Construction method for circular foundation bolt hole reserved for equipment foundation

A technology of equipment foundation and construction method, which is applied in the direction of basic structure engineering, formwork/formwork/working frame, and on-site preparation of building components. Achieve the effects of reducing labor intensity, improving pull-out bearing capacity, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0025] The construction method of reserving circular anchor bolt holes for the equipment foundation includes the following steps:

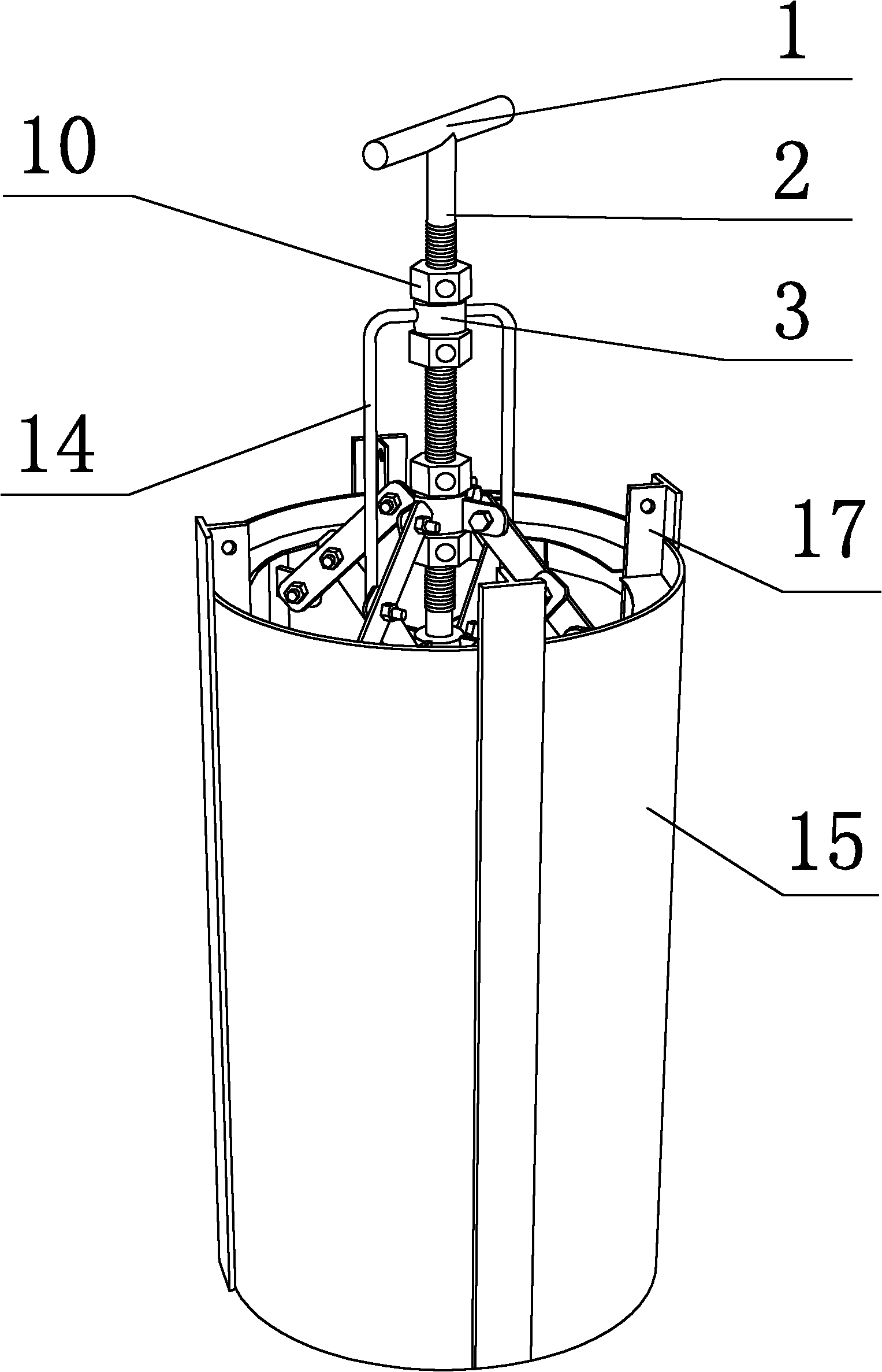

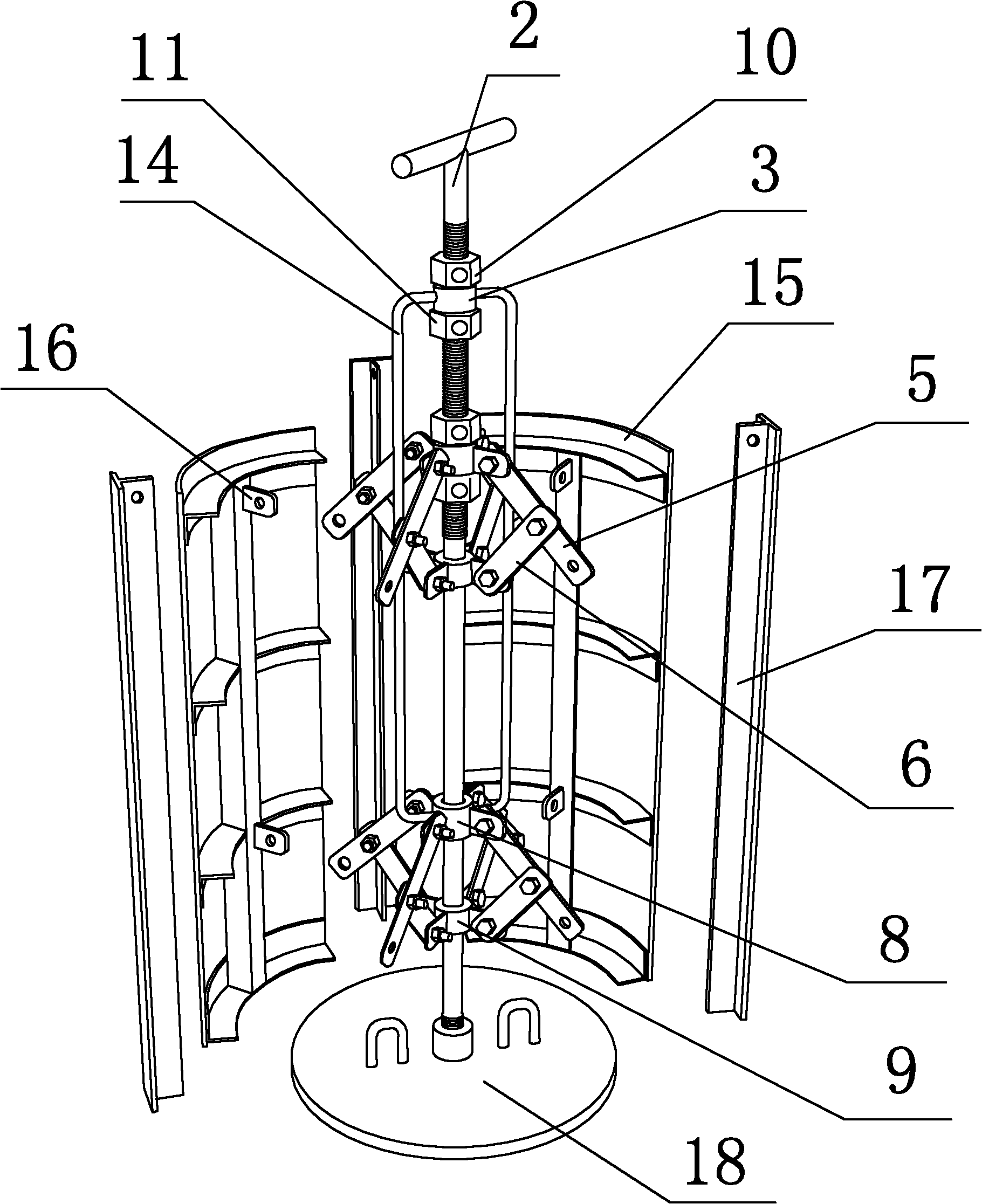

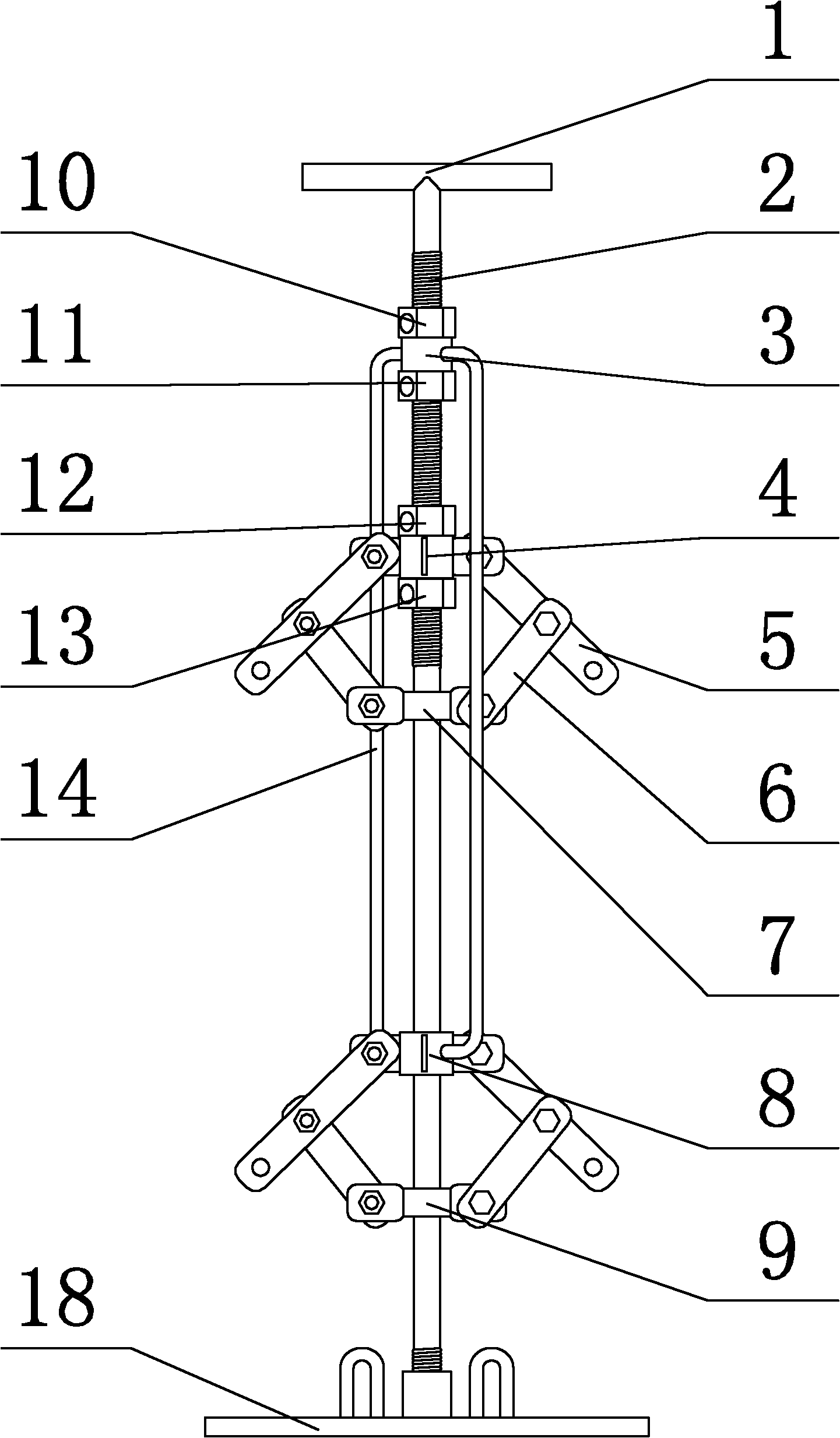

[0026] The first step is to assemble the mold: the equipment foundation reserves a circular anchor bolt hole mold, and its structure is as follows Figure 1 to Figure 3 Shown, it comprises central axis 2, the first stretching and shrinking device, the second stretching and shrinking device, 4 templates 15, 4 seaming plates 17; 4 templates 15 are arc-shaped (the present embodiment 4 templates have the same size), 4 templates 15 are evenly distributed along the circumference, and between the template 15 and the template 15, there are seam repairing plates 17 (the size of the 4 seam repairing plates in this embodiment is the same), and the 4 te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com