Production technology and equipment of concrete plate-shaped components

A technology for concrete slabs and production processes, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of low turnover rate of formwork and low efficiency of manual production quality, so as to improve turnover efficiency, reduce the difficulty of demolding, Avoid occupancy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

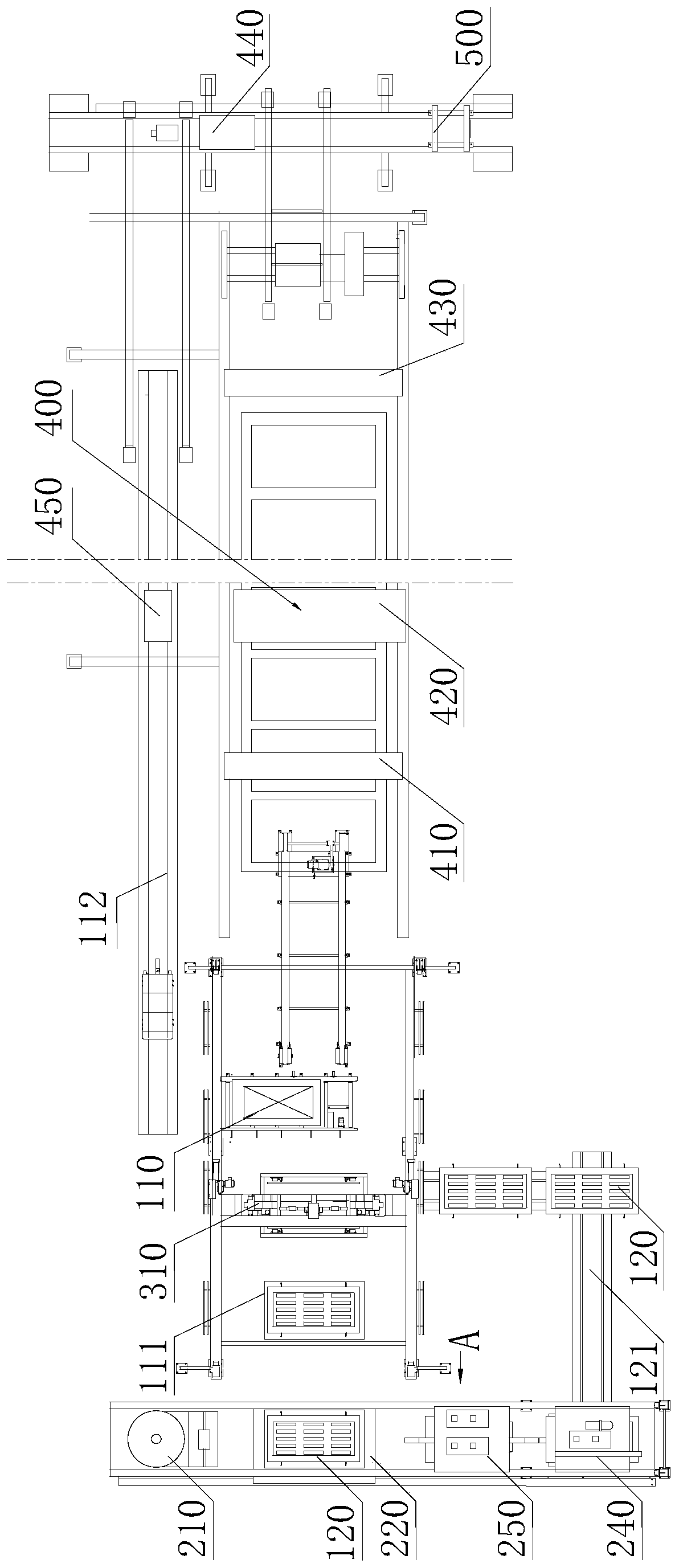

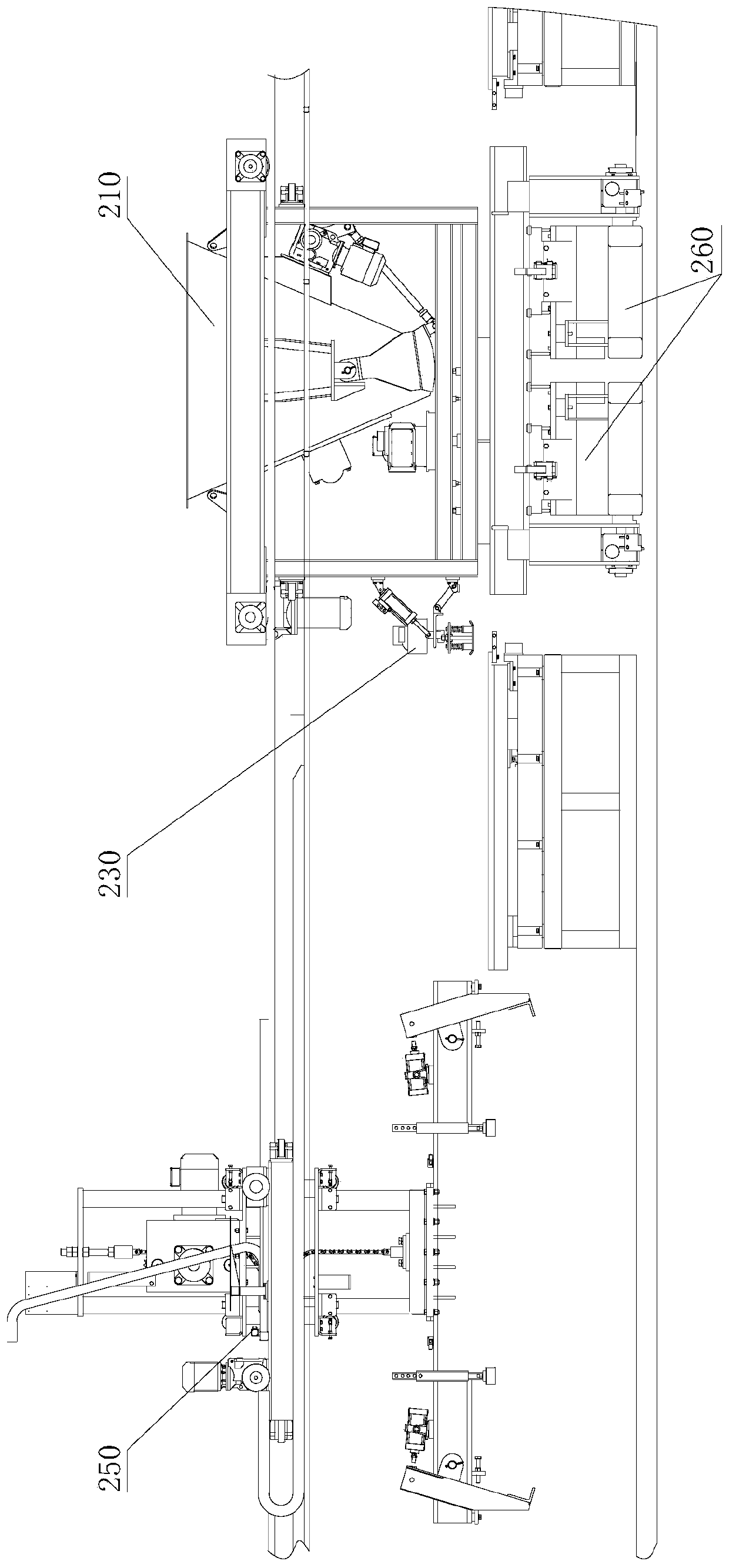

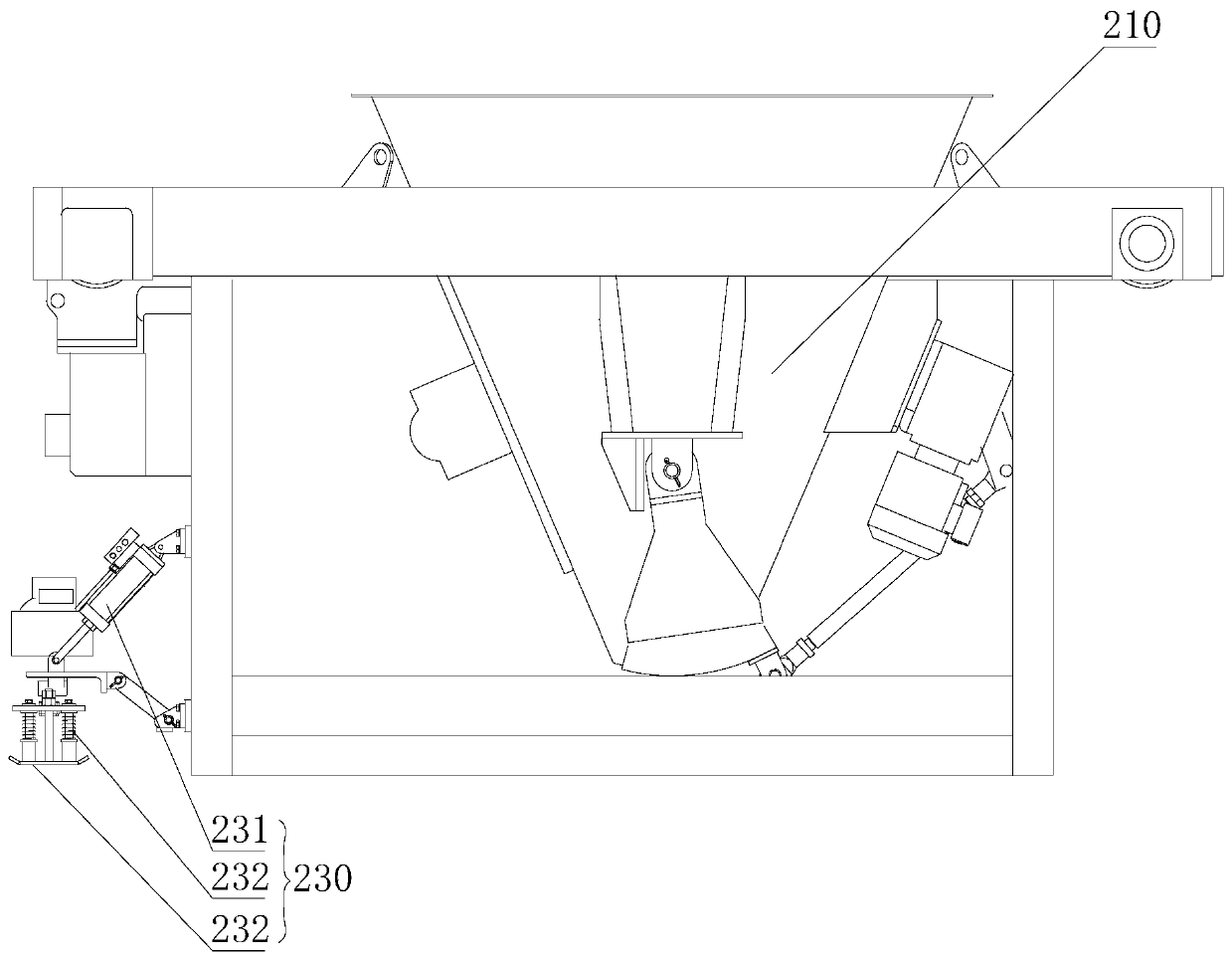

[0026] Please also refer to Figure 1 to Figure 2 As a specific embodiment of the blast furnace ironmaking equipment provided by the present invention, before the plate-shaped member is released from the mold 120, the mold 120 and the plate-shaped member are located on the second tray 111, and in the demoulding step, the first A tray 110 is buckled upside down on the upper surface of the mold 120 and the plate-shaped member. After the whole is turned over, the second tray 111 is removed from the mold 120 and the plate-shaped member, and then the mold 120 is removed from the plate-shaped member. The components are located on the first tray 110 . In the demoulding step in this embodiment, since the uncured plate member is first demoulded and then maintained during the operation, since the mold 120 has not yet been formed at this point in time, the strength is not enough to ensure the quality of direct demoulding Stability, under the condition that the plate-shaped member and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com