Pipe pile structure anchored by steel strands and manufacturing method

A technology for steel strands and pipe piles, which is used in foundation structure engineering, excavation, sheet pile walls, etc. The effect of pulling the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

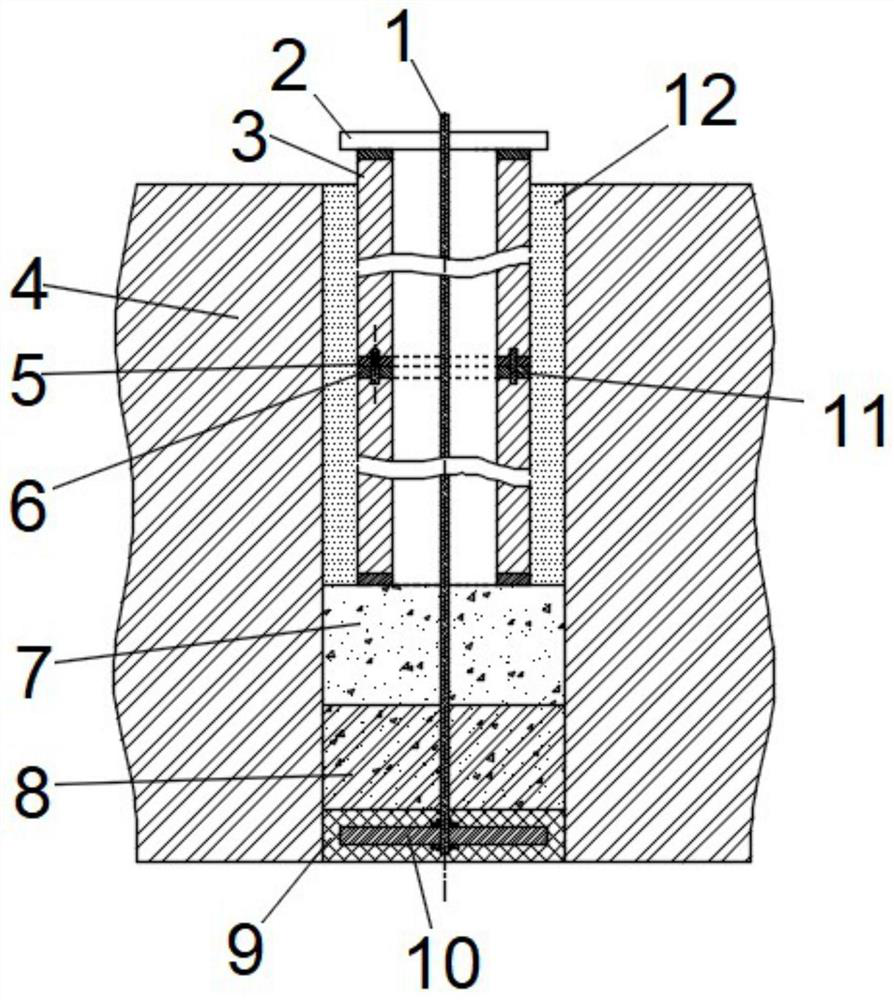

[0026] Refer to attached figure 1 As shown, a pipe pile structure anchored by steel strands includes: pipe pile device, steel strand 1, basement floor 2, anchor plate 10, prefabricated plate 9, concrete layer 8, gravel layer 7 and gap cement slurry layer 12. The bottom end of the steel strand 1 is fixedly installed on the anchor plate 10, the top end of the steel strand 1 is fixed on the basement floor 2, the basement floor 2 is installed on the top of the pipe pile device, and the anchor plate 10 is pre-buried in the prefabricated plate 9, The prefabricated slab 9 is placed at the bottom of the well, the top of the prefabricated slab 9 is the poured concrete layer 8, the crushed stone layer 7 is on the top of the concrete layer 8, the pipe pile device is sunk into the top of the crushed stone layer 7, and the gap cement slurry layer 12 is poured on the top of the pipe pile. The gap between the pile device and the well wall. The bottom end of the steel strand 1 is fixedly con...

Embodiment 2

[0029] A method for manufacturing a pipe pile anchored by a steel strand, comprising the steps of:

[0030] 1), use the geological drilling rig to drill down on the pile position, and the drilling depth will be greater than the design depth of the pipe pile 3;

[0031] 2), one end of the steel strand 1 is fixedly installed on the anchor plate 10, then put into the prefabricated mold, and the anchor plate 10 is pre-embedded in the prefabricated plate 9;

[0032] 3), lower the prefabricated plate 9 with the steel strand 1 into the borehole until it sinks into the bottom of the borehole;

[0033] 4) There is a large amount of water at the bottom of the drilled well. Use the conduit method to penetrate the conduit into the borehole until an appropriate amount of concrete is poured above the prefabricated slab 9 to form a concrete layer 8. During the hardening process of the concrete layer 8, keep a steel strand pull state;

[0034] 5), the pipe pile 3 is connected to the pile th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com