Half-wrapped GFRP shear connector, structural wallboard and processing method of wallboard

A technology for shear-resistant connectors and wall panels, which is applied in the direction of manufacturing tools, building components, building structures, etc., can solve the problems of poor thermal insulation performance of the overall wall panels, and achieve the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

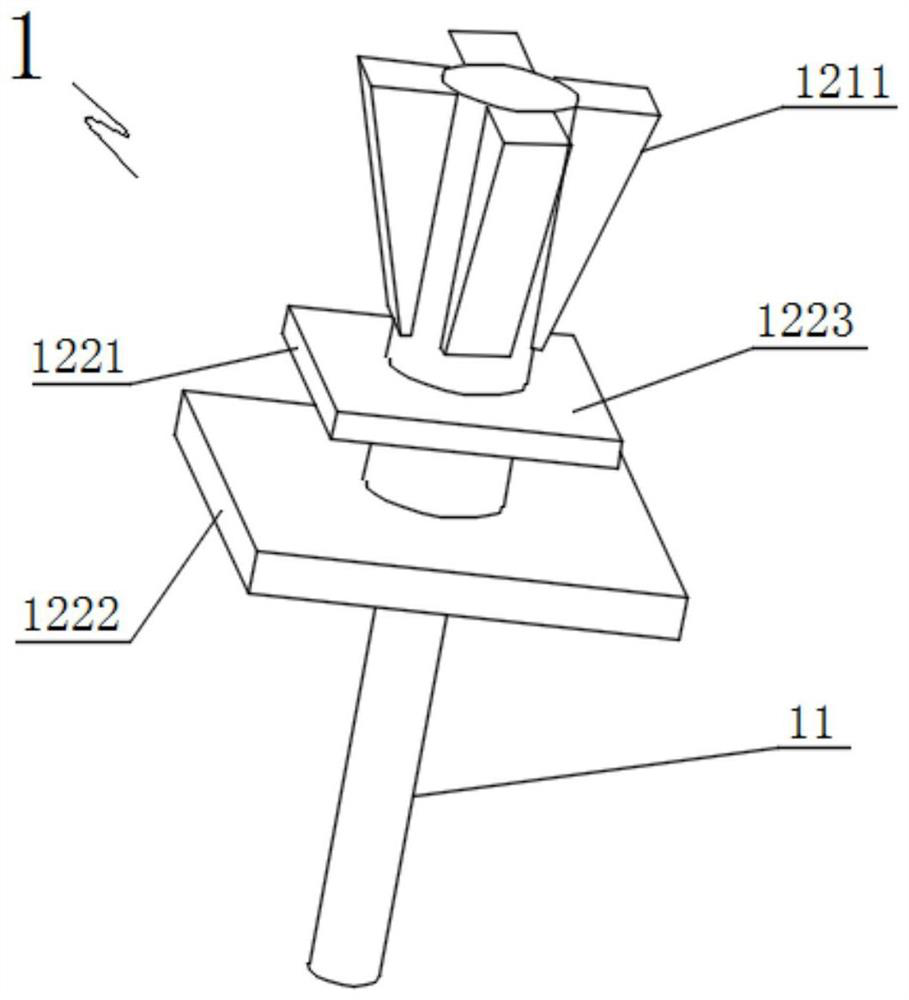

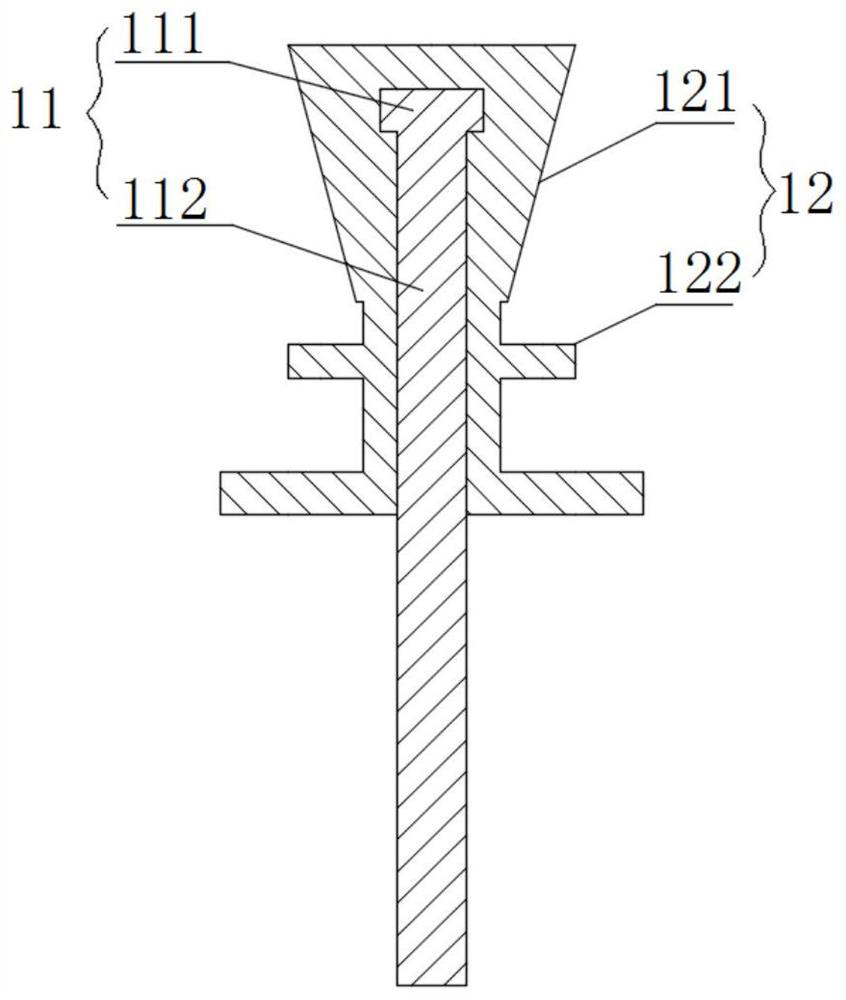

[0040] A half-pack GFRP shear connector such as figure 1 and figure 2 As shown, the half-pack GFRP shear connector is a new shear nail 1 formed by structural improvement on the basis of traditional shear force, which includes a shear nail body 11 and a GFRP inclusion 12 . The shear nail body 11 is provided with a nail head 111 and a mandrel 112 connected to the lower end of the nail head 111 . The GFRP package 12 is composed of a cross cap portion 121 and an abutting portion 122 that is fixedly connected to the lower surface of the cross cap portion 121 and integrally formed with the cross cap portion 121 . The GFRP inclusion 12 is provided with a cavity on the inner surface of the cross cap portion 121 toward the lower surface of the abutment portion 122 that matches the nail head 111 and the mandrel 112 of the shear nail body, and the GFRP inclusion 12 is wrapped around the shear nail body through the cavity. 11 , the total length of the GFRP inclusion 12 is the same as t...

Embodiment 2

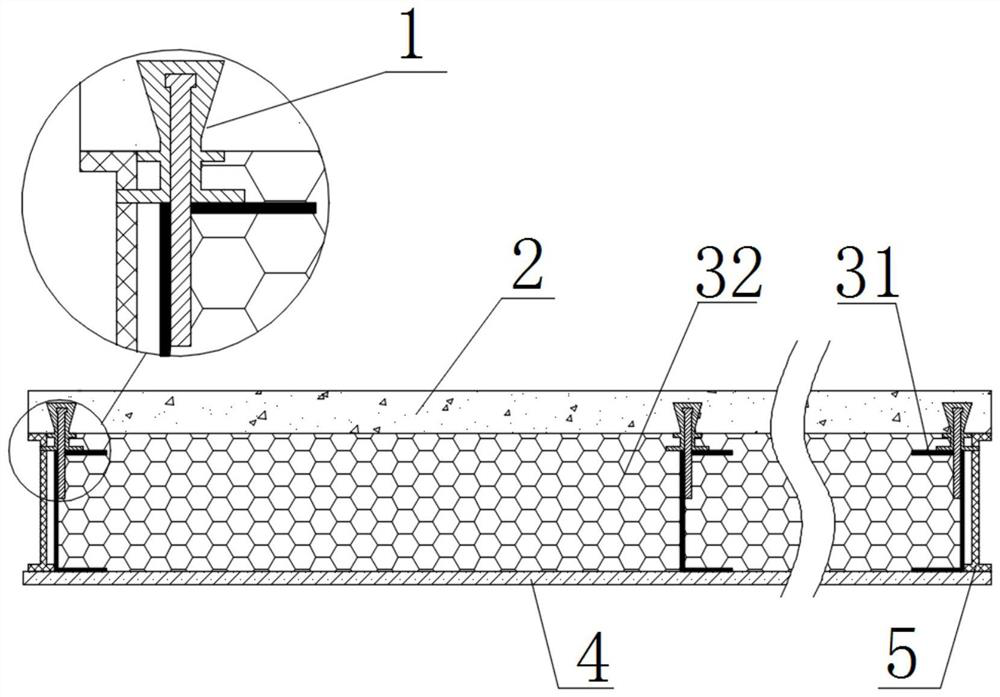

[0043] A structural wall panel such as image 3 and Figure 4As shown, the structural wall panel is provided with an outer panel 2, an inner panel 4, a shear nail 1, a FRP edge panel 5 and a thermal insulation sandwiched between the outer panel 2 and the inner panel 4. Layer 3. The FRP edge sealing plate 5 consists of a vertical support portion 52, a horizontal bottom portion 53 provided at the bottom end of the support portion 52 and extending to both sides, and a horizontal top portion provided at the top of the vertical support portion 52 and extending to one side. 51 composition. The thermal insulation layer 3 is composed of a light steel keel frame 31 composed of U-shaped steel 311 and a rock wool 32 thermal insulation material filled in the keel frame 31 . The upper and lower surfaces of the thermal insulation material and the FRP edge banding board 5 abut against the inner surfaces of the outer wall panel 2 and the inner page wall panel 4 correspondingly, and the low...

Embodiment 3

[0046] like image 3 The processing method of the structural wall panel shown, the processing method comprises the following processing steps:

[0047] Step 1: Prepare materials (shear nail 1, FRP edge plate 5, U-shaped steel, etc.), tools, etc.; according to the keel size on the wall panel drawing, cut the U-shaped steel 311, and then according to the shear nail 1 layout diagram in The upper flange of U-shaped steel 311 is punched, and the punching position must be close to the U-shaped steel web;

[0048] Step 2: Assemble the finished keel into a frame with rivets, and then weld the connection points between the keels; according to the size and bearing requirements of the designed structural wall panel, if necessary, increase the horizontal or / and vertical U in the keel frame 31 Section steel is welded and connected to the keel frame 31 to enhance the overall strength; the upper and lower flanges of the added U-shaped steel are aligned with the upper and lower flanges of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com