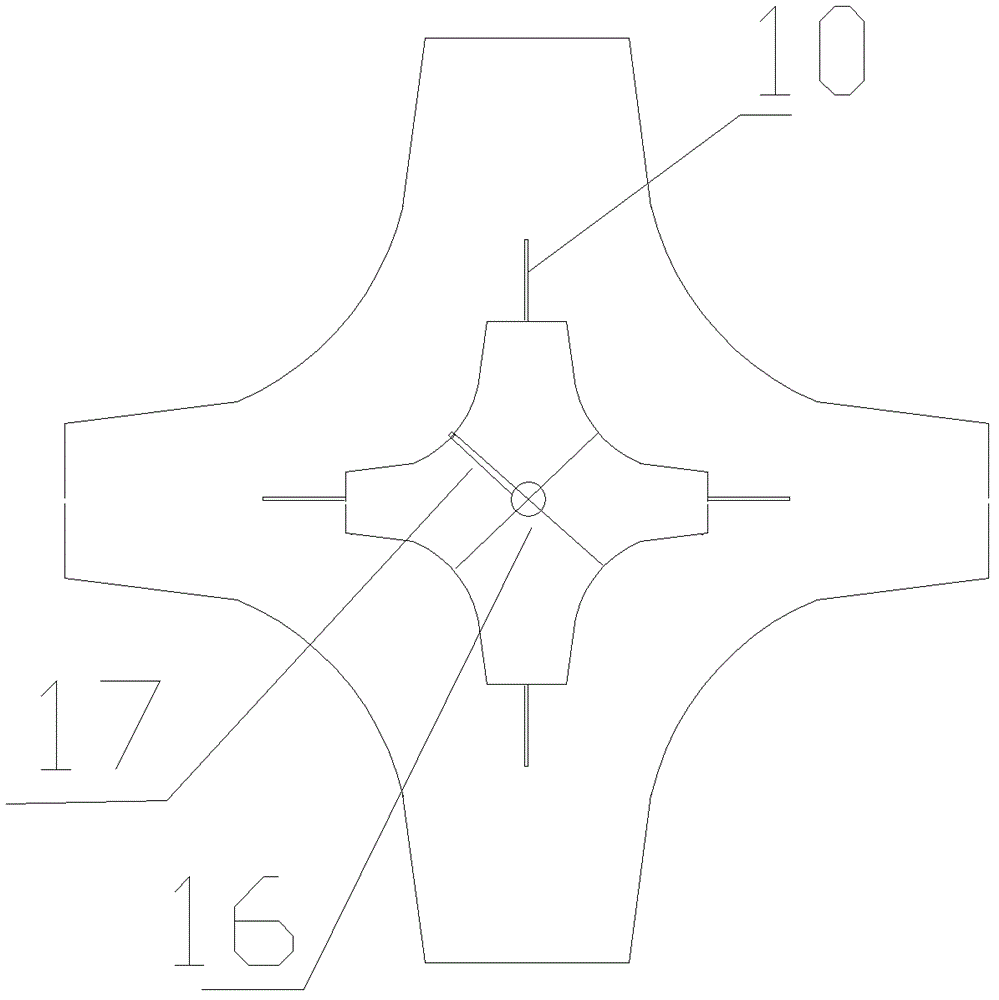

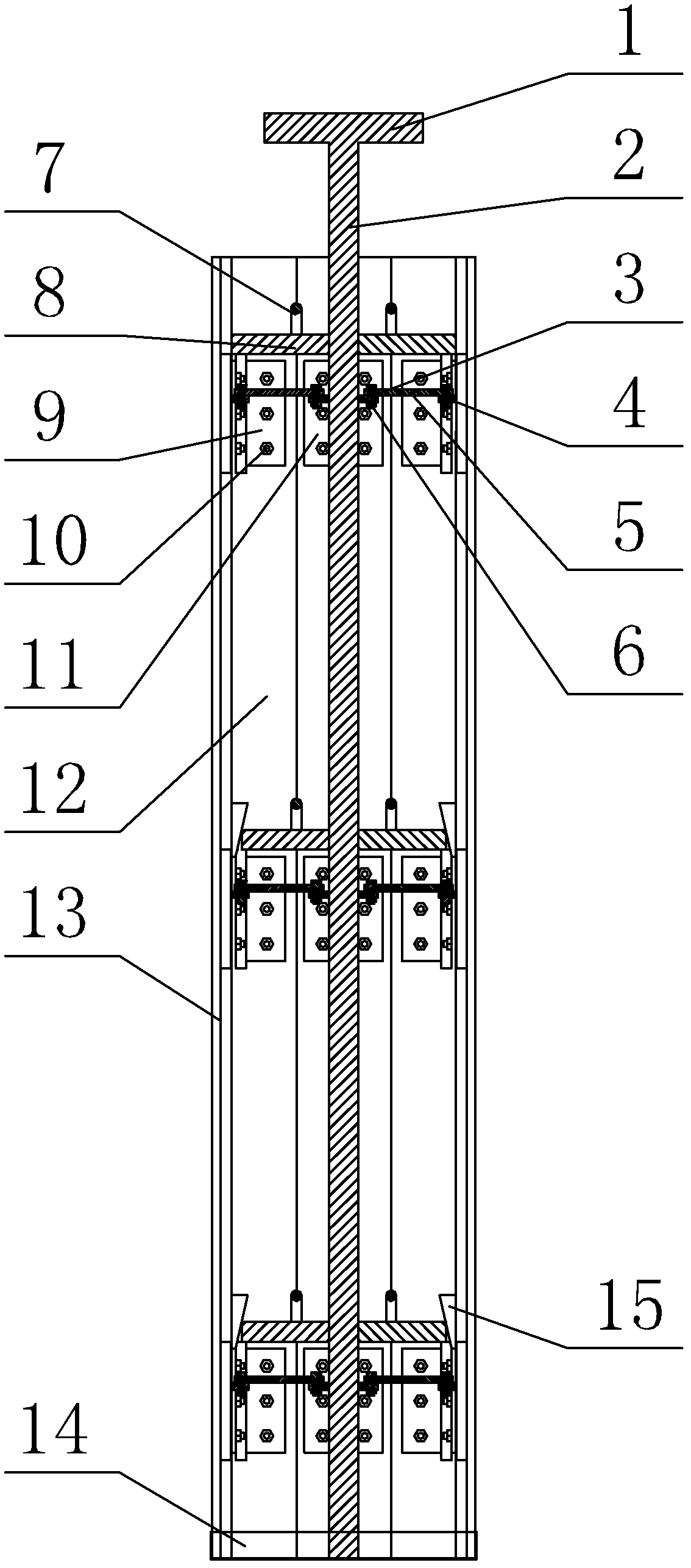

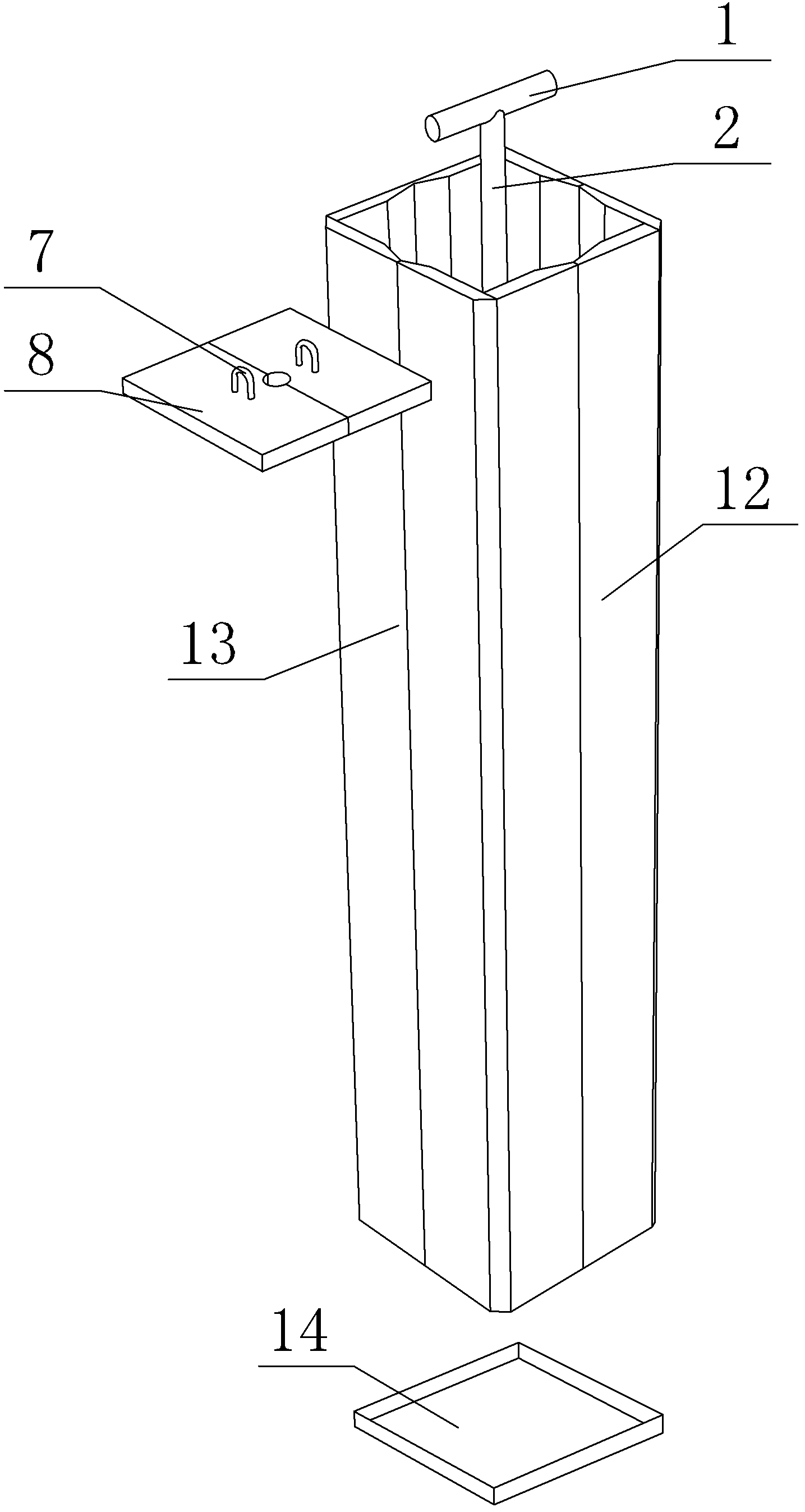

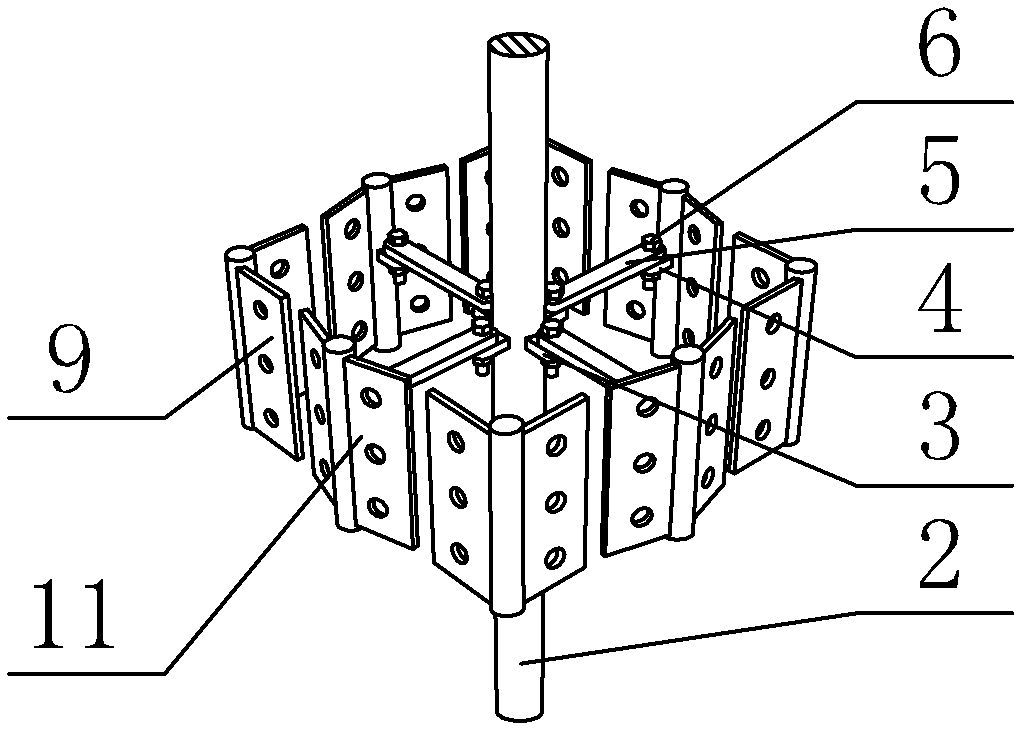

The invention relates to a round hole die of an equipment base pre-reservation anchor bolt hole, in particular to an equipment base pre-reservation round anchor bolt hole die, which is characterized in that the equipment base pre-reservation round anchor bolt hole die comprises a center shaft, a first bracing and shrinking device, a second bracing and shrinking device, four templates and four joint sealing plates, wherein the four templates are all in an arc shape and uniformly distributed along a circumference, each joint sealing plate is inserted between two adjacent templates, the four templates and the four joint sealing plates enclose to form a cylindrical space, first template supports on the four templates are all articulated to the first bracing and shrinking device, second template supports on the four templates are all articulated to the second bracing and shrinking device, the lower part of the center shaft, the first bracing and shrinking device and the second bracing and shrinking device are all arranged in the cylindrical space enclosed by the four templates and the four joint sealing plates, the upper part of the center shaft is arranged above the cylindrical space and is provided with outside threads, and a handle is arranged at the upper end of the center shaft. The die is simple to operate and rapid to disassemble and can be used repeatedly.

Owner:CHINA FIRST METALLURGICAL GROUP

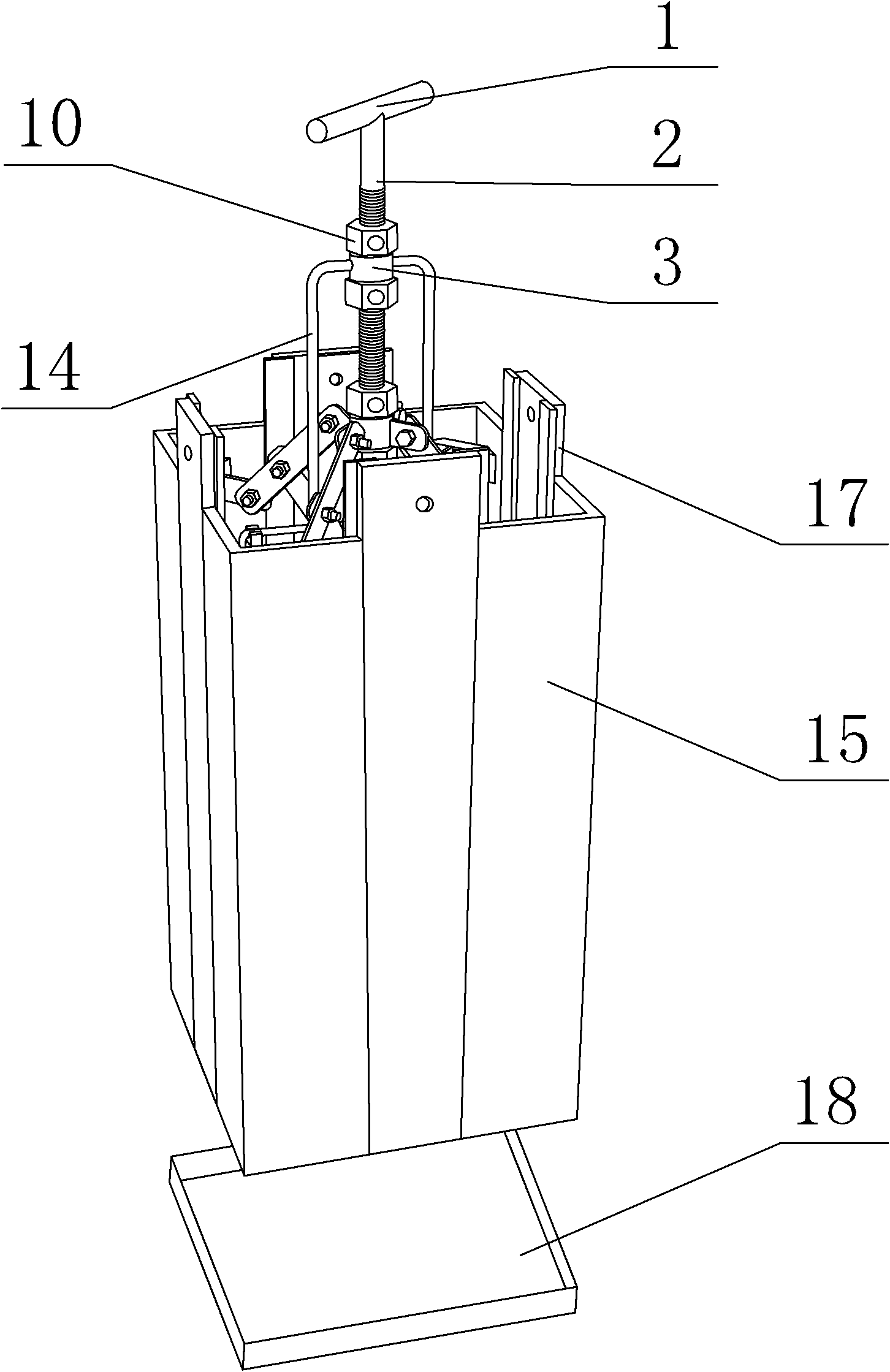

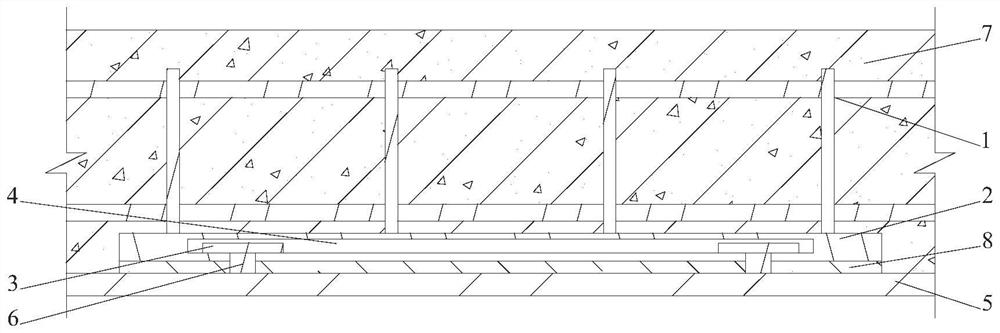

Reusable die for equipment foundation reserved square hole

ActiveCN102493480AFlexible demolitionQuick dismantlingForms/shuttering/falseworksFoundation engineeringEngineeringMechanical engineering

Owner:CHINA FIRST METALLURGICAL GROUP

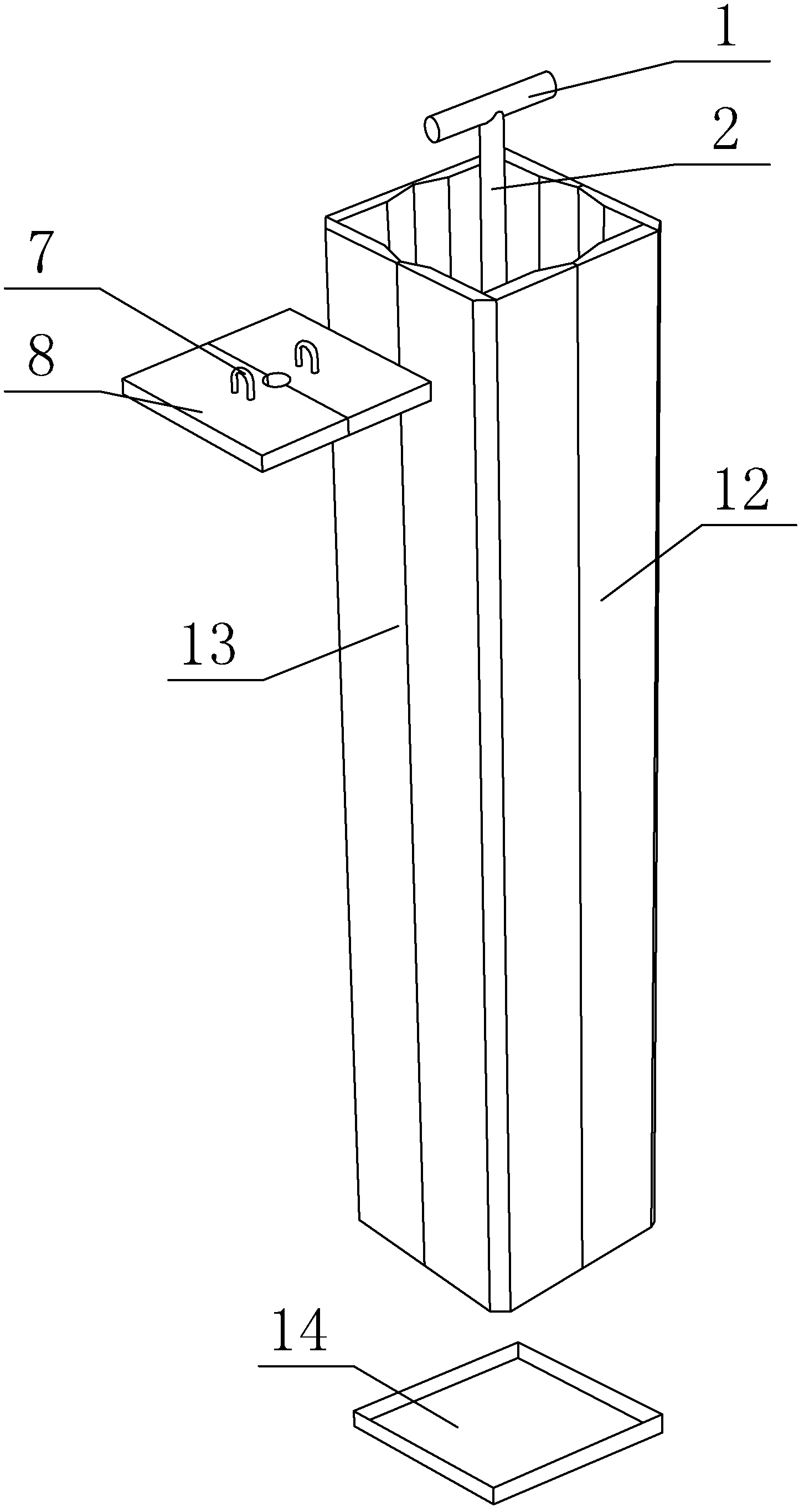

Construction method of large equipment foundation reserved foundation bolt hole

ActiveCN102493481AFlexible supportFlexible demolitionFoundation engineeringForms/shuttering/falseworksSquare cavityAnchor bolt

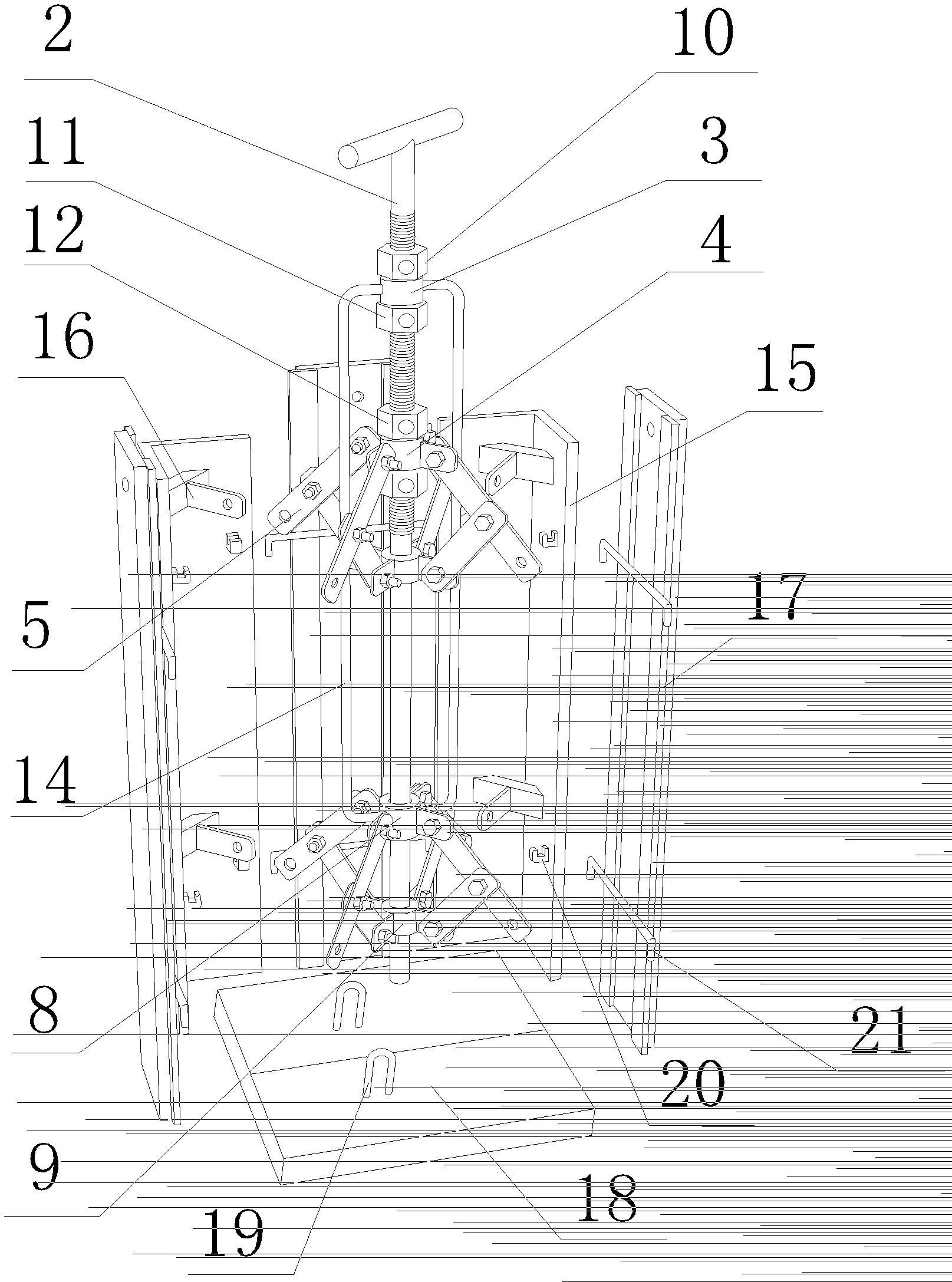

The invention relates to a construction method of a large equipment foundation reserved foundation bolt hole. The construction method of the large equipment foundation reserved foundation bolt hole is characterized by comprising the following steps: first step, assembling a die, wherein the die comprises a central shaft, two to four opening and shrinking devices, eight die plates and an upper plate, every two die plate are arranged on one side, eight die plates can enclose a square, the two to four opening and shrinking devices are positioned in the square cavity enclosed by the eight die plates, the lower end of the central shaft penetrates through the two to four opening and shrinking devices, and the upper end of the central shaft is welded a handle; second step, erecting the die; third step, pouring concrete; fourth step, removing the die and leaving a hole opening; fifth step, cleaning the hole opening: gigging the concrete surface surrounding the hole opening by using an iron hook or a steel wire brush, cleaning up the garbage in the hole and sealing the hole opening to obtain the large equipment foundation reserved foundation bolt hole. The method is simple, and the used die is simple to operate, is fast to disassemble and can be reused.

Owner:CHINA FIRST METALLURGICAL GROUP

Screw anchor mounted suction barrel foundation

The invention discloses a screw anchor mounted suction barrel foundation. The screw anchor mounted suction barrel foundation comprises a screw anchor power mounting system, a suction barrel mounting vacuumizing system, a suction barrel and a screw anchor. The screw anchor power mounting system comprises a second motor, a power driving device and a driving shaft; the second motor and a first motorare mounted in a mounting ship; and the second motor is connected with the power driving device, and the driving shaft is driven to move. The suction barrel mounting vacuumizing system comprises a high-power water pumping pump, the first motor and a water pumping pipe; a screw anchor top cover is disposed at the top end of the screw anchor and arranged on one side of the bottom end of a top plateof the suction barrel; a screw plate is disposed on the outer ring of a screw anchor main rod; a through hole is formed in the center of a suction barrel top cover; the driving shaft penetrates through the through hole to be connected to the screw anchor top cover; a seal rubber ring is disposed between the driving shaft and the wall of the through hole of the suction barrel top plate; and the water pumping pipe is disposed on the inner side of the suction barrel and connected with the high-power water pumping pump. By means of the screw anchor mounted suction barrel foundation provided by theinvention, both high horizontal load capacity and high anti-pull bearing capacity are achieved.

Owner:TIANJIN UNIV +1

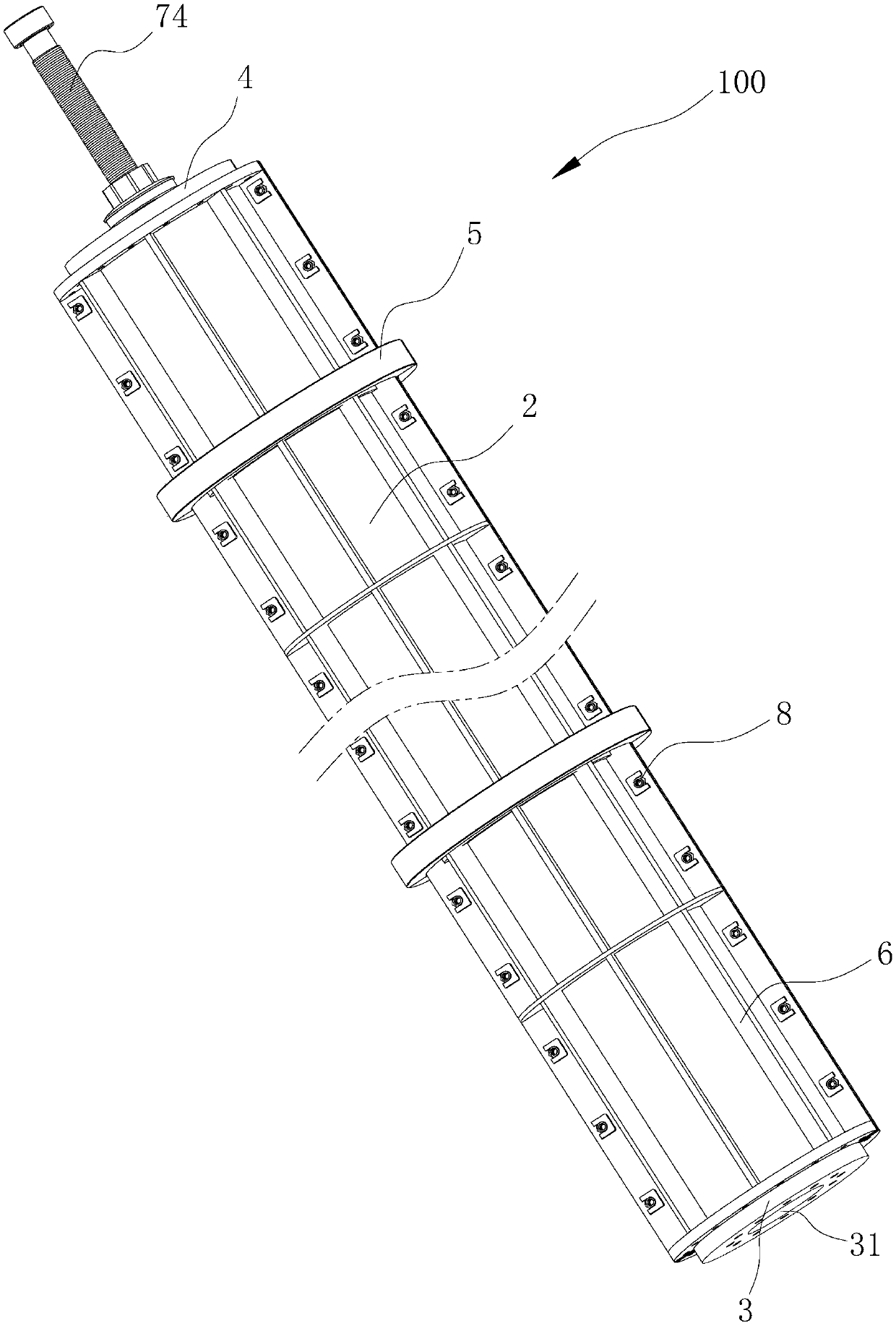

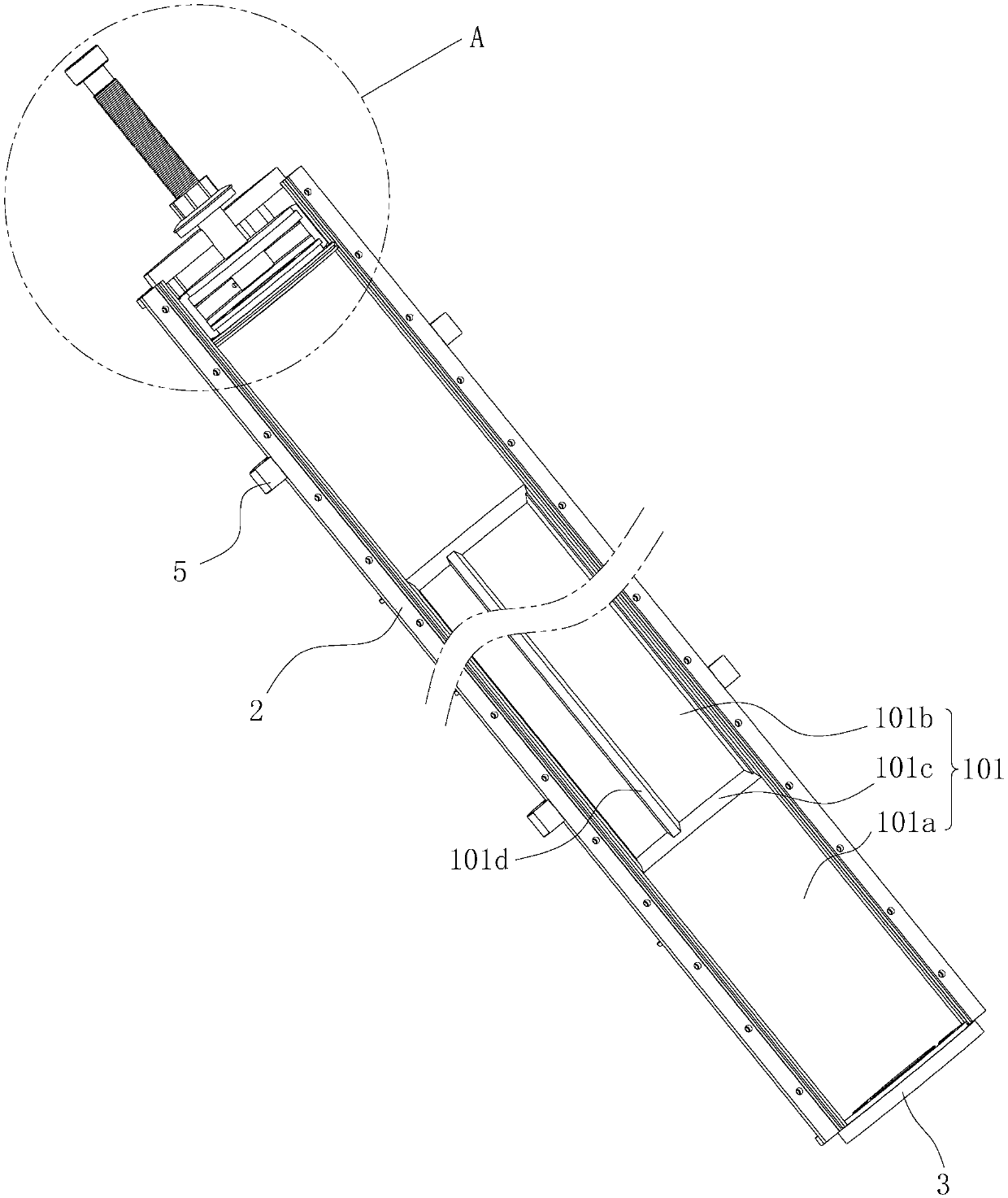

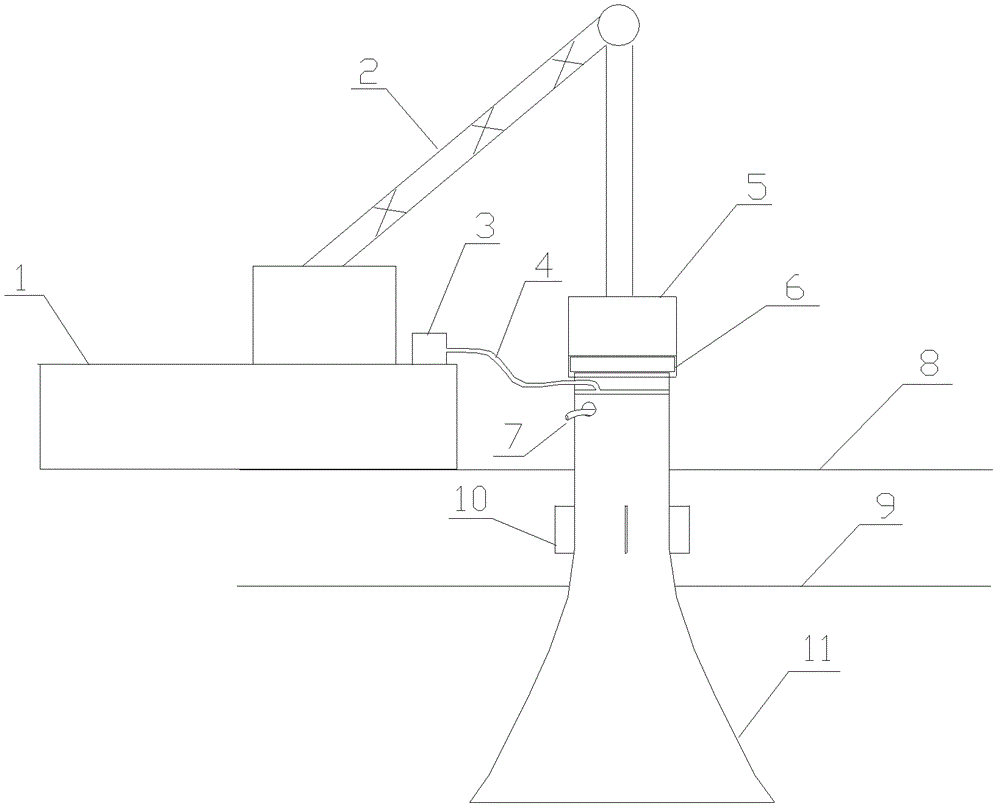

Reaming equipment for anchoring system with multiple plates and construction method

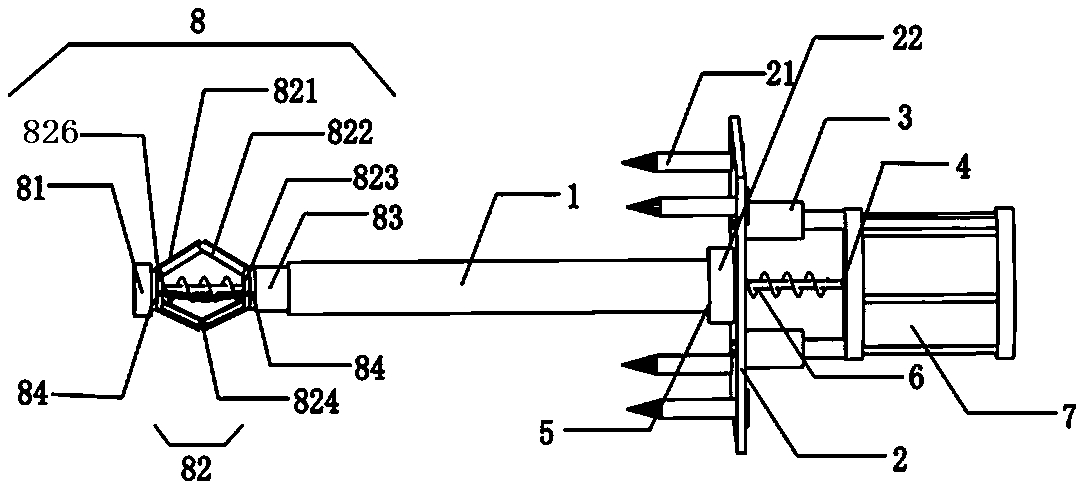

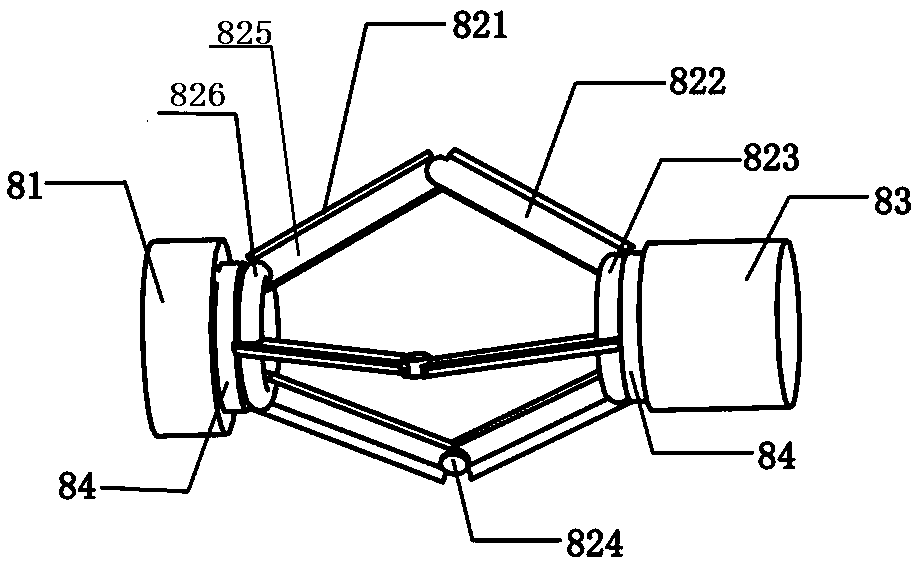

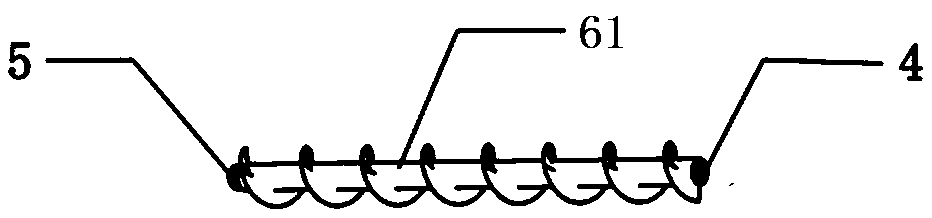

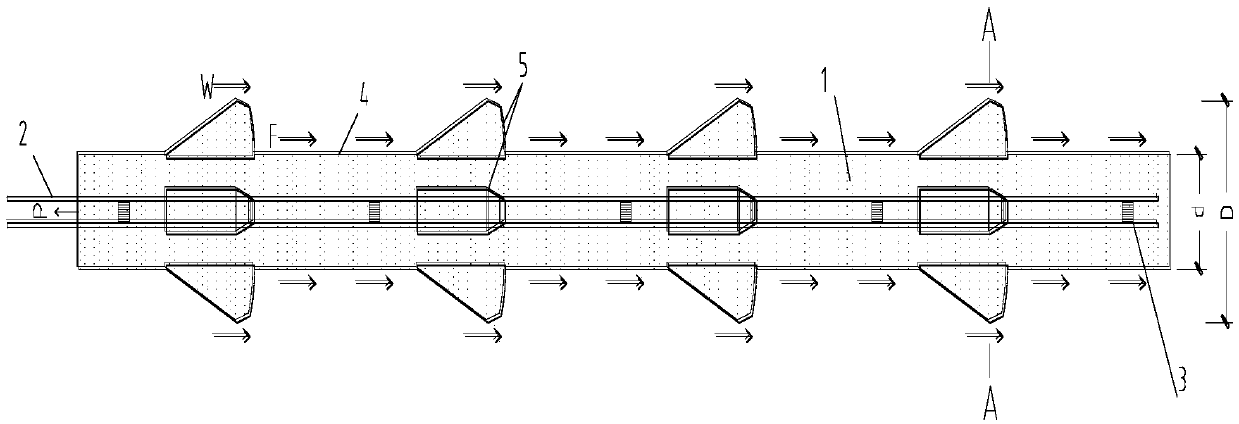

ActiveCN110700760AEasy to useExcellent hole expandabilityDrill bitsDrilling rodsHydraulic cylinderElectric machine

The invention relates to reaming equipment for an anchoring system with multiple plates and a construction method. The reaming equipment comprises a fixed plate used for being fixed at an anchor holeof the soil body, wherein a hollow pipe used for extending into the anchor hole is connected to the fixed plate, the rear side of the fixed plate is connected with a motor through a hydraulic cylinder, a main shaft of the motor is connected with a spiral soil cleaning rod penetrating through the hollow pipe, and the front end of the hollow pipe is provided with a hole expanding head which is driven by the spiral soil cleaning rod to rotate and controlled to expand and contract by the axial movement of the spiral soil cleaning rod. According to the reaming equipment for the anchoring system with the multiple plates, reaming is carried out by adopting a method of pressure-cutting-soil-transporting slag, the use is convenient and rapid, and the hole expanding effect is good; the reaming equipment can be used to ream the rock soil bodies with different conditions, whether the rock soil body is soft soil or high-compaction soil body, and the hole expanding effect is remarkable; and the structure design is compact and reasonable, the limited anchor hole space is not occupied, and the reaming efficiency is maximized.

Owner:FUZHOU UNIV

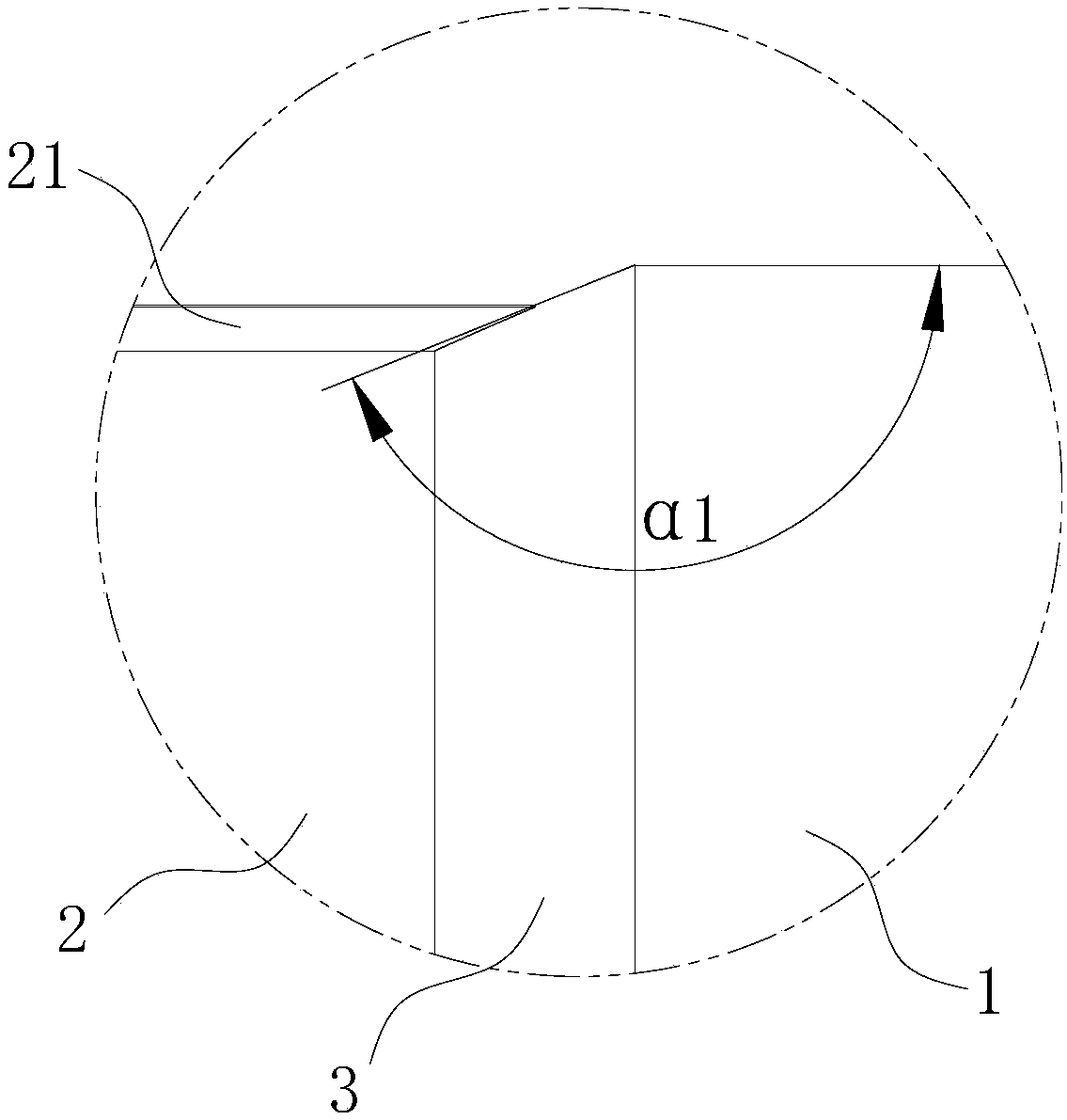

Polygonal prefabricated pile

ActiveCN110528506AEnhanced pull-out load bearing performanceLarge specific surface areaBulkheads/pilesFriction forceLoad carrying

The invention discloses a polygonal prefabricated pile which comprises at least one thin pile section and at least one thick pile section. The thin pile section and the thick pile section form an integrated structure in a linear direction. Outwards-protruding ribbed plates are arranged on the whole or part of the outer wall surfaces of the thin pile sections. In the cross section of the thin pilesections, the maximum linear distance between the outer end surfaces of the ribbed plates and the central axis of the polygonal prefabricated pile is L1, in the cross section of the thick pile sections, the minimum linear distance between the outer wall faces of the thick pile sections and the central axis of the polygonal prefabricated pile is L2, and the minimum linear distance L2 is larger thanthe maximum linear distance L1. By means of the polygonal prefabricated pile, it can be ensured that a soil body around the thin pile sections forms an integrated structure, so a pile body and the soil body around have a larger contact area and a closer fitting effect, the friction force between the pile body and the soil body around is improved, and then the anti-pull load-carrying property of the polygonal prefabricated pile can be greatly enhanced.

Owner:周兆弟

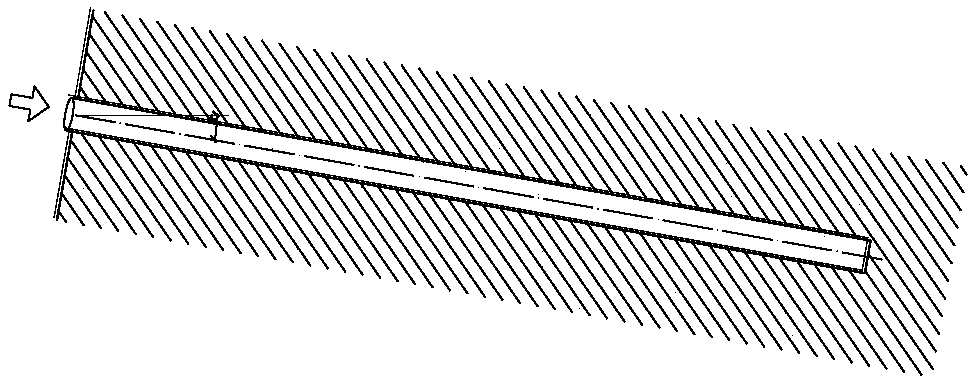

Ocean engineering drag anchor capable of improving anti-pull bearing capacity

The invention discloses an ocean engineering drag anchor capable of improving anti-pull bearing capacity. The ocean engineering drag anchor comprises an anchor claw and an anchor handle which are connected with each other, and the contact surfaces of the anchor claw and anchor handle with seabed soil are coated with a curable seabed soil diffusion coating. The ocean engineering drag anchor capableof improving the anti-pull bearing capacity has the advantages that the seabed soil around the drag anchor is solidified and hardened through the diffusion coating and a slip casting mechanism to improve the strength of the surrounding seabed soil, thereby improving the anti-pull bearing capacity; the contact area between the drag anchor and the seabed soil is increased during drag through an ejectable externally extending plate to increase the friction between the seabed soil and the drag anchor, thereby further improving the anti-pull bearing capacity.

Owner:HOHAI UNIV

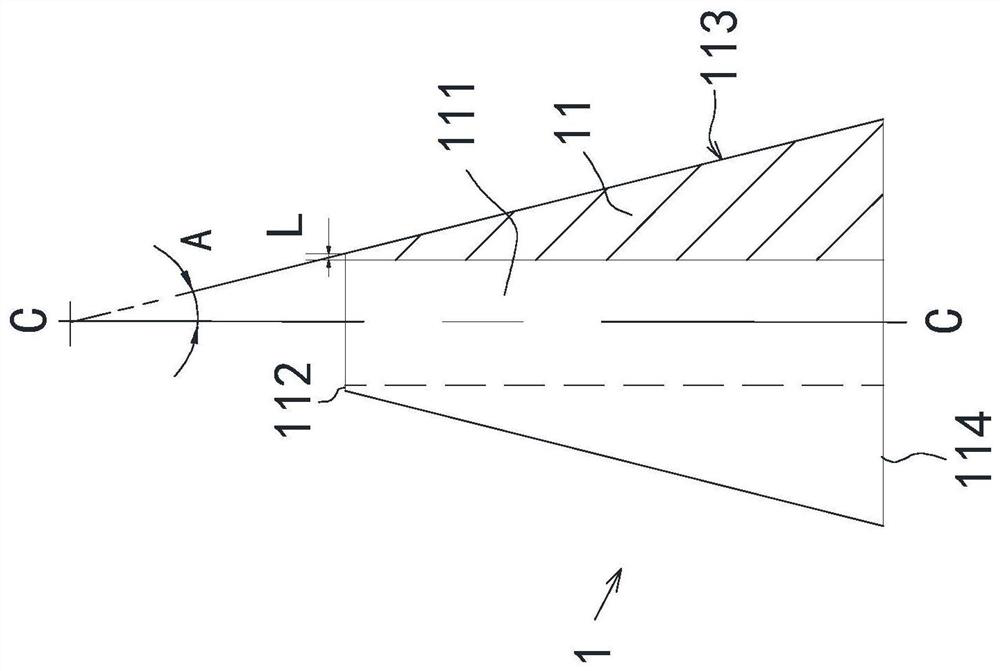

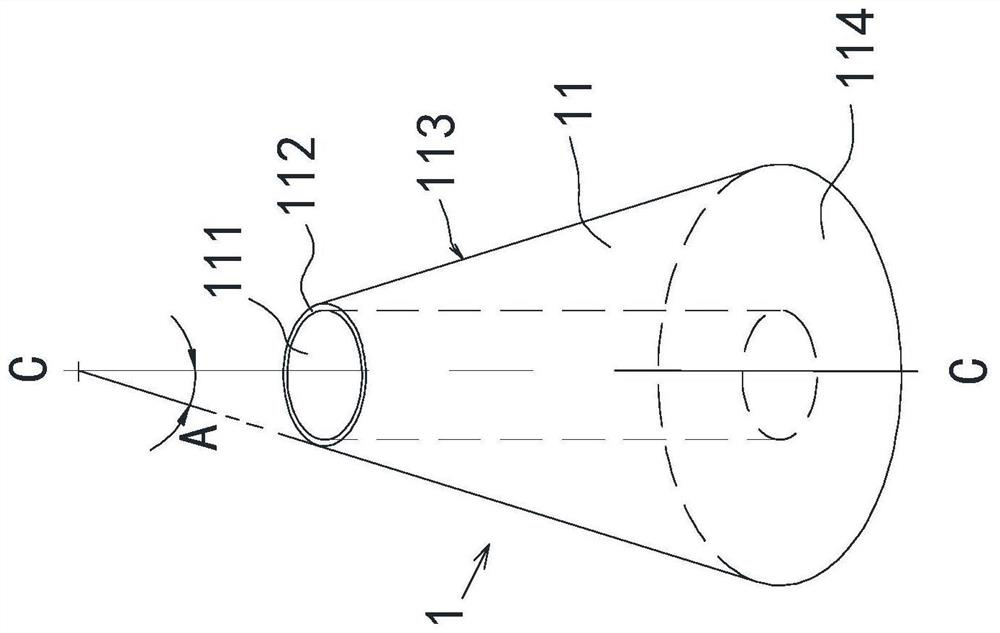

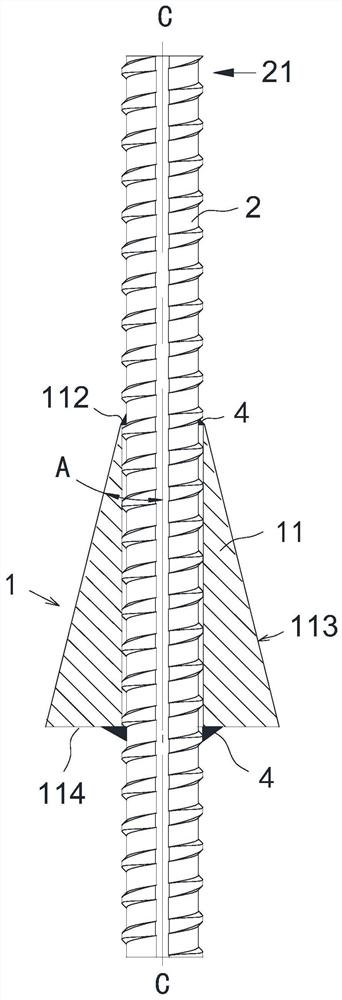

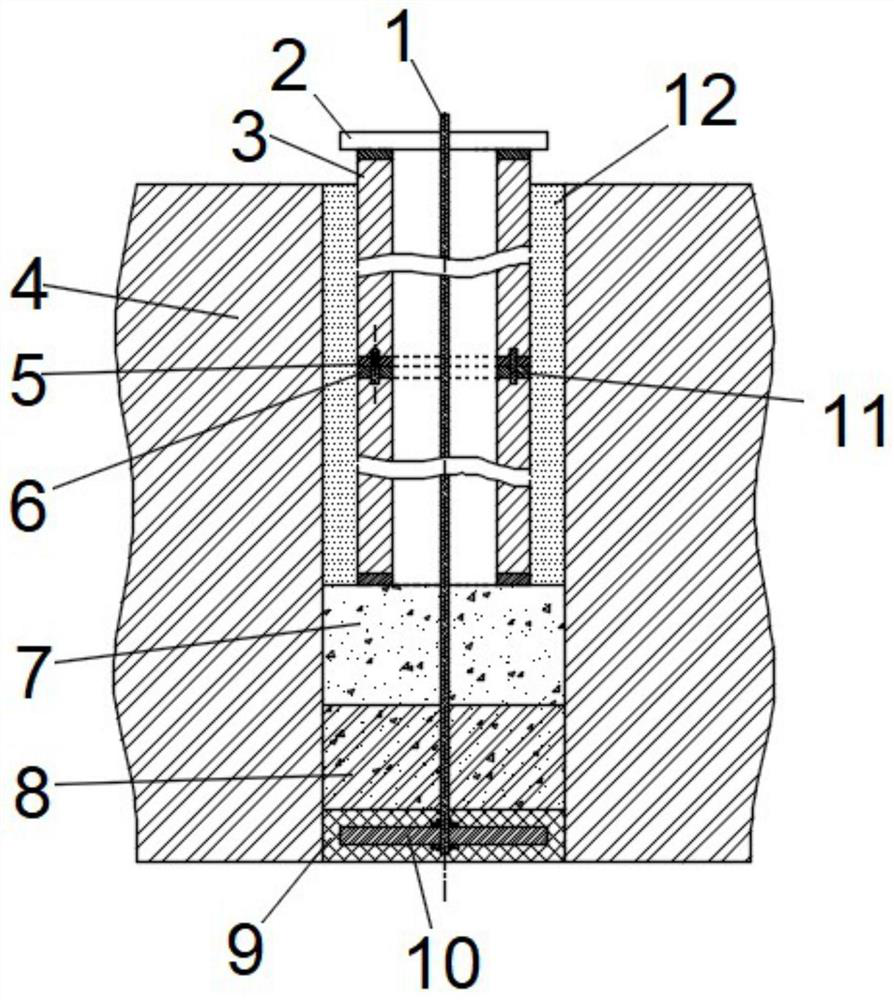

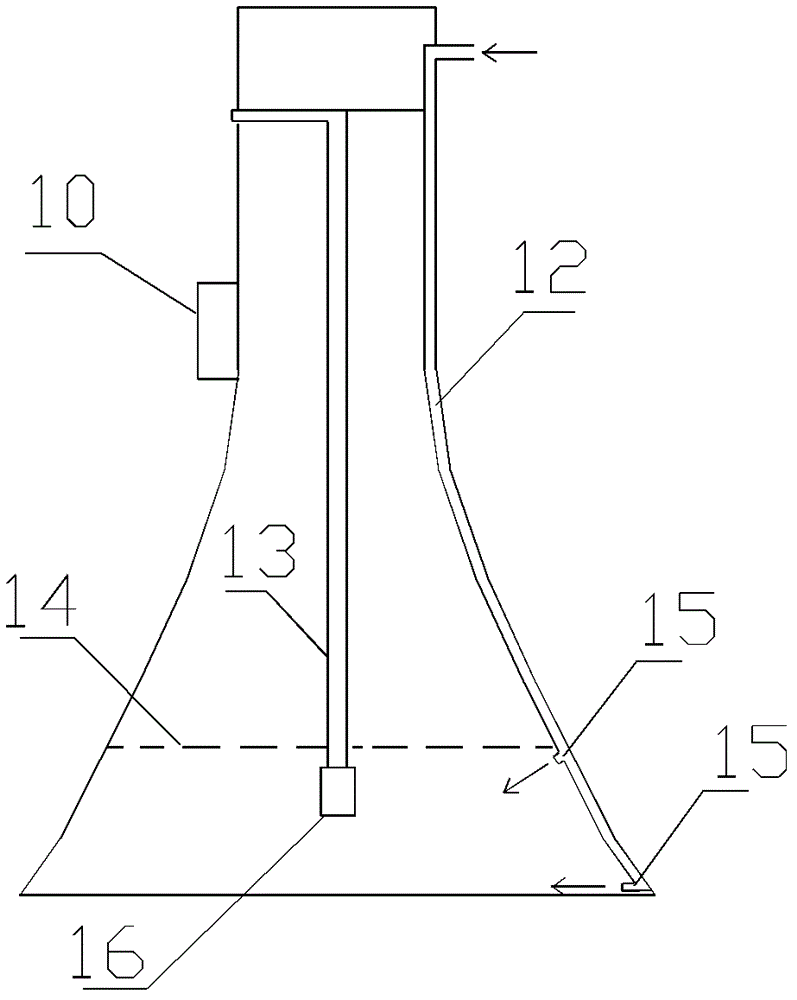

Conical barrel supporting body used for anchor bolt and anchor bolt

PendingCN111733810AImprove pullout resistanceHigh mechanical strengthBulkheads/pilesAnchoring boltsClassical mechanicsRock bolt

The invention provides a conical barrel supporting body used for an anchor bolt. The conical barrel supporting body is formed by a barrel wall in a surrounding mode. A central hole formed by the barrel wall in the surrounding mode adapts to a bolt body of the anchor bolt, and is used for sleeving the bolt body of the anchor bolt. The barrel wall is provided with a top, a bottom and an outer wall surface, wherein the outer diameter of the top is smaller than that of the bottom, the outer wall surface is a conical surface, and an included angle formed between the conical surface and the axis ofthe central hole is smaller than 45 degrees. The invention further provides the anchor bolt. The anchor bolt comprises the bolt body of the anchor bolt and the conical barrel supporting body mounted on the bolt body. The top of the conical barrel supporting body faces the front end of the bolt body. The conical surface faces the eye wall of an anchor eye. According to the conical barrel supportingbody and the anchor bolt provided by the invention, when the anchor bolt is stretched, the conical surface on the conical barrel supporting body can extrude a grouting body towards the eye wall of the anchor eye along the normal of the conical surface by moving around the axis of the bolt body of the anchor bolt by 360 degrees, positive pressure is produced between the grouting body and the eye wall of the anchor eye, the positive pressure produces frictional resistance which is then converted into pulling resistance of the anchor bolt, the pulling resistance is greatly improved, the anchoring reliability is correspondingly improved, and the service life is also correspondingly prolonged.

Owner:深圳钜联锚杆技术有限公司

Extrusion reaming anchor rod and construction method

The invention discloses an extrusion anchor rod with larger pulling resistance and a construction method of the extrusion anchor rod. The anchor rod is formed in the way that after mechanical hole forming is conducted, an anchor rod main reinforcing bar is added, and grouting and cementing are conducted. After grouting, an anchor rod anchoring body is formed and comprises a main anchor rod body ofa standard anchoring section and multiple anchor rod diameter expansion bodies of an embedded extrusion and expanding section; the diameter expansion bodies are formed by compacting side-wall rock and earth mass by an extrusion reamer; the anchor rod diameter expansion bodies are arranged at intervals in the longitudinal direction of the main anchor rod body, and each anchor rod diameter expansion body comprises multiple protrusions which are symmetrically arranged; the maximal diameter formed by the anchor rod diameter expansion bodies is not less than twice the diameter of the main anchor rod body. The construction method comprises the steps of advance hole forming, sequential extrusion and reaming, anchor bar installing, grouting, and stretching and drawing for locking. Extrusion and reaming are conducted by a drilling tool according to designed spacing, and the diameter of the anchoring body is increased in section, so that the purposes of compacting the side wall of the anchoringbody, and improving the strength of the rock and earth mass are achieved; meanwhile, an embedded reaming body section is formed, the single stress mode of the anchor rod body is improved, thus the anti-pulling capability of the anchor rod is effectively improved, the labor is saved, and the engineering cost is reduced.

Owner:成都四海岩土工程有限公司

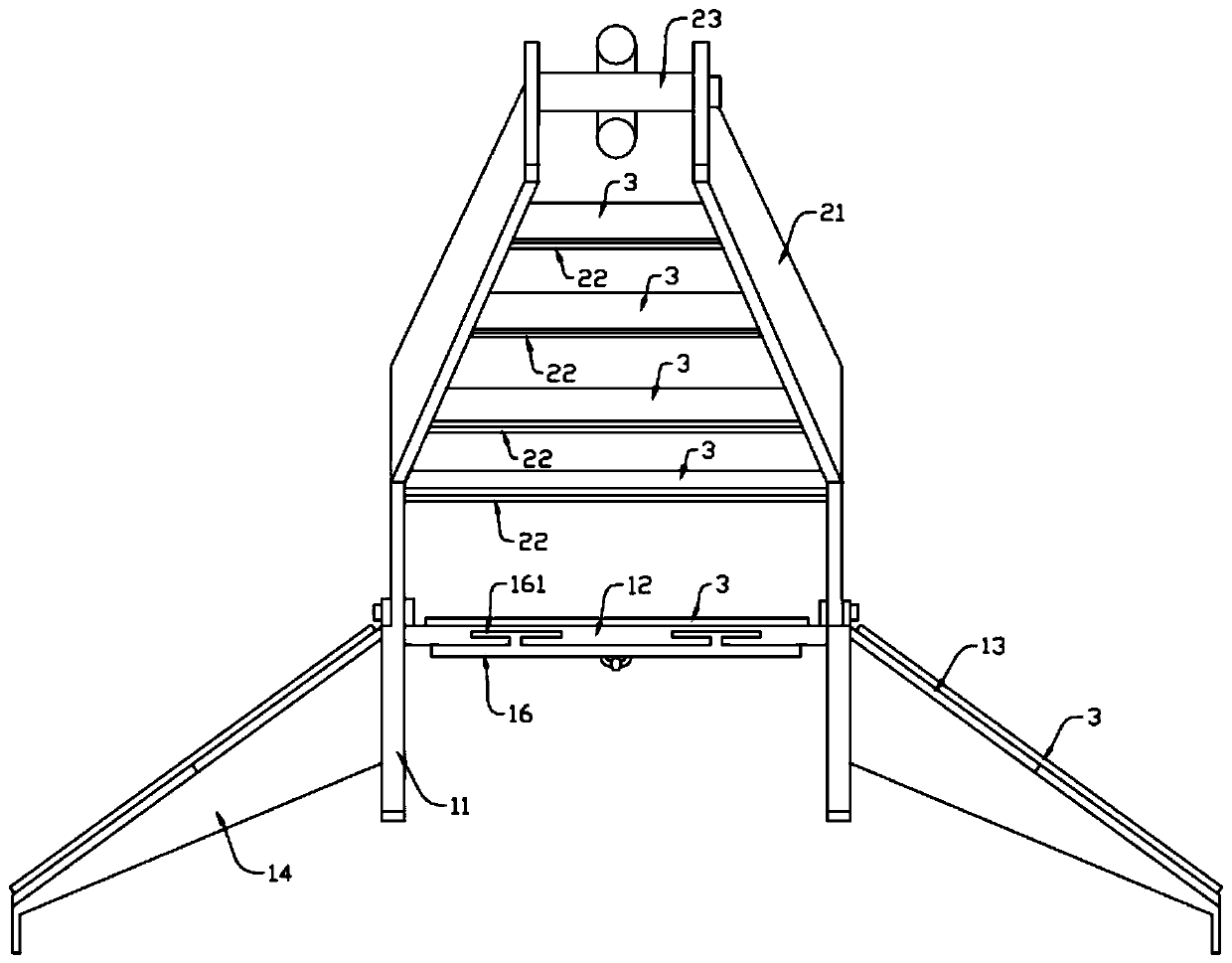

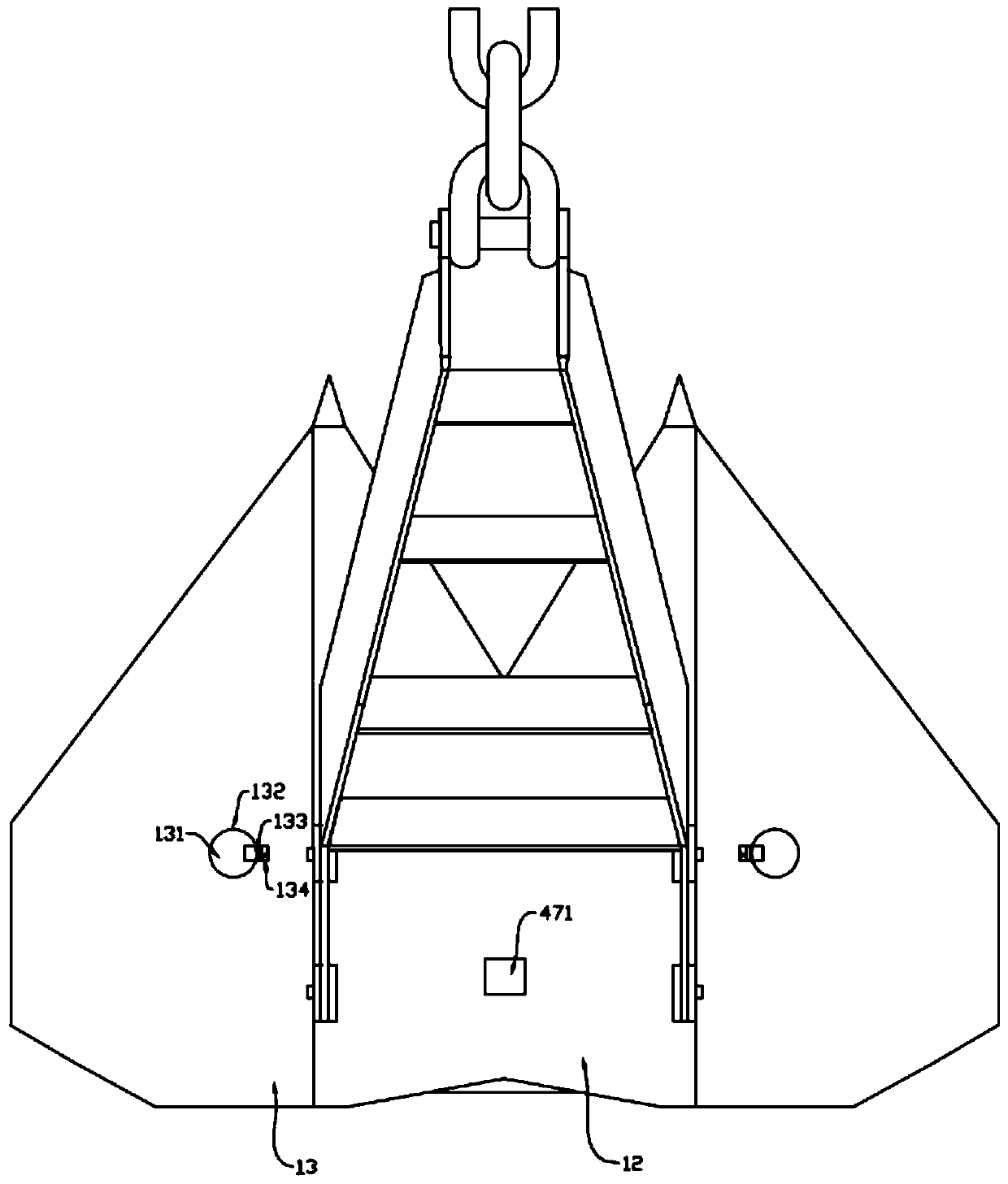

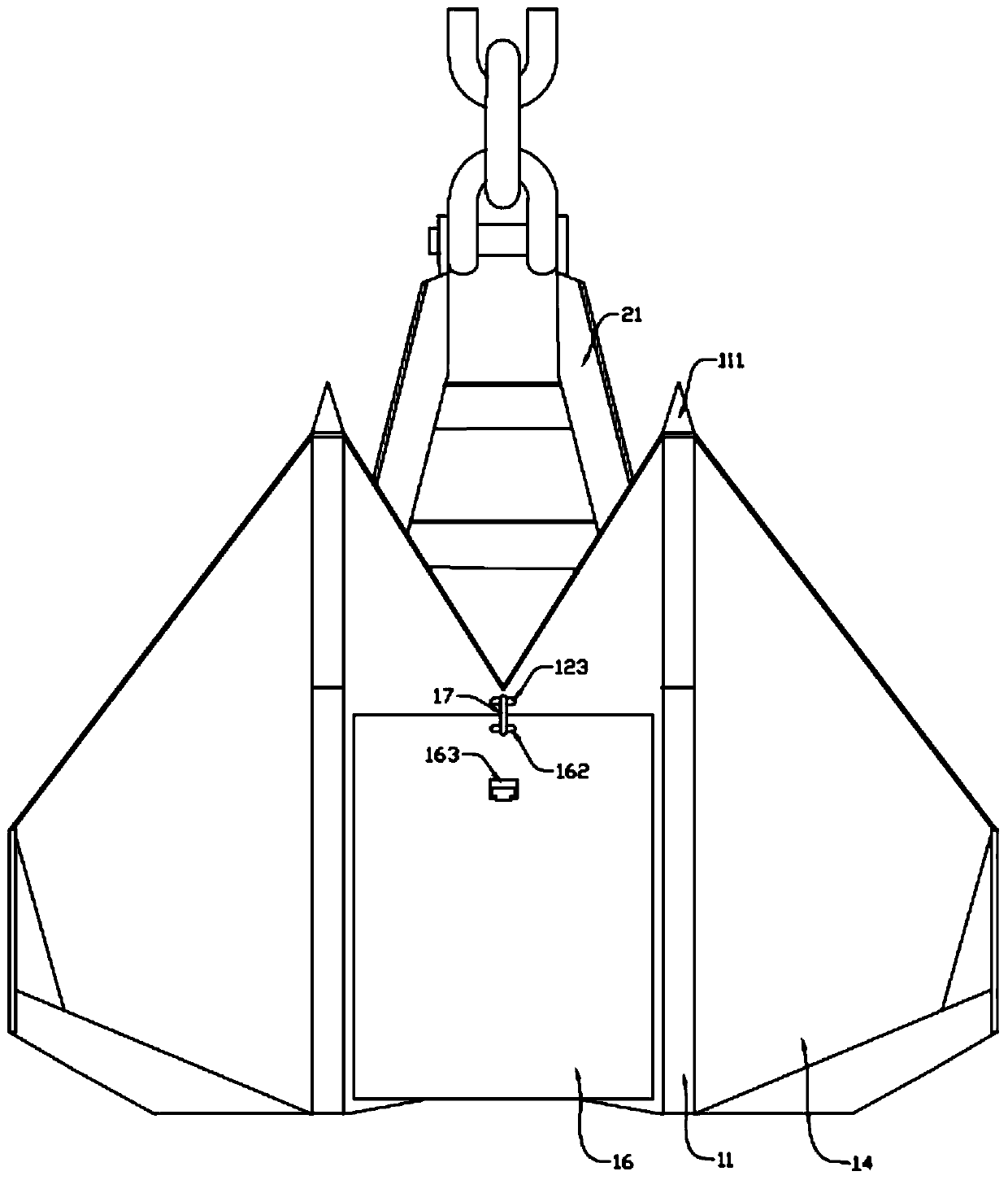

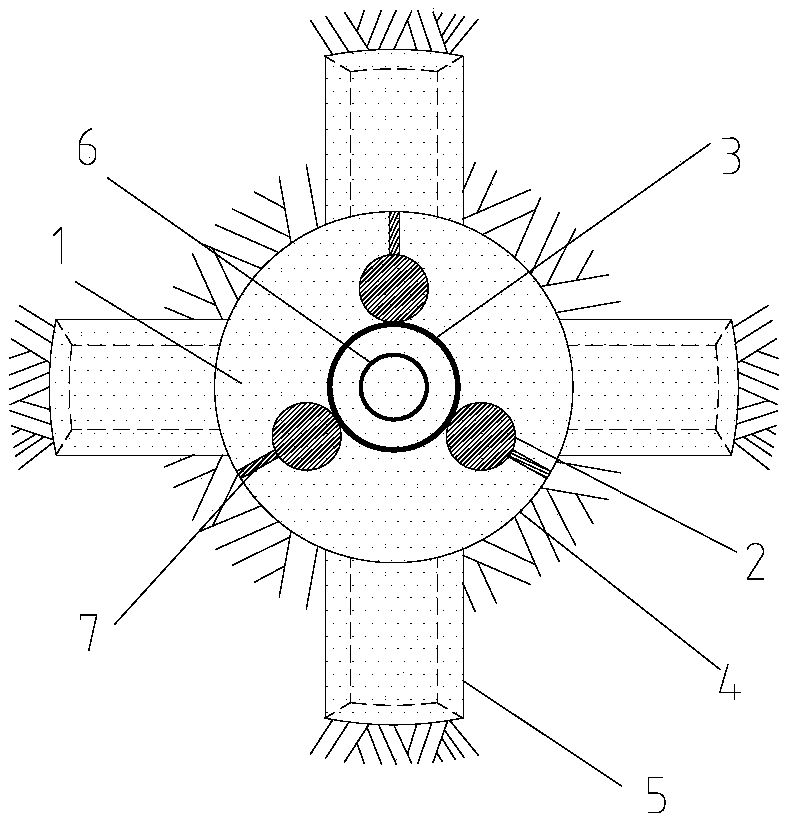

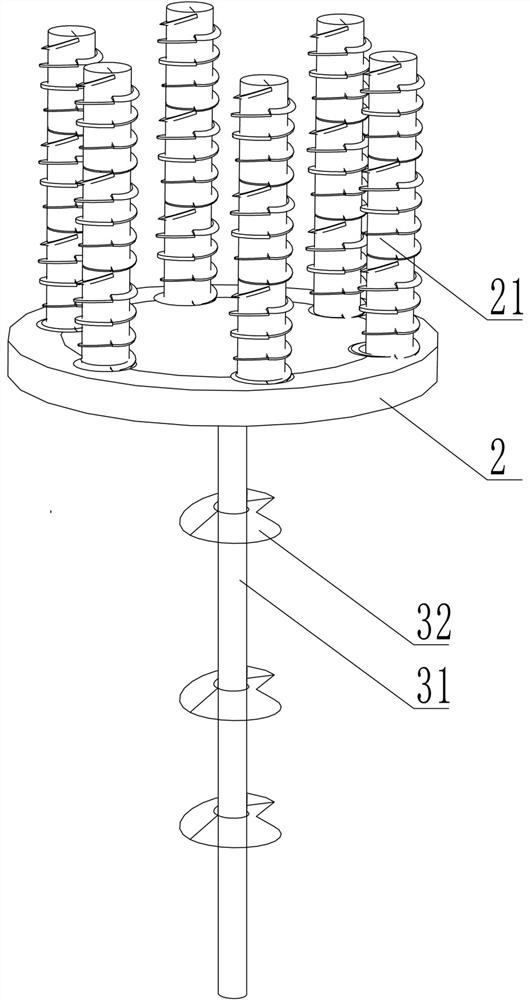

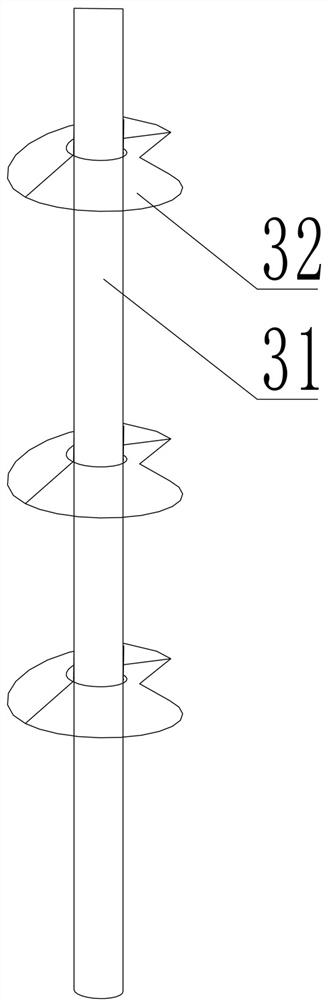

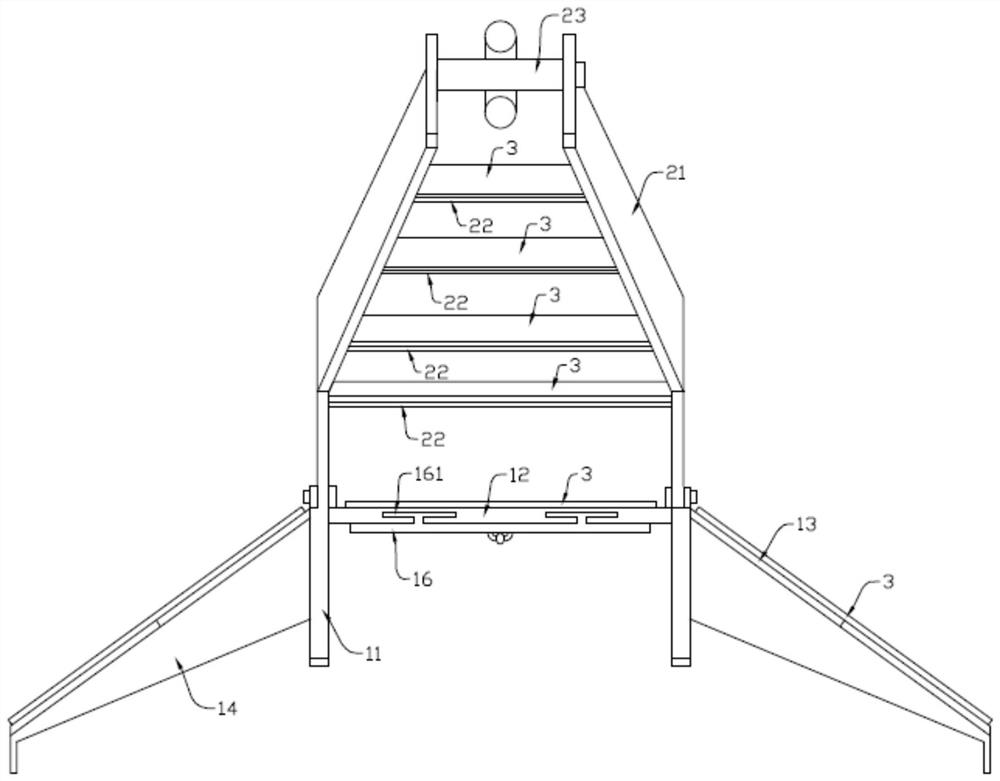

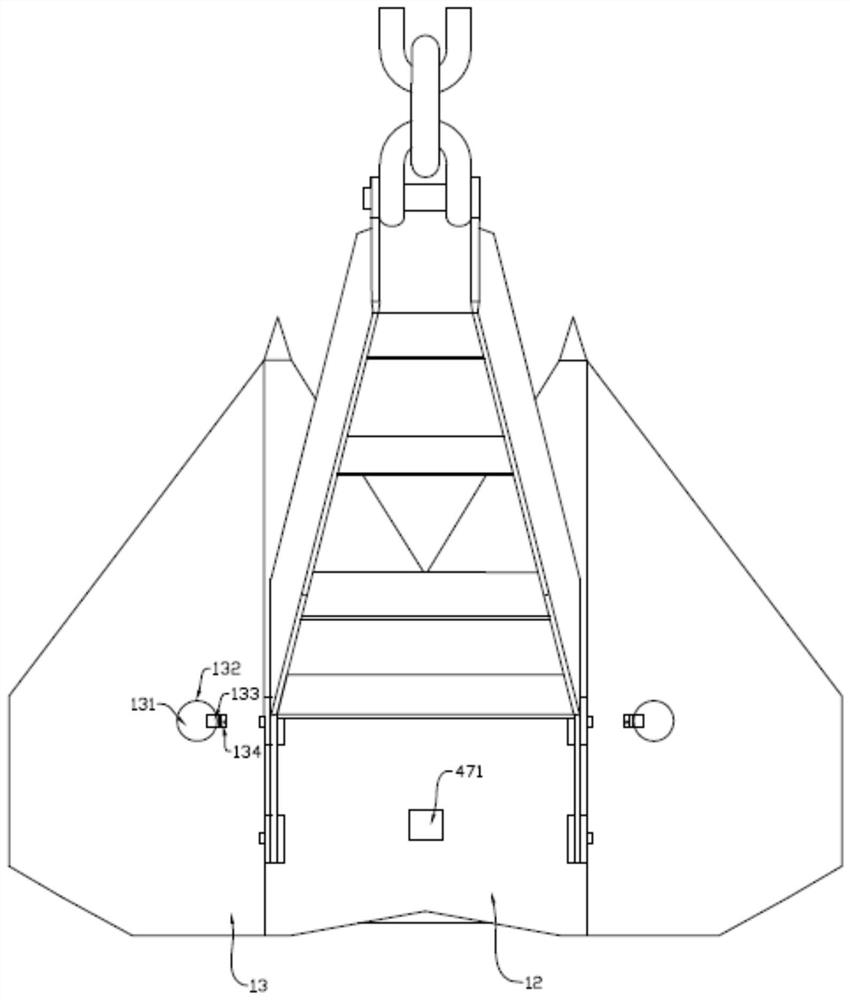

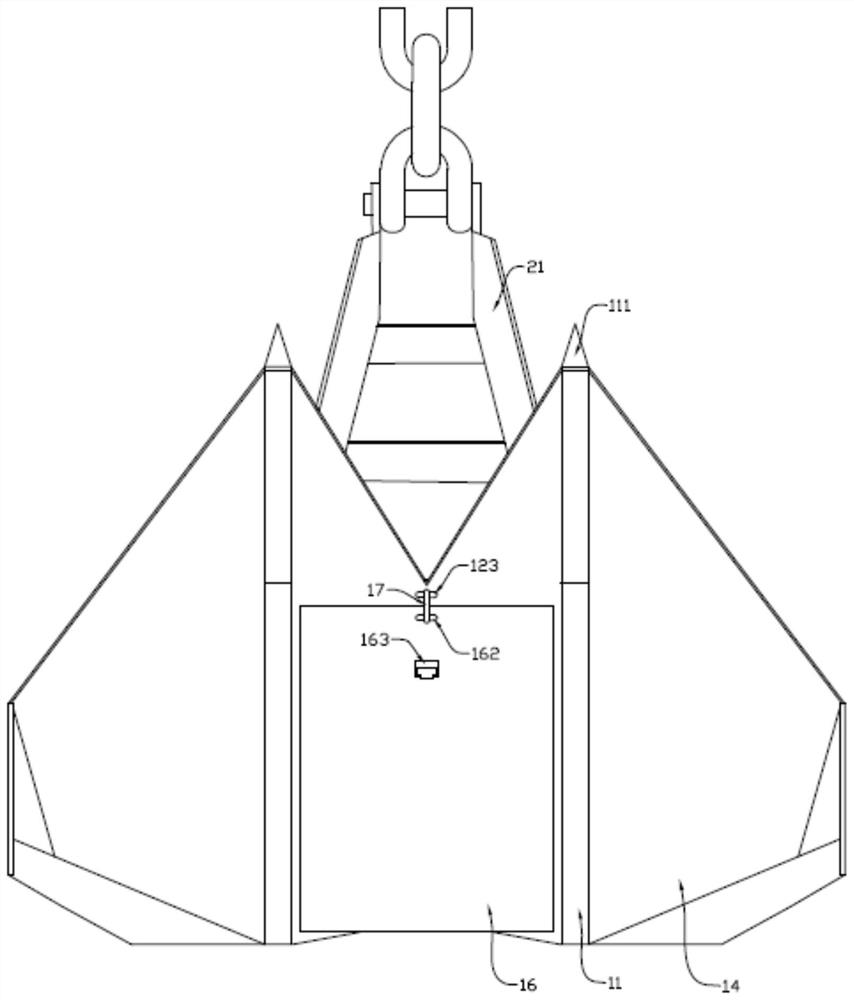

Anchoring foundation suitable for floating type fan and construction method of anchoring foundation

ActiveCN113071605AImprove stabilityEnhanced pull-out load bearing performanceWind energy generationAnchoring arrangementsArchitectural engineeringStructural engineering

The invention provides an anchoring foundation suitable for a floating type fan and a construction method of the anchoring foundation, which comprises an anti-sinking plate, a flange, spiral anchors and an anchor chain assembly, the flange is arranged on the lower portion of the anti-sinking plate, the flange is connected with the anti-sinking plate and the spiral anchors, the anchor chain assembly is fixedly connected with the upper side face of the anti-sinking plate, and the multiple spiral anchors are arranged in a triangular shape. An anchor cable connected with anchor chain assembly extends upwards towards center of triangle to be connected with platform. According to the invention, the problems that an original traditional floating platform mooring tension balancing structure is complex in installation process and high in manufacturing cost are solved, and the floating platform mooring tension balancing structure has the advantages of being simple in construction process, high in construction efficiency, convenient to assemble and transport, low in cost and easy and convenient to operate.

Owner:CHINA THREE GORGES CORPORATION +1

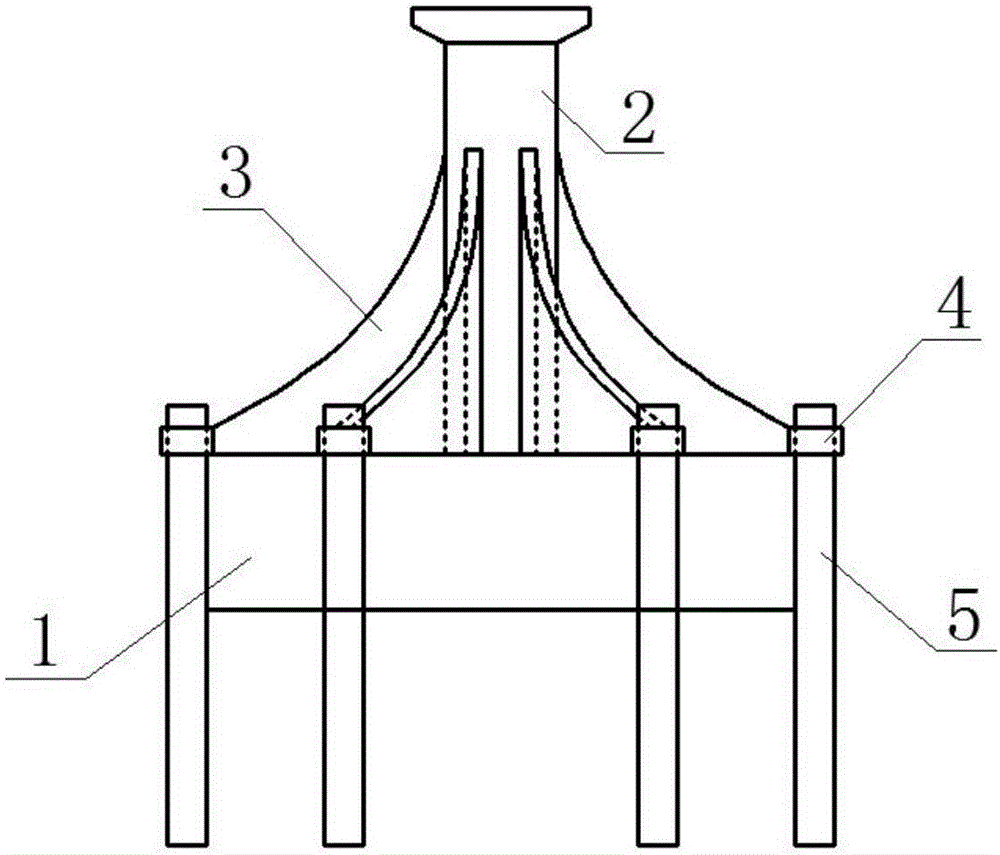

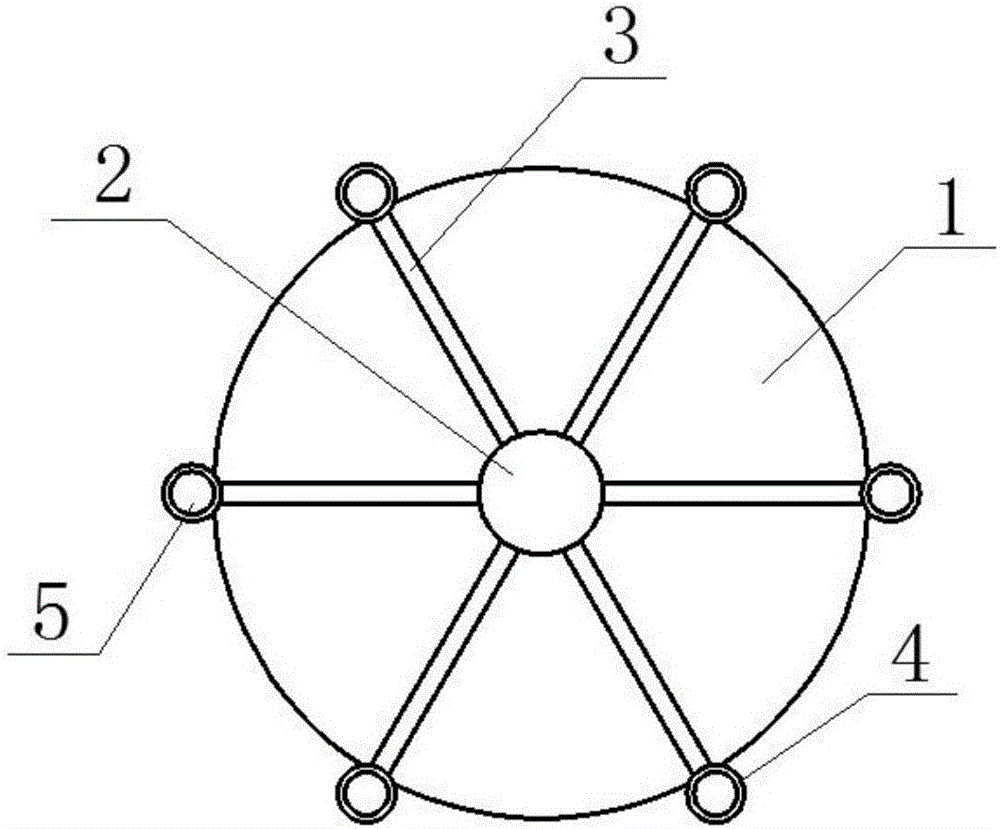

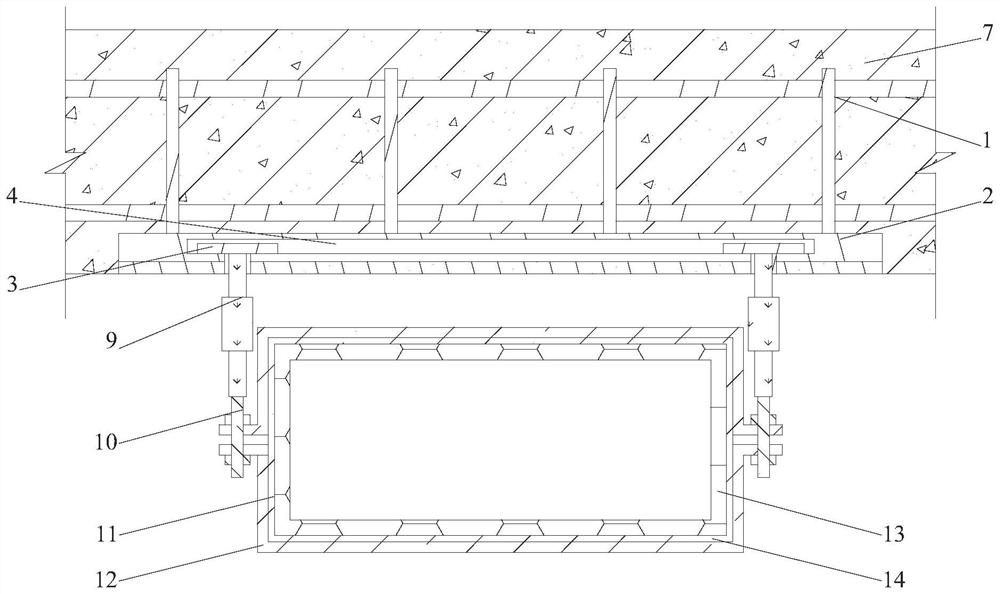

Composite cylinder type foundation with auxiliary piles added in later period

InactiveCN106049524AEnhanced pull-out load bearing performanceSimple structureFoundation engineeringEngineeringBending moment

A composite cylinder type foundation with auxiliary piles added in the later period is composed of a cylindrical foundation body, a transition section, reinforcing ribs, auxiliary pile fixing ring sleeves and the auxiliary piles. The center of a cylindrical foundation body top cover is fixedly connected with the transition section. The transition section is connected with a fan tower cylinder through a flange. The reinforcing ribs are evenly distributed on the transition section and the cylindrical foundation body top cover annularly and radially. The reinforcing ribs, the transition section and the cylindrical foundation body top cover are prefabricated into a whole. The auxiliary pile ring sleeves are arranged at the bottom ends of the outer sides of the reinforcing ribs. After a cylindrical foundation structure is sunk, the auxiliary piles are driven into the cylindrical foundation structure, and the auxiliary piles are driven into a seabed through the auxiliary pile ring sleeves; and the auxiliary piles are fixedly connected with the auxiliary pile ring sleeves. The composite cylinder type foundation has the beneficial effects that due to the fact that auxiliary pile structures radially distributed on the edge of the composite cylinder type foundation have large pulling-resistant bearing capacity, the composite cylinder type foundation can resist the higher transverse load and the bending moment load; and by means of the cylinder type foundation, the standardized production and one-step type installation of the structure can be achieved, production and installation efficiency is improved greatly, and the production cost is lowered.

Owner:THE FRONTIER TECH RES INST OF TIANJIN UNIV

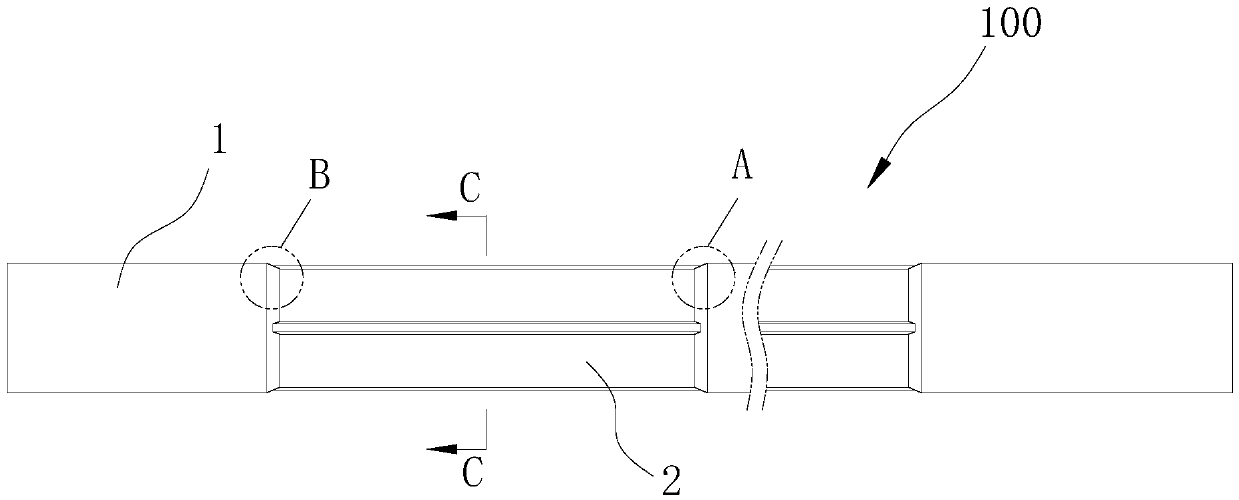

Method for constructing circular hole of anchor bolt reserved by equipment foundation

ActiveCN102493643BFlexible demolitionQuick dismantlingForms/shuttering/falseworksFoundation engineeringEngineeringGap filling

This invention relates to a method for constructing a circular hole of an anchor bolt reserved by equipment foundation, which comprises the following steps: step 1, assembling a mould; step 2, bracing the mould; step 3, pouring concrete; step 4, detaching the mould and leaving a circular hole; and step 5, cleaning the hole so as to obtain the circular hole of the anchor bolt reserved by the equipment foundation, wherein the mould for reserving the circular hole by the equipment foundation comprises a central shaft, a first opening and contracting device, a second opening and contracting device, four templates, four gap filling boards; the four templates are arc-shaped and are evenly distributed along a circumference; the gap filling boards are inserted between the templates; and a cylindrical space is enclosed by the four templates and the four gap filing boards. The method disclosed by this invention is characterized by simple operation and quick mould detachment; and the mould can be reused.

Owner:CHINA FIRST METALLURGICAL GROUP

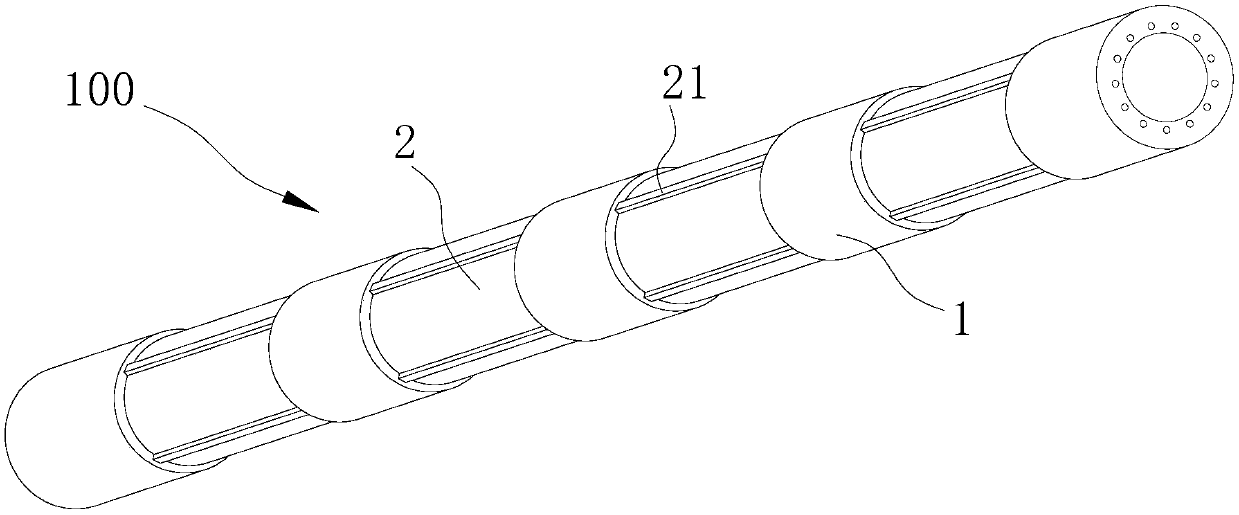

Prefabricated pile

InactiveCN110528507AEnhanced pull-out load bearing performanceLarge specific surface areaBulkheads/pilesEngineeringFriction force

The invention discloses a prefabricated pile. The prefabricated pile comprises at least one fine pile section and at least one thick pile section which are formed into an integrated structure in the axial direction, the circular peripheral wall of the fine pile section is annularly provided with a plurality of convex rib plates, wherein, the length direction of the rib plates is consistent with the length direction of the prefabricated pile, the radial distance from the top end surfaces of the rib plates to the central axis of the prefabricated pile is less than the exradius of the thick pilesection, and a shaft shoulder surface is formed between the fine pile section and the adjacent thick pile section. According to the structural design, the part of the fine pile section has more contact area with a surrounding soil mass, it is also guaranteed that the surrounding soil mass of the fine pile section is surrounded into an integrated structure, the surrounding soil mass is more closelyattached to the outer wall of the fine pile section, thus, the more contact area and the closer attaching effect between the fine pile section and the surrounding soil mass improve friction force between the pile body and the surrounding soil mass, and thus the uplift bearing capacity of the prefabricated pile can be greatly enhanced.

Owner:周兆弟

Die for forming concrete pipe pile

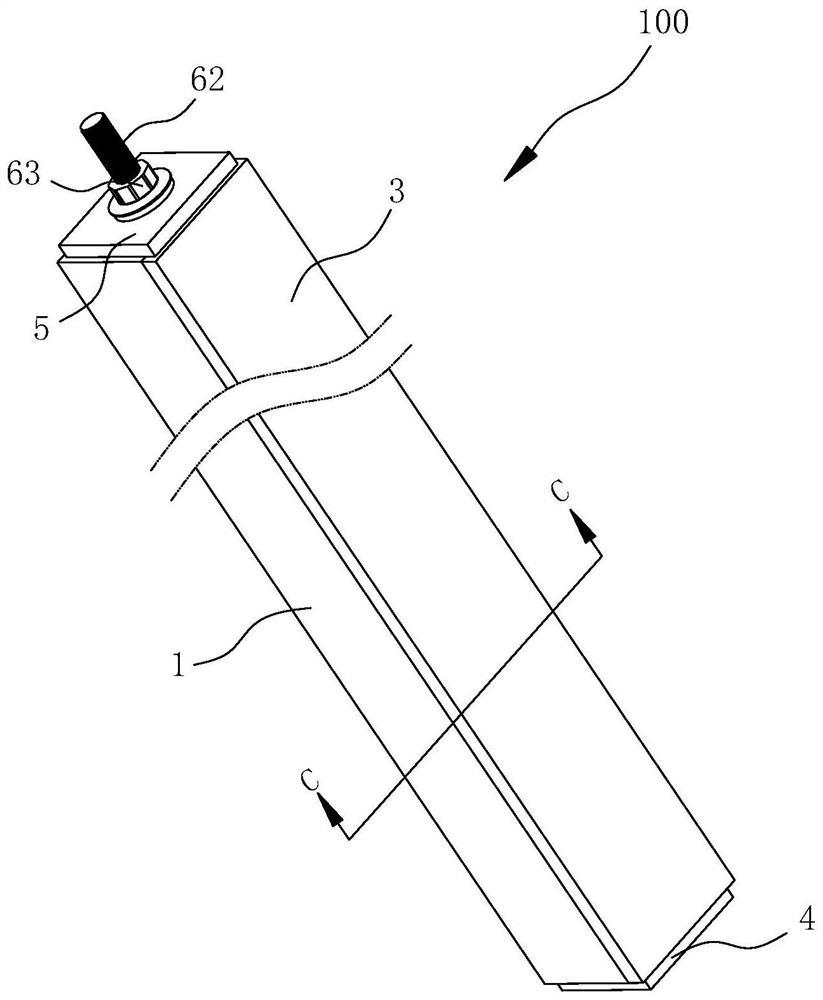

PendingCN110524713AImprove structural strengthAvoid deformationMouldsEngineeringUltimate tensile strength

The invention discloses a die for forming a concrete pipe pile, which is characterized in that a die cavity of the die is equipped with at least one thick pile hole section and at least one thin pilehole section along a length direction, and the thick pile hole section is communicated with the thin pile hole section, wherein at least one groove is formed in the hole wall of the thin pile hole section, the length direction of the groove is consistent with the length direction of the die, the difference between the radius value of an inner hole of the thick pile hole section and the radius value of an inner hole of the thin pile hole section is larger than the groove depth of the groove, and a shaft shoulder surface is formed between the hole wall of the thick pile hole section and the holewall of the adjacent thin pile hole section. The die for forming the concrete pipe pile has the advantage of being simple in structure, the concrete pipe pile with better anti-pulling bearing performance can be conveniently manufactured and formed, but also the overall structural strength of the die is greatly improved, and the die is prevented from deforming.

Owner:周兆弟

Construction method of equipment foundation reserved square hole

ActiveCN102493482AFlexible supportFlexible demolitionForms/shuttering/falseworksFoundation engineeringEngineeringPlastic film

The invention belongs to a construction method of an equipment foundation reserved square hole. The construction method of the equipment foundation reserved square hole is characterized by comprising the following steps: first step, assembling a die; second step, erecting the die: adjusting the dimensions of an upper opening of the reusable die of the equipment foundation reserved square hole, unscrewing a fourth positioning nut, moving a second sliding adjustment seat downwards to reach the rectangular dimensions of a corner die plate upper opening, unscrewing a second positioning nut, moving a first sliding adjustment seat downwards to reach the rectangular dimensions of an corner die plate lower opening, then screwing a third positioning nut and a first positioning nut, and taking a plastic film or a binding tape as a protective layer of the die plate to wrap up on the outside walls of the corner die plate and a middle die plate; third step, pouring concrete; fourth step, removing the die plates, extracting the corner die plate and leaving a square hole opening; and fifth step, cleaning the hole opening to obtain the equipment foundation reserved square hole. The method is simple to operate and is fast in die removal, and the die can be reused.

Owner:CHINA FIRST METALLURGICAL GROUP

A marine engineering dragging anchor that can improve the uplift bearing performance

The invention discloses an ocean engineering drag anchor capable of improving anti-pull bearing capacity. The ocean engineering drag anchor comprises an anchor claw and an anchor handle which are connected with each other, and the contact surfaces of the anchor claw and anchor handle with seabed soil are coated with a curable seabed soil diffusion coating. The ocean engineering drag anchor capableof improving the anti-pull bearing capacity has the advantages that the seabed soil around the drag anchor is solidified and hardened through the diffusion coating and a slip casting mechanism to improve the strength of the surrounding seabed soil, thereby improving the anti-pull bearing capacity; the contact area between the drag anchor and the seabed soil is increased during drag through an ejectable externally extending plate to increase the friction between the seabed soil and the drag anchor, thereby further improving the anti-pull bearing capacity.

Owner:HOHAI UNIV

Pipe pile structure anchored by steel strands and manufacturing method

PendingCN113863315AImprove the pull-out capacityEnhanced pull-out load bearing performanceExcavationsBulkheads/pilesCorrosion preventionDrill hole

The invention discloses a pipe pile structure anchored by steel strands and a manufacturing method, and belongs to the technical field of pipe piles. The pipe pile structure comprises a pipe pile device, a steel strand, a basement bottom plate, an anchoring plate, a prefabricated plate, a concrete layer, a gravel layer and an interstitial cement paste layer; the bottom end of the steel strand is fixedly installed on the anchoring plate, the top end of the steel strand is fixed to the basement bottom plate, the basement bottom plate is installed at the top end of the pipe pile device, the anchoring plate is embedded in the prefabricated plate, the prefabricated plate is placed at the bottom end of a drilling well, the top end of the prefabricated plate is the poured concrete layer, the gravel layer is arranged at the top end of the concrete layer, and the pipe pile device sinks into the top end of the gravel layer. The interstitial cement paste layer is poured into a gap between the pipe pile device and a well wall. According to the pipe pile structure anchored by the steel strands and the manufacturing method, the anchoring plate is pre-buried at the bottom end of a drill hole, the basement bottom plate is placed at the top end of a pipe pile, and the steel strand is connected with the anchoring plate and the basement bottom plate, so that the uplift bearing capacity of the pipe pile is enhanced, and corrosion prevention of the pipe pile is also facilitated.

Owner:NINGBO CONSTR GUANGTIAN COMPONENT PART +1

Equipment base pre-reservation round anchor bolt hole die

ActiveCN102433989BFlexible demolitionQuick dismantlingForms/shuttering/falseworksEngineeringScrew thread

The invention relates to a round hole die of an equipment base pre-reservation anchor bolt hole, in particular to an equipment base pre-reservation round anchor bolt hole die, which is characterized in that the equipment base pre-reservation round anchor bolt hole die comprises a center shaft, a first bracing and shrinking device, a second bracing and shrinking device, four templates and four joint sealing plates, wherein the four templates are all in an arc shape and uniformly distributed along a circumference, each joint sealing plate is inserted between two adjacent templates, the four templates and the four joint sealing plates enclose to form a cylindrical space, first template supports on the four templates are all articulated to the first bracing and shrinking device, second template supports on the four templates are all articulated to the second bracing and shrinking device, the lower part of the center shaft, the first bracing and shrinking device and the second bracing and shrinking device are all arranged in the cylindrical space enclosed by the four templates and the four joint sealing plates, the upper part of the center shaft is arranged above the cylindrical space and is provided with outside threads, and a handle is arranged at the upper end of the center shaft. The die is simple to operate and rapid to disassemble and can be used repeatedly.

Owner:CHINA FIRST METALLURGICAL GROUP

A mold for forming variable-section piles

ActiveCN110524686BEasy to makeEasy to manufactureMouldsMould auxillary partsTriacontagonStructural engineering

The invention discloses a mold for forming variable-section piles. The mold cavity of the mold forms at least one regular polygonal thick hole section and at least one regular polygonal fine hole section along the length direction, and the regular polygonal thick hole section and the regular polygonal thick hole section The regular polygon fine hole section is connected; wherein, the hole wall of the regular polygon fine hole section is provided with at least one groove; the mold is in the cross section of the regular polygon coarse hole section, and the hole wall reaches the mold The shortest linear distance of the central axis is D1; the mold is in the cross-section of the regular polygon fine hole section, the shortest linear distance from the hole wall to the central axis of the mold is D2, and the difference between D1 and D2 is greater than The groove depth of the groove. The mold for forming variable-section piles has the advantage of simple structure, and can meet the requirements of forming variable-section piles with better pullout resistance and bearing performance.

Owner:周兆弟

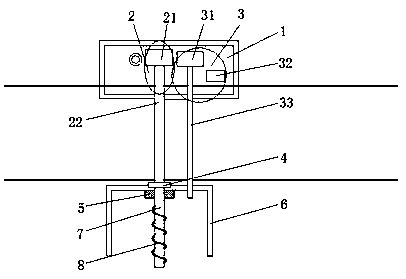

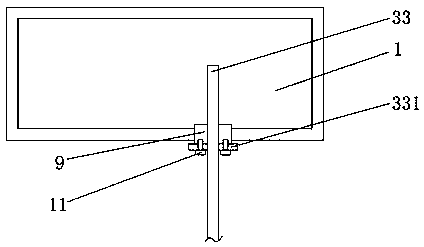

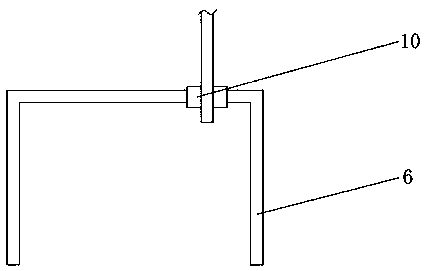

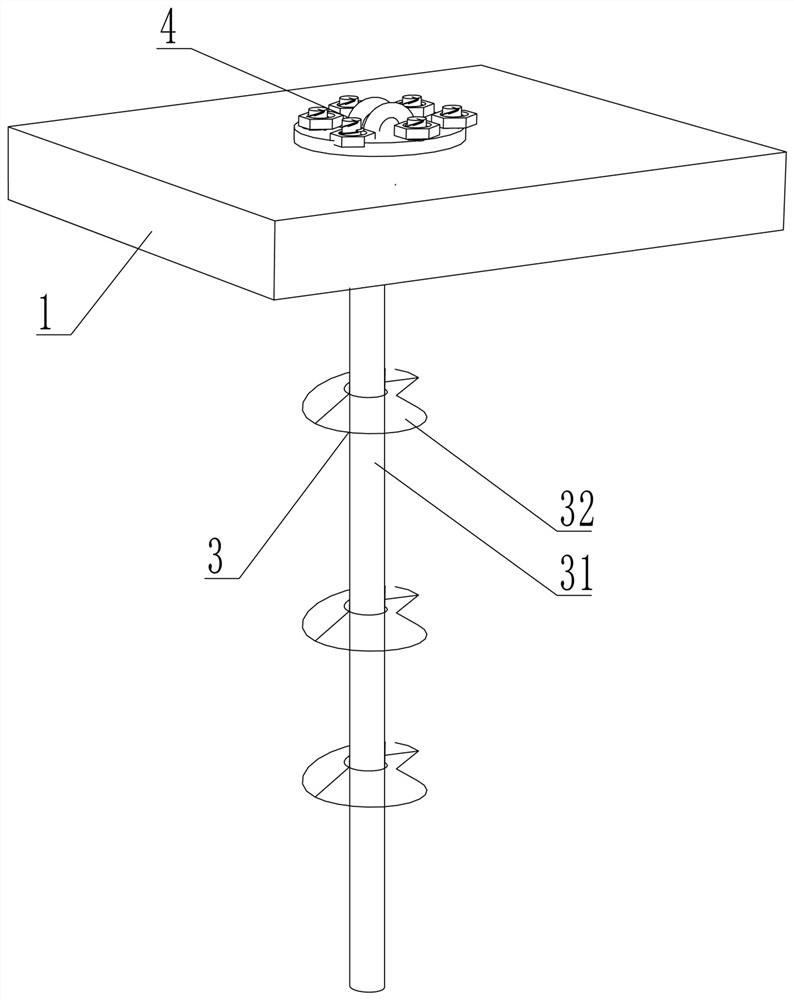

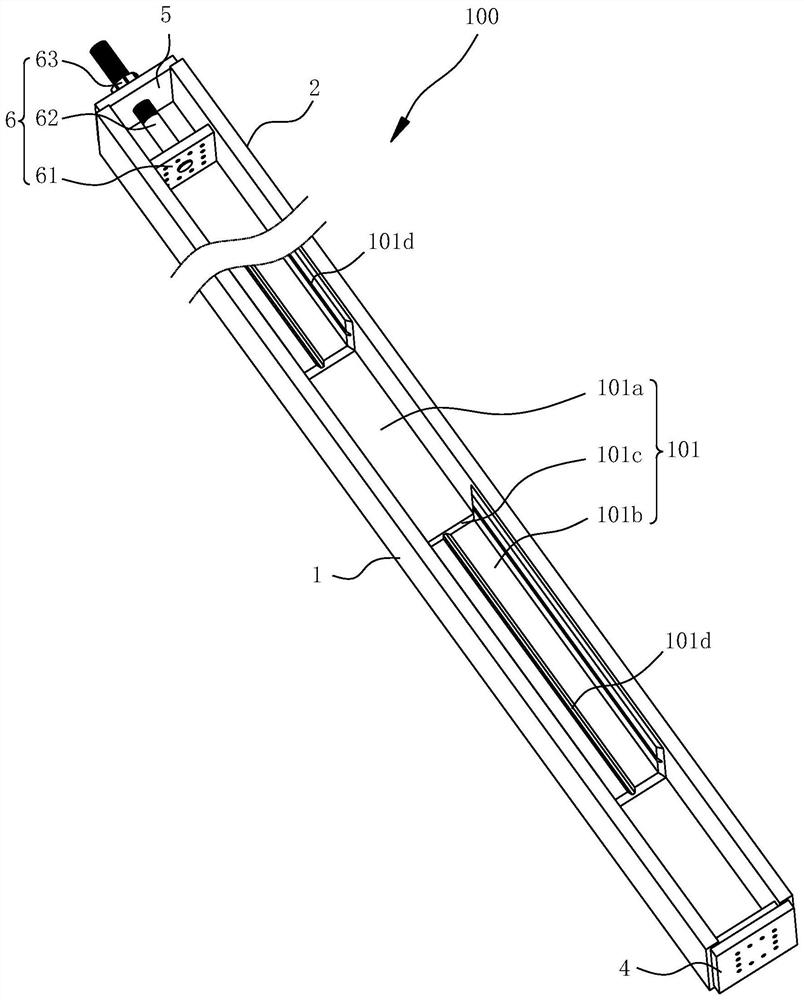

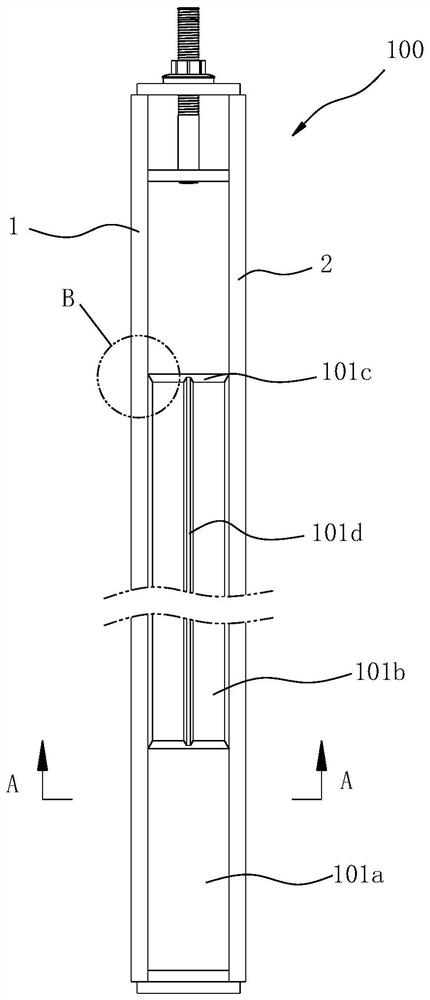

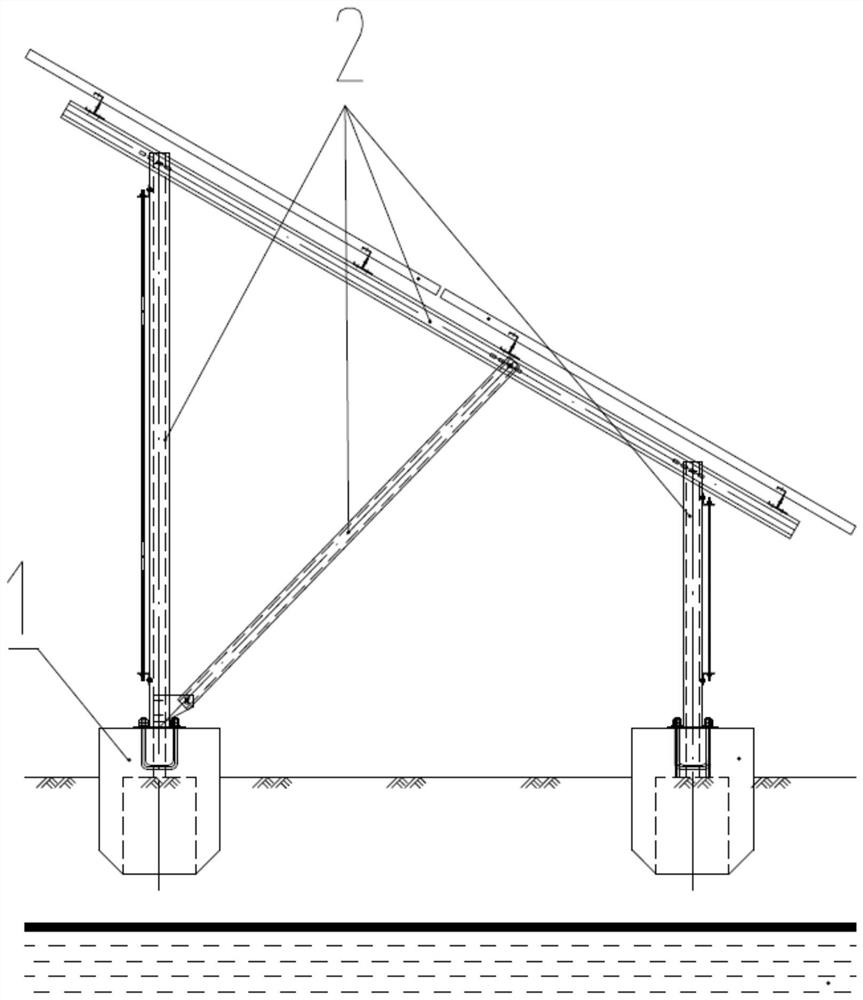

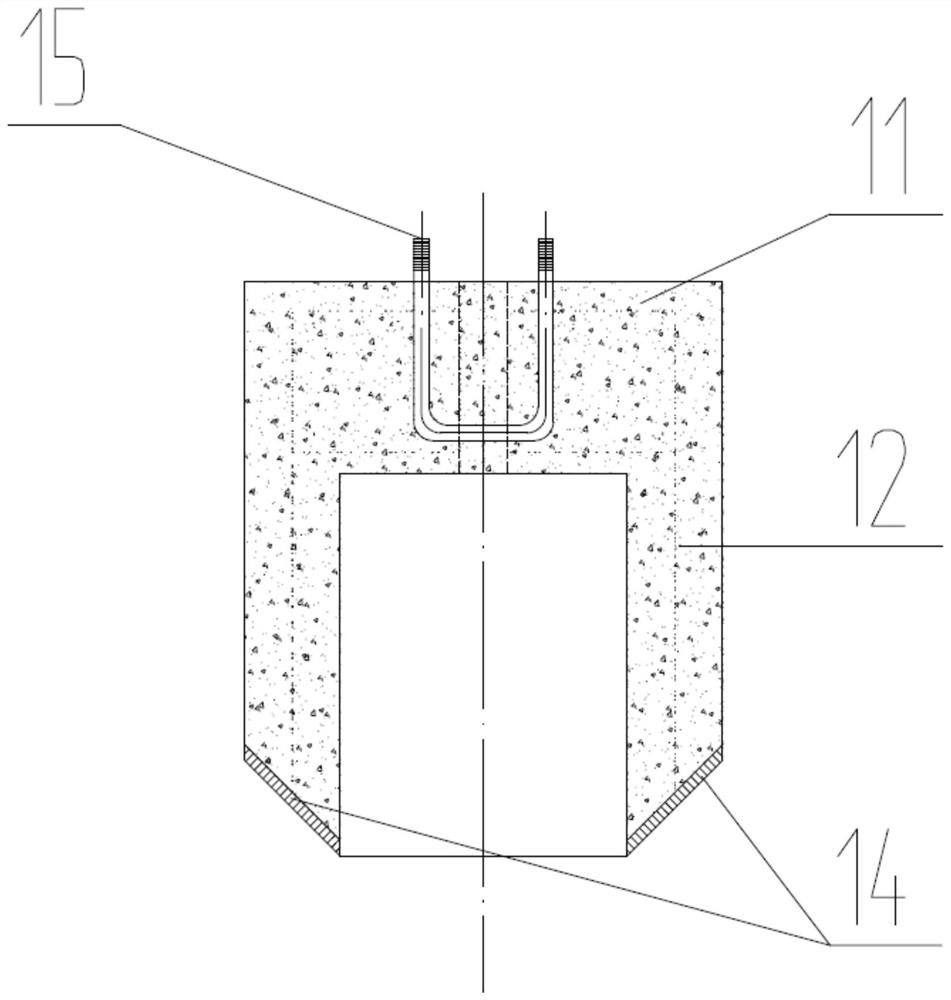

Shallow surface soil layer area photovoltaic support prefabricated barrel-shaped foundation and design method

PendingCN113774949AEnhanced pull-out load bearing performanceImprove the compressive bearing capacityFoundation engineeringPhotovoltaic energy generationArchitectural engineeringRebar

The invention discloses a shallow surface soil layer area photovoltaic support prefabricated barrel-shaped foundation and a design method. The prefabricated barrel-shaped foundation comprises a barrel wall and a barrel top plate, and the barrel wall is arranged below the barrel top plate; steel bars are arranged in the barrel wall and the barrel top plate; an embedded bolt and an air hole are arranged in the barrel top plate, the threaded section of the embedded bolt is higher than the upper surface of the barrel top plate, and the embedded bolt is connected with a photovoltaic support to realize the fixation of the photovoltaic support; and a boot plate is arranged below the barrel wall. The barrel-shaped foundation interacts with foundation soil to provide anti-pulling, anti-pressing and anti-horizontal bearing capabilities; the foundation is ensured to have enough bearing capacity, and the cost of foundation engineering is reduced; and through factory prefabrication and standardized batch production, the foundation quality is improved, the construction period is shortened, and the foundation is very suitable for shallow surface soil layer area photovoltaic power station engineering.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

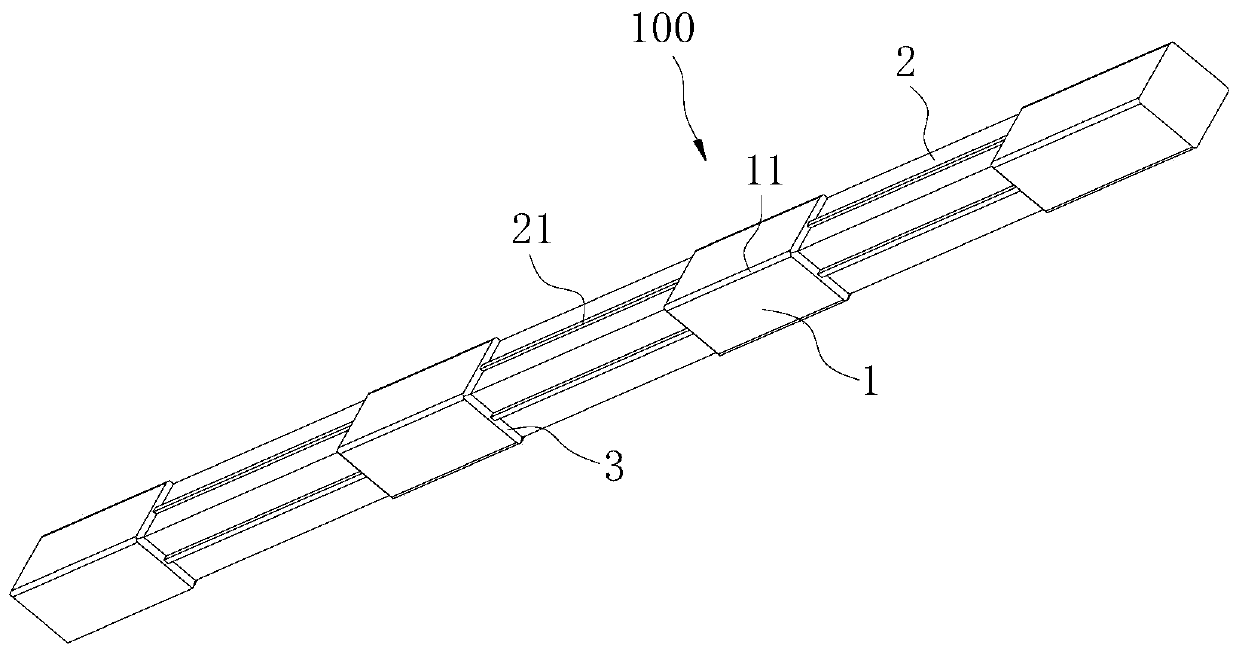

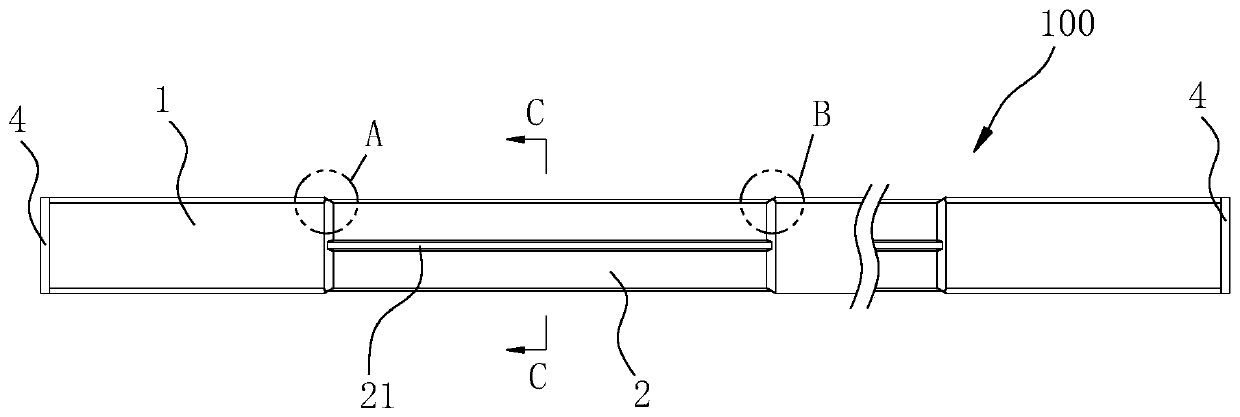

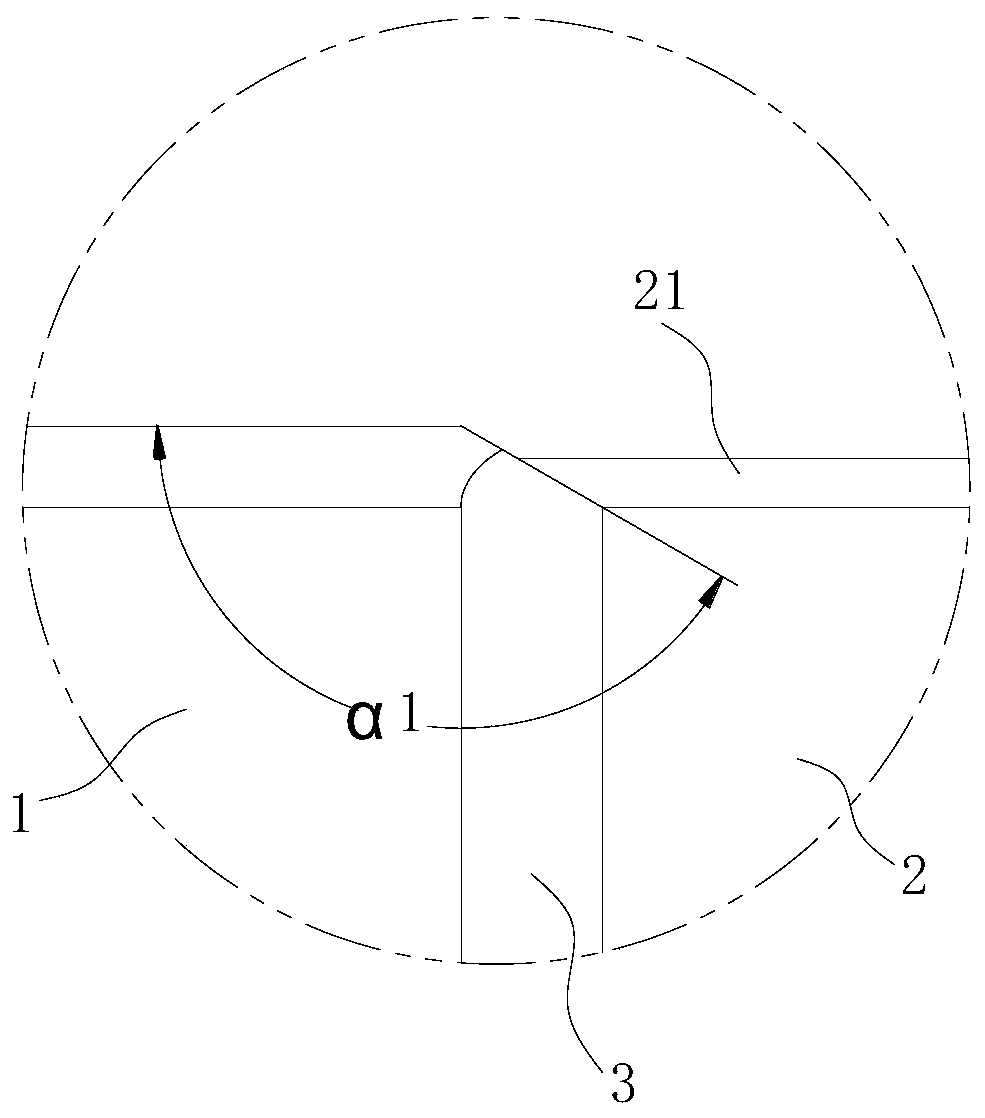

Continuous trepanning type steel folded plate connecting device and manufacturing method

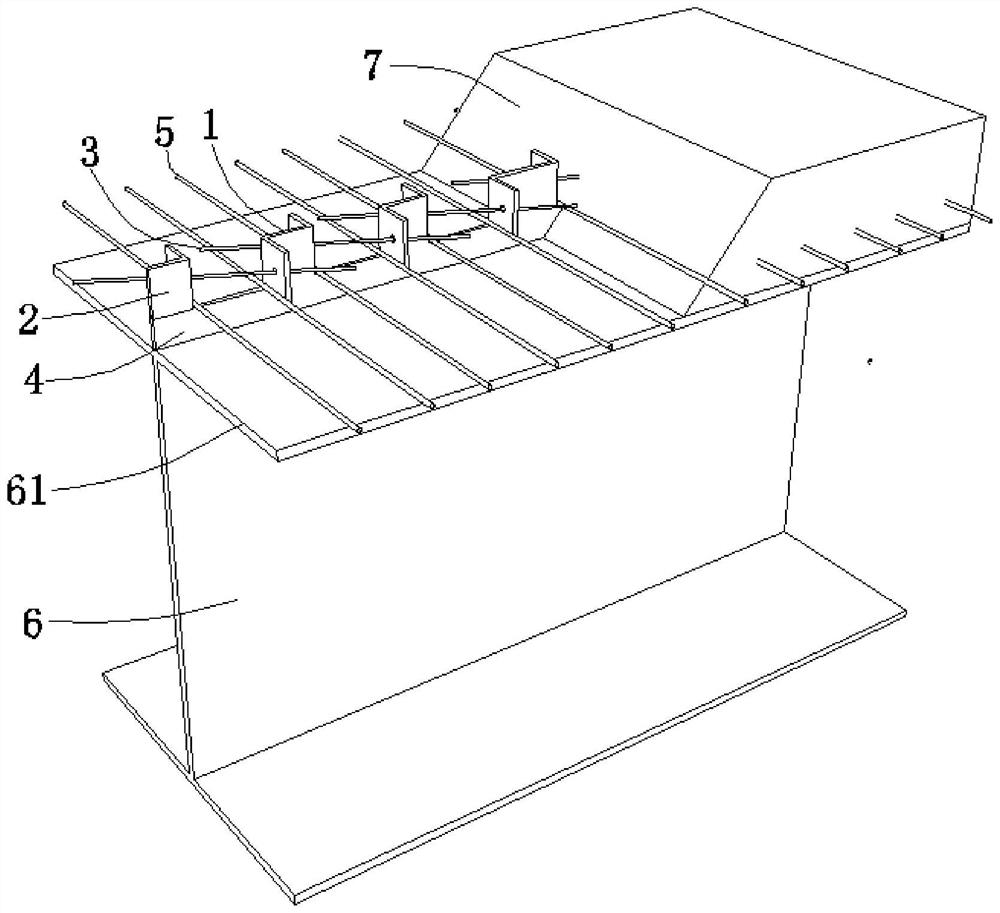

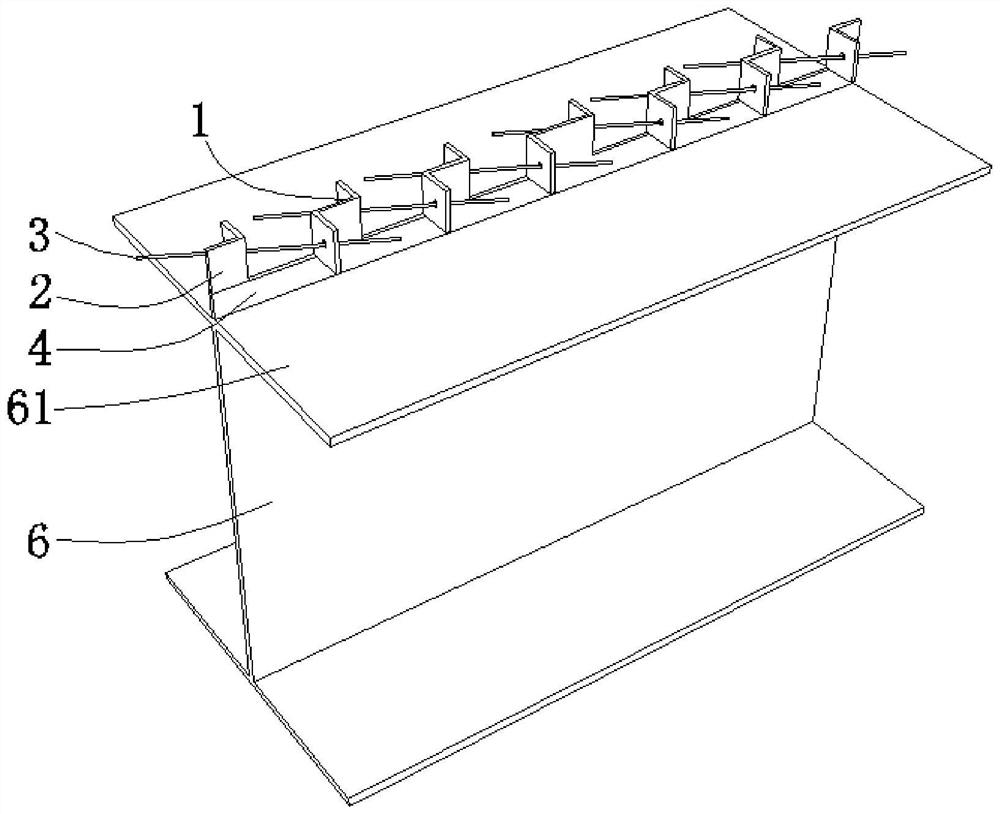

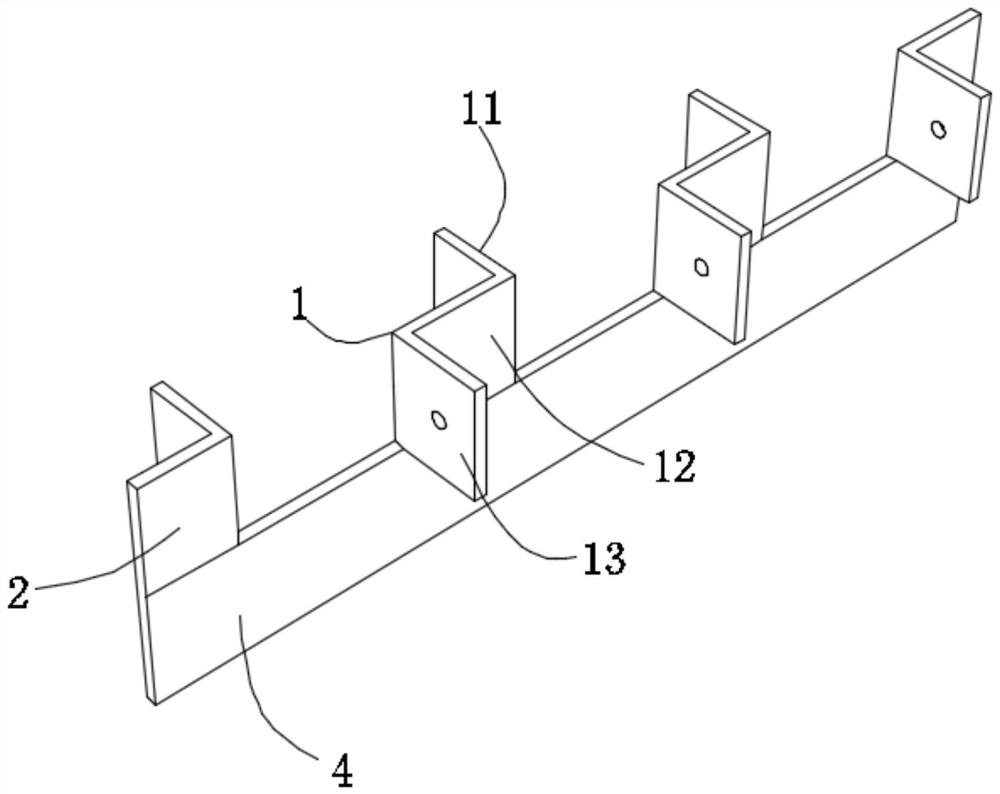

PendingCN113322786AHigh degree of spatial interlacingIncreased longitudinal shear capacityBridge structural detailsRebarMechanical engineering

The invention discloses a continuous trepanning type steel folded plate connecting device and a manufacturing method. The continuous trepanning type steel folded plate connecting device comprises a base, at least two first folded plates and two second folded plates, the first folded plates and the second folded plates are fixed to the base, and all the first folded plates are located between the two second folded plates; the two adjacent first folded plates are connected through corresponding first steel bars, and the second folded plates and the adjacent first folded plates are connected through corresponding first steel bars. The first folded plate comprises a first flat plate, a second flat plate and a third flat plate, the first flat plate and the third flat plate are arranged in parallel, the two ends of the second flat plate are connected with the first flat plate and the third flat plate respectively, and the second flat plate is connected with the base. The space staggering degree of the connecting device is higher, after concrete is poured, the first folded plates are embedded into the concrete, compressed concrete blocks are formed between the adjacent first folded plates, the action area of the first folded plates in the longitudinal shear force direction is large, the compressed concrete blocks with the larger size are formed, and the longitudinal shear bearing capacity of the connecting device is improved.

Owner:SOUTH CHINA UNIV OF TECH +2

Construction method of preserved foundation bolt hole of equipment foundation

ActiveCN102425300BFlexible demolitionQuick dismantlingForms/shuttering/falseworksBuilding material handlingStructural engineeringSquare cavity

The invention relates to a construction method of a preserved foundation bolt hole of an equipment foundation. The construction method is characterized by comprising the following steps of: 1, assembling a mould, wherein the mould comprises a center shaft, 2-4 spreading and contracting devices, 8 templates and an upper plate, every two templates are positioned on one side, the 8 templates are enclosed to form a square, the 2-4 spreading and contracting devices are positioned in a square cavity formed by enclosing the 8 templates, the lower end of the center shaft penetrates through the 2-4 spreading and contracting devices, a handle is welded on the upper end of the center shaft; 2, erecting the mould; 3, pouring concrete; 5, dismantling the mould, preserving a hole; and 5, cleaning the hole: galling the concrete surface around the hole by using an iron hook or steel brush, cleaning waste in the hole, and sealing the hole to obtain the preserved foundation bolt hole of the equipment foundation. The construction method is simple; and the used mould is simple in operation and high in template-dismantling speed, and can be repeatedly used.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method for circular foundation bolt hole reserved for equipment foundation

ActiveCN102493479BFlexible demolitionQuick dismantlingForms/shuttering/falseworksFoundation engineeringEngineeringStructural engineering

The invention relates to a construction method for a circular foundation bolt hole reserved for an equipment foundation. The construction method is characterized by comprising the following steps of: step one. assembling a mold for manufacturing the circular hole reserved for the equipment foundation, wherein the mold comprises a central shaft, a first propped open and contracting device, a second propped open and contracting device, four mold plates and four joint sealing plates; the four mold plates are arc-shaped and distributed along the circumference, the joint sealing plates are inserted between the mold plates, and the four mold plates and the four joint sealing plates form a cylindrical space in a surrounding manner; step two. supporting the mold; step three. pouring concrete; step four. removing the mold, and reserving the circular hole; at the moment, plastic films serving as protective layers of the mold plates in the circular hole and cement paste on the surface of the concrete come off in the initial setting and are convenient to clean; and step five. cleaning the hole, and obtaining the circular foundation bolt hole reserved for the equipment foundation. The construction method is simple to operate, is fast in mold dismantling; and the mold can be repeated used.

Owner:CHINA FIRST METALLURGICAL GROUP

Reusable mould for basic foundation bolt holes of large-scale equipment

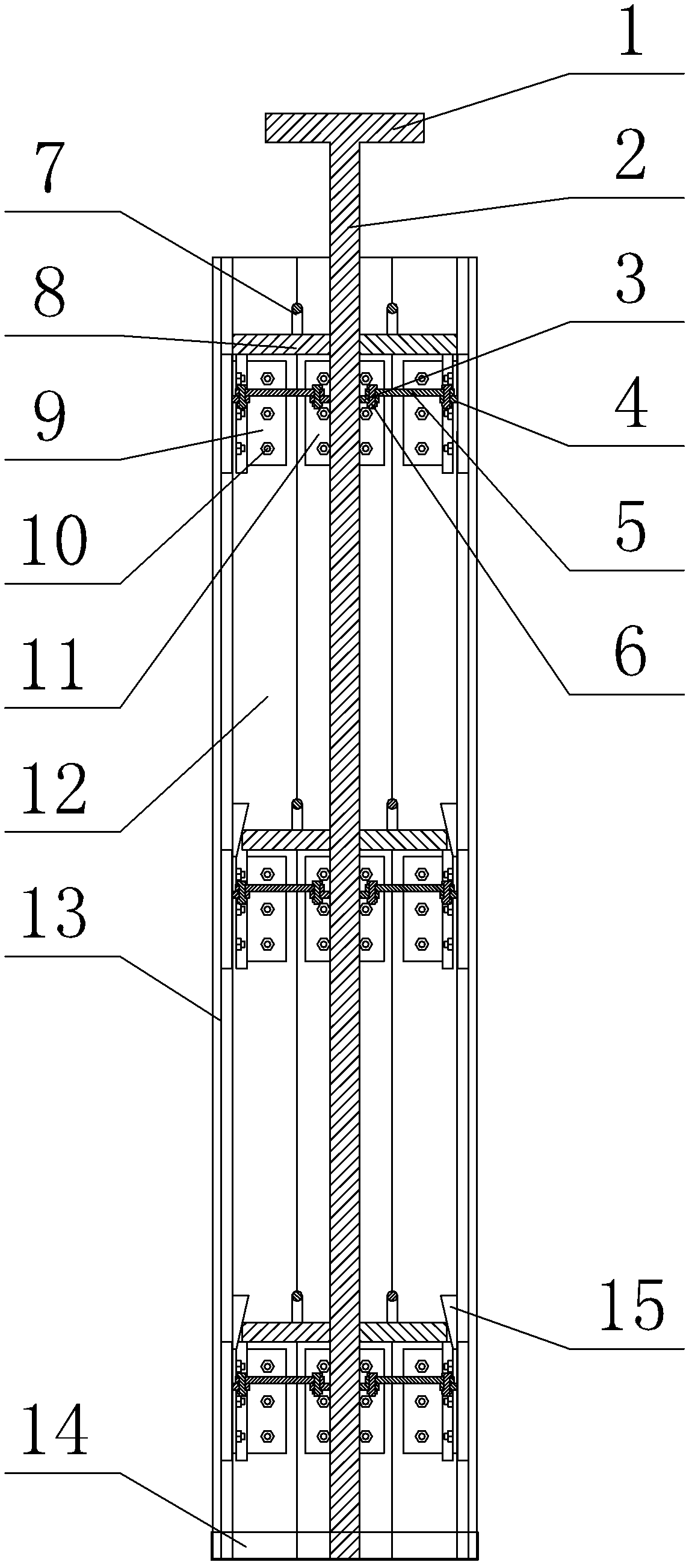

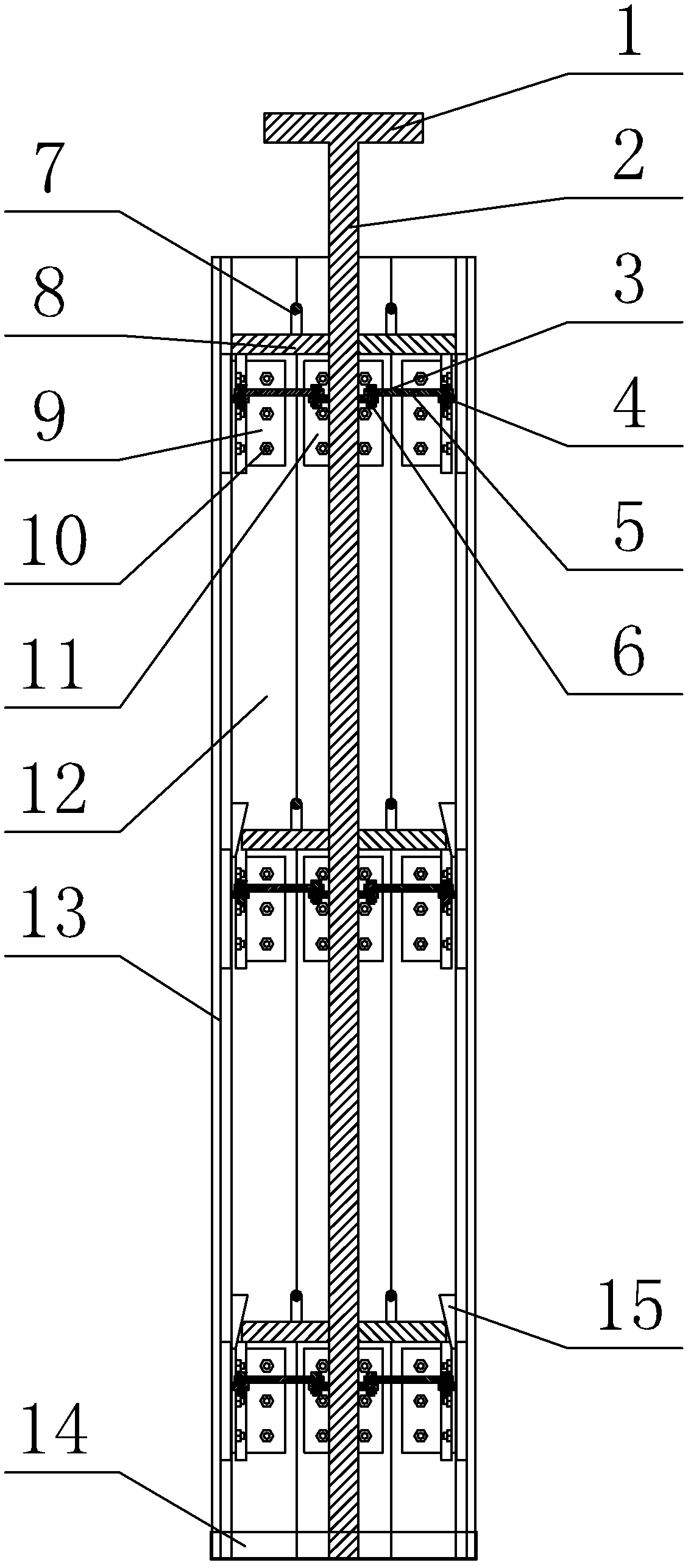

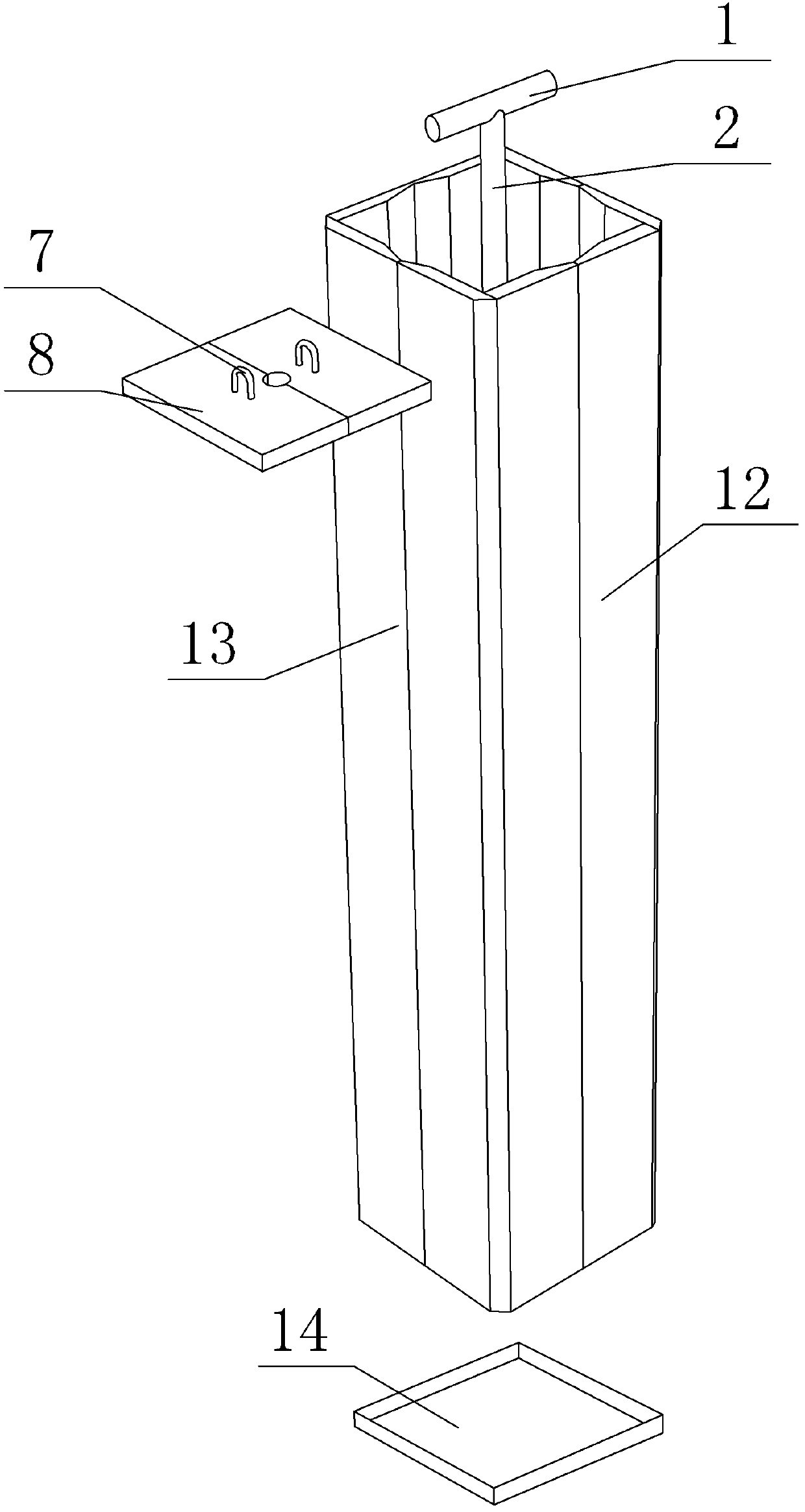

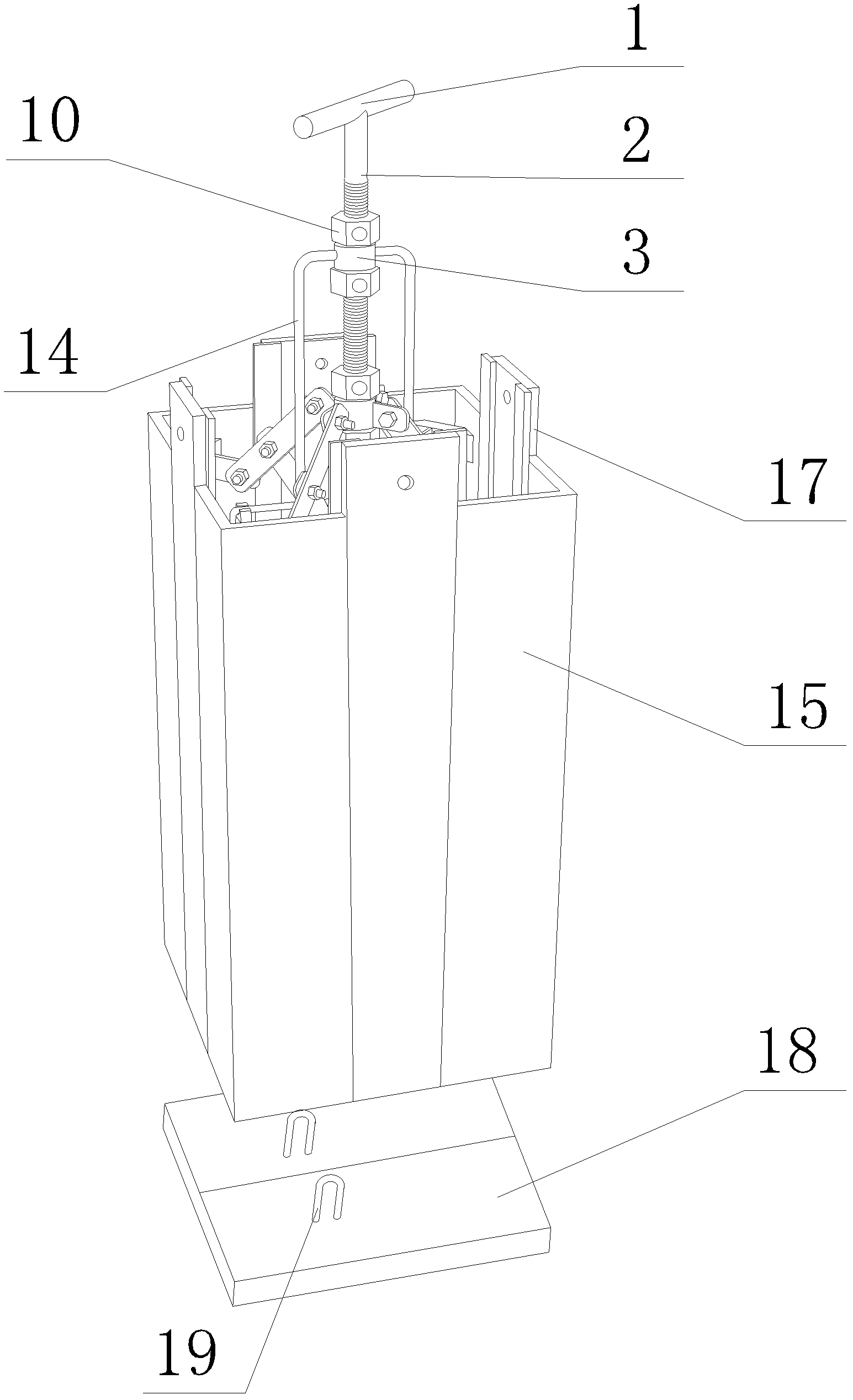

ActiveCN102433990AFlexible supportFlexible demolitionForms/shuttering/falseworksEngineeringSquare cavity

The invention relates to a reusable mould for basic foundation bolt holes of large-scale equipment. The reusable mould for the basic foundation bolt holes of the large-scale equipment is characterized by comprising a central shaft, 2 to 4 spreading and contracting devices and 8 templates; every two templates are positioned on one side, and the 8 templates define a square; the 2 to 4 spreading and contracting devices are positioned in the square cavity defined by the 8 templates; the lower end of the central shaft passes through the 2 to 4 spreading and contracting devices, and a handle is welded at the upper end of the central shaft; each spreading and contracting device comprises an inner link rod seat, an outer link rod seat, a movable link rod, a middle connecting hinge and a corner connecting hinge; the inner end of the movable link rod is hinged with the inner link rod seat, the outer end of the movable link rod is hinged with the outer link rod seat, and the outer link rod seat is welded and fixed with the middle connecting hinge; and the two adjacent templates positioned on the same side are hinged by the middle connecting hinge, and the two templates at a corner of two adjacent edges are hinged by the corner connecting hinge. The reusable mould is simple to operate, can be quickly dismounted and can be used repeatedly.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method of equipment base pre-reservation anchor bolt square hole

ActiveCN102433994BFlexible demolitionEasy to operateForms/shuttering/falseworksBuilding material handlingEngineeringPlastic film

The invention relates to a construction method of an equipment base pre-reservation square hole, in particular to a construction method of an equipment base pre-reservation anchor bolt square hole, which is characterized by comprising the following steps that, firstly, a die is assembled; secondly, the die is erected: the size of an upper hole of the die of the equipment base pre-reservation square hole, which can be repeatedly used, is regulated according to a drawing, a fourth locating nut is unscrewed, a second sliding regulation seat moves downwards so that the rectangular size of the upper hole of an angle template is reached, a second locating nut is unscrewed, a first sliding regulation seat moves downwards so that the rectangular size of a lower hole of the angle template is reached, the third locating nut and a first locating nut are screwed, and a plastic film or an adhesive tape wraps on the outer walls of the angle template and a middle template as a protective layer; thirdly, concrete is poured; fourthly, the template is disassembled, the angle template is extracted, a wood bottom plate is lifted out, and a square hole is left; and fifthly, the hole is cleaned, and the equipment base pre-reservation anchor bolt square hole is acquired. The construction method has the advantages that the operation is simple, die stripping is rapid, and the die can be repeatedly used.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method of large equipment foundation reserved foundation bolt hole

ActiveCN102493481BFlexible demolitionQuick dismantlingFoundation engineeringForms/shuttering/falseworksStructural engineeringSquare cavity

The invention relates to a construction method of a large equipment foundation reserved foundation bolt hole. The construction method of the large equipment foundation reserved foundation bolt hole is characterized by comprising the following steps: first step, assembling a die, wherein the die comprises a central shaft, two to four opening and shrinking devices, eight die plates and an upper plate, every two die plate are arranged on one side, eight die plates can enclose a square, the two to four opening and shrinking devices are positioned in the square cavity enclosed by the eight die plates, the lower end of the central shaft penetrates through the two to four opening and shrinking devices, and the upper end of the central shaft is welded a handle; second step, erecting the die; third step, pouring concrete; fourth step, removing the die and leaving a hole opening; fifth step, cleaning the hole opening: gigging the concrete surface surrounding the hole opening by using an iron hook or a steel wire brush, cleaning up the garbage in the hole and sealing the hole opening to obtain the large equipment foundation reserved foundation bolt hole. The method is simple, and the used die is simple to operate, is fast to disassemble and can be reused.

Owner:CHINA FIRST METALLURGICAL GROUP

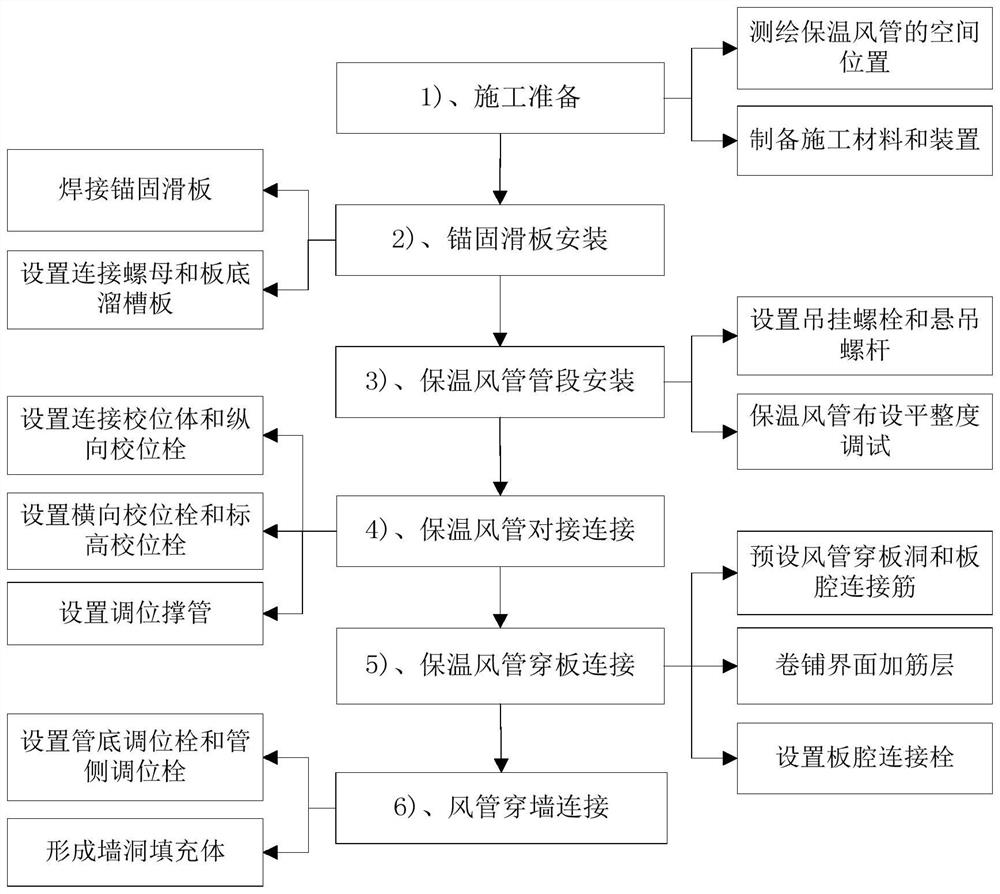

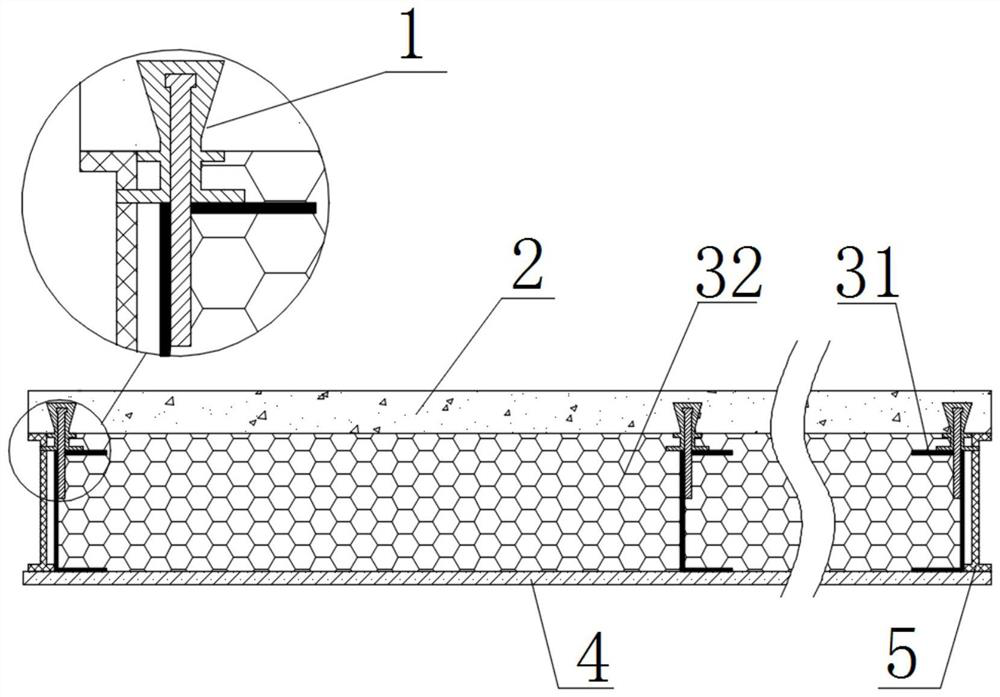

Construction method of internal thermal insulation metal air duct

PendingCN114182921AEnhanced pull-out load bearing performanceReduce difficultyFloorsForms/shuttering/falseworksFloor slabThermal insulation

The invention provides an internal thermal insulation metal air duct construction method which comprises the following steps: presetting an anchoring sliding plate in an upper floor slab, connecting a connecting nut with the anchoring sliding plate through a bolt hanging plate, and connecting the anchoring sliding plate with a floor slab reinforcement cage; the mounting flatness of the heat preservation air pipe is adjusted through the hanging bolt; two groups of connection correcting bodies are arranged on the support platform plate, and the spatial position of the heat preservation air pipe joint part is accurately controlled through a transverse correcting bolt, a standard height correcting body and a longitudinal correcting body; an inner supporting box body and an inner supporting bag are arranged in a pipe cavity of the heat preservation air pipe. Plate cavity connecting ribs connected with the pipe side connecting ribs are pre-arranged in the air pipe plate penetrating holes of the upper floor slab; a pipe bottom position adjusting bolt and a pipe side position adjusting bolt are arranged between the air pipe through-wall hole and the heat preservation air pipe, and a gap between the heat preservation air pipe and the masonry wall is sealed through light concrete. The construction efficiency can be improved, the mounting and positioning precision is improved, and the construction difficulty is reduced.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY +1

Great-diameter variable section irregularly-shaped resistance-increased steel pipe pile system and construction method thereof

The invention discloses a great-diameter variable section irregularly-shaped resistance-increased steel pipe pile system, which comprises an offshore work platform. Lifting equipment and a high-pressure pump are arranged on the offshore work platform. The high-pressure pump is connected with a plurality of high-pressure injection pipes on the inner wall of a steel pipe pile. A pile cap is arranged at the top end of the steel pipe pile. A vibratory hammer connected with the lifting equipment is arranged on the upper part of the pile cap. A slurry pump bracket is arranged in the steel pipe pile. A slurry discharge pipe is supported on the slurry pump bracket. The lower part of the slurry discharge pipe is connected with a slurry pump, and the upper part of the slurry discharge pipe is communicated with a slurry discharge opening in the lateral surface of the steel pipe pile. The invention also discloses a construction method for the great-diameter variable section irregularly-shaped resistance-increased steel pipe pile system. The great-diameter variable section irregularly-shaped resistance-increased steel pipe pile system and the construction method thereof are adapted to various kinds of foundation engineering with special technical requirements on the pressure resistance, pulling resistance, bending resistance and the like of pile foundations, particularly to a large-sized single body structure of offshore engineering such as a bridge pier and an offshore wind turbine, and have the characteristics of convenience for construction, low construction cost, easy control over construction quality, and the like.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Reusable mould for basic foundation bolt holes of large-scale equipment

ActiveCN102433990BEnhanced pull-out load bearing performanceFree from damageForms/shuttering/falseworksEngineeringSquare cavity

Owner:CHINA FIRST METALLURGICAL GROUP

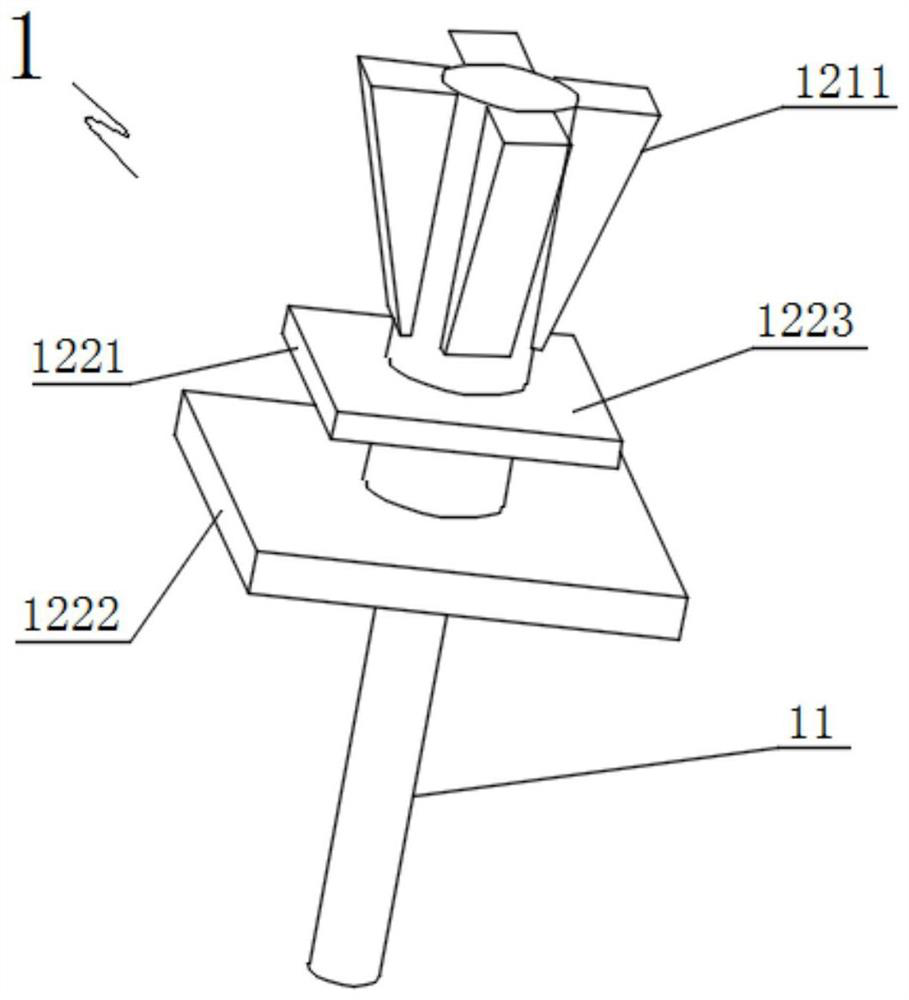

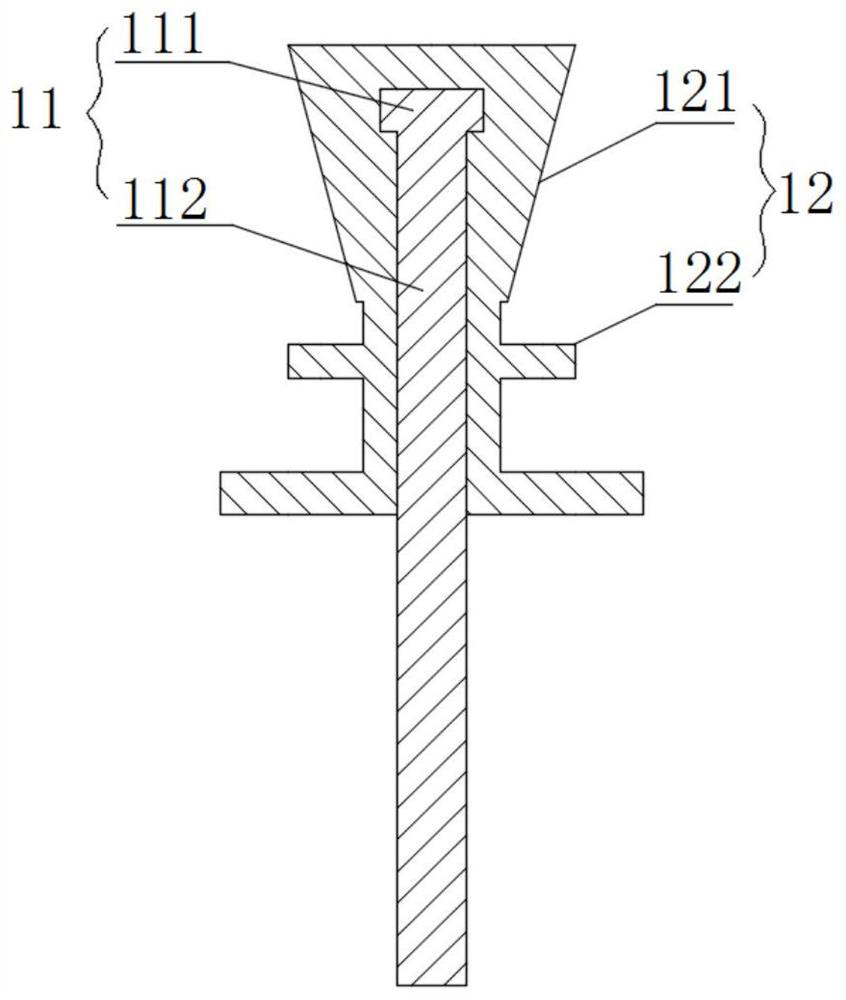

Half-wrapped GFRP shear connector, structural wallboard and processing method of wallboard

PendingCN114718191AImprove insulation effectEnhanced pull-out load bearing performancePassive housesCeramic shaping apparatusMechanical engineeringWall plate

The invention discloses a half-wrapped GFRP shear connector, a structural wallboard and a wallboard processing method.The half-wrapped GFRP shear connector is formed by wrapping the upper end of a traditional shear nail with a GFRP wrapping body made of GFRP materials, the GFRP wrapping body is provided with a cross-shaped cap part and an abutting part, the abutting part is fixedly connected to the lower surface of the cross-shaped cap part and integrally formed with the cross-shaped cap part, and the cross-shaped cap part and the GFRP wrapping body are integrally formed. The nail head part is completely positioned in the cross-shaped cap part; the cross-shaped cap portion is of a big-end-up structure, and an abutting face exceeding the lower end face of the cross-shaped cap portion is formed at the position, connected with the cross-shaped cap portion, of the abutting portion. The structural wallboard is a light steel keel wallboard, and U-shaped steel of a light steel keel and an outer wallboard of the structural wallboard adopt half-wrapped GFRP shear connectors. The half-wrapped GFRP shear-resistant connecting piece is used for effectively blocking a heat exchange path inside and outside a wallboard when an outer wallboard on the wallboard is connected with a keel, and the heat preservation performance of the wallboard and the anti-pulling bearing capacity of the wallboard are improved.

Owner:苏州思萃融合基建技术研究所有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com