Composite cylinder type foundation with auxiliary piles added in later period

A cylindrical foundation and auxiliary pile technology, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of high risk, overall structure damage, and high cost, and achieve the effects of improving efficiency, improving shear resistance and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

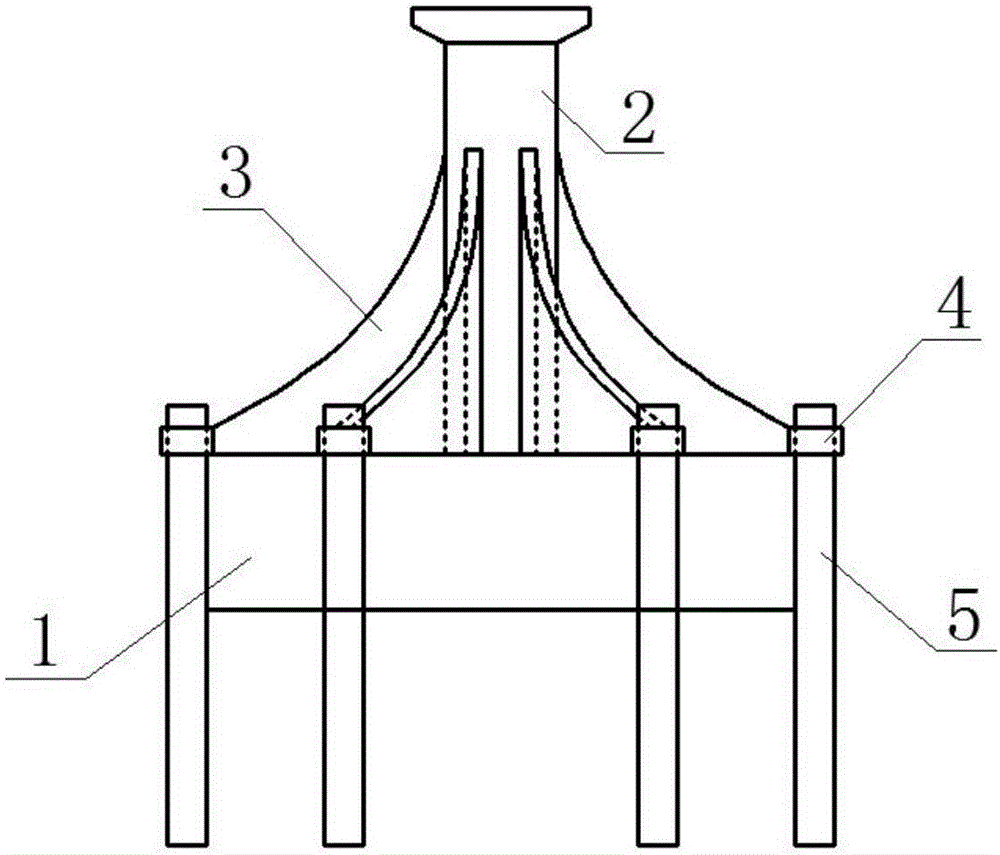

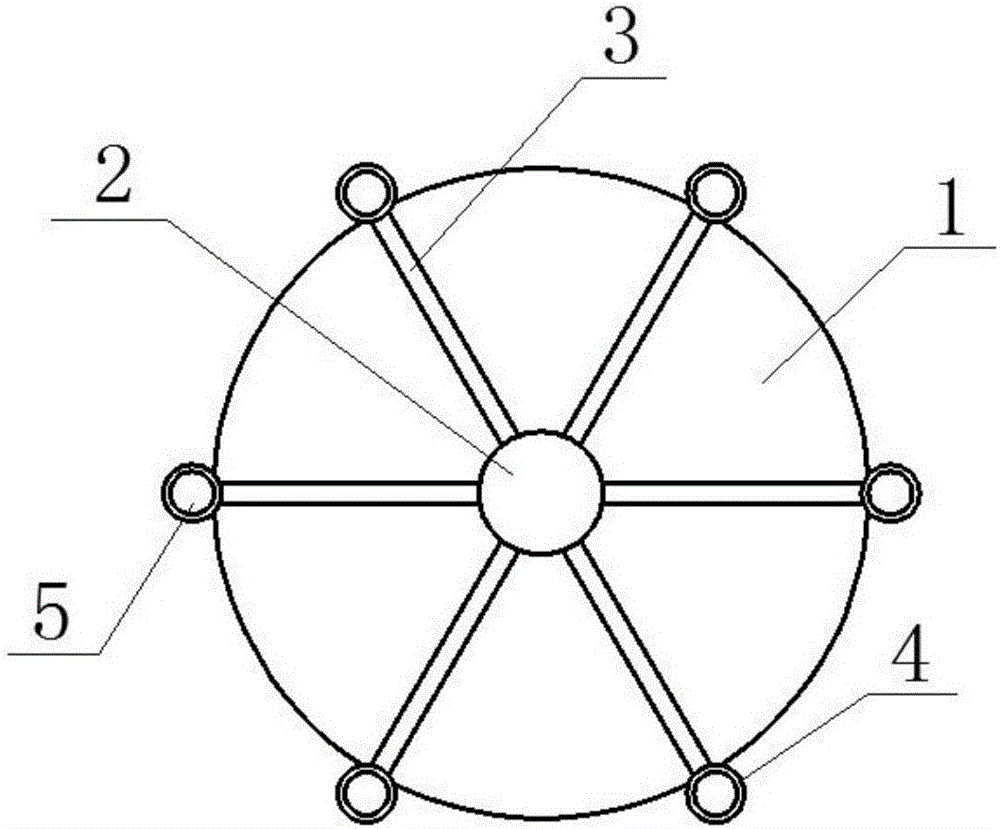

[0013] A composite cylindrical foundation with auxiliary piles added later, such as Figure 1-2 As shown, it is composed of a cylindrical foundation 1, a transition section 2, a reinforcing rib 3, an auxiliary pile fixing ring 4 and an auxiliary pile 5. The top cover of the cylindrical foundation 1 is a reinforced concrete structure, and the side wall is a steel structure; the cylindrical foundation 1 The center of the top cover is fixedly connected to the transition section 2; the transition section 2 is a steel structure with a diameter equal to the diameter of the lower end of the fan tower and connected to the fan tower through a flange; the transition section 2 and the top cover of the cylindrical foundation 1 are provided with six rings The reinforcing ribs 3 are evenly distributed radially; the reinforcing ribs 3 are steel structures, prefabricated with the transition section 2 and the top cover of the cylindrical foundation 1 as a unified whole; the outer bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com