Construction method of preserved foundation bolt hole of equipment foundation

A technology for anchor bolts and equipment foundations, which is applied in the construction field where anchor bolt holes are reserved for equipment foundations. It can solve the problem of inability to meet the cross-section requirements of large lower openings and small upper openings, affecting the strength of anchor bolt holes, and templates that cannot be repeated Use and other issues to achieve the effect of reducing labor intensity, easy promotion, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

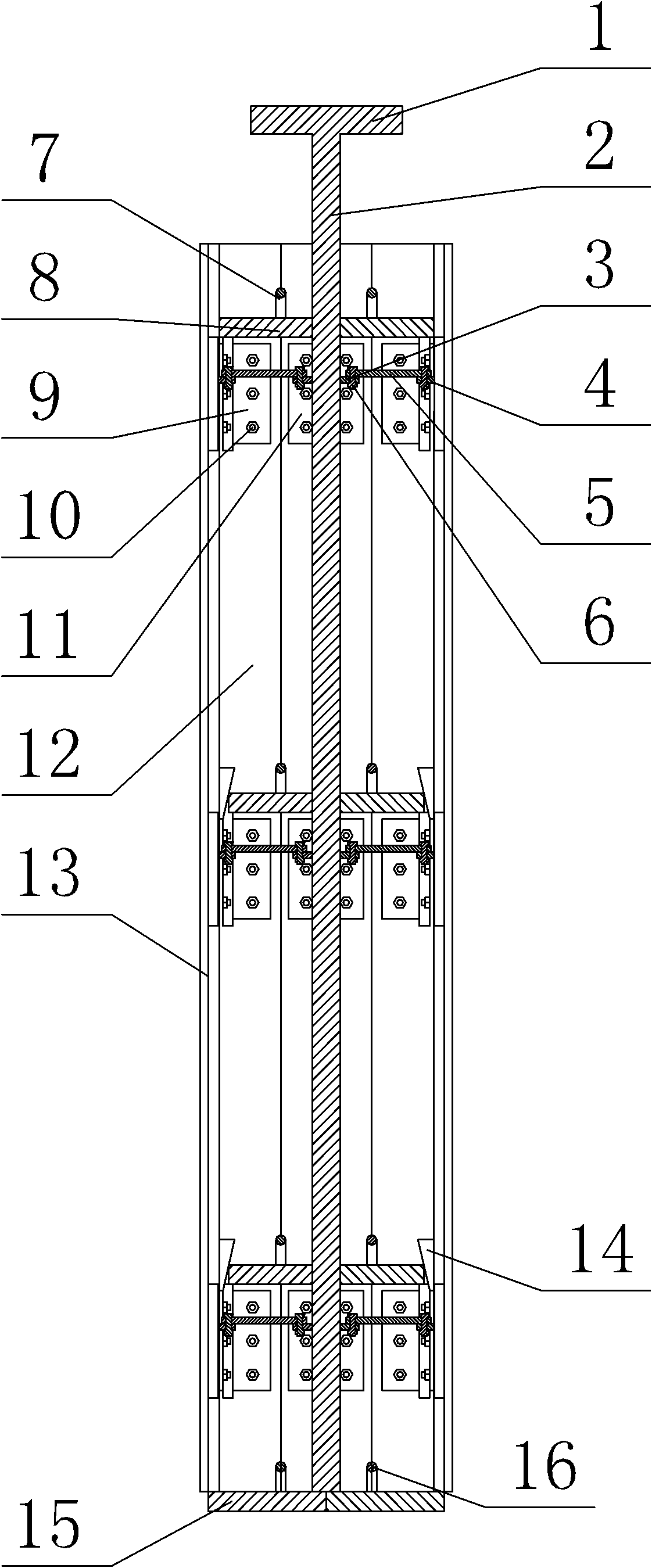

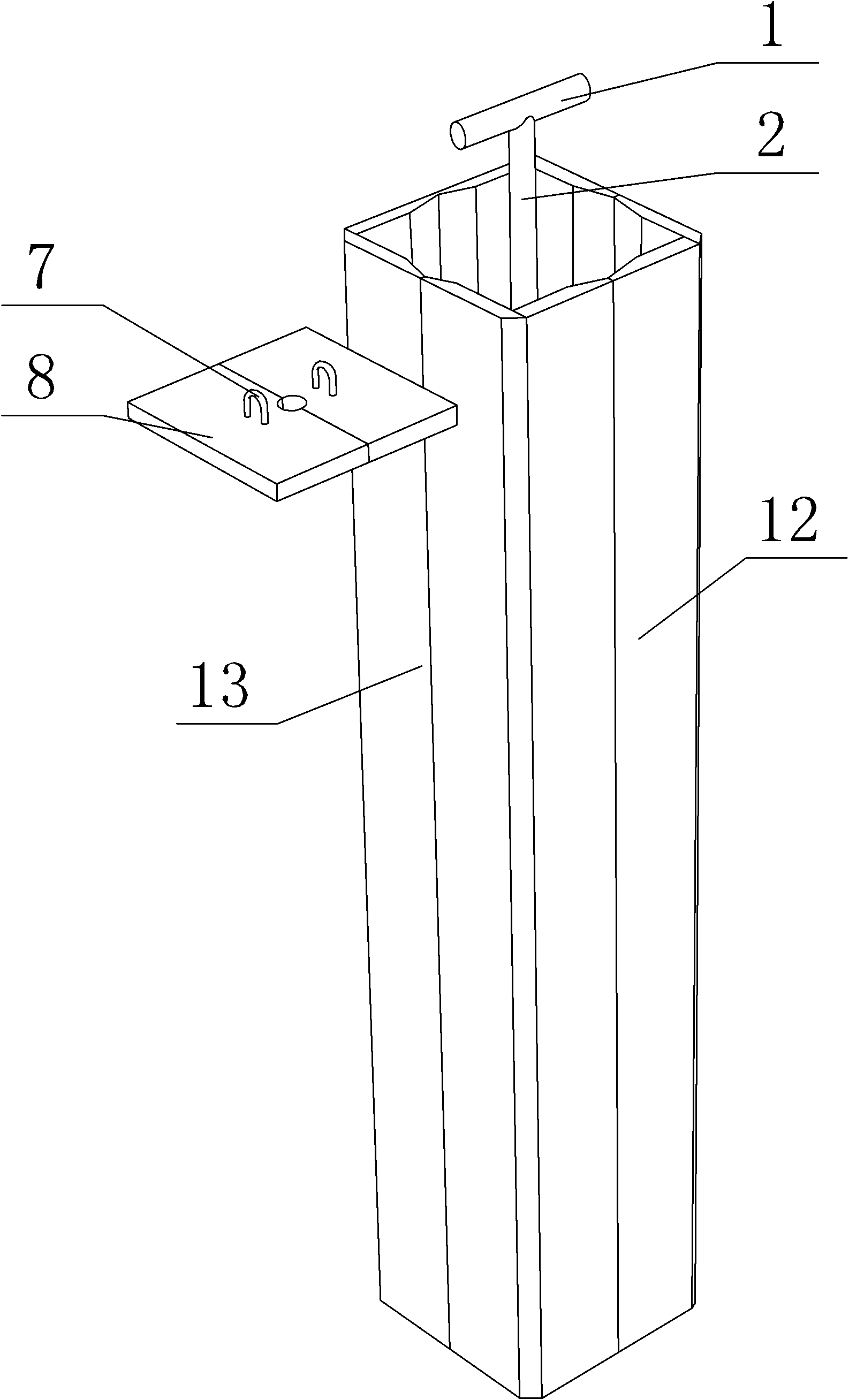

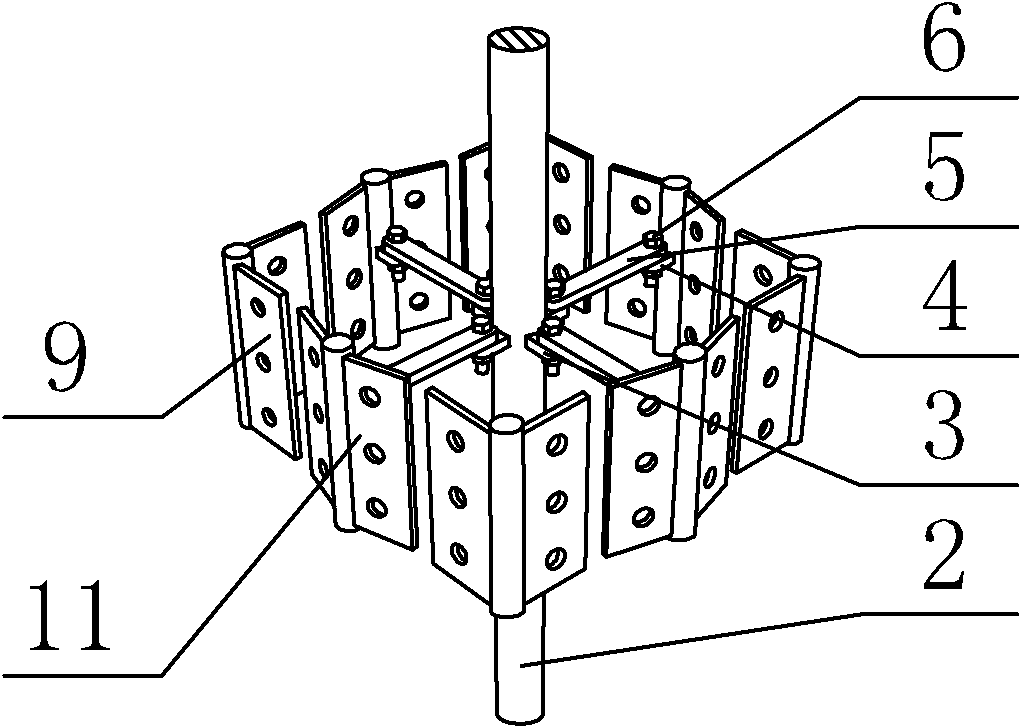

[0026] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0027] The construction method of the reserved anchor bolt hole of the equipment foundation provided by the present invention comprises the following steps:

[0028] The first step, assemble the mold:

[0029] A reusable mold for the anchor bolt holes of the equipment foundation (its structure is as follows Figure 1 to Figure 5 As shown), it includes a central axis 2, 2-4 expansion and contraction devices, and 8 templates (the templates are rectangular, respectively the first template 12, the second template 13, the third template, the fourth template, the fifth template Templates, sixth templates, seventh templates, eighth templates), upper plate 8; each 2 templates are located on one side, and 8 templates form a square (square or rectangle); 2-4 expansion and contrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com