A mold for forming variable-section piles

A technology of variable-section piles and molds, applied in molds, ceramic molding machines, mold auxiliary parts, etc., can solve the complex structure of concave-convex prefabricated pile molds, the inconsistency between the arc block and the outer wall of the small diameter section, and the pile body and the small diameter section. The relative friction of the surrounding soil is limited, so as to prevent the deformation of the mold, closely fit the effect, and enhance the anti-pulling bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

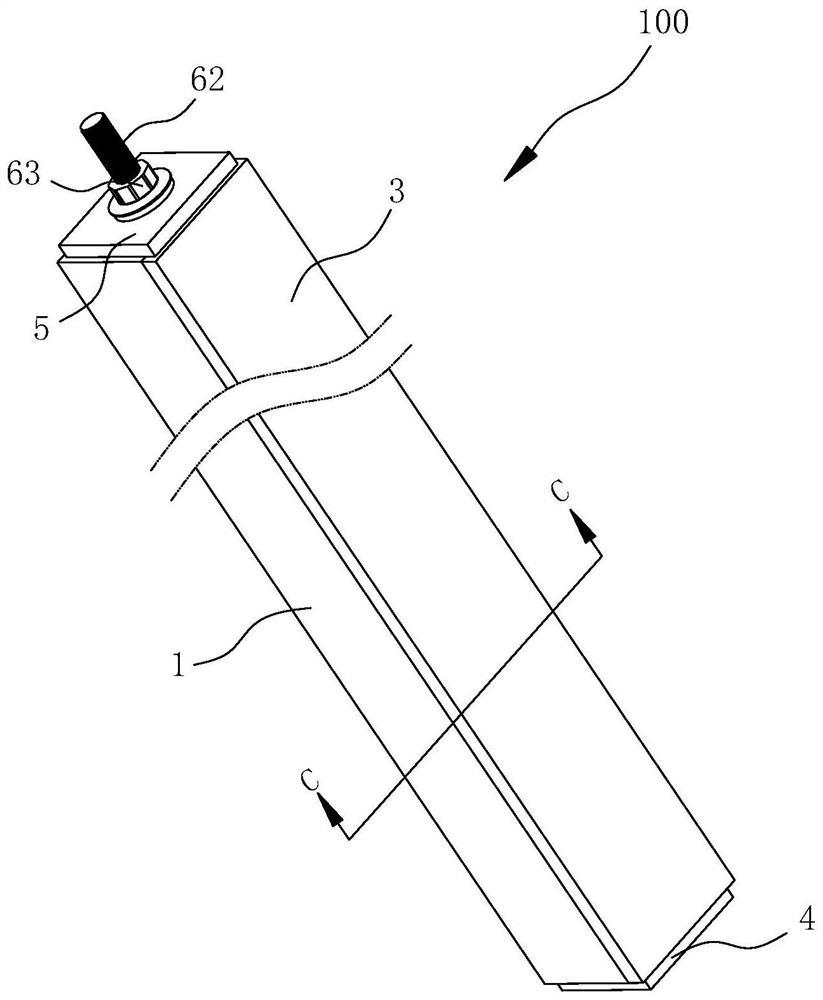

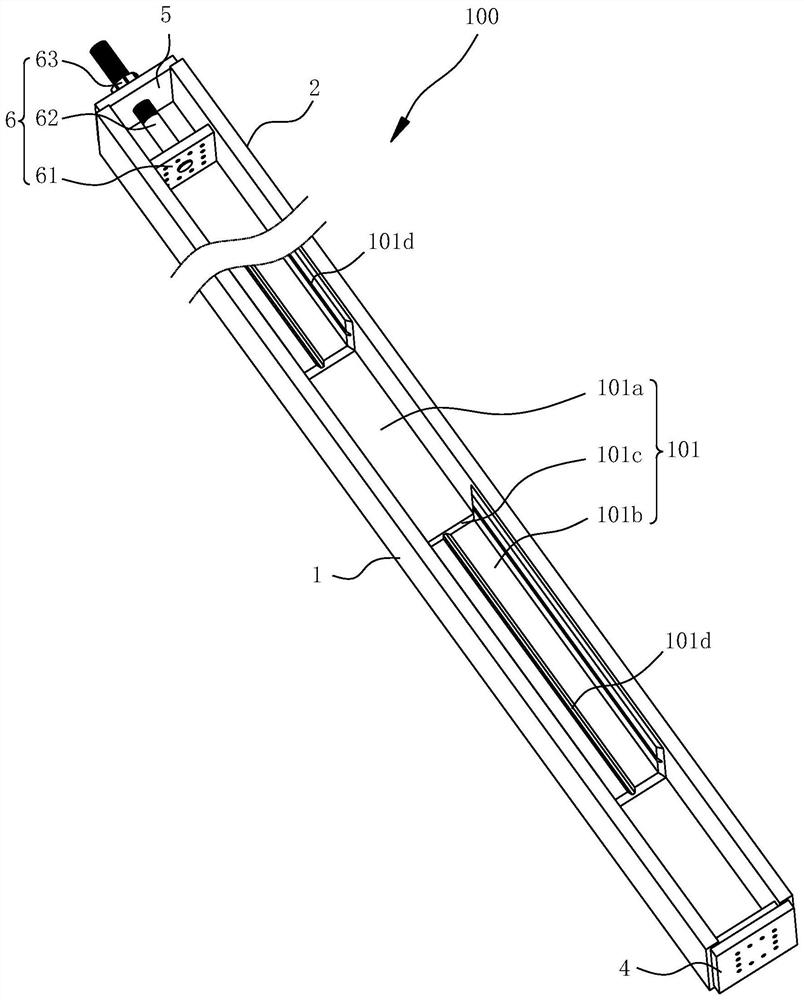

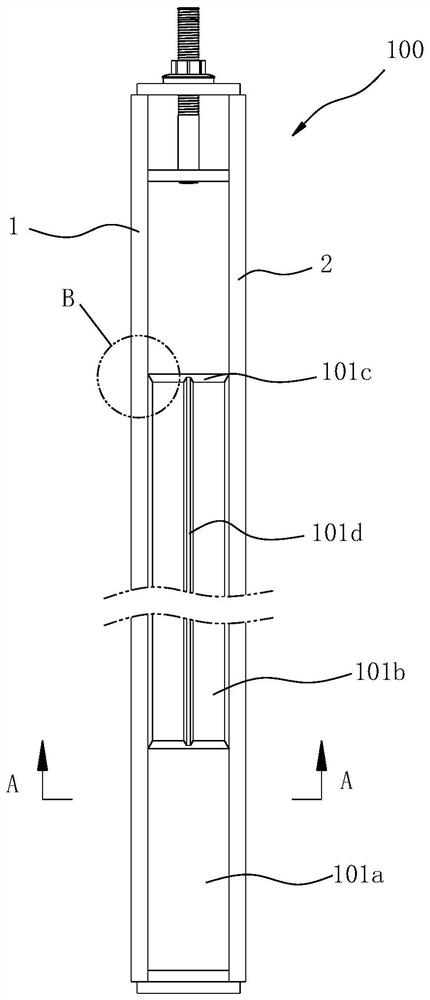

[0057] Such as figure 1 and figure 2 As shown, the present embodiment provides a mold 100 for forming variable-section piles. The mold cavity 101 of the mold 100 forms a plurality of regular polygonal thick-hole sections 101a and a plurality of regular polygonal fine-hole sections 101b along the length direction, each regular polygon The polygonal coarse-pore segments 101a and the regular polygonal fine-pore segments 101b are alternately arranged and communicated with each other. Of course, in the mold provided by the present invention, the mold cavity 101 of the mold forms at least one regular polygonal coarse hole segment 101a and at least one regular polygonal fine hole segment 101b along the length direction, and the regular polygonal coarse hole segment 101a and the regular polygonal fine hole segment 101b Just connect.

[0058] Such as Figure 2 to Figure 5 As shown, a shoulder surface 101c is formed between the hole wall of the regular polygon coarse-hole section 10...

Embodiment 2

[0072] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0073] Such as Figure 16 As shown, compared with Embodiment 1, the mold 200 for forming variable-section piles provided by this embodiment also has the following structure:

[0074] The hole wall of the regular polygon rough hole section 101a is provided with a plurality of ribs 101k at intervals around the central axis. Specifically, the hole wall of the regular polygon rough hole section 101a is provided with two ribs 101k on each flat surface, and the length of the mold 200 direction, the ribs 101k and the grooves 101d are staggered. Certainly, in the mold provided by the present invention, at least one rib 101k may be provided on the hole wall of each regular polygonal rough hole section 101a, or only part of the regular polygon rough hole section 101a is provided with the rib 101k. It is also possible tha...

Embodiment 3

[0083] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0084] Such as Figure 22 As shown, compared with the first embodiment, the mold 300 for forming variable-section piles provided by this embodiment also has the following structure:

[0085] The mold 300 for forming variable-section piles at least includes; the first regular polygon coarse hole section 301a, the second regular polygon coarse hole section 301b, the third regular polygon coarse hole section 301c, the first regular polygon fine hole section 302a and the second regular polygonal pore segment 302b.

[0086] Wherein, in the straight line direction from the second end plate 5 to the first end plate 4, the cross-sectional dimensions of the first regular polygon rough hole section 301a, the second regular polygon rough hole section 301b and the third regular polygon rough hole section 301c increase sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com