Conical barrel supporting body used for anchor bolt and anchor bolt

A technology of bearing body and anchor rod, which is applied in the direction of installing anchor rods, sheet pile walls, mining equipment, etc., can solve the problems of small bearing area, small pull-out resistance, and low mechanical strength, and achieve pull-out resistance of anchor rods The effects of increased force, improved pull-out resistance, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

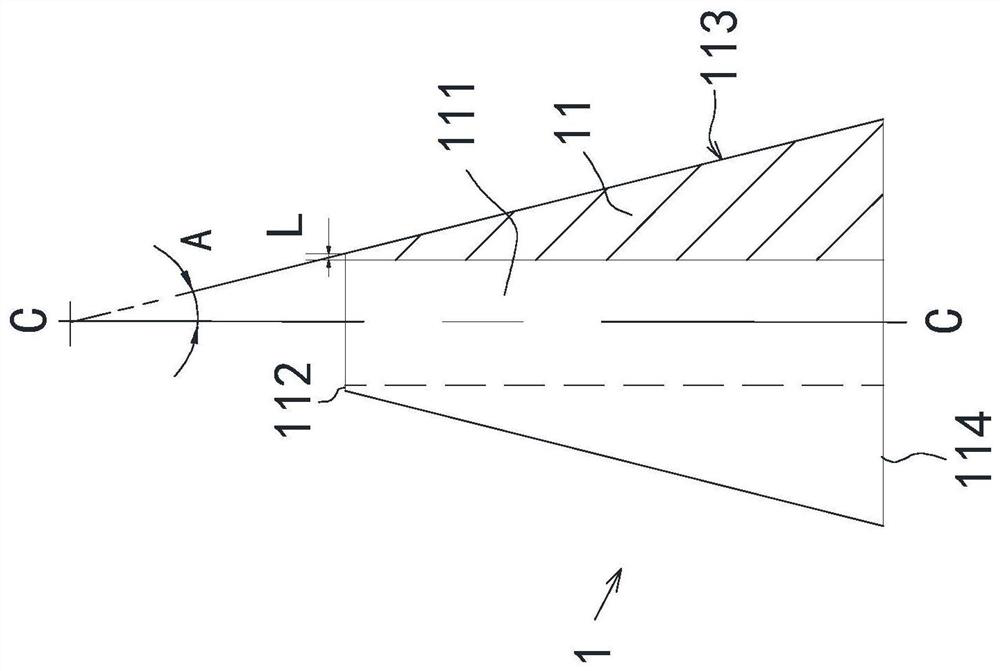

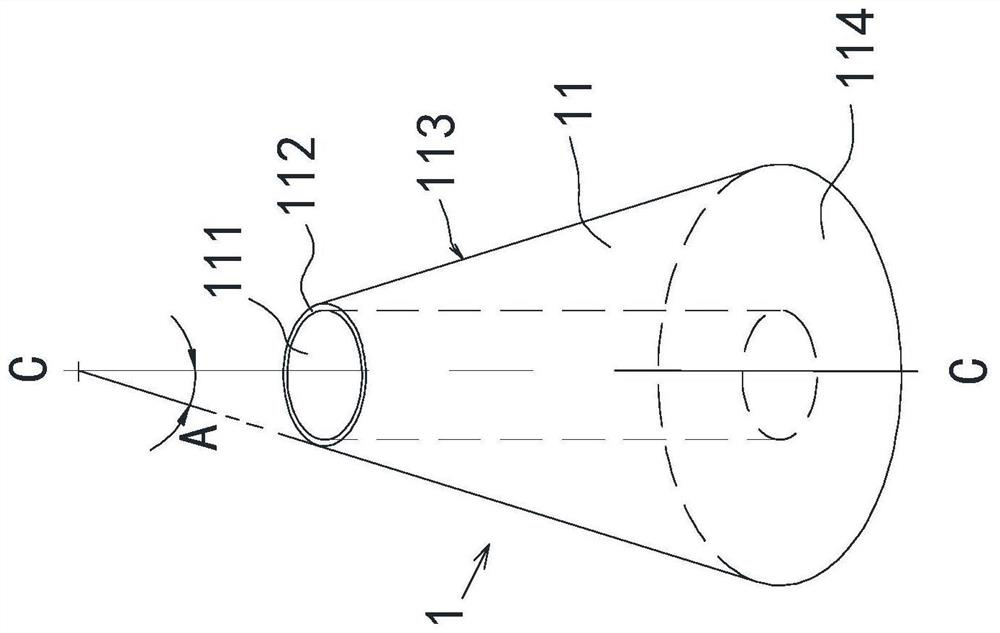

[0070] Such as Figures 1A-1B , figure 2 As shown, the present embodiment 1 provides a conical tube carrier 1, which is formed by a tube wall 11 surrounded by a tube wall 11 to form a central hole 111, the central hole 111 is a straight-through light hole, The hole diameter is slightly larger than the outer diameter of the rod body 2 of the anchor rod, and the diameter difference is less than 4mm. The rod body 2 of the anchor rod penetrates the central hole 111, so that the cone carrier 1 is sleeved on the rod body 2 of the anchor rod.

[0071] In this embodiment, the cross section of the top 112 and the bottom 114 of the cylinder wall 11 is a hollow circle, the conical surface 113 is a conical surface surrounding the central hole 111, and the included angle A between the conical surface and the axis C-C of the central hole 111 is 10° , the cone carrier body 1 has a cone structure.

[0072] In this embodiment, the wall thickness L of the cylinder wall top 112 is 2 mm. The t...

Embodiment 2

[0074] see Figure 4 , Figure 5 , The second embodiment provides a conical cylinder carrier 1, including a cylinder wall 11, the cylinder wall 11 is a conical cylinder structure, and the external structure is consistent with the first embodiment. The difference from Embodiment 1 is that in this embodiment, the inner thread 1111 is processed on the wall of the central hole 111, which matches the outer thread on the rod body 2 of the anchor rod, and is used as the cone carrier 1 and the anchor rod. The connecting structure between the rod bodies 2 makes the cone carrier body 1 occluded and connected to the rod body 2 of the anchor rod.

[0075] In this embodiment, the cone carrier 1 has an internal thread 1111 on the wall of the central hole 111, so no welding equipment is needed during on-site construction, and the cone carrier 1 can be directly screwed to the position set by the rod body 2 of the anchor rod. Easy to operate.

Embodiment 3

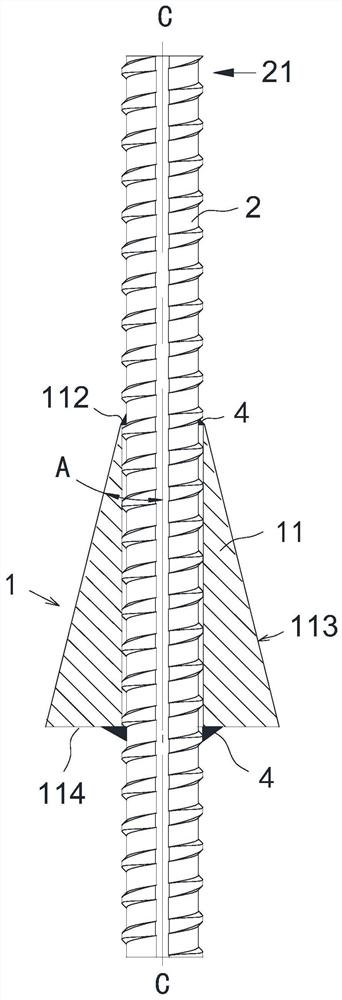

[0077] see Figures 6A-6B , a conical cylinder carrier 1 provided in the third embodiment, the conical cylinder carrier is formed by the cylinder wall 11, the central hole 111 formed after the cylinder wall 11 is surrounded is a straight through light hole, and the rod body 2 of the anchor rod passes through into the central hole 111, and the cone bearing body 1 is set on the rod body 2 of the anchor rod. Different from Embodiments 1 and 2, the cross-sections of the top 112 and bottom 114 of the cylinder wall in this embodiment are both hollow hexagons, and the conical surface 113 is a hexagonal conical surface surrounding the central hole 11. The conical cylinder carrier 1 It has a hexagonal pyramid structure, and the included angle A between the cone surface 113 and the axis C-C of the central hole 111 is about 15°. On the plane where the top 112 and bottom 114 of the cylinder wall meet the rod body 2 of the anchor rod, weld seams 4 are piled up, and the cone carrier 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com