Construction template

A formwork technology for construction, applied in the direction of architecture, building structure, formwork/formwork components, etc., can solve the problems of forest resource consumption, weak rigidity, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

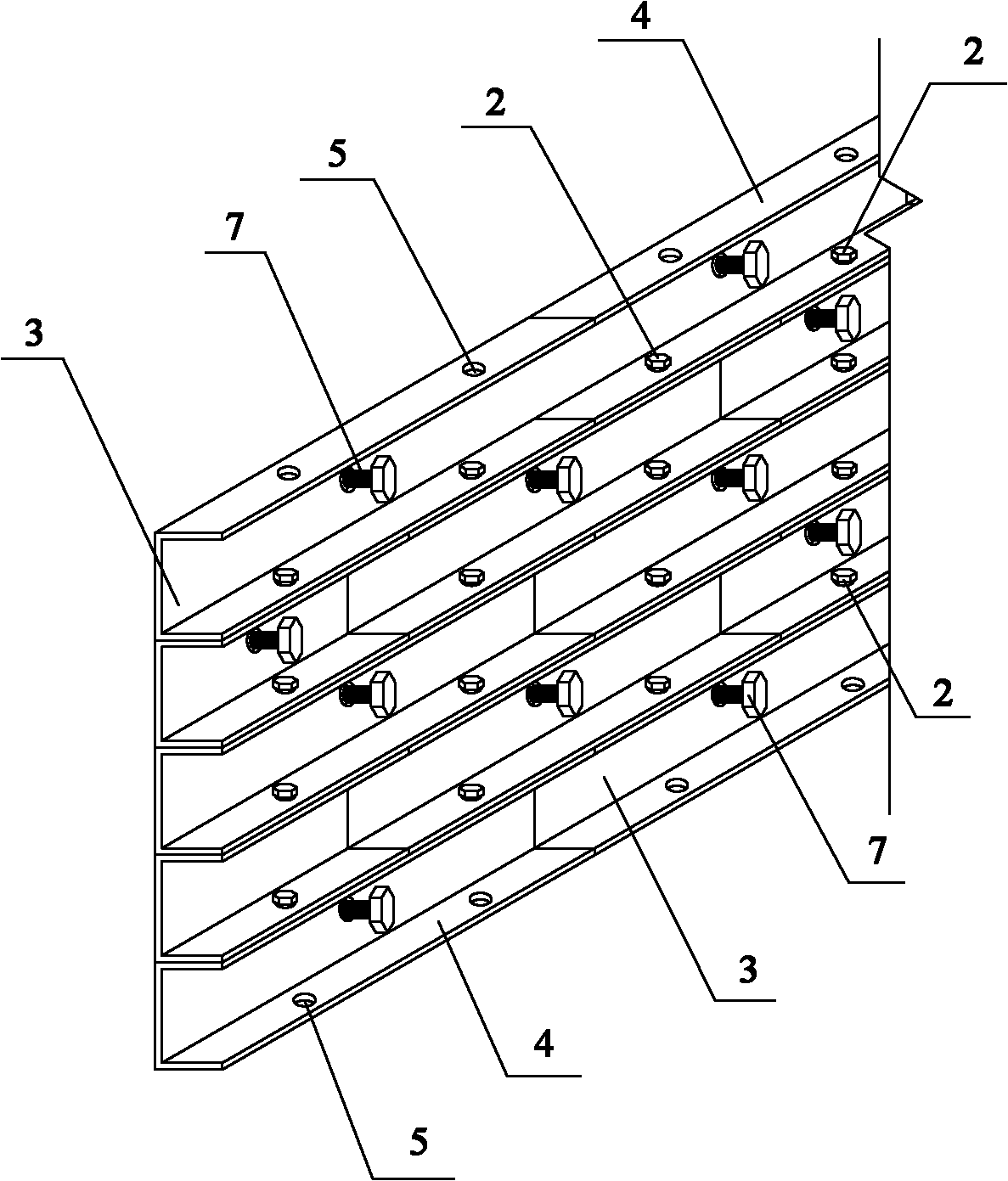

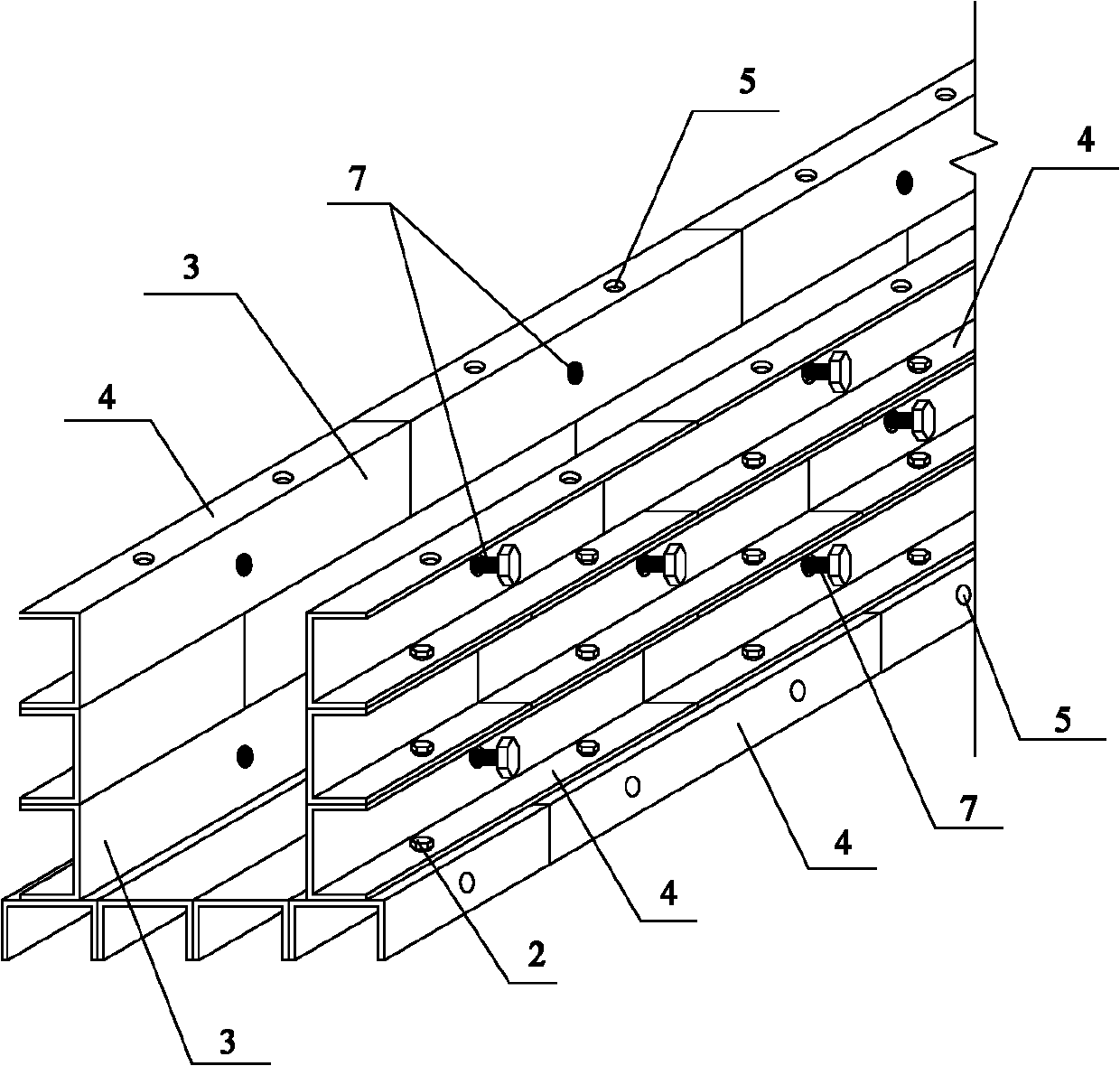

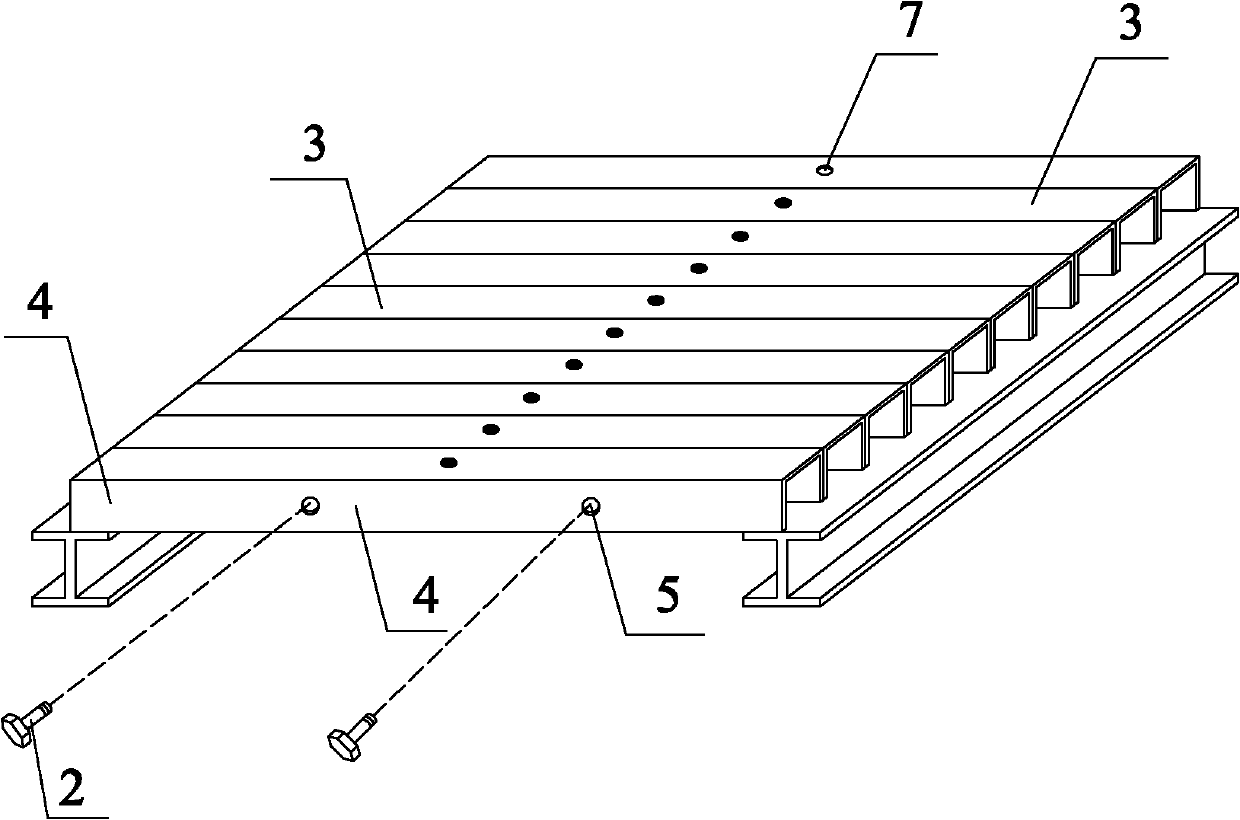

[0014] The invention is attached Figure 1-7 As shown, a formwork for construction includes a trough-shaped module 1, bolts 2 or bolts, holes 5 are provided on the two flanges 4 of the trough-shaped module 1, and the holes 5 on the two flanges 4 are aligned with each other. Bolts 2 or bolts pass through the holes 5 on the flanges 4 of the trough-shaped modules 1 to connect multiple trough-shaped modules 1, and then connect multiple trough-shaped modules 1 in turn to form a building formwork. figure 1 Assembling schematic diagrams for building formwork, such as figure 1 , The slotted modules 1 are connected by bolts 2 or bolts. The template can be used in the construction of beams, slabs, columns and shear walls of cast-in-place concrete. Figure 2-5 They are schematic diagrams of the overall assembly of beams, slabs, columns and shear wall formwork. As shown in the figure, the uniform small-sized trough-shaped module 1 is composed of hard materials, with high rigidity and hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com