Reusable die for equipment foundation reserved square hole

A technology of equipment foundation and square hole, which is applied in the direction of infrastructure engineering, formwork/formwork/working frame, and on-site preparation of building components. problem, to achieve the effect of improving the pull-out bearing capacity, reducing the labor intensity and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

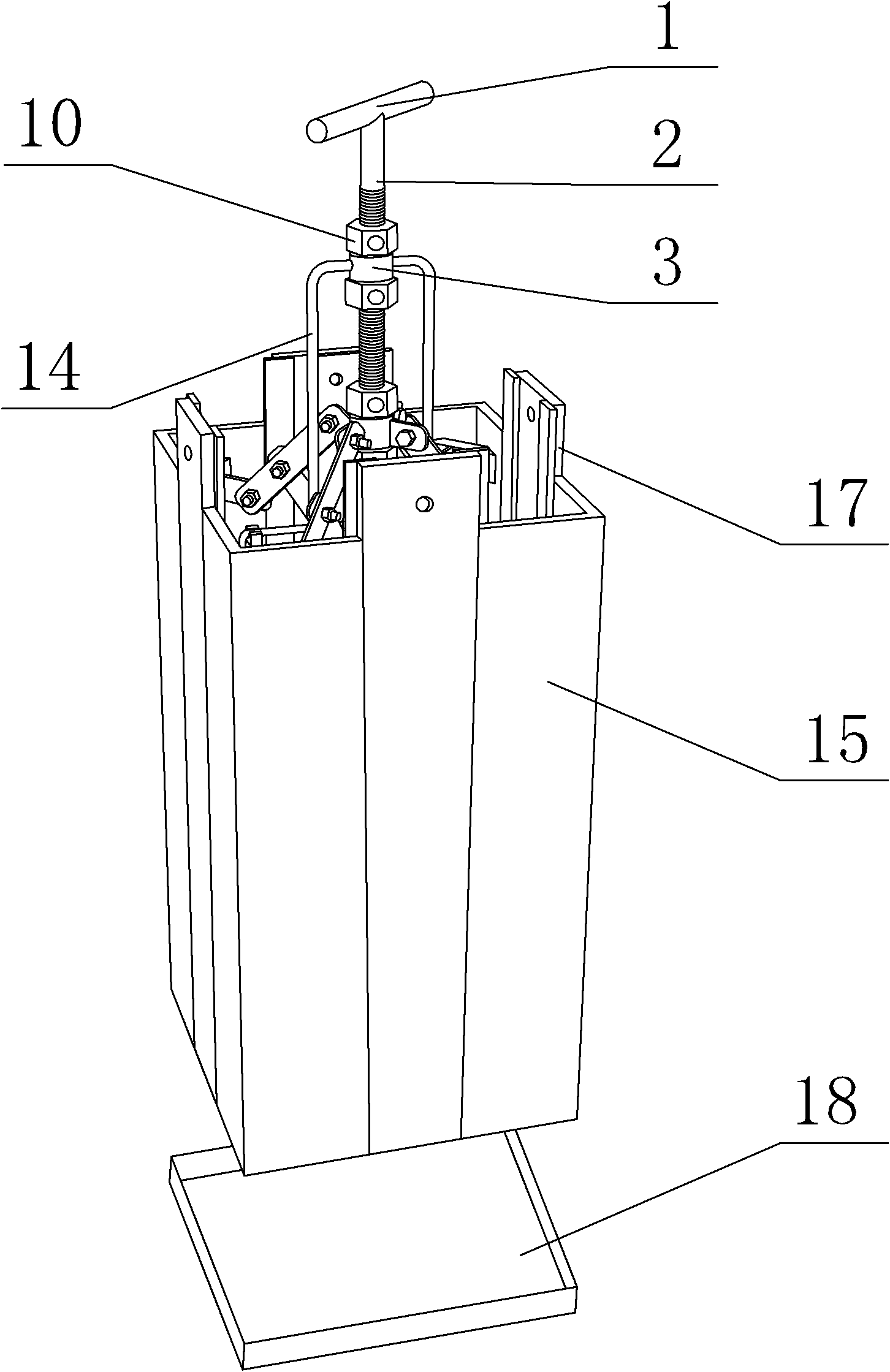

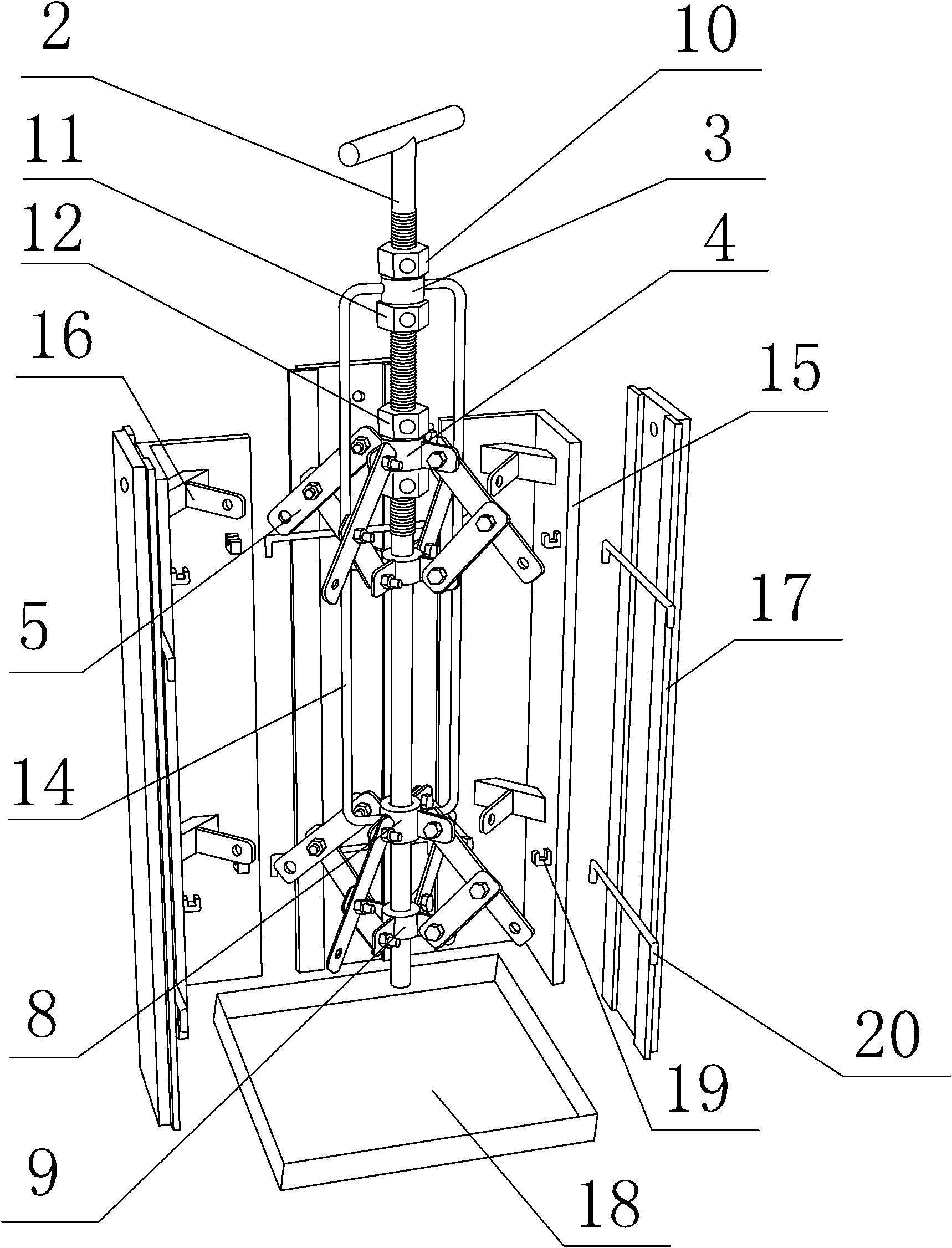

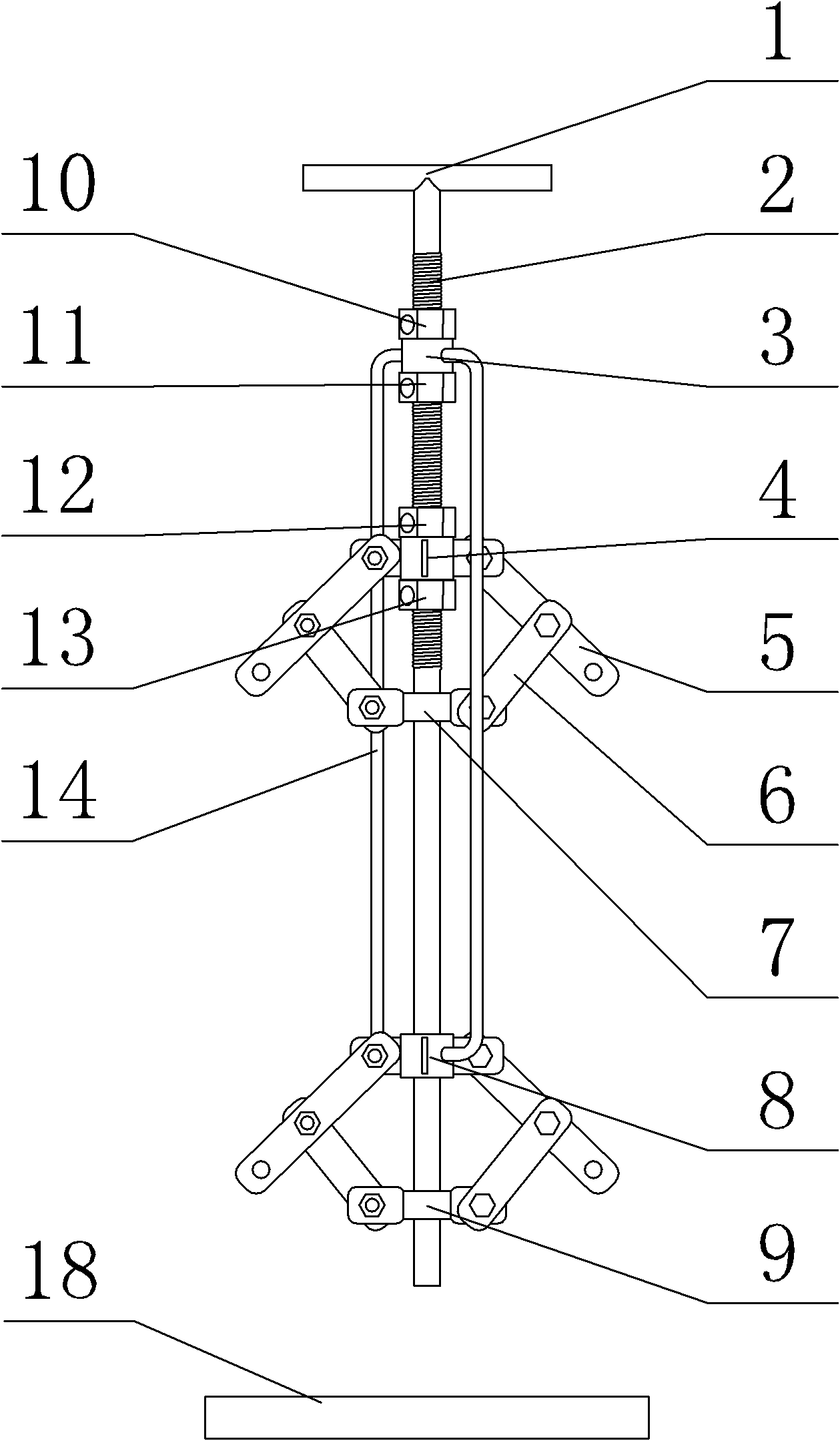

[0019] A reusable mold with square holes reserved for the equipment foundation, its structure is as follows Figure 1 to Figure 3 As shown, it includes a central axis 2, a first expansion and contraction device, a second expansion and contraction device, 4 corner templates 15, and 4 middle templates 17; 4 corner templates 15 are L-shaped at right angles, 4 The three corner templates 15 are distributed at 4 corners, the middle template 17 is inserted between the corner templates and the corner templates on the same side, the space surrounded by 4 corner templates 15 and 4 middle templates 17, 4 corner templates 15 Two formwork supports 16 (respectively the first formwork support and the second formwork support) are arranged on the inner side of the corner formwork, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com