Die for forming concrete pipe pile

A technology of concrete pipe piles and molds, which is applied in the direction of molds, etc., can solve the problem of limited increase in relative friction between the pile body and the surrounding soil, loose fit between arc blocks and the outer wall of the small diameter section, and complex structure of concave-convex prefabricated pile molds and other problems, to achieve the effect of preventing mold deformation, simple structure, and enhancing pull-out bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

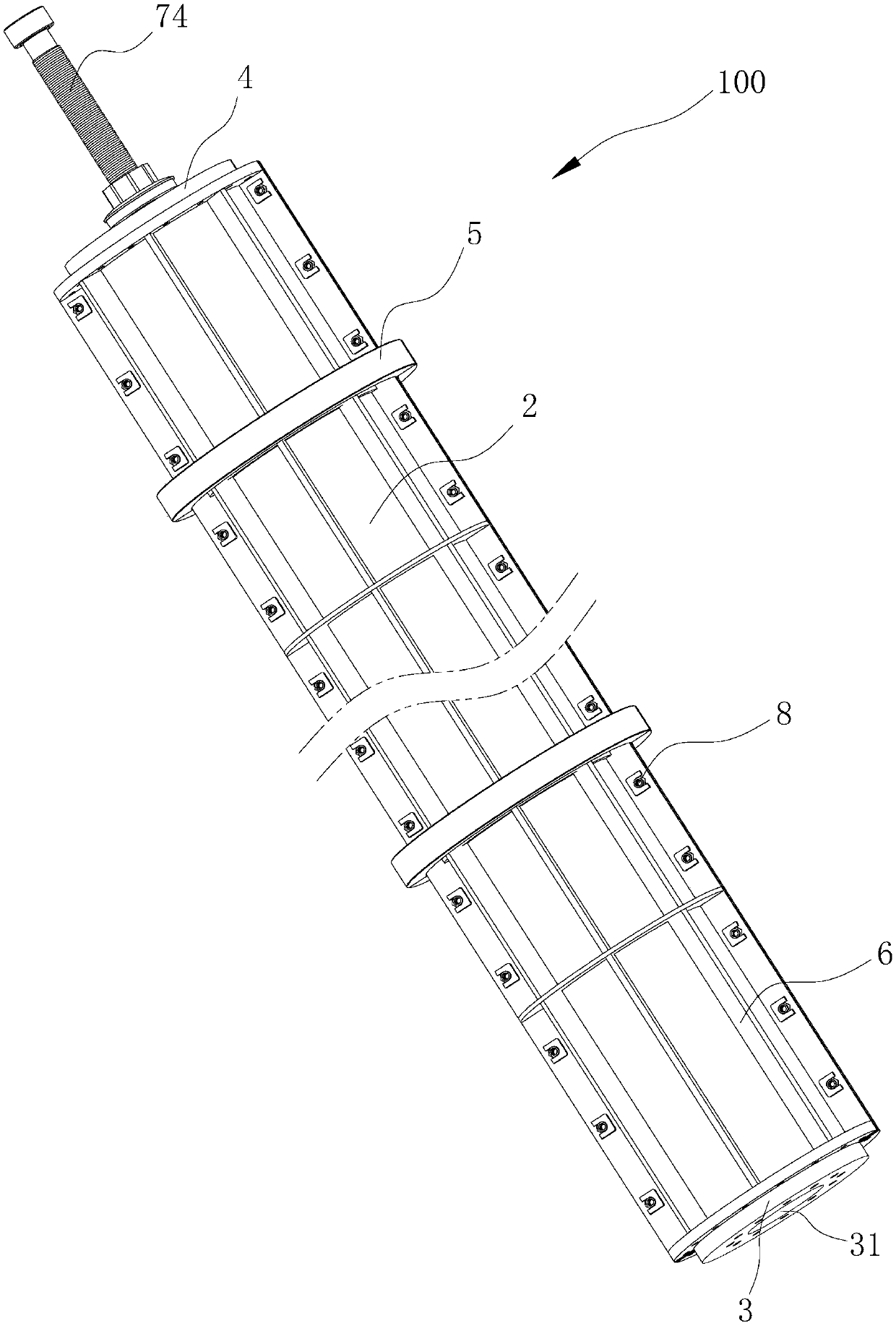

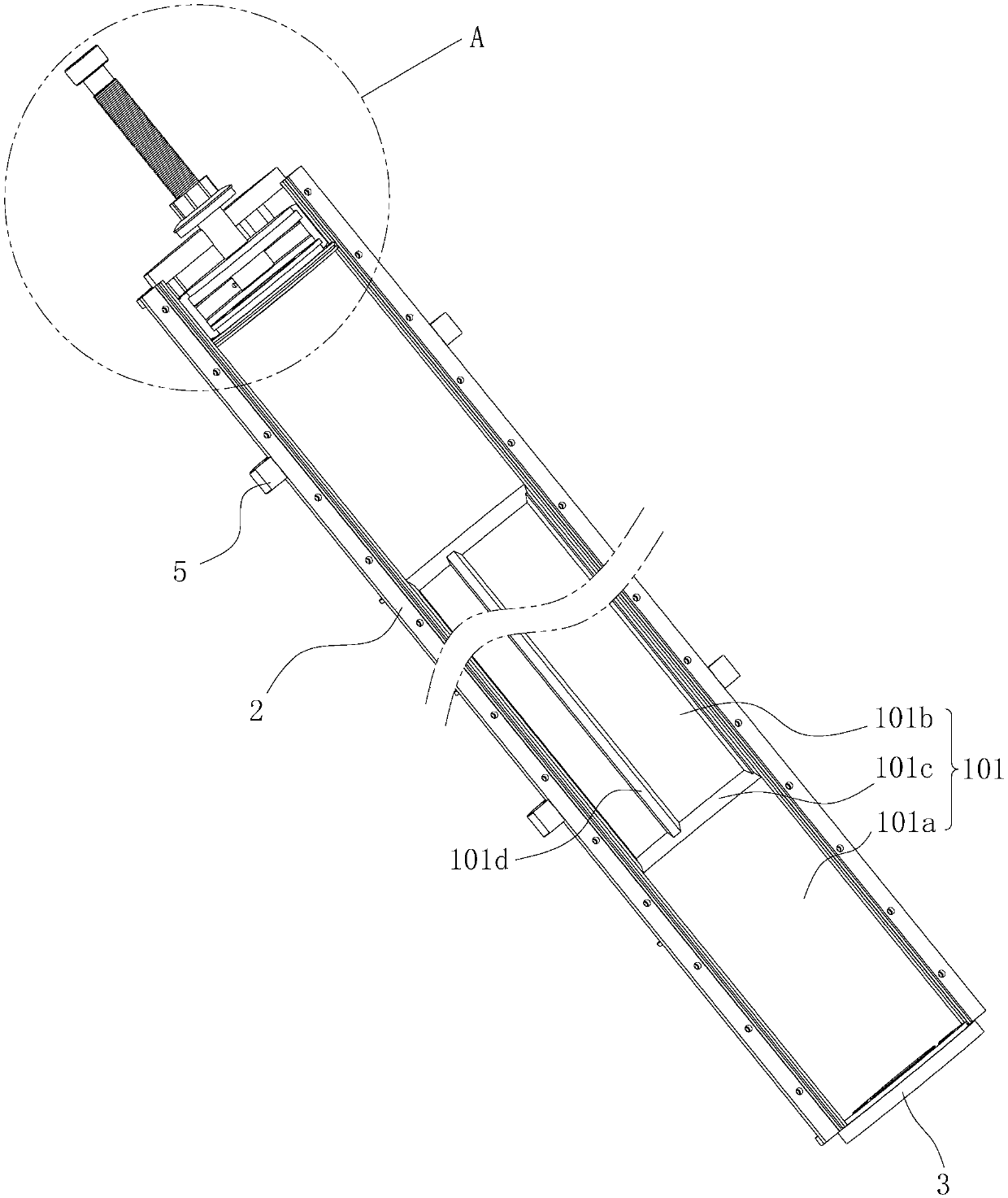

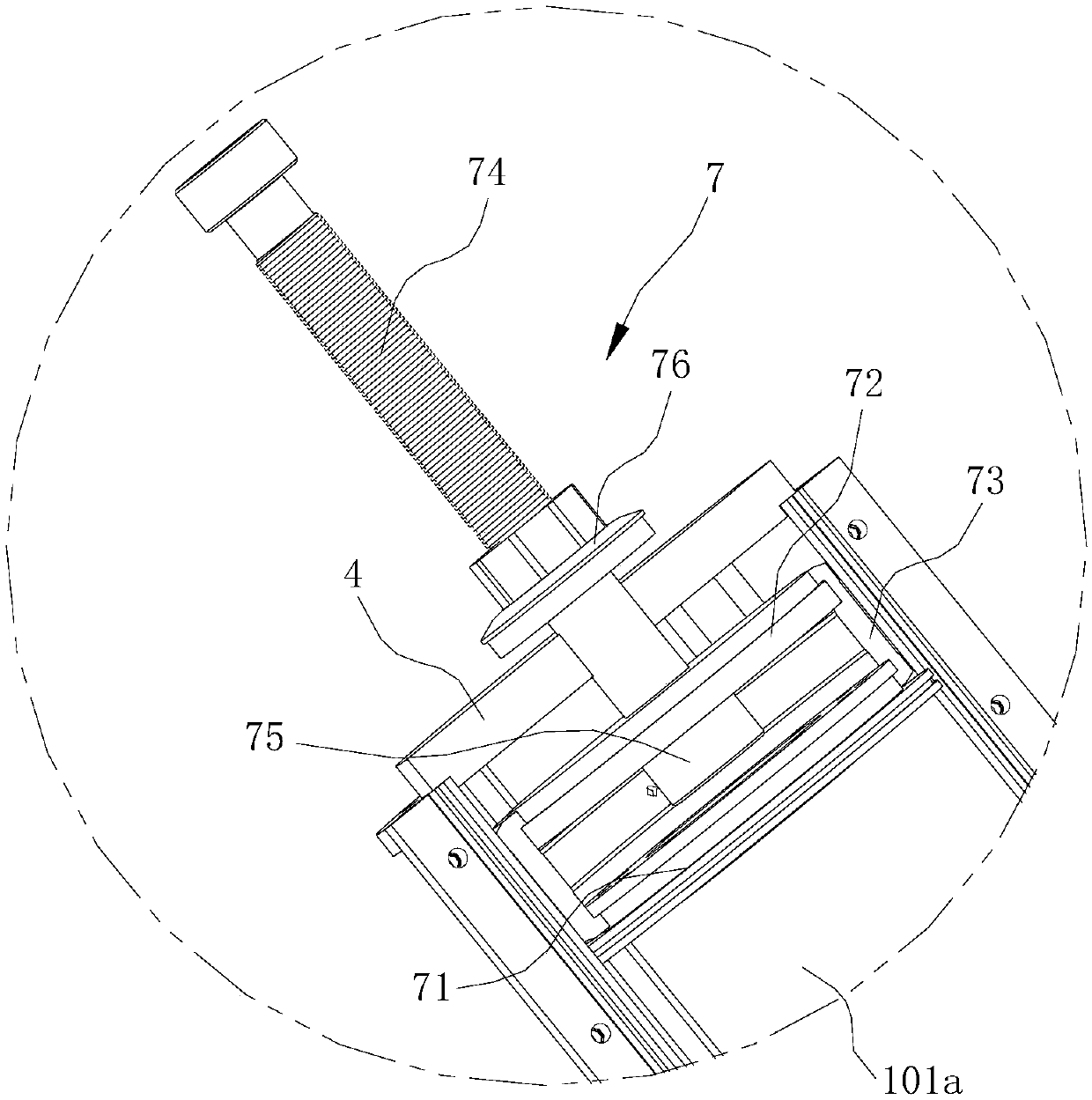

[0079] like figure 1 and figure 2 As shown, the present embodiment provides a mold 100 for forming concrete pipe piles, the mold cavity 101 of the mold 100 forms a plurality of thick pile hole sections 101a and a plurality of thin pile hole sections 101b along the length direction, each thick pile hole The sections 101a and the thin pile hole sections 101b are alternately arranged and communicated with each other. Of course, in the mold 100 provided by the present invention, at least one thick pile hole section 101 a and one thin pile hole section 101 b are formed along the length direction of the mold cavity 101 of the mold 100 .

[0080] like figure 2 and Figure 5 As shown, the hole wall of the thin pile hole section 101b is circularly uniformly distributed with four grooves 101d around the central axis. The lengthwise direction of the groove 101d coincides with the lengthwise direction of the mold 100 . Certainly, in the mold 100 provided by the present invention, a...

Embodiment 2

[0096] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0097] like Figure 8 to Figure 9 As shown, compared with Embodiment 1, the mold 100 for forming concrete pipe piles provided by this embodiment also has such a structure:

[0098]The hole wall of the thick pile hole section 101a is provided with four ribs 101e at equal intervals around the central axis, wherein the length direction of the ribs 101e is consistent with the length direction of the mold 100, and in the radial direction of the mold 100, the ribs 101e The convex height H2 is less than the difference between the inner hole radius R1 of the thick pile hole section 101a and the inner hole radius R2 of the thin pile hole section 101b.

[0099] like Figure 9 As shown, in this embodiment, in order to facilitate demoulding, the two side walls of the rib 101e are provided with a draft angle α2 of 1° to 75°...

Embodiment 3

[0106] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0107] like Figure 11 As shown, compared with Embodiment 1, the mold 100 for forming concrete pipe piles provided by this embodiment also has such a structure: in the length direction of the mold 100 from the first end plate 3 to the second end plate 4 or by In the length direction of the mold 100 from the second end plate 4 to the first end plate 3, the inner diameters of the thick pile hole sections 101a increase sequentially, and the inner diameters of the thin pile hole sections 101b increase sequentially.

[0108] Of course, in the mold 100 provided by the present invention, it can also be in the length direction of the mold 100 from the first end plate 3 to the second end plate 4 or the length of the mold 100 from the second end plate 4 to the first end plate 3 direction, only the inner diameter of each t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com