Shallow surface soil layer area photovoltaic support prefabricated barrel-shaped foundation and design method

A barrel-shaped foundation and photovoltaic support technology, applied in infrastructure engineering, construction, etc., can solve the problems of increased construction period and environmental impact of cast-in-place operations, inability to bear the load of photovoltaic support, and insufficient embedment depth, etc., to achieve The effect of shortening the construction period, reducing costs and increasing the pull-out bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

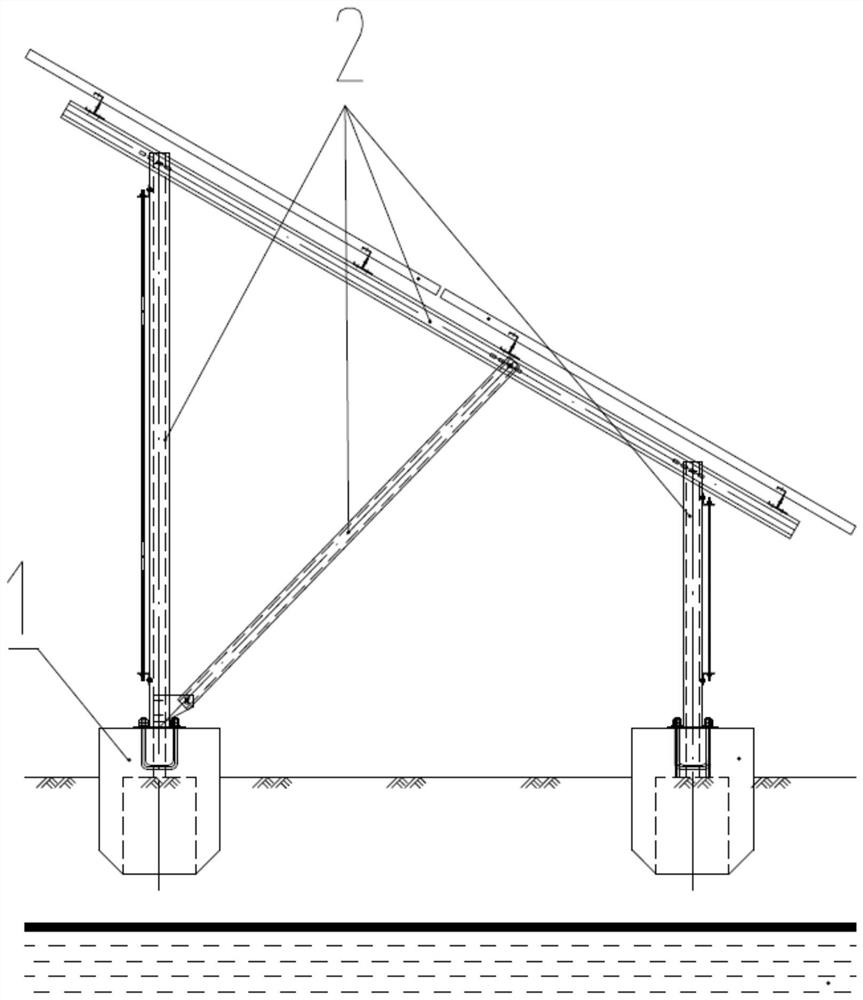

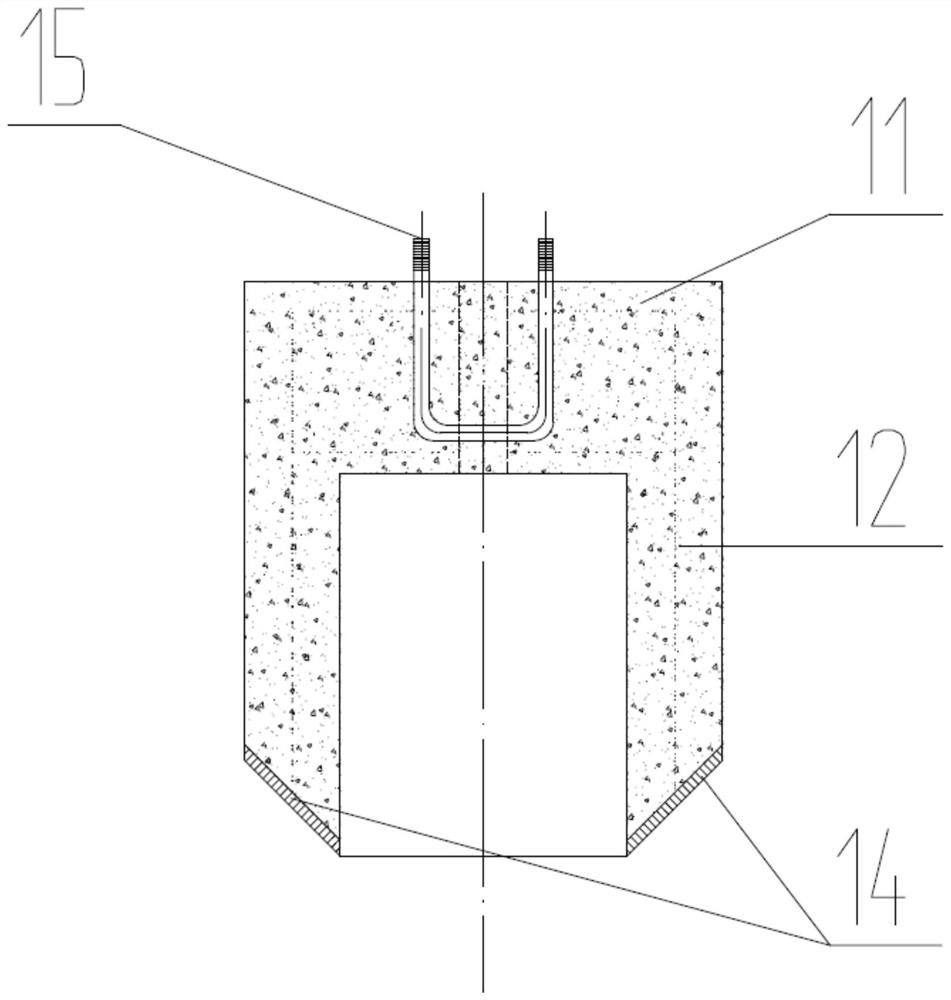

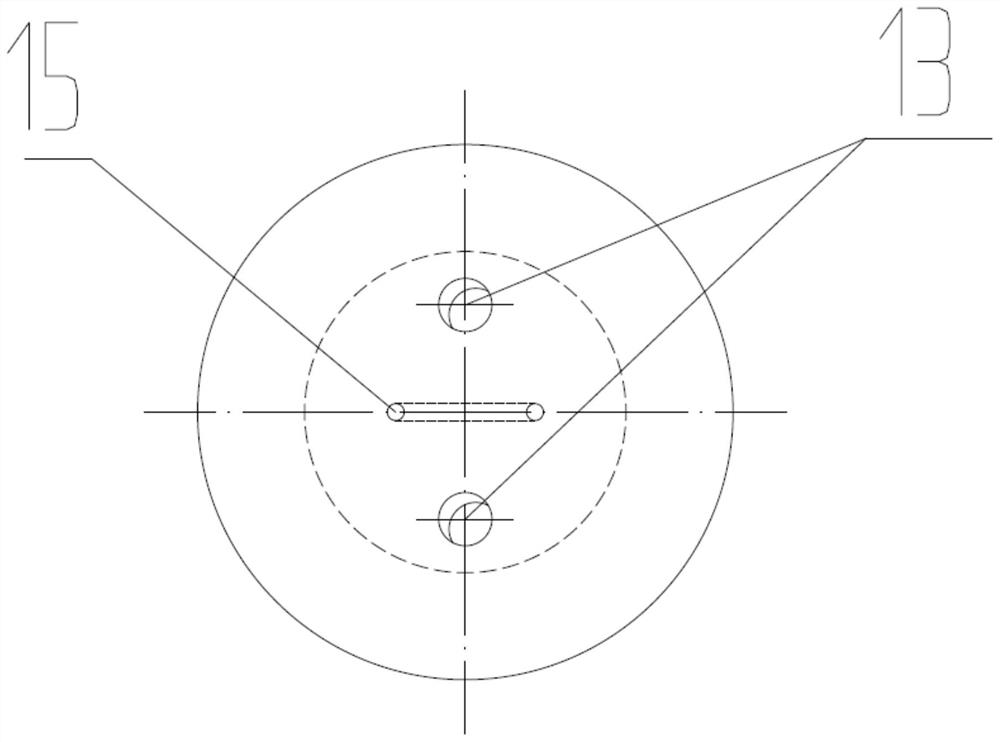

[0036] see Figure 1-4 , a prefabricated barrel-shaped foundation for photovoltaic support in the shallow surface soil layer area, including a barrel-shaped foundation 1, the barrel-shaped foundation 1 is a hollow barrel-shaped foundation 1 with prefabricated steel bars 16 concrete, by adopting the barrel-shaped structure, With a small amount of concrete, the contact area between the foundation and the soil is enlarged to ensure that the foundation has sufficient bearing capacity.

[0037] The barrel-shaped foundation 1 specifically includes two parts: a barrel wall 11 and a barrel roof 12. The barrel wall 11 is arranged below the barrel roof 12; the barrel wall 11 and the barrel roof 12 are provided with steel bars 16 for reinforcement. Preferably, due to the barrel shape The force of the foundation 1 is mainly the overall force, and the reinforcement of the foundation is structural reinforcement. It is recommended to use φ10 for the 12 steel bars 16 of the barrel roof, and φ...

Embodiment 2

[0056] The second embodiment is the application of a prefabricated barrel-shaped construction method for the photovoltaic support 2 in the shallow surface soil layer in a certain ash field photovoltaic power station in Northwest China.

[0057] The thickness of the superficial filling layer of the ash yard is about 0.6m; using the barrel foundation 1, specifically, the diameter of the barrel foundation 1 is 0.5m, the depth of entry is 0.4m, and the thickness of the barrel roof 12 is 0.2m. The total height of the barrel foundation 1 is 0.6m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com