Station canopy construction movable framework and station canopy construction method

A technology for moving formwork and formwork, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of low safety factor, high labor cost, complicated process, etc., and achieve bearing capacity Large, improve construction quality, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

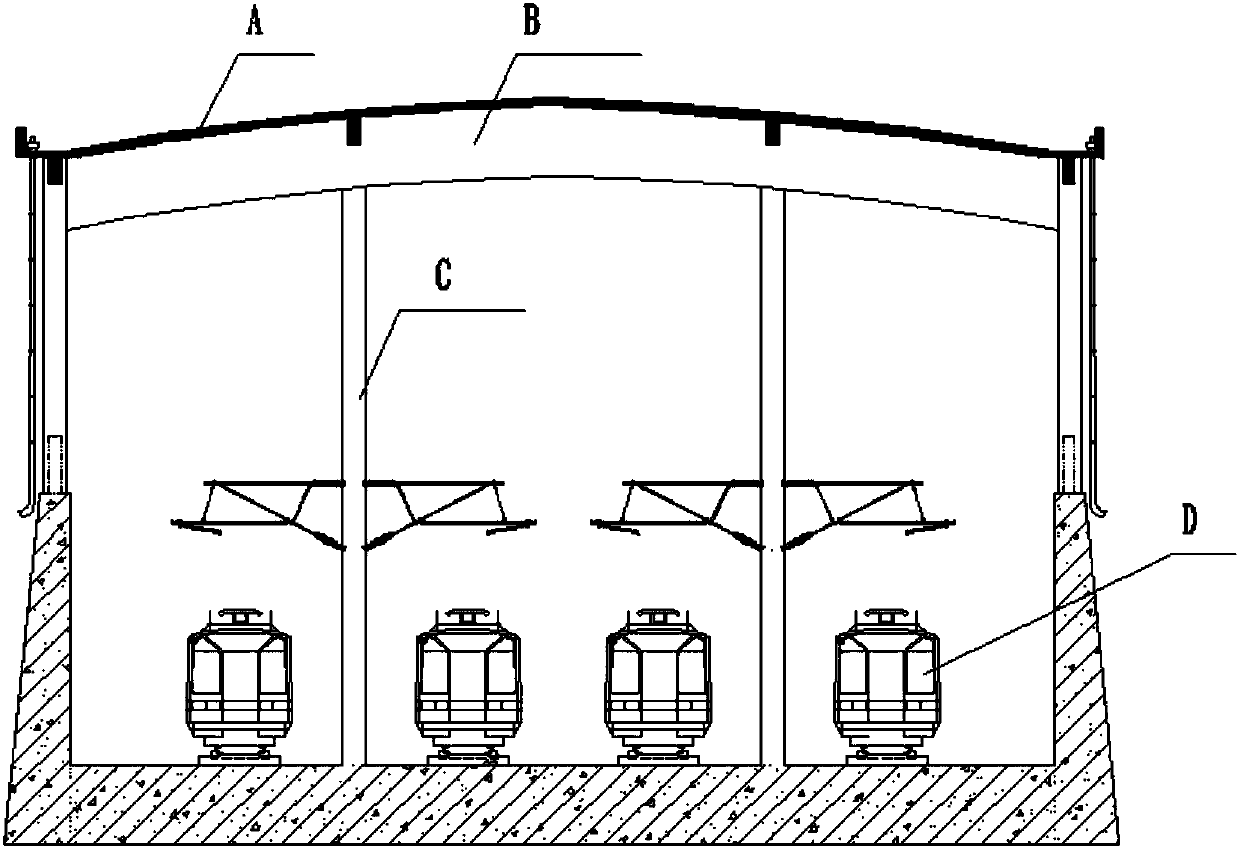

[0073] Such as figure 1 As shown, the built canopy A is connected to the beam structure B, the lower part of the beam structure B is fixedly connected with the column C, the column C is fixed on the platform, and D is the train on the platform.

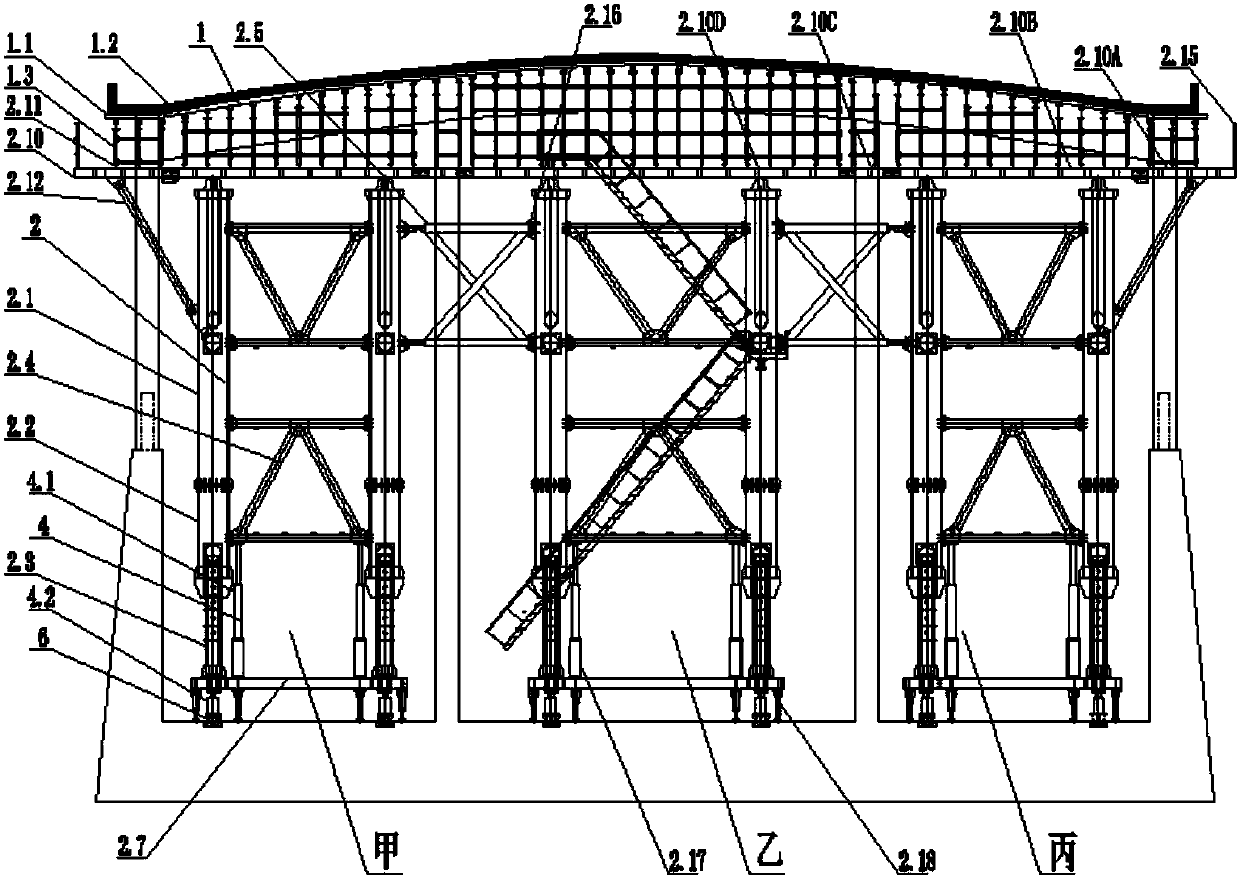

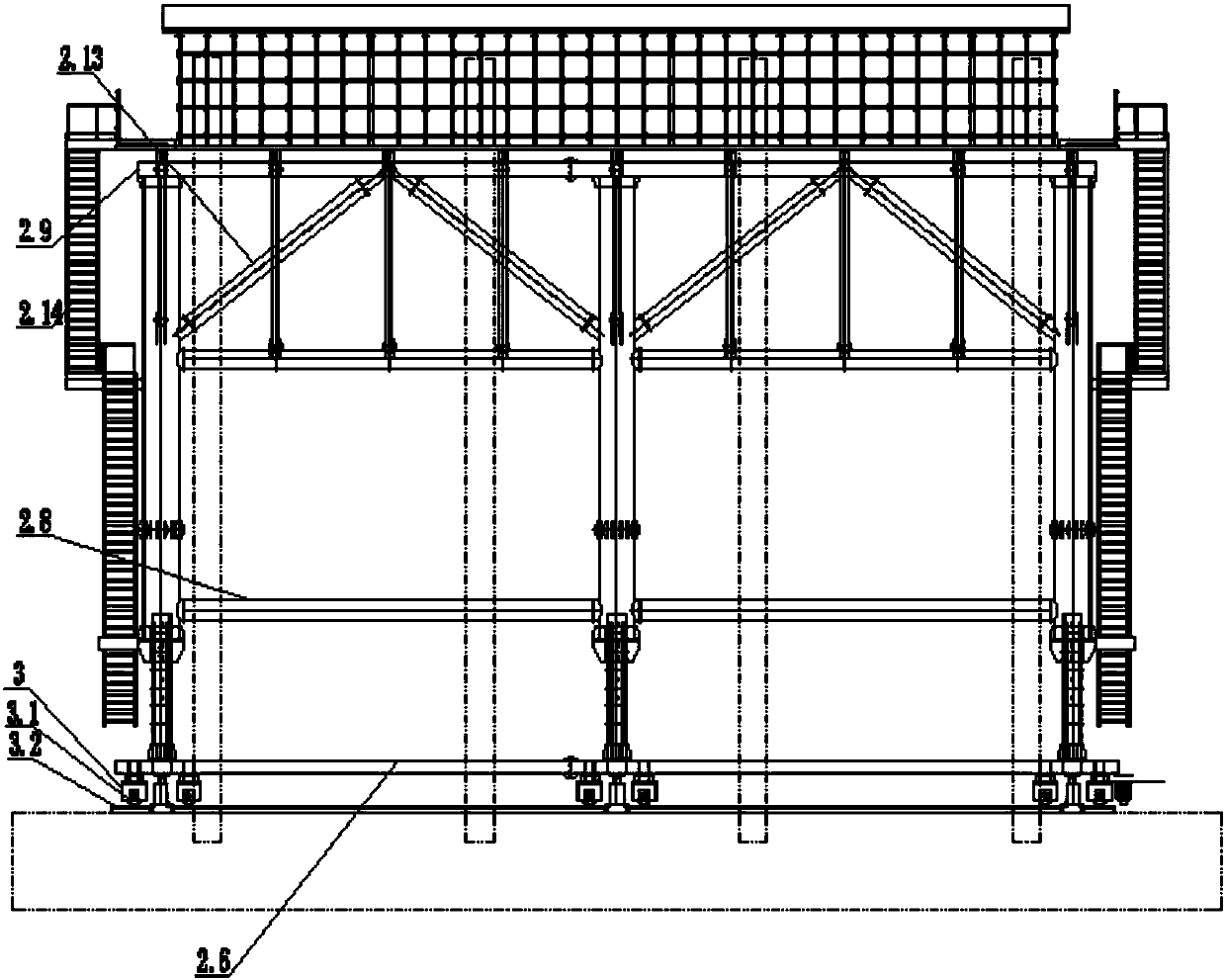

[0074] In a typical embodiment of the present invention, such as figure 2 Elevation of mobile formwork, image 3 Side view of the mobile formwork and Figure 13 As shown in the perspective view of the mobile formwork, a mobile formwork for station canopy construction includes a left warehouse formwork (A), a middle warehouse formwork (B) and a right warehouse formwork (C), and the left warehouse formwork ( A), the middle warehouse formwork (B) and the right warehouse formwork (C) respectively include formwork system 1, portal frame system 2, walking system 3, hydraulic system 4, control system 5 and bottom Support 6; the formwork system 1 of the left warehouse formwork (A), the middle warehouse formwork (B) and the right warehouse...

Embodiment 2

[0093] The construction process of the station canopy is to complete the structural construction and concrete pouring of the canopy A and the beam structure B block by block along the direction of the train track. In order to realize the continuous work of the station canopy and reduce the reinstallation process of formwork and scaffolding, the invention Provided is a station canopy construction method, using a station canopy construction mobile formwork provided by the present invention, the construction method includes the following steps:

[0094] In the first step, the formwork wheel of the formwork traveling system contacts the rail, and the formwork moves forward to the position where construction is required;

[0095] In the second step, the formwork rises as a whole for the first time;

[0096] The third step is the formwork system connection and truss connection of the formwork;

[0097] The fourth step is the second overall rise of the formwork, the installation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com