Reusable mould for basic foundation bolt holes of large-scale equipment

A technology for anchor bolts and large-scale equipment, applied in the field of molds, can solve the problems affecting the strength of anchor bolt holes, difficulty in applying force, and inconvenient removal, and achieve the effects of reducing labor intensity, improving pullout bearing capacity, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

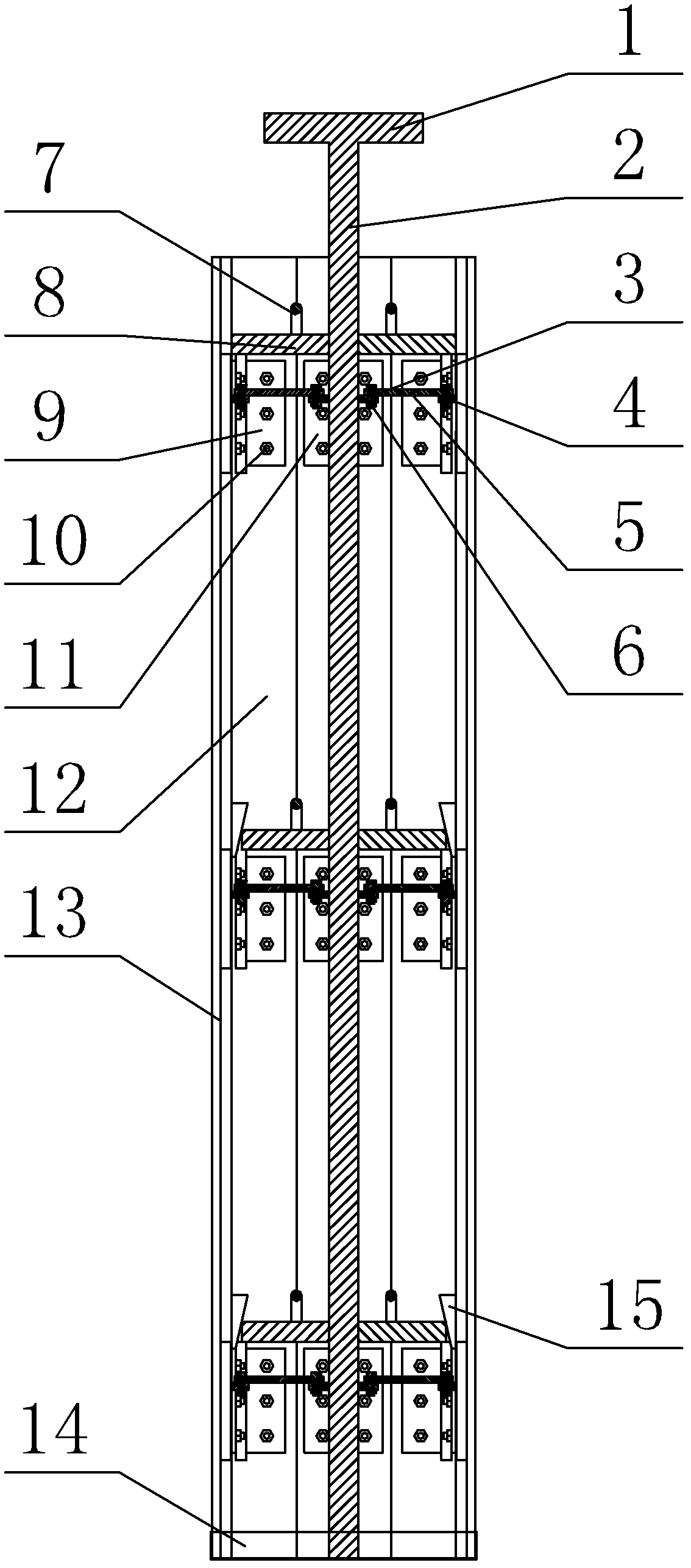

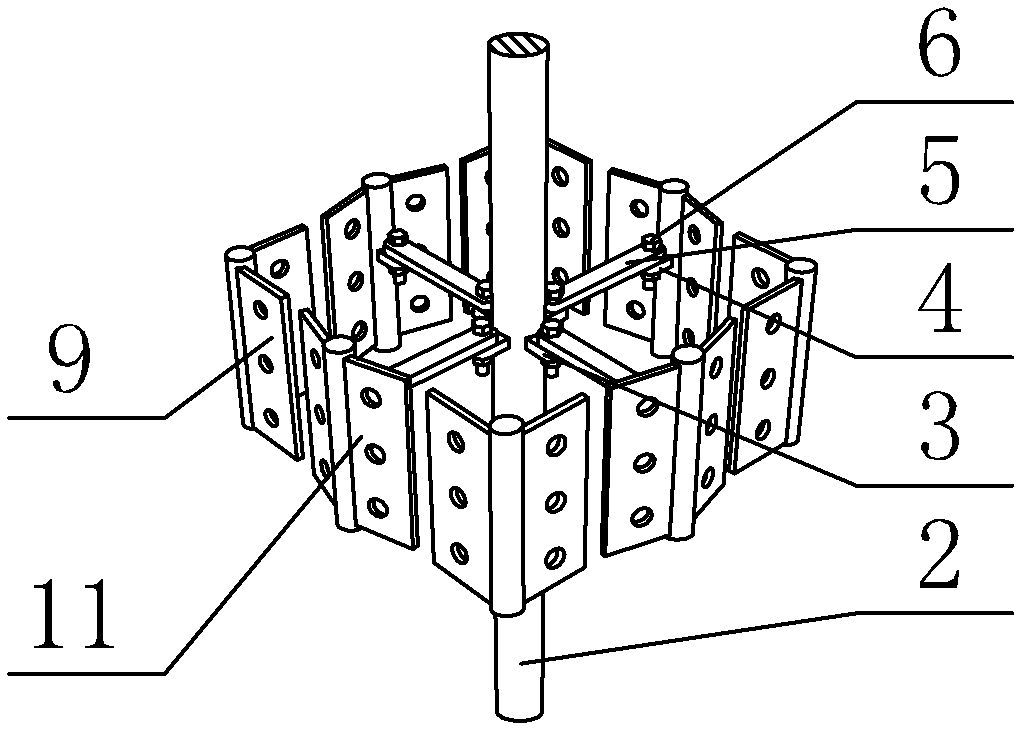

[0025] Reusable mold for anchor bolt holes of large equipment foundation (its structure is as follows Figure 1 to Figure 5 shown), it includes central axis 2, 2-4 expansion and contraction devices, 8 templates (the templates are rectangular, respectively the first template 12, the second template 13, the third template, the fourth template, the fifth template Templates, sixth templates, seventh templates, eighth templates), upper plate 8; according to every 2 templates on one side, 8 templates form a square (square or rectangle); 2-4 expansion and contraction devices are located on 8 In the square cavity (or claim square body cavity) surrounded by two templates, the lower end of central axis 2 passes through 2-4 stretching and shrinking devices (this embodiment adopts 3 stretching and shrinking devices, the first stretching and shrinking device The expansion and contraction device is located above the second expansion and contraction device, and the second expansion and contr...

Embodiment 2

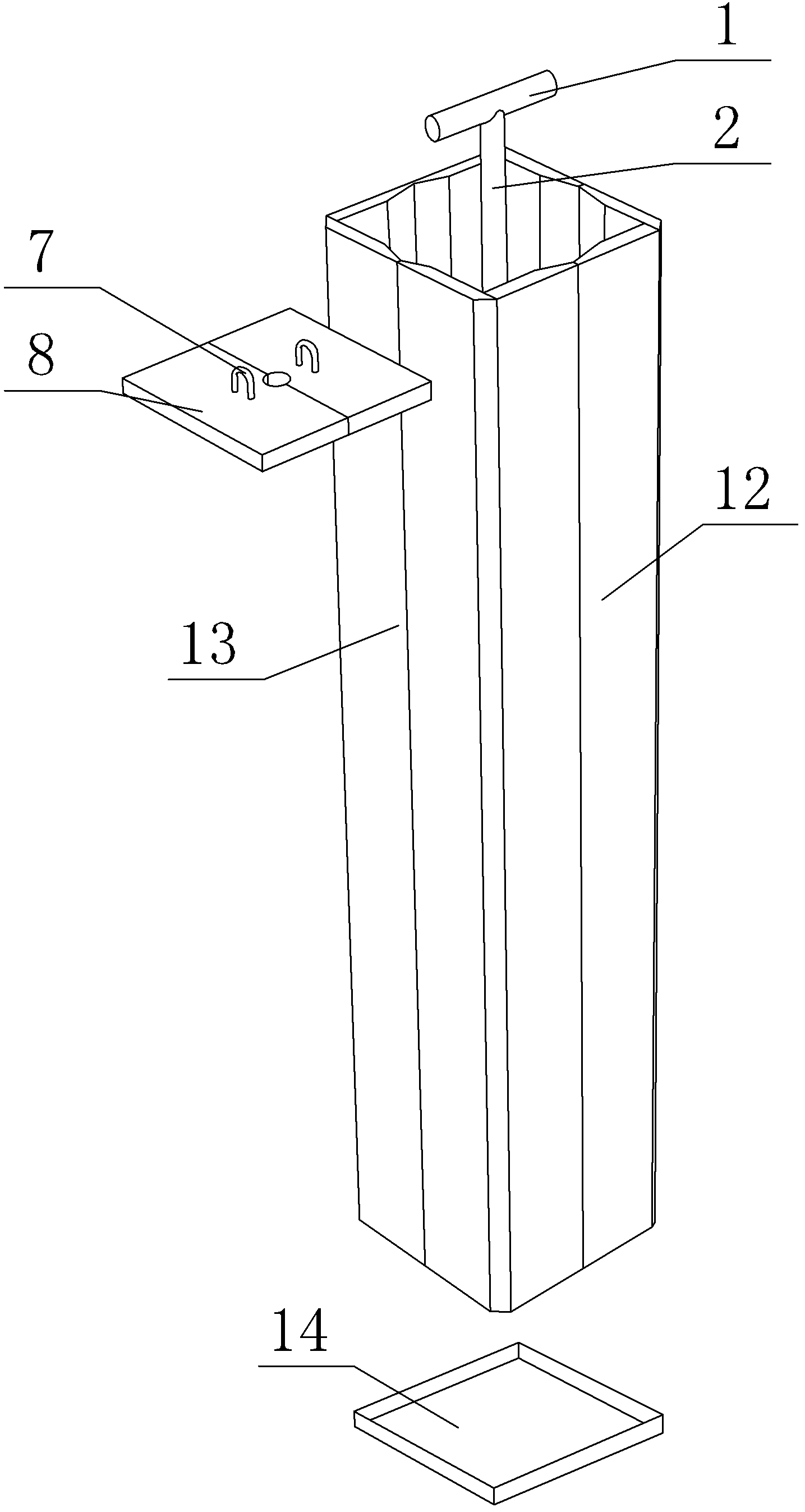

[0038] Such as Figure 6 , Figure 7 As shown, it is basically the same as Embodiment 1, the difference is that the base plate 14 is changed to a wooden base plate 16, and the base plate lifting ear 17 is arranged on the wooden base plate 16.

[0039] Described wooden floor 16 adopts plank to make, and its structure is that two boards are spliced, and a floor lifting lug 17 is respectively installed in the partial middle position of two boards, so that when pulling wooden floor 16, one end of the floor faces upwards, Reduce drag.

[0040] The second construction method of the reserved anchor bolt holes for large-scale equipment foundation provided by the present invention.

[0041] The first step, assembling the mold: the specific structure is as above;

[0042] The second step, supporting the mold: Rotate the handle 1, adjust the inner rod seat 3, the outer rod seat 4, and the movable link 5 to a line, and the template is stretched, such as Figure 4 As shown; the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com