Separated precast prestressed concrete slab type stairway and production process thereof

A concrete slab and prestressing technology, applied in stairs, manufacturing tools, ceramic molding machines, etc., can solve the problems of complex production process and self-heavy slab stairs, and achieve the effect of simple construction process, large span and template saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

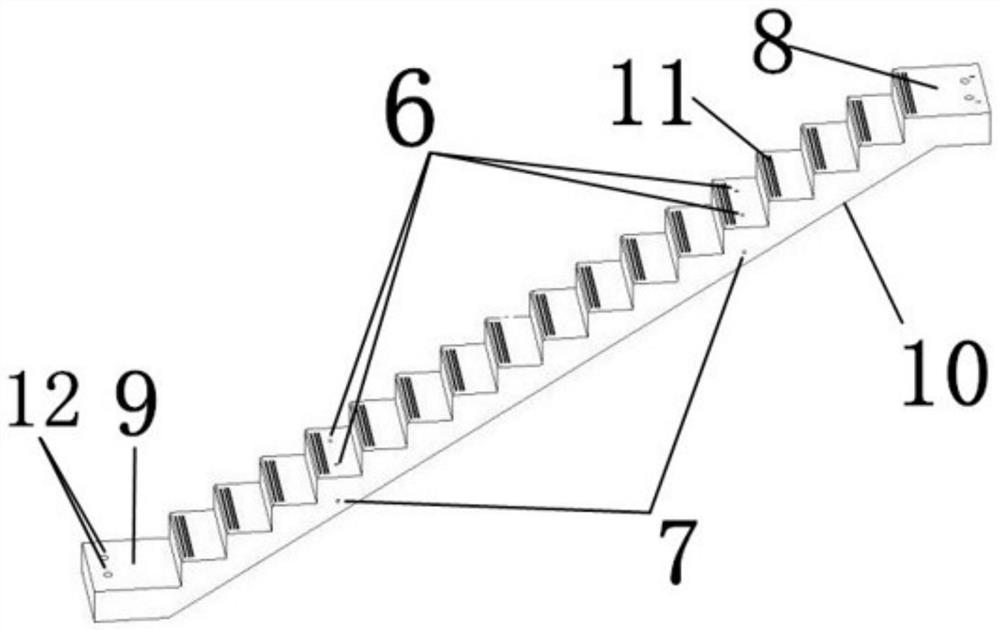

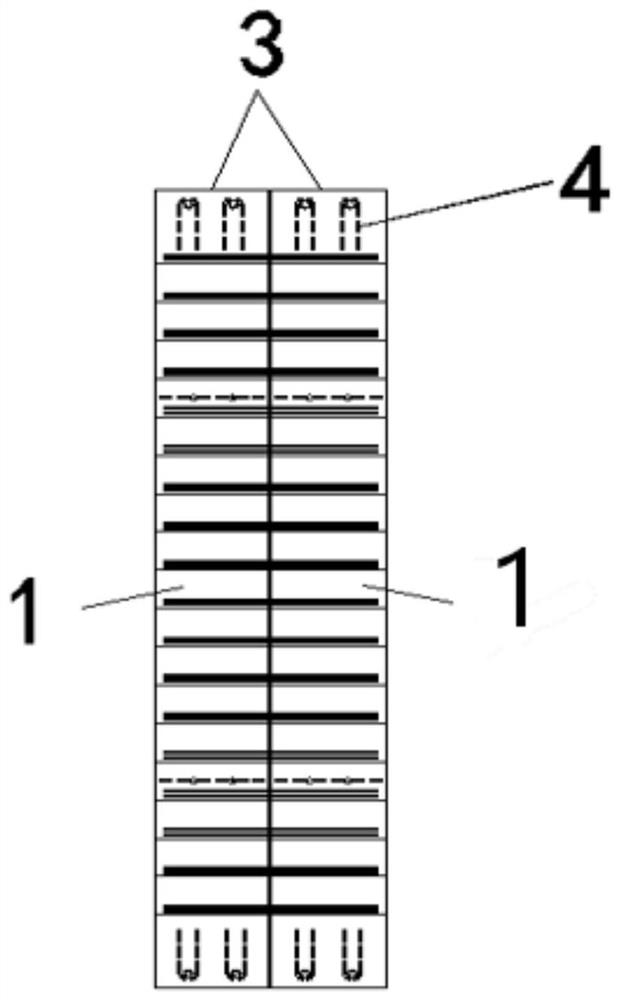

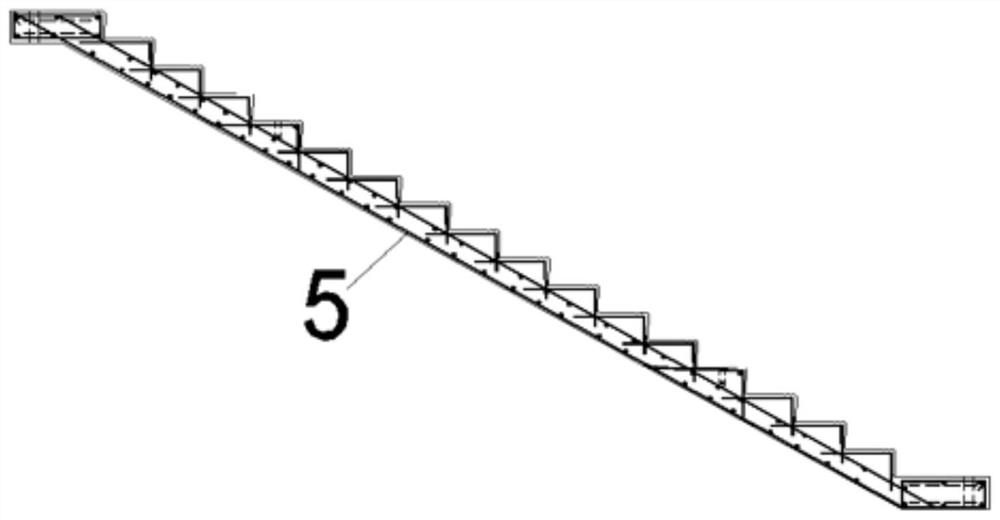

[0036] Embodiment one: by Figure 1 to Figure 5 Given, the separated prefabricated prestressed concrete slab staircase includes a staircase body 1, and the staircase body 1 sequentially includes an integrally formed upper platform slab 8, a step section slab 10 and a lower platform slab 9 from top to bottom, and the staircase body 1. The prestressed steel bar 5 is arranged along the length direction at the inner lower part. The surface of the upper platform slab 8 and the lower platform slab 9 have reserved mounting holes 12 and ribs 4 for the reserved holes respectively. The stair section slab 10 has a lifting The hanging point 6 and the demoulding lifting point 7, the prestressed reinforcement 5 is provided with a reserved prestressed reinforcement plugging groove 13 at the outlet hole of each plane plate.

Embodiment 2

[0037] Embodiment 2: On the basis of Embodiment 1, the lifting point 6 includes a set of lifting points and two sets of lifting points, the distance between the set of lifting points and the upper platform board 8 and the distance between the two sets of lifting points and the lower platform The distances between the boards 9 are the same, and anti-slip strips 11 are provided on the step surfaces of the step boards 10 .

[0038] In the above-mentioned embodiment, the prestressed steel bar adopts 1570-grade ΦH9.0 stress-relieving spiral rib steel wire.

Embodiment 3

[0039] Embodiment 3: In the above embodiment, each individual staircase body 1 is used as a separated prefabricated prestressed concrete slab staircase, which can be assembled to form an integral prefabricated prestressed concrete slab staircase 3. The concrete strength grade used is C45, and the steel bar The thickness of the protective layer is 20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com