Polygonal prefabricated pile

A prefabricated pile and polygon technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of limited increase in relative friction, poor fit, and the uplift bearing performance of variable-section hollow square piles needs to be strengthened. To achieve the effect of improving friction, enhancing anti-pulling bearing performance, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

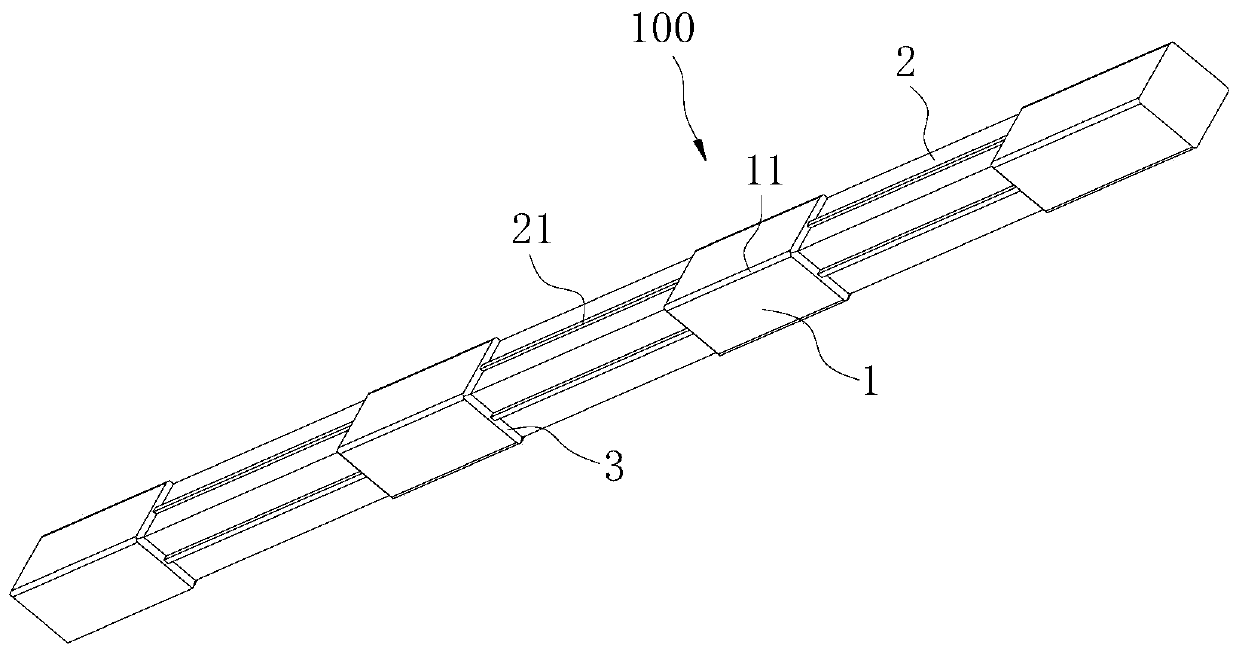

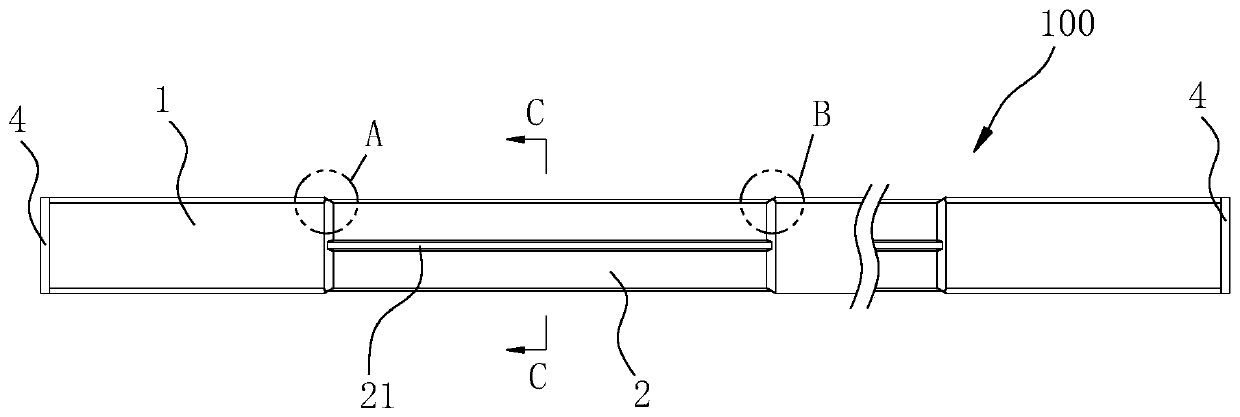

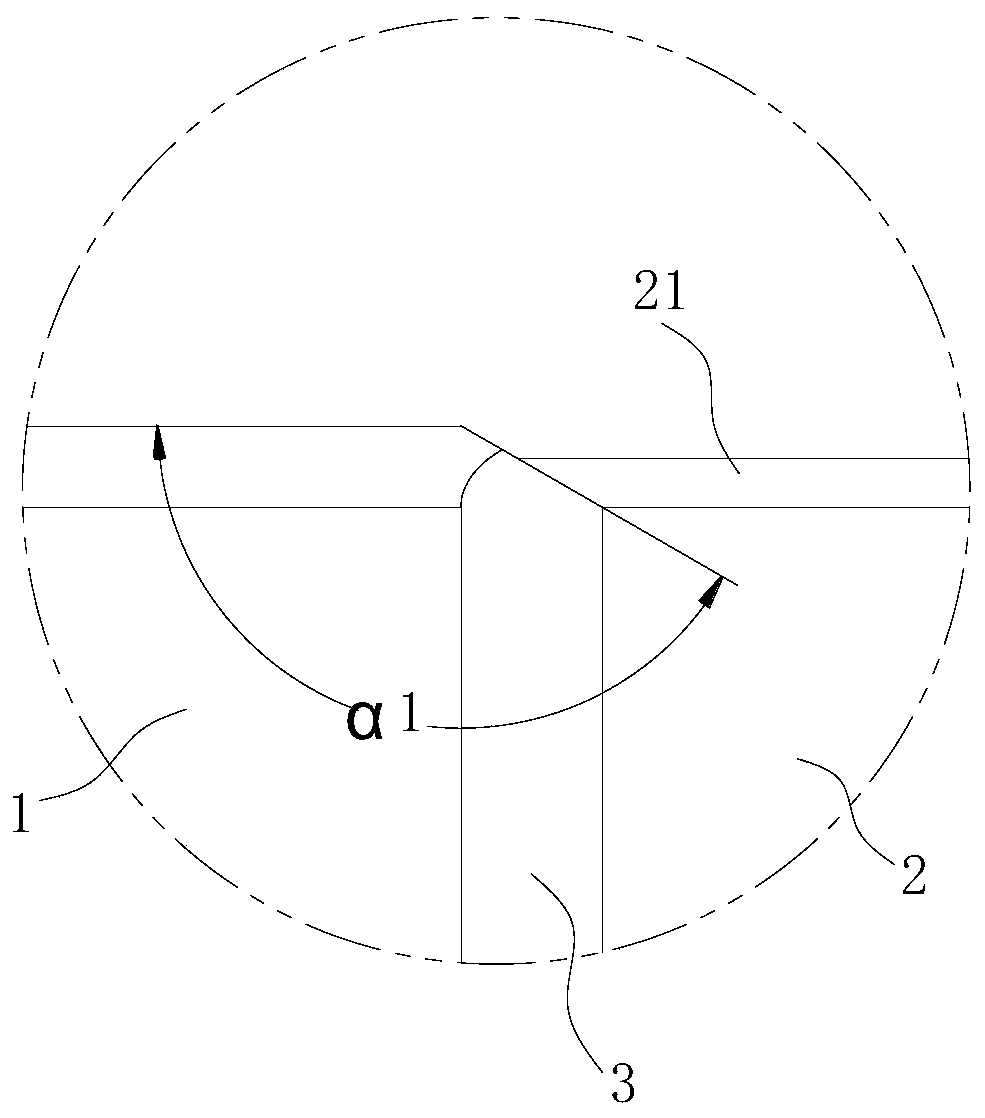

[0063] Such as figure 1 As shown, the polygonal prefabricated pile 100 provided in this embodiment is formed by pouring concrete in a mold (including at least an upper mold and a lower mold), wherein the polygonal prefabricated pile 100 is embedded with a reinforcement cage or a rigid skeleton. The polygonal prefabricated pile 100 includes a multi-section thick pile section 1 and a multi-section thin pile section 2 forming an integrated structure along a straight line direction (that is, the length direction of the polygonal prefabricated pile 100), and the thin pile section 2 and the thick pile section 1 are aligned along the axial direction. Alternately. In this embodiment, the polygonal prefabricated pile 100 is preferably a solid square pile. Of course, the polygonal prefabricated pile 100 provided by the present invention can also be any regular polygonal solid pile or regular polygonal hollow pile such as regular triangular piles, regular pentagonal piles, regular hexag...

Embodiment 2

[0082] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0083] Such as Figure 18 As shown, compared with Embodiment 1, the polygonal prefabricated pile 100 provided by this embodiment also has such a structure: each thick pile section 1 is provided with four grooves 12 arranged around the central axis of the polygonal prefabricated pile 100 on the outer wall. The longitudinal direction of the groove 12 is consistent with the longitudinal direction of the polygonal prefabricated pile 100 . Of course, in the polygonal prefabricated pile 100 provided by the present invention, the number of grooves 12 provided on the outer wall of each thick pile section 1 can be any number such as one, two, three, four, five, etc. In addition, it is also possible that at least one thick pile section 1 has a plurality of grooves 12 on the outer wall; it is also possible that the number ...

Embodiment 3

[0089] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0090] Such as Figure 23 As shown, compared with Embodiment 1, the polygonal prefabricated pile 100 provided by this embodiment also has such a structure: in the length direction of the polygonal prefabricated pile 100, the diameters of the circumscribed circles of each thin pile segment 2 increase sequentially, and each thick The diameter of the circumscribed circle of pile segment 1 increases sequentially. Of course, in the polygonal prefabricated pile 100 provided by the present invention, in the length direction of the polygonal prefabricated pile 100, only the diameters of the circumscribed circles of the thin pile sections 2 can be increased successively, or only the diameters of the circumscribed circles of the thick pile sections 1 can be successively increased. increase. In the structural situation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com