Patents

Literature

40results about How to "Simplify on-site construction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water acid-sensitivity deformation magnetic tracer function self-suspension propping agent and preparation method thereof

InactiveCN105670600AReservoir damage is smallSave time and costFluid removalDrilling compositionMagnetic tracerSurface hydration

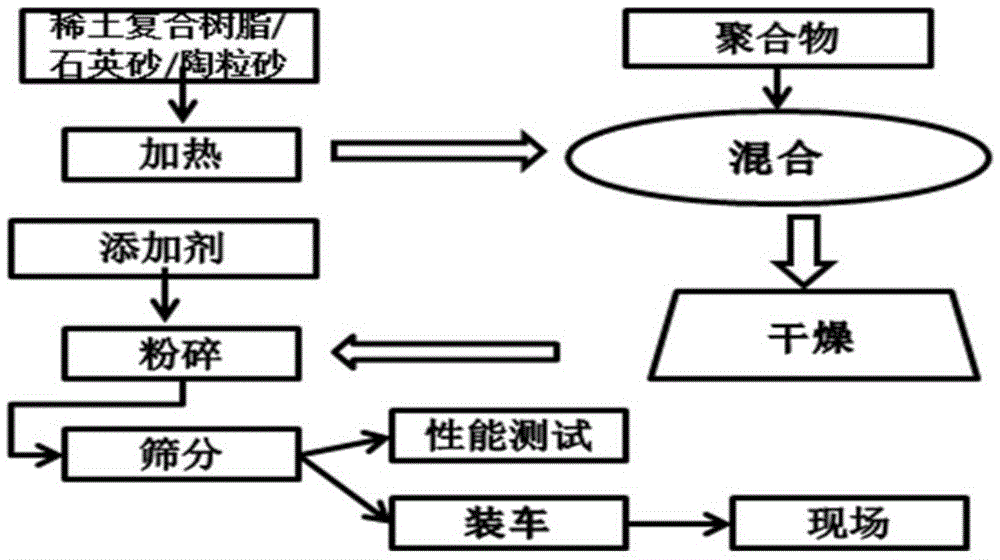

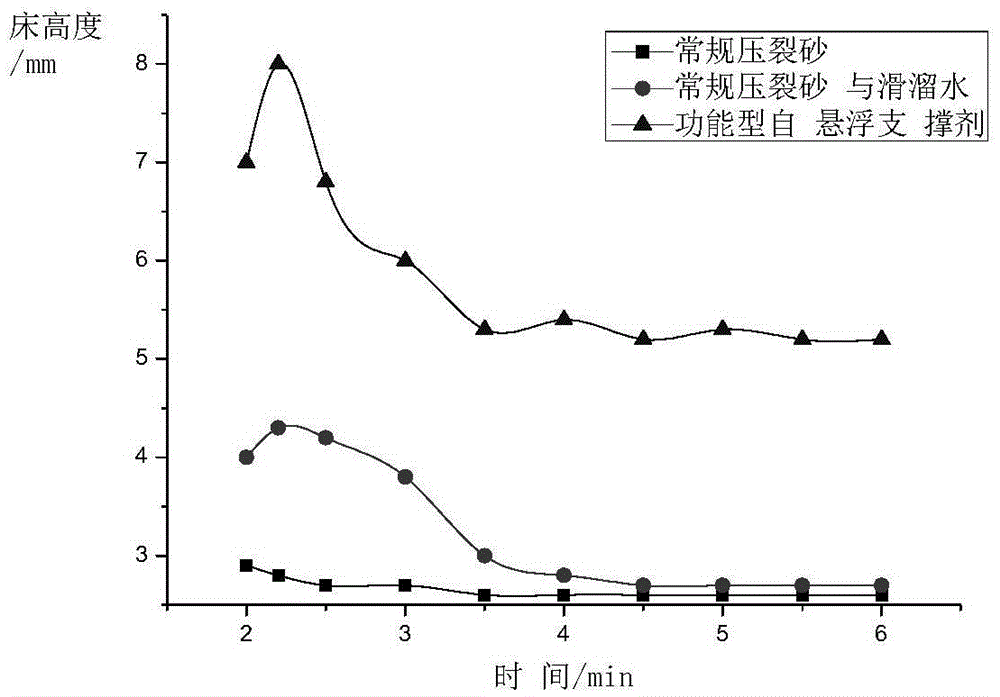

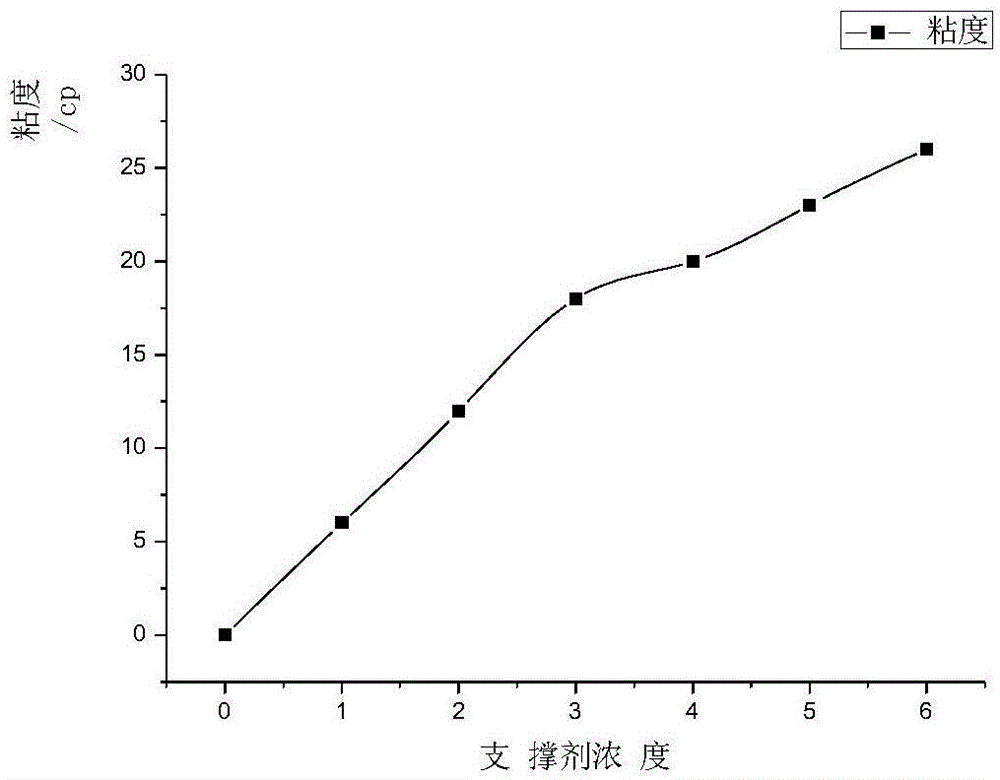

The invention belongs to the technical field of oil-gas field fracturing production-increase propping agent preparation, and relates to a water acid-sensitivity deformation magnetic tracer function self-suspension propping agent and a preparation method thereof. The propping agent comprises an aggregate and a surface hydration layer, wherein the aggregate is one of magnetic rare earth composite resin, quartz sand or ceramsite and like material; the surface hydration layer is composed of three layers, the innermost layer is a cationic macromolecule inner polymer layer or a modifier layer, the middle layer is an anionic macromolecule outer polymer layer, and the outer layer is anti-caking agent. The propping agent has the acid-sensitivity deformation self-suspension function of producing buoyant force while encountering water and breaking gel to precipitate while encountering the acid, and a tracer function of monitoring flow guiding position of the propping agent through electromagnetic imaging; in the process of exerting the fracturing engineering on shale, compact oil-gas or coal bed base and like argillaceous plasticity micronano hole reservoir, the fracturing liquid with the propping agent has excellent flow guiding characters of suspension sand-adding of non-floating to the roof and not sinking to the bottom; the permeation is improved, the hurt is avoided, the propping agent is efficient and capable of increasing production, the construction cost is lowered, and the application prospect is wide.

Owner:王展旭

Efficient wax inhibitor for oilfields

InactiveCN105086976ASimplify on-site construction processImprove mobilityDrilling compositionSolventWax

The invention discloses an efficient wax inhibitor for oilfields. The efficient wax inhibitor, namely an oil-based wax inhibitor, is obtained by compounding of a wax-crystal modifier, a wax-crystal dispersant, a nonionic surfactant and a solvent; the wax-crystal modifier is a mixture of pentabasic copolymers and ethylene-vinyl acetate, and the weight ratio of the pentabasic copolymers to the ethylene-vinyl acetate is 1:2; the efficient wax inhibitor comprises, by weight, 0.5-1.5% of the wax-crystal modifier, 10-30% of the wax-crystal dispersant, namely mahogany petroleum sulfonate, 5-25% of the nonionic surfactant, namely AE-type surfactant or AR-type surfactant, and the balance solvent. The efficient wax inhibitor has the advantages that production cost is reduced greatly, production efficiency is improved, well flushing cycle is prolonged to about 50 days, application effect is good, and average daily incremental oil rate reaches 10%.

Owner:CHINA PETROLEUM & CHEM CORP

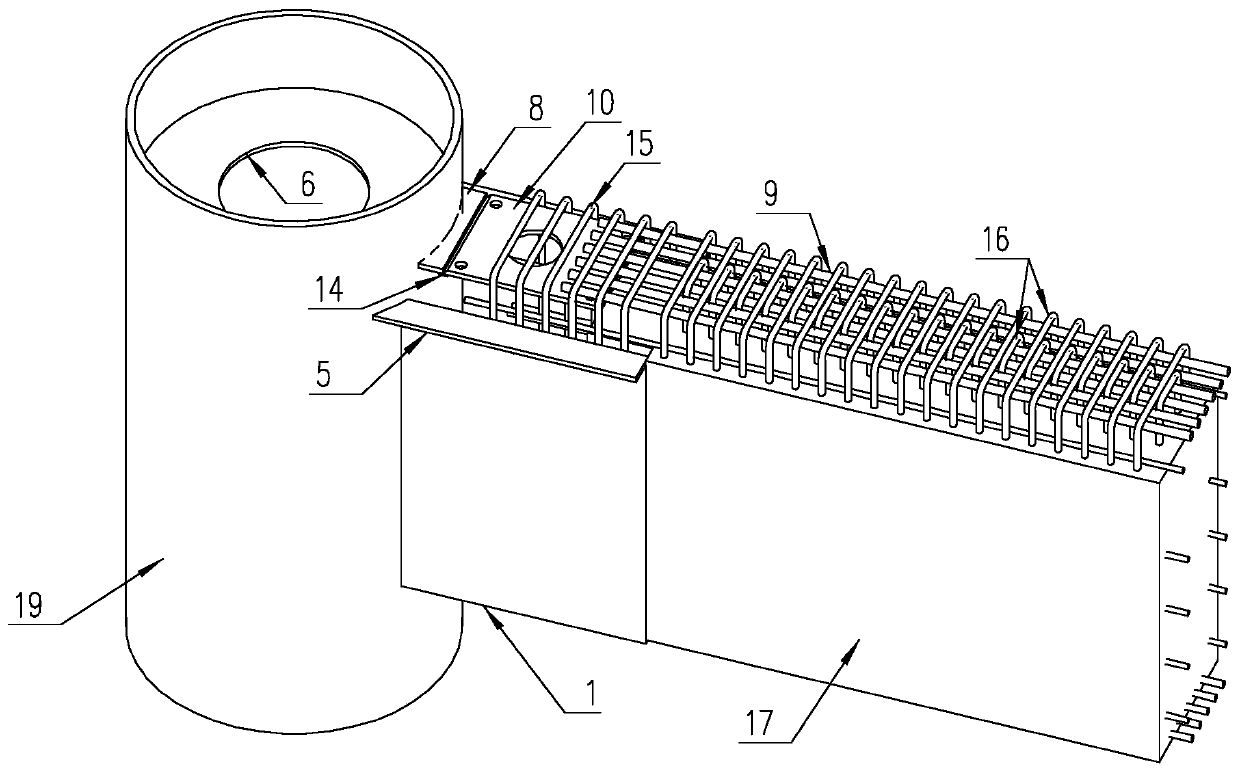

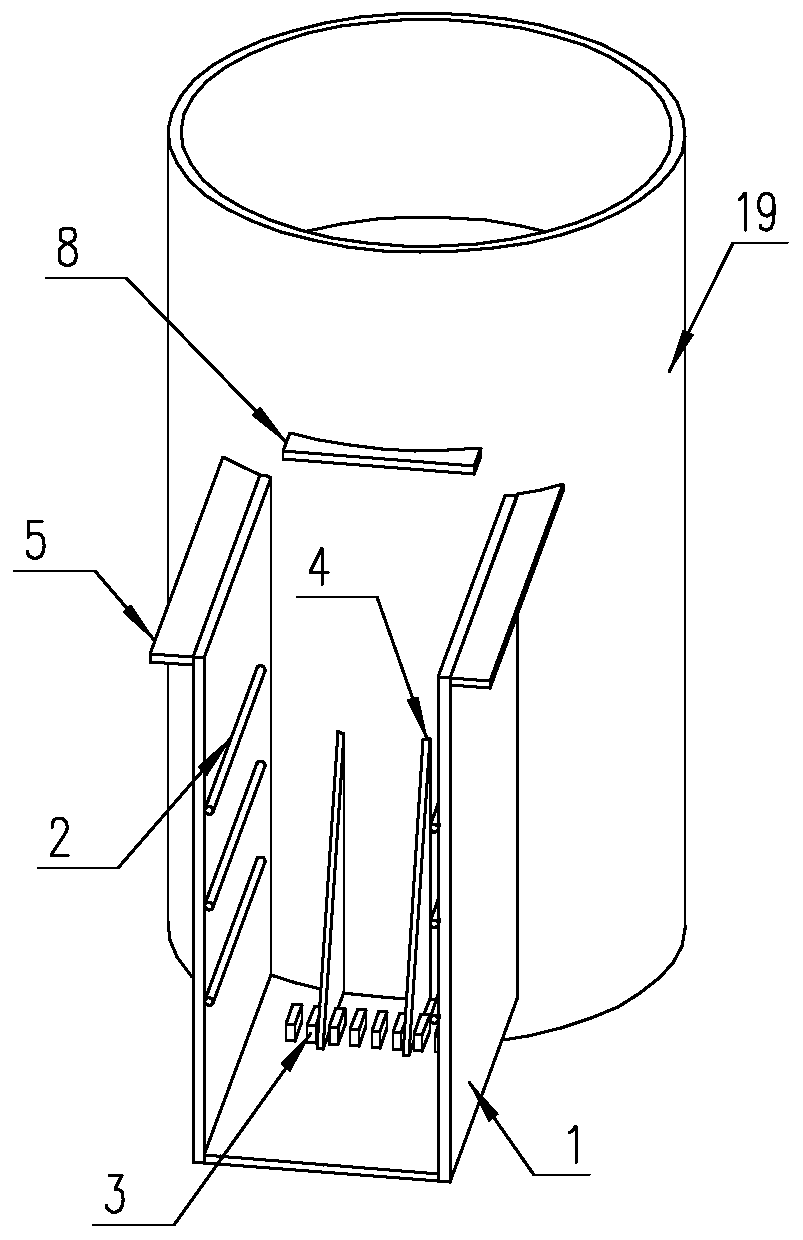

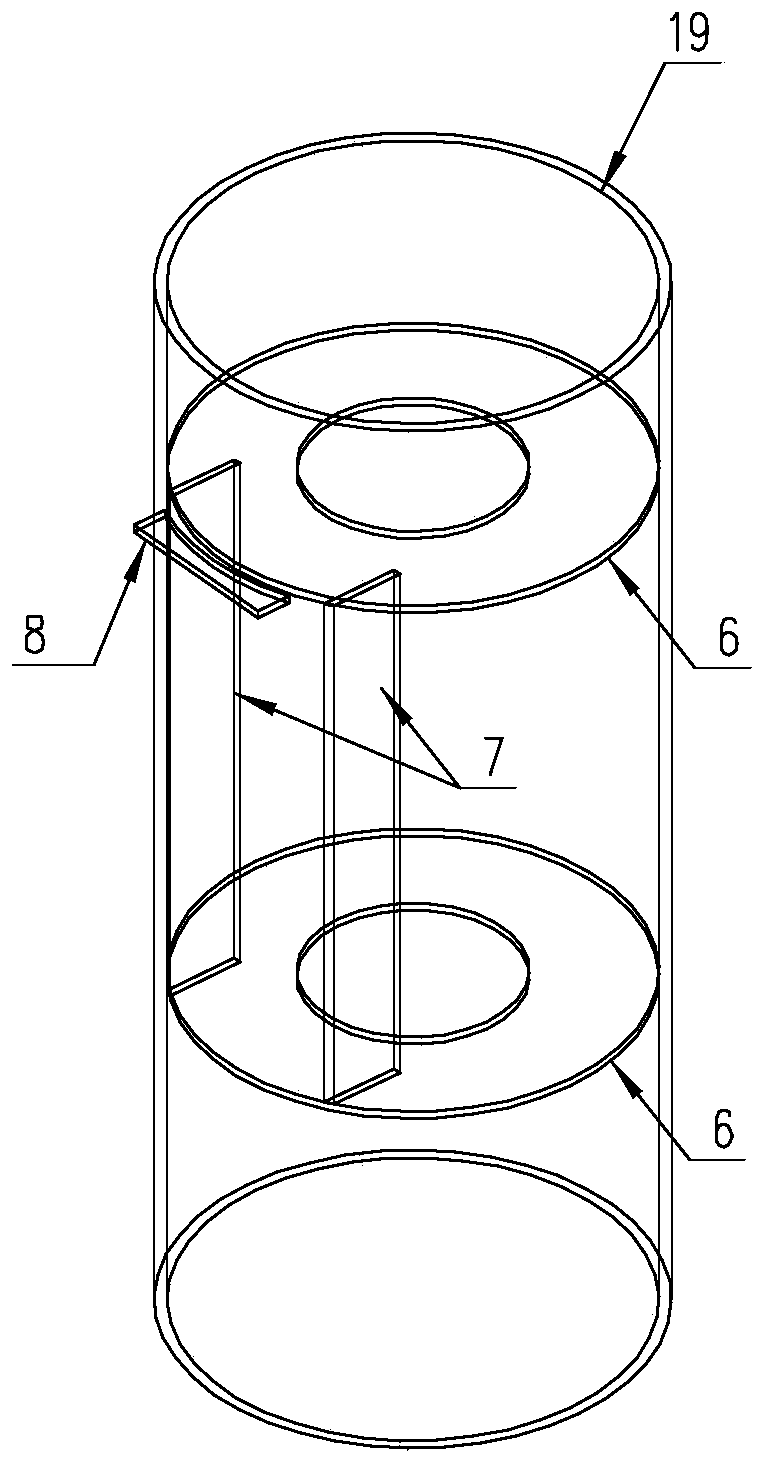

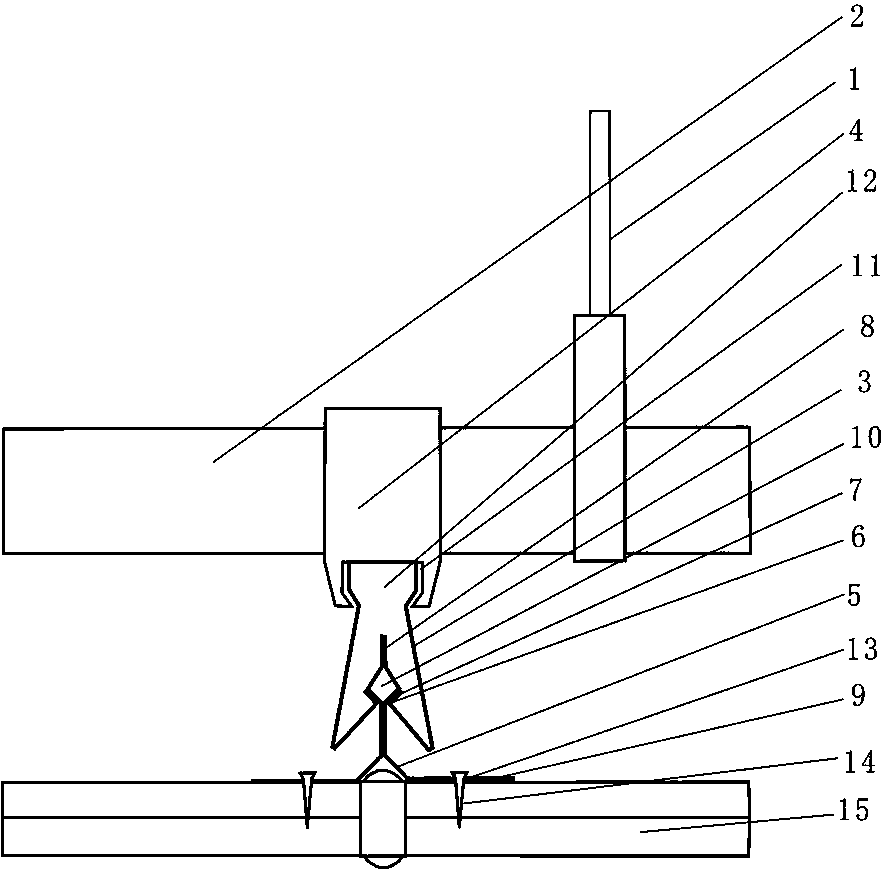

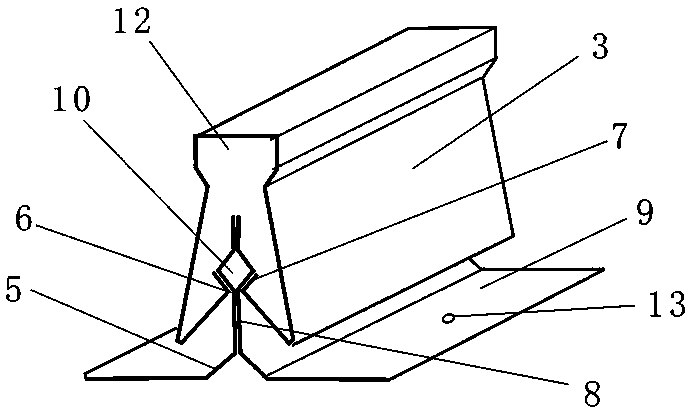

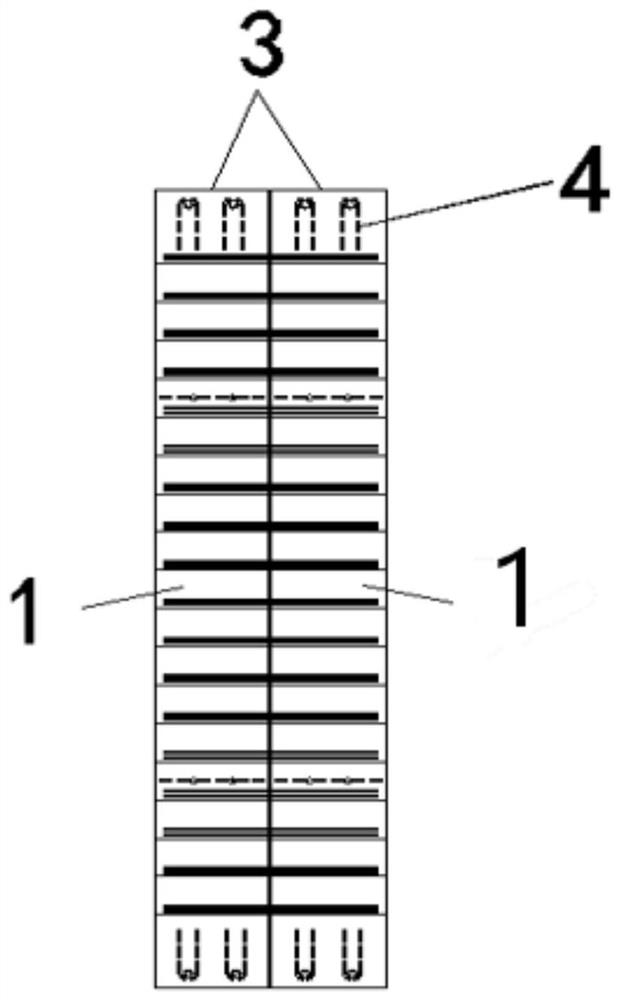

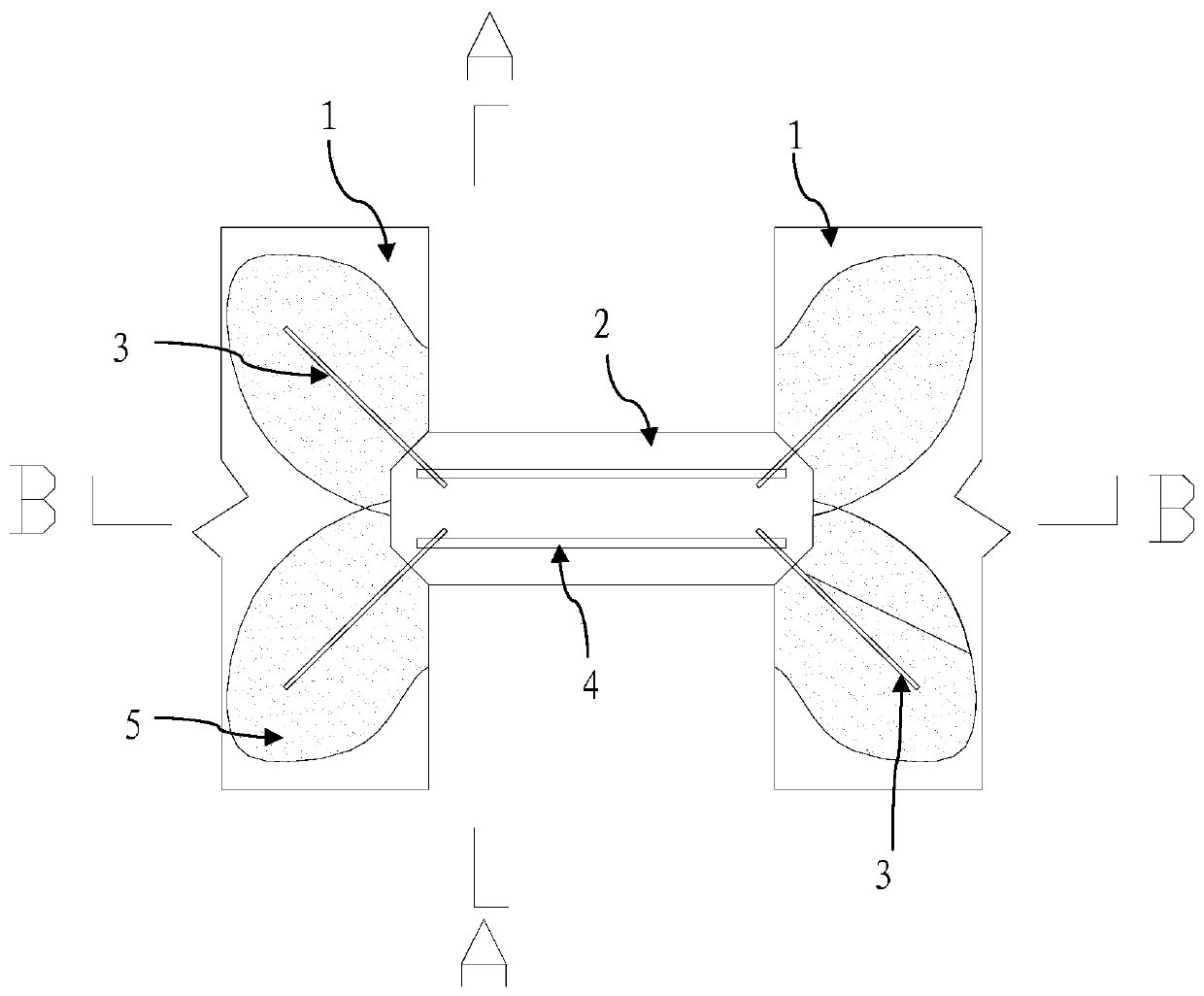

Steel pipe concrete column-precast concrete superposed beam assembly type building connection node

The invention discloses a steel pipe concrete column-precast concrete superposed beam assembly type building connection node. The steel pipe concrete column-precast concrete superposed beam assembly type building connection node comprises a steel pipe concrete column and a precast concrete superposed beam, wherein the outer wall of the steel pipe concrete column is provided with a U-shaped steel tank and a prewelded outer ring steel plate in a welded manner, the prewelded outer ring steel plate is horizontally arranged and located above the U-shaped steel tank, the U-shaped steel tank is provided with a bottom plate and side plates, the bottom plate is provided with bottom steel bar clamping buckle devices, and the tops of the side plates are provided with upper flanges being folded outwards; and the precast concrete superposed beam is installed inside the U-shaped steel tank in an inserted manner, the bottom of the precast concrete superposed beam is connected with the bottom steel bar clamping buckle devices in a clamped manner, the top of the precast concrete superposed beam is welded to the prewelded outer ring steel plate, a mutual plug-in mounting area of the precast concretesuperposed beam and the U-shaped steel tank is a superposed area, and concrete is poured into the superposed area after lap joint and assembly of the precast concrete superposed beam. The steel pipeconcrete column-precast concrete superposed beam assembly type building connection node is convenient and fast to install without bolts and mold supporting, and the production and construction efficiency can be effectively improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

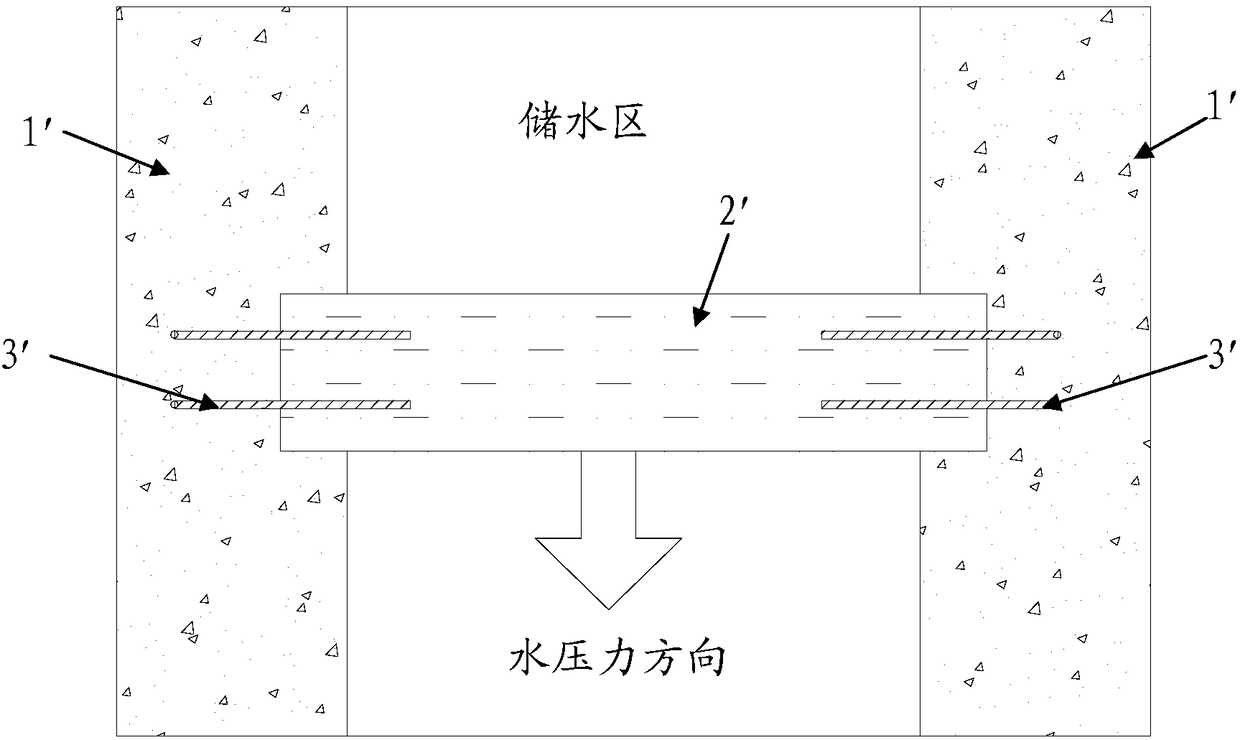

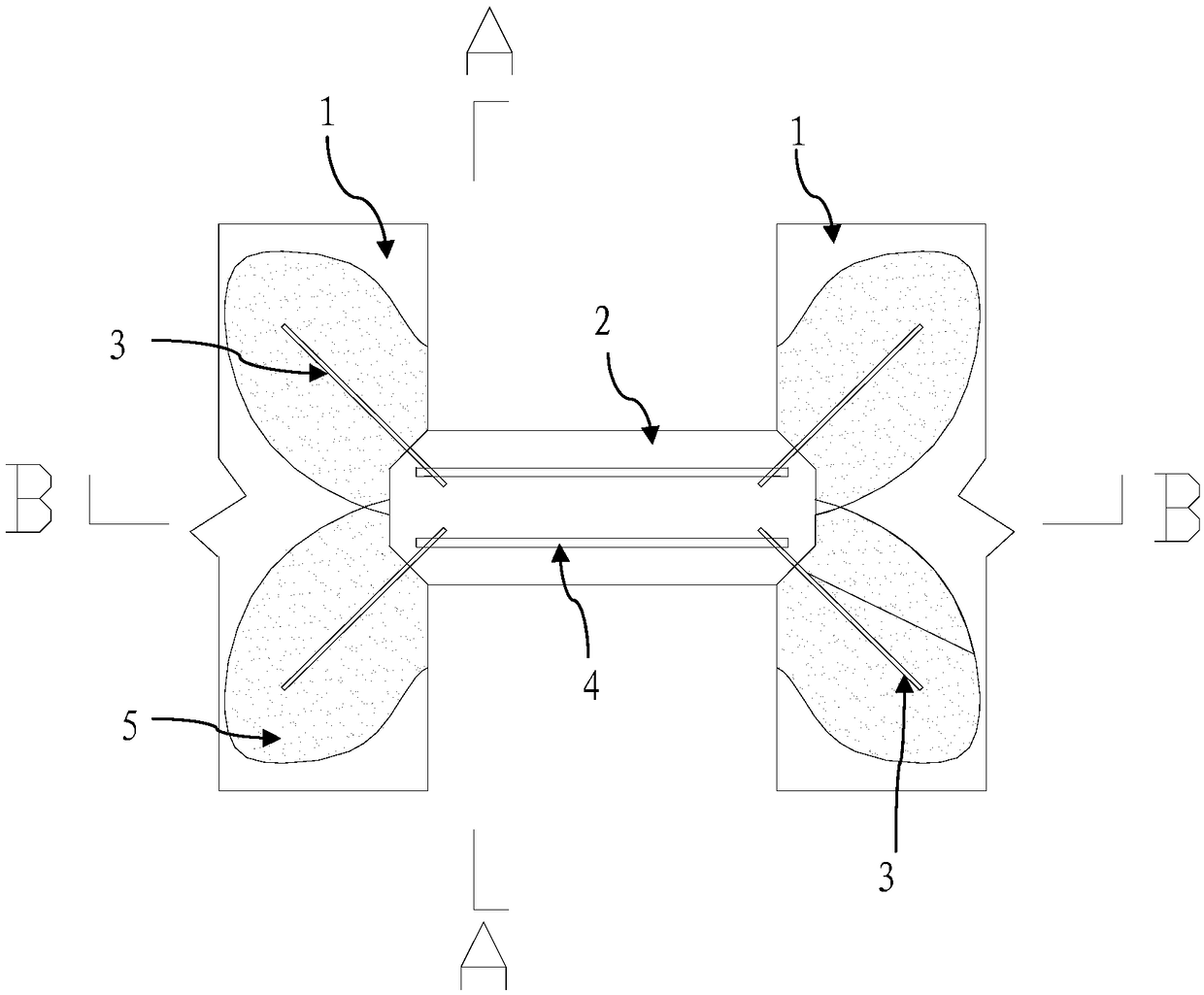

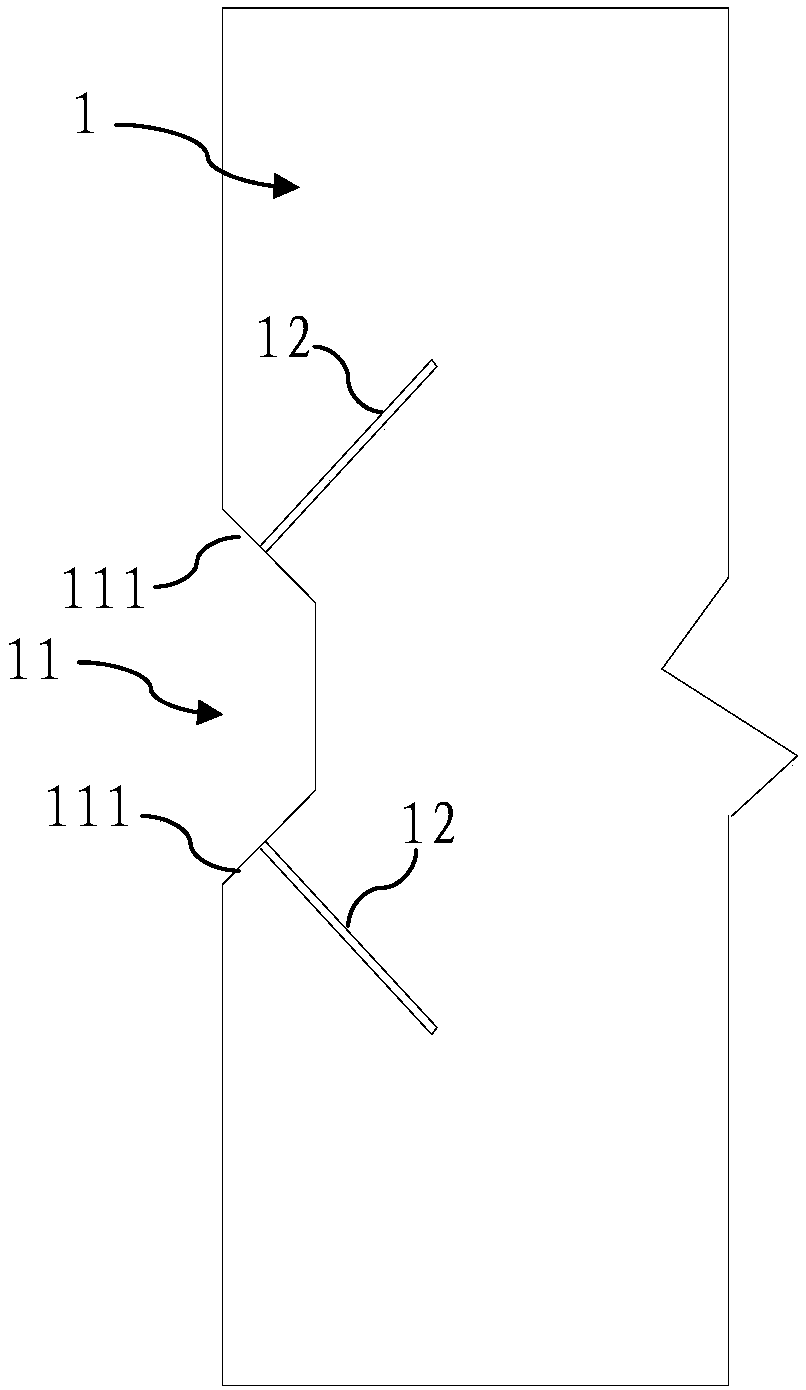

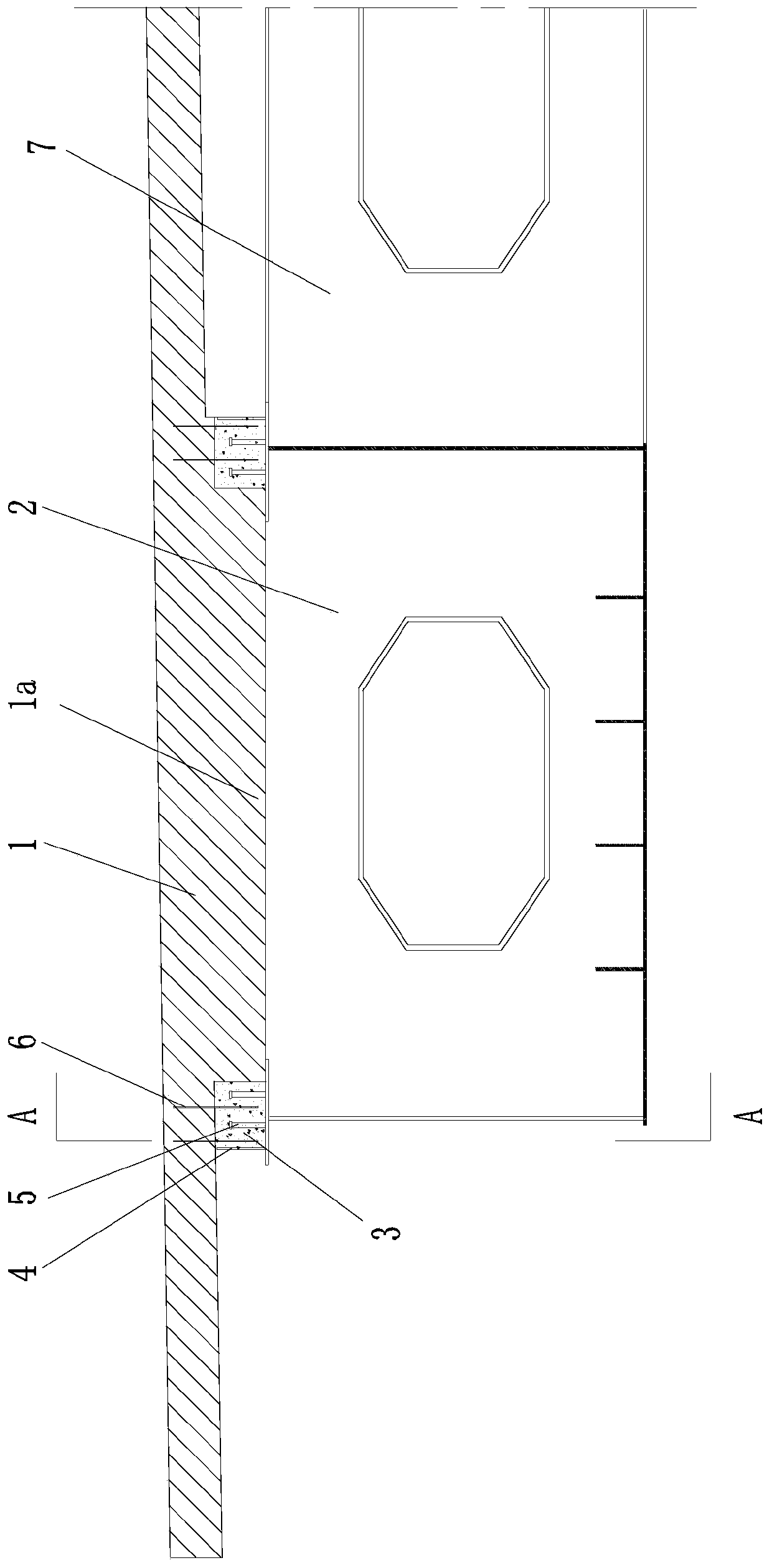

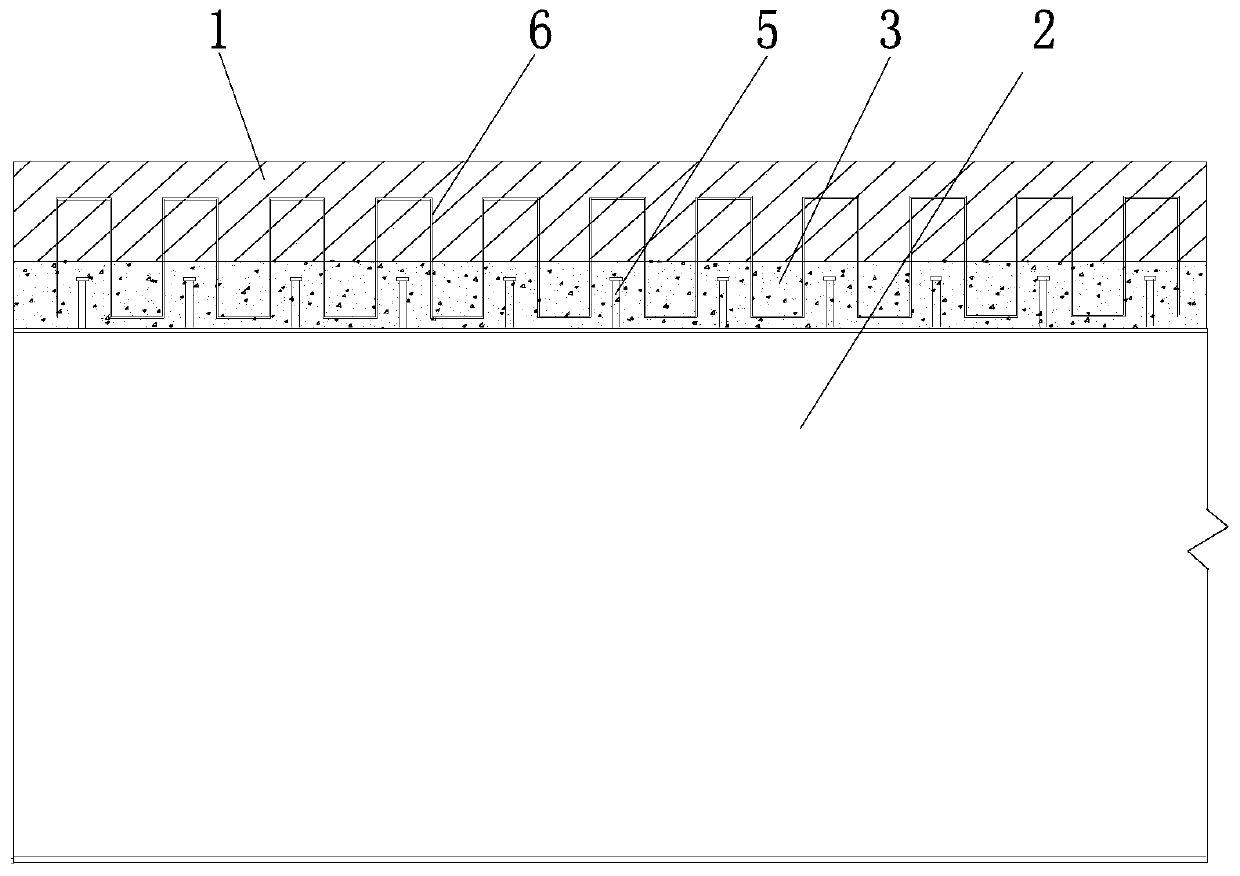

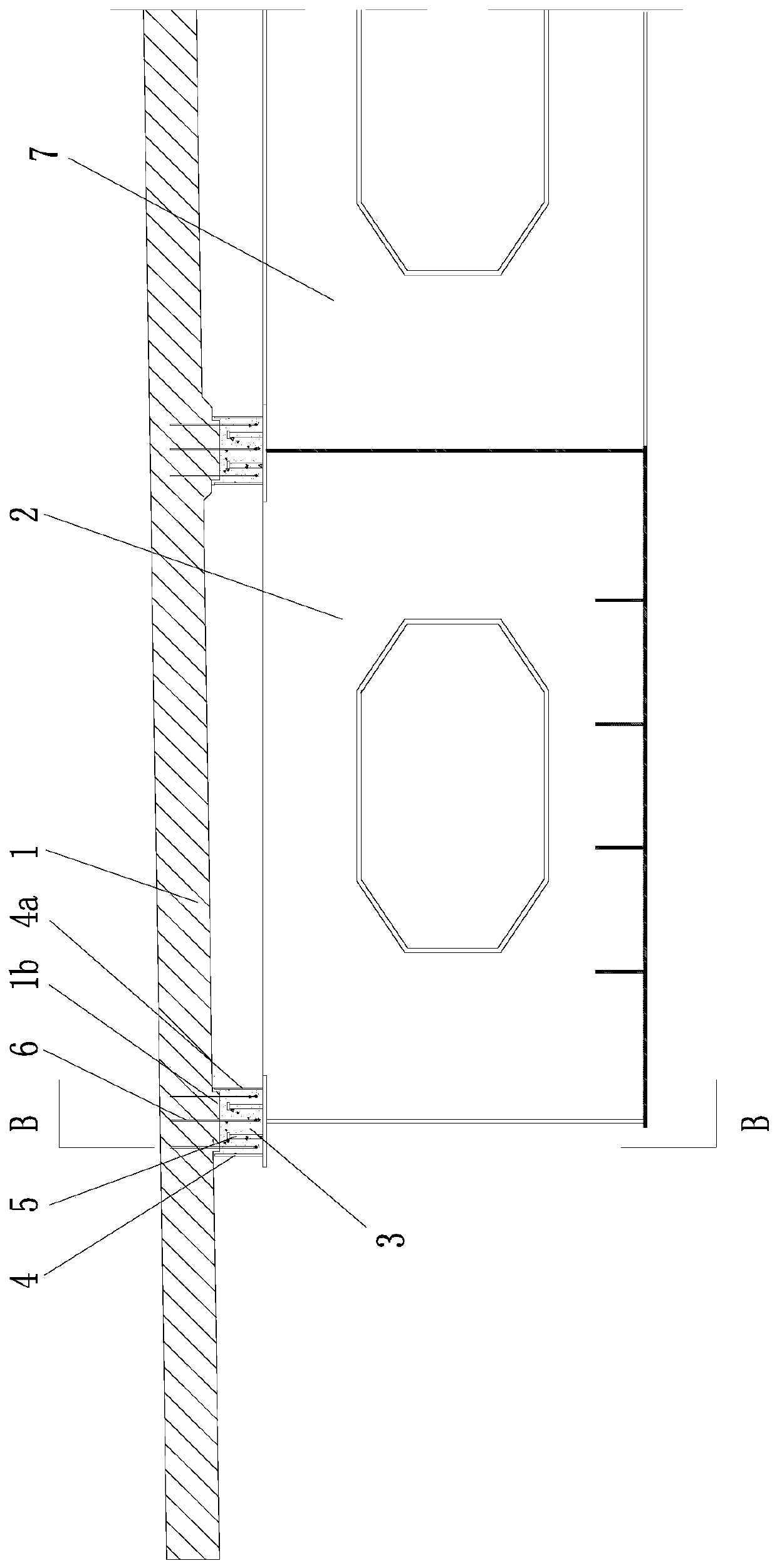

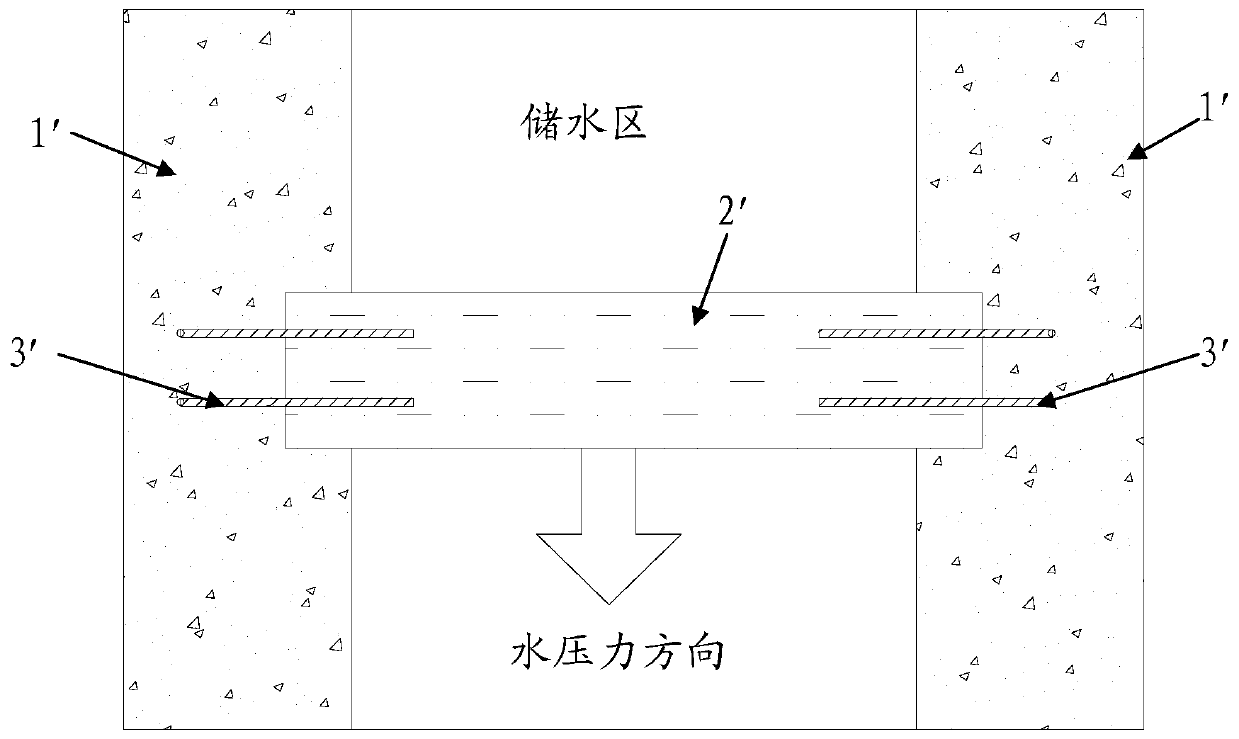

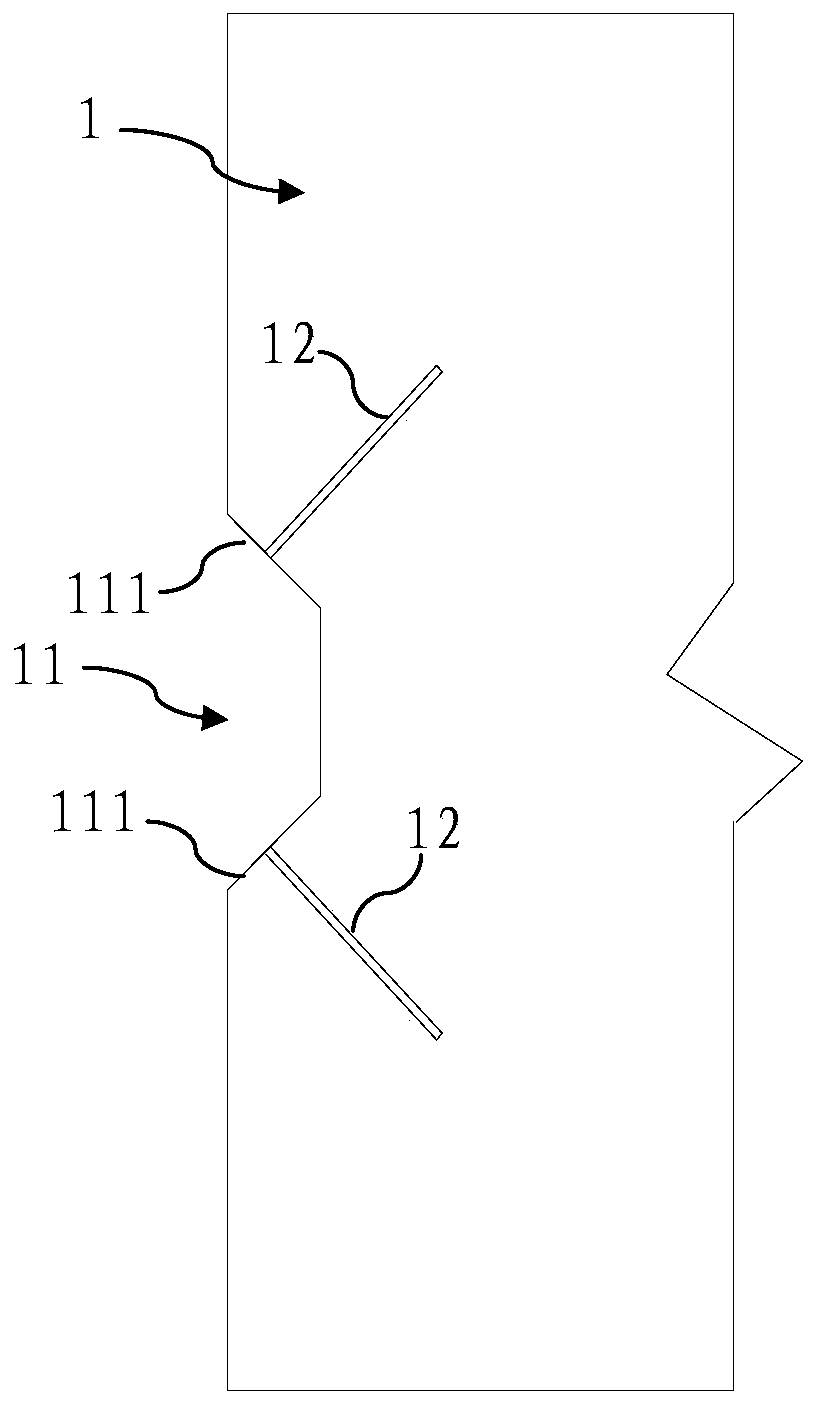

Underground reservoir artificial dam body and coal pillar dam body connecting structure and construction technology thereof

The invention discloses an underground reservoir artificial dam body and coal pillar dam body connecting structure and further discloses a construction technology of the underground reservoir artificial dam body and coal pillar dam body connecting structure. The underground reservoir artificial dam body and coal pillar dam body connecting structure comprises an artificial dam body and a coal pillar dam body. A dam body groove is formed in the coal pillar dam body and provided with a groove oblique surface, and an acute angle is formed between the extending directions of the groove oblique surface and the artificial dam body. Anchor rod drill holes are formed in the groove oblique surface, and the extending directions of the anchor rod drill holes are perpendicular to the extending direction of the groove oblique surface. An inverted-hook-type grouted anchor rod is fastened in each anchor rod drill hole, and a plurality of reinforcement framework beams are arranged in the artificial dambody. The two ends of each reinforcement framework beam are in fastening connection with the ends of the inverted-hook-type grouted anchor rods on the two sides of the reinforcement framework beam correspondingly. According to the underground reservoir artificial dam body and coal pillar dam body connecting structure and the construction technology thereof, the connecting strength and stability are improved, and the construction technology is further simplified.

Owner:CHINA SHENHUA ENERGY CO LTD +2

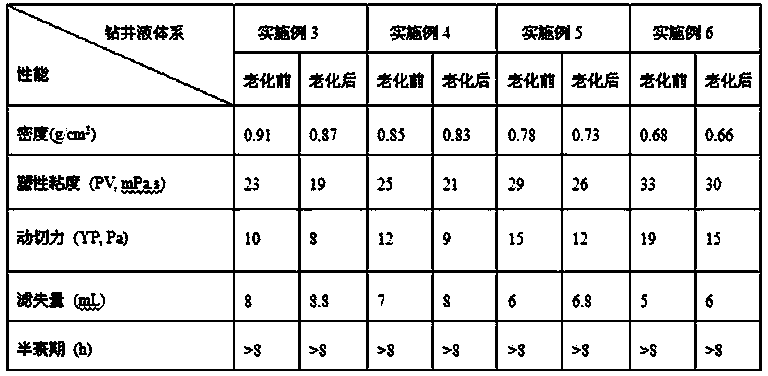

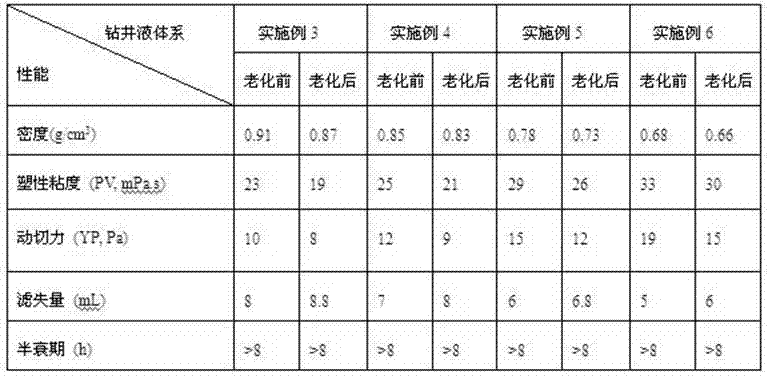

High temperature-resistant and solid-free micro-foam drilling fluid or completion fluid

ActiveCN104046342AHigh temperature resistanceReduce harmDrilling compositionFoaming agentWell drilling

The invention discloses a high temperature-resistant and solid-free micro-foam drilling fluid or completion fluid. The drilling fluid is prepared from the following raw materials by weight: (1) 0.5-1 part of a high temperature-resistant tackifier; (2) 0.5-1 part of a high temperature-resistant foaming agent; (3) 0.2-0.3 part of a high temperature-resistant protective agent; (4) 2-3 parts of a high temperature-resistant fluid loss additive; (5) 0.6-1 part of a high temperature-resistant flow type conditioning agent; (6) 0.2-0.3 part of soda ash; and (7) 100 parts of water. The preparation method includes: adding the above (1)-(6) components into the component (7) according to the content sequentially under the conditions of normal pressure and temperature and mechanical stirring in a usual way, and then conducting stirring for 2-6h. The drilling fluid or completion fluid provided by the invention has the advantages of excellent rheological properties, good fluid loss reducing performance, good stability and high temperature resistant ability, and can be applied to well drilling or completion construction in high temperature, low pressure and likely leaking stratums.

Owner:CHINA PETROCHEMICAL CORP +1

Hypersalinity solid-free micro-foam drilling fluid or completion fluid

ActiveCN104087273AStrong salt resistanceSuitable for drillingDrilling compositionFoaming agentWell drilling

The invention discloses a hypersalinity solid-free micro-foam drilling fluid or completion fluid. The drilling fluid is prepared from the following raw materials in parts by weight: (1) 0.3-0.6 parts of a tackifier, (2) 0.3-0.5 parts of a foam stabilizing agent, (3) 0.7-1.1 parts of a foaming agent, (4) 2-3 parts of a filtrate reducer, (5) 0.3-0.5 parts of a flow-pattern adjusting agent, (6) 0.2-0.3 parts of sodium carbonate and (7) 100 parts of a base fluid. The preparation method comprises: successively adding the compositions (1)-(6) according to the weight ratio into the composition (7) under the conditions of normal temperature, normal pressure and mechanical stirring in a routine manner, and stirring for 2-6 h after all compositions are added. The related hypersalinity solid-free micro-foam drilling fluid or completion fluid has excellent rheological performance, relatively good filtrate reducing performance and relatively good stability, and is applicable to well-drilling or well-completion construction of high-salinity (salt bed), low-pressure and easily-leaked stratums.

Owner:中石化石油工程技术服务有限公司 +2

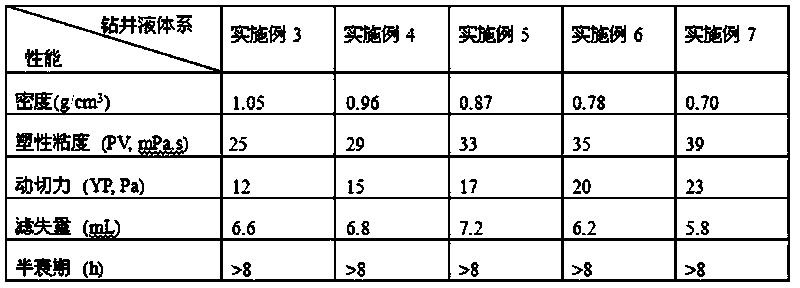

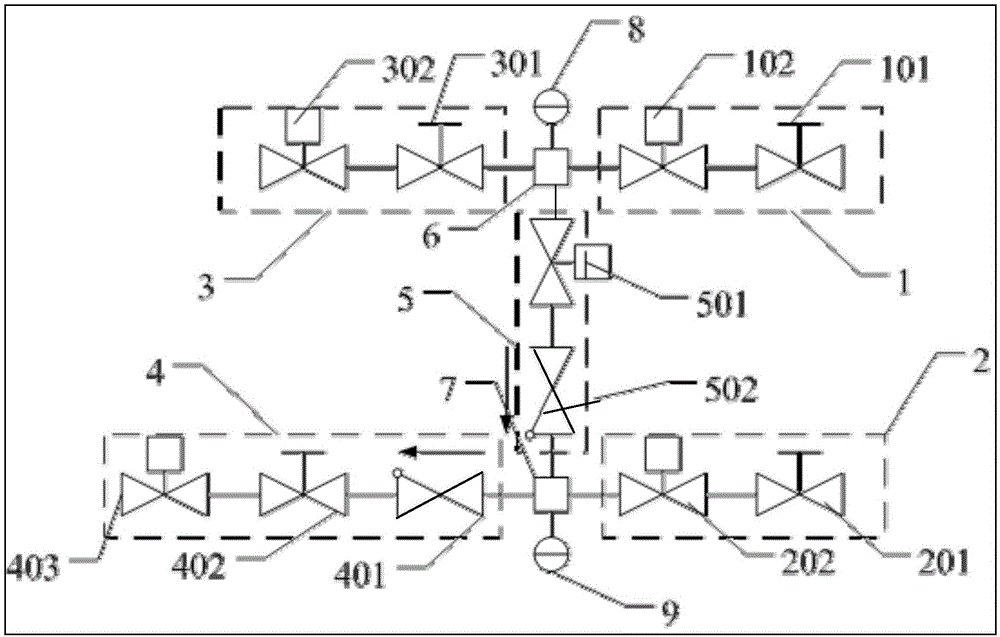

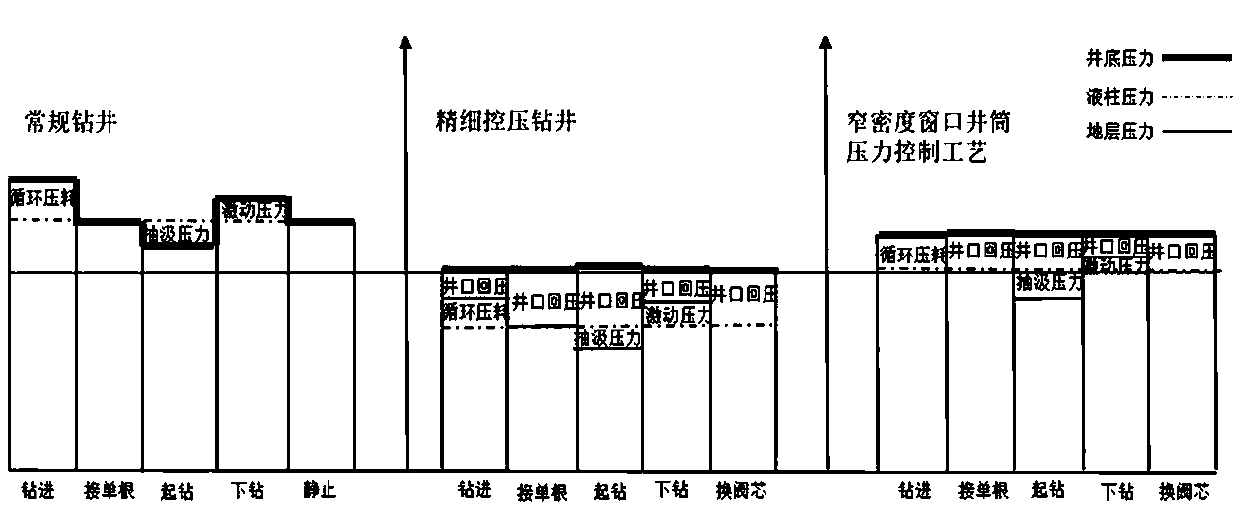

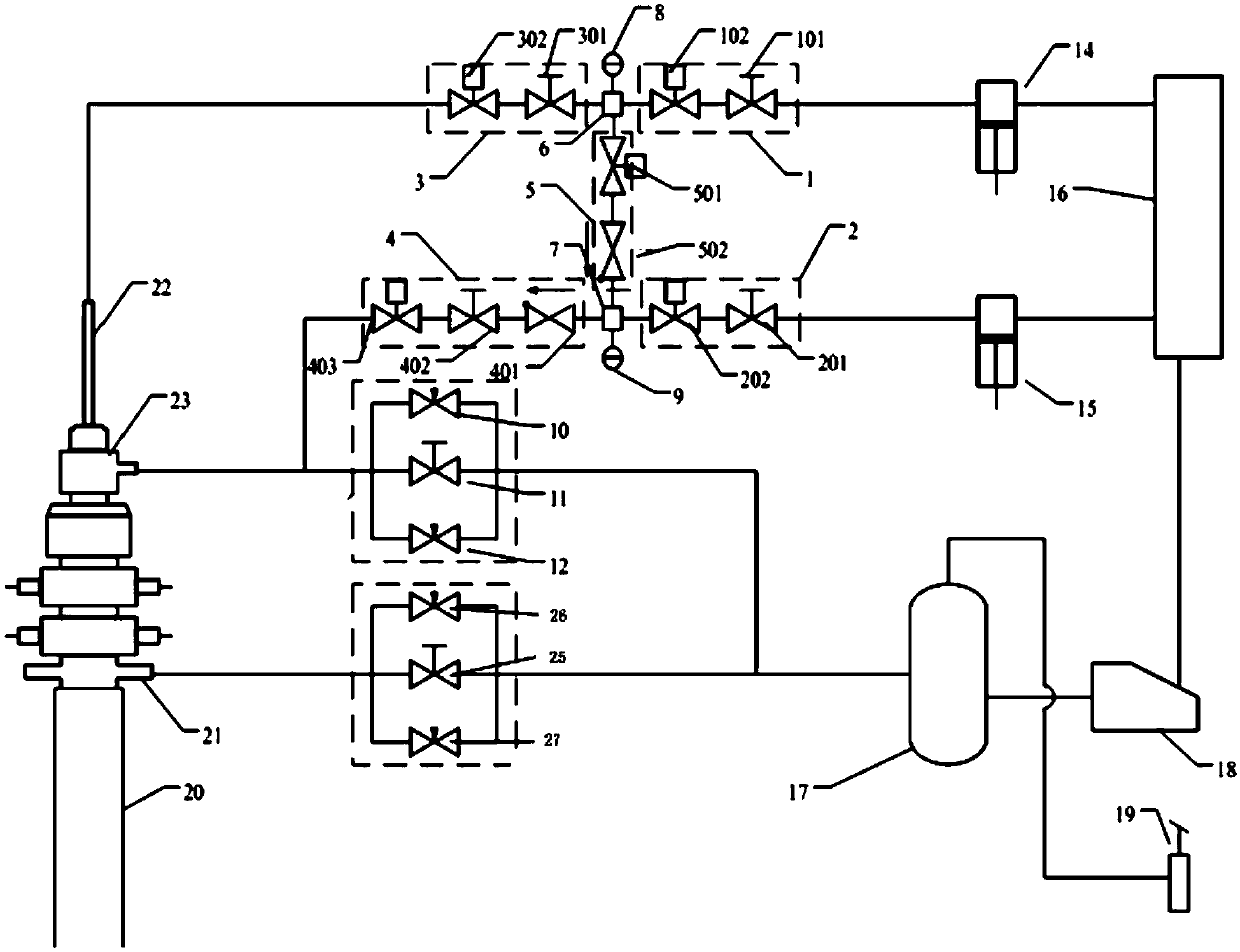

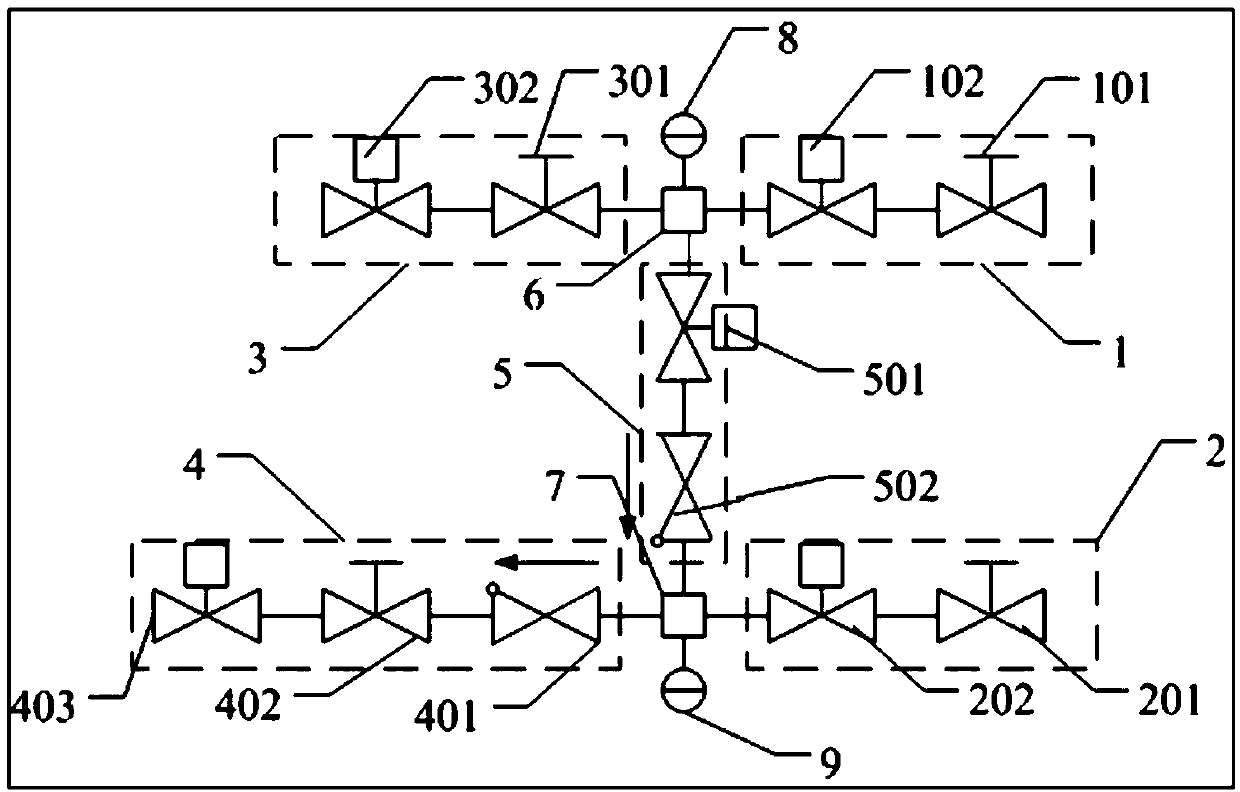

Pressure-control drilling system utilizing automatic shunt manifold for pressure-control drilling and pressure-control drilling method

ActiveCN106401512ASmall pressure fluctuationsImprove controlFlushingBottom hole pressureWell drilling

The invention discloses a pressure-control drilling system utilizing an automatic shunt manifold for pressure-control drilling and a corresponding pressure-control drilling method. The pressure-control drilling system comprises a drilling spool, a rotary control head, a drilling column, an automatic shunt manifold, an automatic throttle manifold and a throttle manifold; the drilling spool, the rotary control head and the drilling column are arranged at a wellhead at the upper part of a mineshaft; and the automatic shunt manifold, the automatic throttle manifold and the throttle manifold respectively communicate with the drilling column, a by-pass pipeline of the rotary control head and a by-pass pipeline in the blowout direction of the drilling spool. Due to the arrangement ways of all the manifolds and the mutual opening / closing matching between hydromatic valves and check valves arranged on all the manifolds and the utilization of a drilling fluid pump equipped for a drilling crew at present, the pressure-control drilling operation is realized; and through controlling the automatic shunt manifold for pressure-control drilling in connection making and tripping processes, the fluctuation of bottom hole pressure can be reduced, the control capacity for the bottom hole pressure can be improved, the no-drilling time can be shortened, the drilling cost can be reduced, and the operation incapability caused by a fault of a pressure return pump can be avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

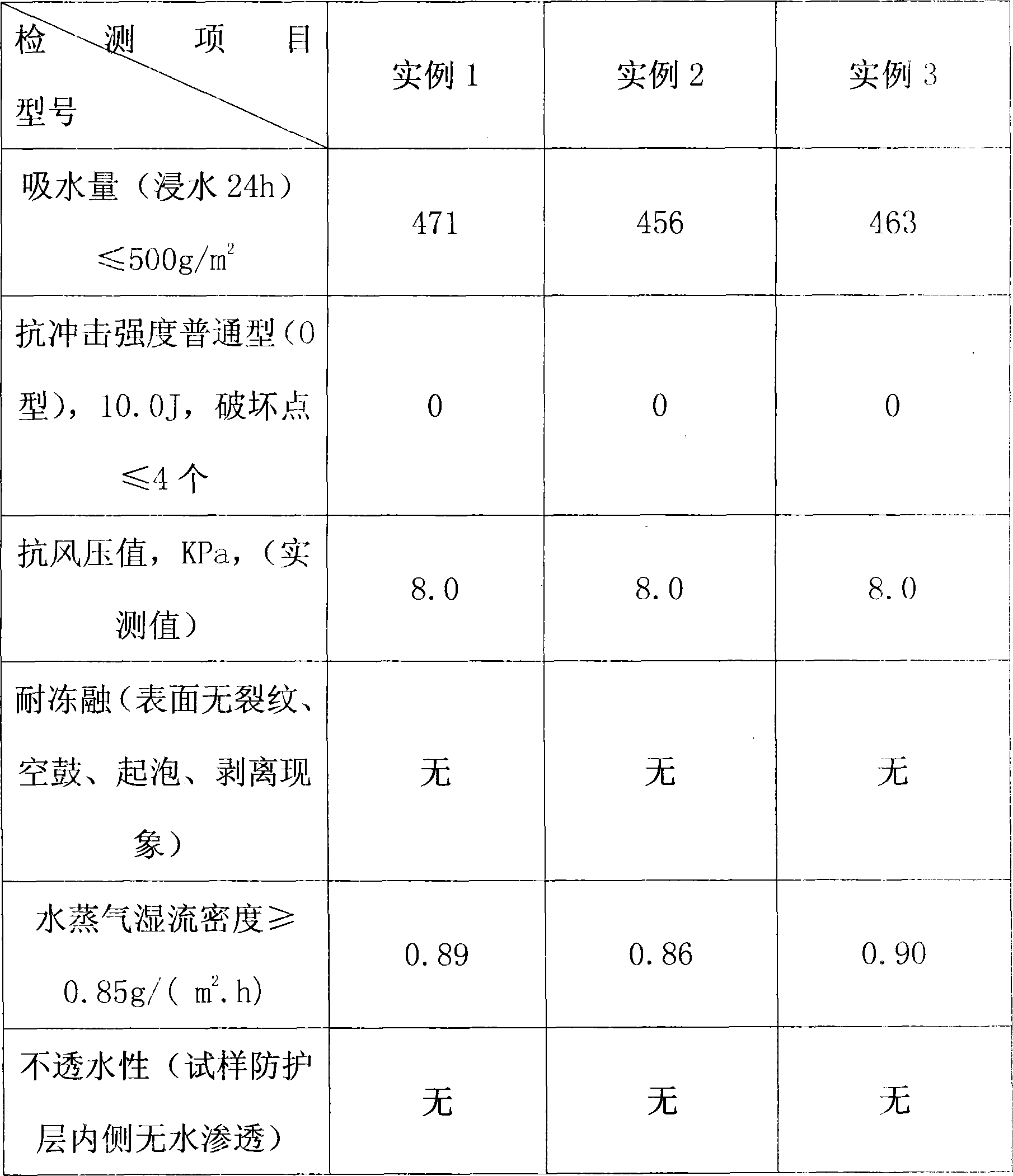

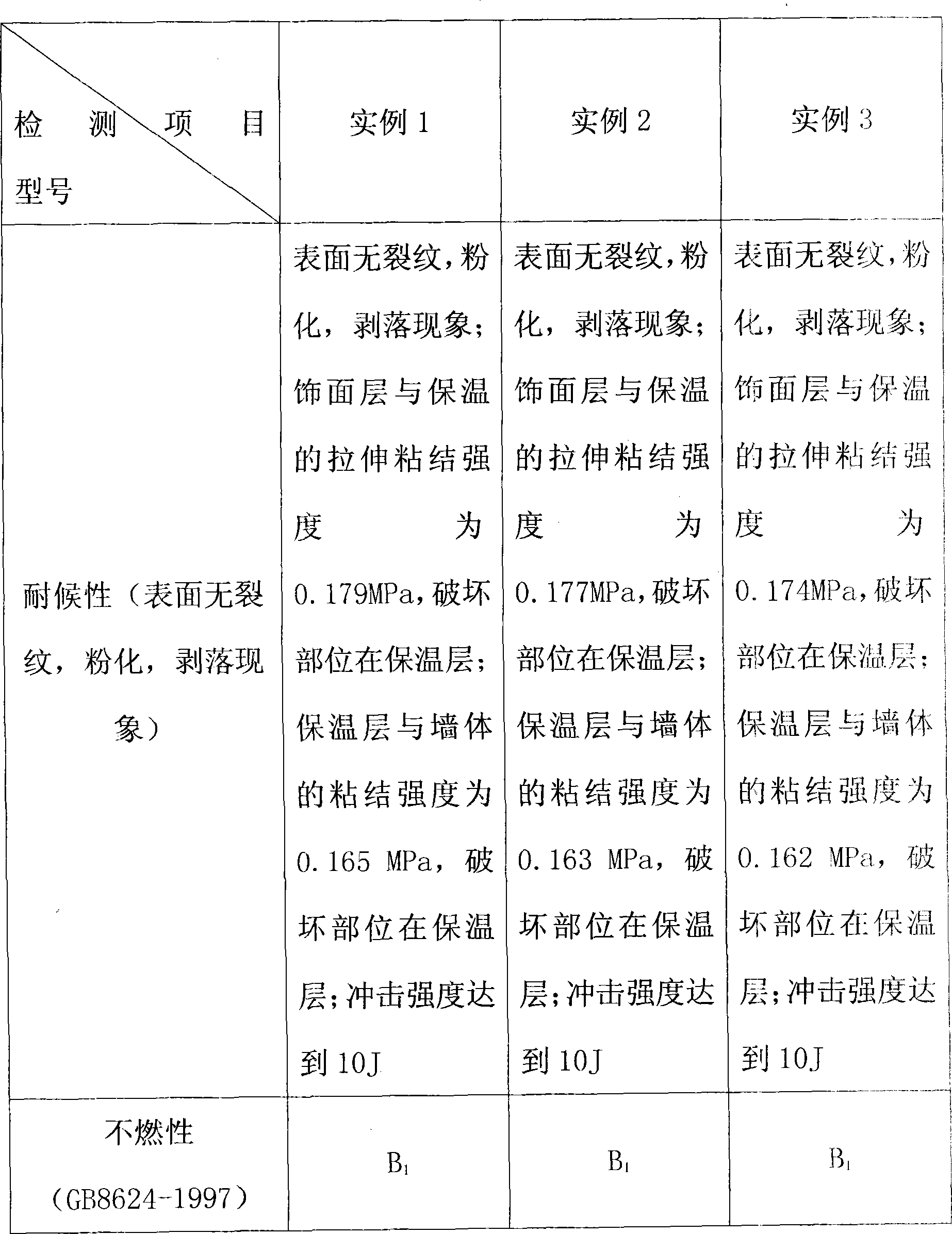

Process for manufacturing heat insulation decoration board

InactiveCN101195292AImprove securitySimplify on-site construction processLiquid surface applicatorsLamination ancillary operationsAdhesiveEngineering

The invention belongs to the technical field of architectural decoration material, which discloses a process for preparing an insulating decoration board. The process for preparing the insulating decoration board includes fixing the thickness of a decorative panel by a thickness-fixing machine, ensuring the deviance of a guiding rule of 2 m is less than 0.2 millimeter, then coating the surface of the decorative panel which contacts with air, applying the decorative panel and an insulating board via adhesive, then compressing the glued insulating decoration board 4 to 6 hours by a cold press the compression of which is 0.1 to 0.2 MPa, consequently obtaining a finished product by trimming surfaces. The process of the invention greatly simplifies the on-live construction art, shortens the project period, and increases the safety of aloft work. Parts of the processes are moved to a factory to achieve quantitative production, which increases the working efficiency and lowers the cost. The working is carried out in a factory, thereby the influence of environment factors which can not be controlled by human beings is avoided, such as wind force, temperature, rainfall, pollution and the like, and the quality is preferably controlled.

Owner:深圳市明远氟建筑装饰工程有限公司

Well drilling pressure control facility and operation method of ultra-deep well

The invention discloses a well drilling pressure control facility and operation method of an ultra-deep well. The well drilling pressure control facility comprises a mud input pipeline, a first mud reversing out pipeline, a second mud reversing out pipeline, a kill line, a back pressure pipeline, a throttle pipeline, and a well control device; the operation method comprises the steps that a normaldrilling mode is conducted, the normal drilling mode is converted to a single root mode, the normal drilling mode is converted to a drilling starting mode, a drilling downward mode and a valve element changing mode; and control equipment eliminates a backpressure pump and other facilities, a throttle pipeline control device is simplified, the facility cost is lowered, the on-site construction process is simplified, and the stress control aspect is safer and more efficient. The well drilling pressure control facility and operation method can decrease the degree of well leakage, the difficultyof plugging is reduced, Chinese oil and gas standards are met, and the safe drilling purpose is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

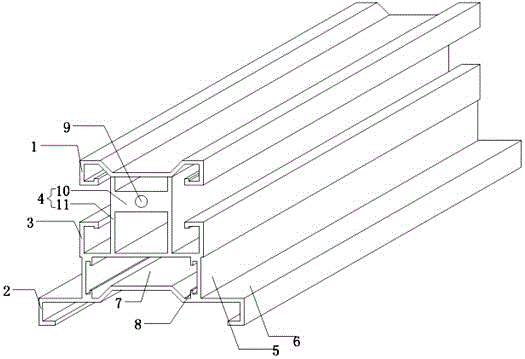

Connecting device for suspended ceiling

ActiveCN103669675AMeet the requirements of material diversityRealize factory productionCeilingsKeelEngineering

The invention discloses a connecting device for a suspended ceiling. The connecting device for the suspended ceiling comprises a suspension rod, a primary keel and a secondary keel, wherein the upper end of the suspension rod is fixed to a building body, the lower end of the suspension rod is fixedly connected with the primary keel, a connecting piece is connected to the primary keel, and the upper end portion of the secondary keel is fixedly connected with the connecting piece. The connecting device for the suspended ceiling further comprises two suspension pieces, wherein an inward and upward bent portion is arranged on the secondary keel to form a clamping groove, an overturned edge is arranged at the tail end of the clamping groove, each suspension piece comprises a vertical secondary keel connecting piece and a transverse suspended ceiling plate fixing surface, the vertical secondary keel connecting pieces of the two suspension pieces abut against each other, each secondary keel connecting piece of the two suspension pieces is provided with a buckling structure which expands outwards, the vertical secondary keel connecting pieces of the two suspension pieces are inserted into the clamping groove of the secondary keel, and the lower ends of the buckling structures of the secondary keel connecting pieces of the two suspension pieces abut against the overturned edge arranged at the tail end of the clamping groove of the secondary keel. According to the structure of the connecting device for the suspended ceiling, the structure is firm, the requirement for diversity of materials of decorative sheets in the process of decoration can be met, the project amount on the site can be reduced, and the site construction technology is simplified.

Owner:ZHEJIANG YASHA DECORATION

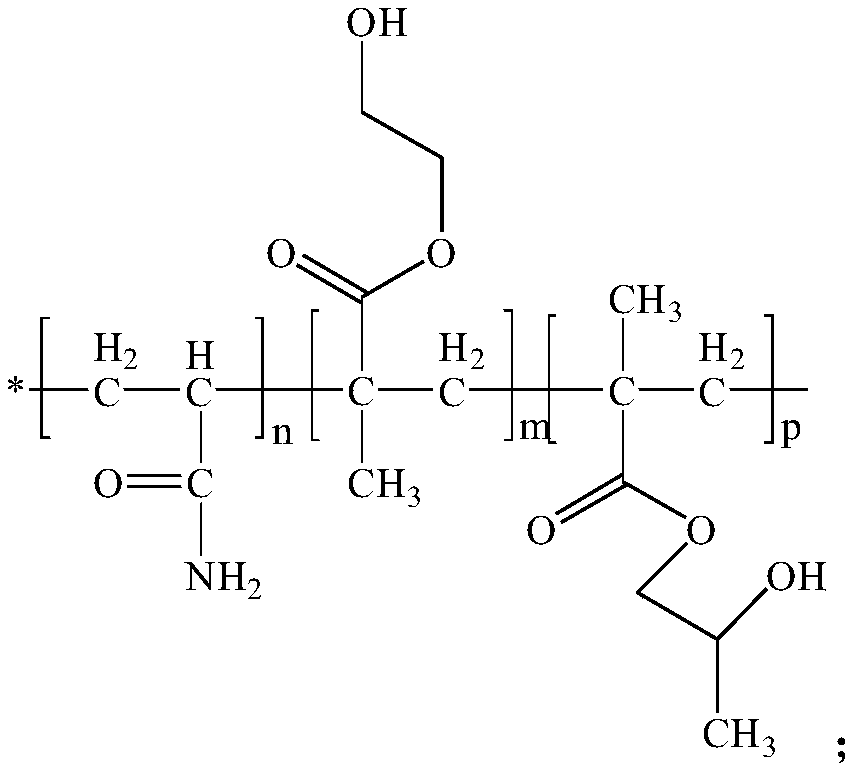

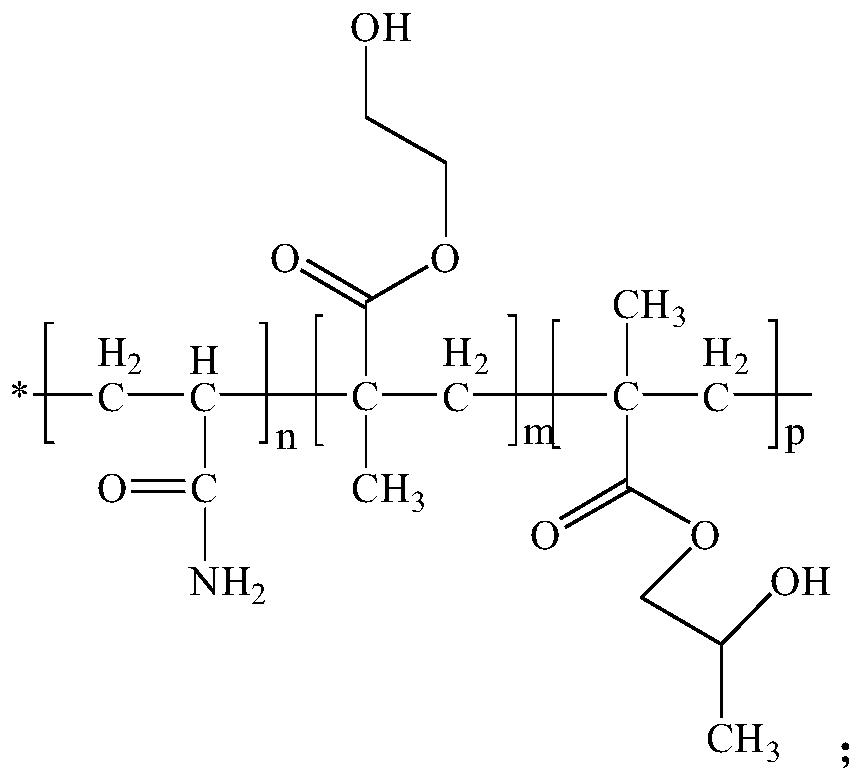

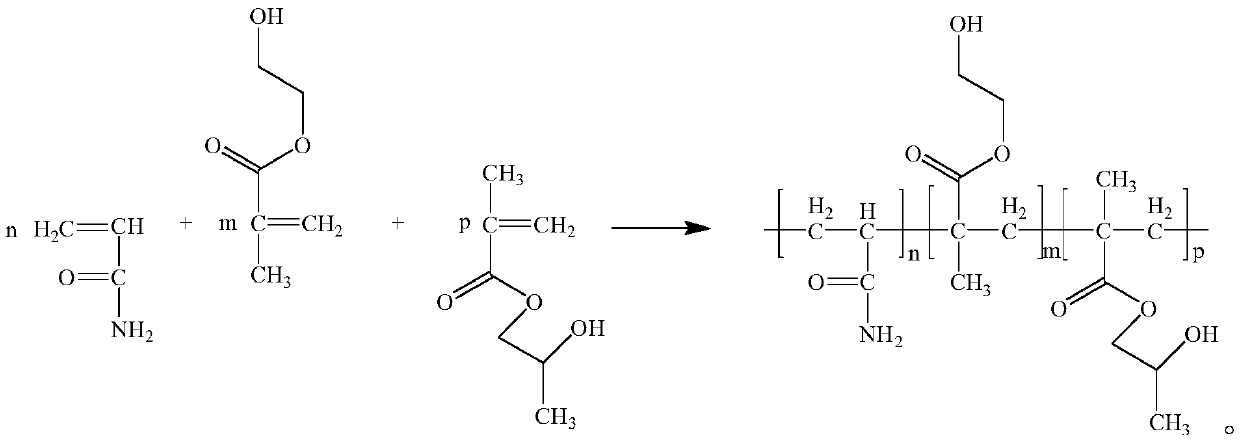

Emulsion type fracturing fluid resistance reducing agent and preparation method thereof

ActiveCN111518239AImprove solubilitySimplify on-site construction processDrilling compositionSolventEthylenediaminetetraacetic acid

The invention relates to a fracturing fluid resistance reducing agent for development of crude oil in low-permeability reservoirs, in particular to an emulsion type fracturing fluid resistance reducing agent and a preparation method thereof. The method comprises the following steps: mixing acrylamide, hydroxyethyl methylacrylate, 2-hydroxypropyl methacrylate, urea and ethylenediamine tetraacetic acid disodium salt, dissolving the formed mixture in water, and regulating a pH value with a sodium hydroxide solution to form a water phase; mixing ethyl distearate-based hydroxyethyl methylammonium methylsulfate with solvent oil to form an oil phase; and subjecting the water phase and the oil phase to mixing and heating, introducing nitrogen, and adding a water-soluble initiator for polymerization so as to form the emulsion type fracturing fluid resistance reducing agent. The resistance reducing agent has the advantages that production time is short, production process is greatly simplified,and production cost is reduced; good mineralization resistance is achieved, and e salt tolerance reaches 120000 mg / L or above; and meanwhile, the friction resistance of a fracturing fluid can be effectively reduced at low concentration, and a resistance reduction rate reaches 90% or above when the concentration of the resistance reducing agent is 500 ppm.

Owner:DONGYING SPRING PETROLEUM ENG TECH

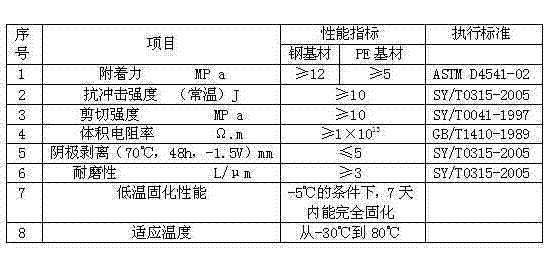

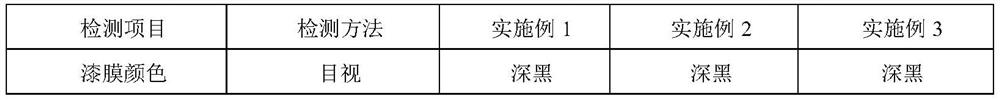

Repairing coating

InactiveCN102775881AImprove performanceLow viscosityAnti-corrosive paintsEpoxy resin coatingsLiquid stateRepair material

The invention relates to a repairing coating, solving the problem that an ordinary repairing method is low in on-site repairing quality. The repairing coating comprises base stock and a curing agent, wherein the base stock mainly comprises the following ingredients: liquid state bisphenol A, F epoxy resin, thixotropic agent, toughening agent, filler, pigment and the like; a liquid state amine type curing agent is used as the curing agent, and the use proportioning of the base stock and the curing agent is 100:23. The repairing coating is used for repairing pipes; the combination strength of a combination plane of the repairing material and a 3PE (Poly Ethylene) erosion resistant layer of a pipeline main body can meet the requirements on repairing standard of a 3PE pipeline; and moreover, the on-site engineering process is simple, the mechanization can be realized, the influence of artificial and environment factors on the engineering is reduced, and the repairing coating can be brushed and coated at low temperature of -5 DEG C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

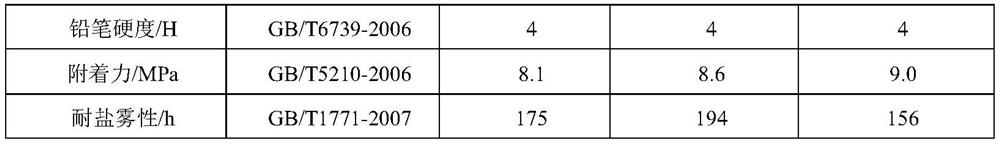

Novel composite water-based rust conversion primer and preparation method thereof

PendingCN112391071ASimplify on-site construction processTo achieve the purpose of anticorrosionAnti-corrosive paintsPriming paintsEmulsionPolymer emulsion

The invention discloses a novel composite water-based rust conversion primer and a preparation method thereof. The novel composite water-based rust conversion primer is prepared from water-based polymer emulsion, a rust conversion agent, an antirust pigment, a filler, an antifoaming agent, a dispersing agent, a coalescing agent, an emulsion stabilizer, a thickener, a leveling agent and deionized water. According to the novel composite water-based rust conversion primer and the preparation method thereof, one-time coating is achieved in the using process, the field construction process is simplified, the primer is more convenient and practical, the primer can effectively react with rust to generate a stable black chelate, and the anti-corrosion purpose is achieved by forming the isolation effect.

Owner:CHANGZHOU UNIV

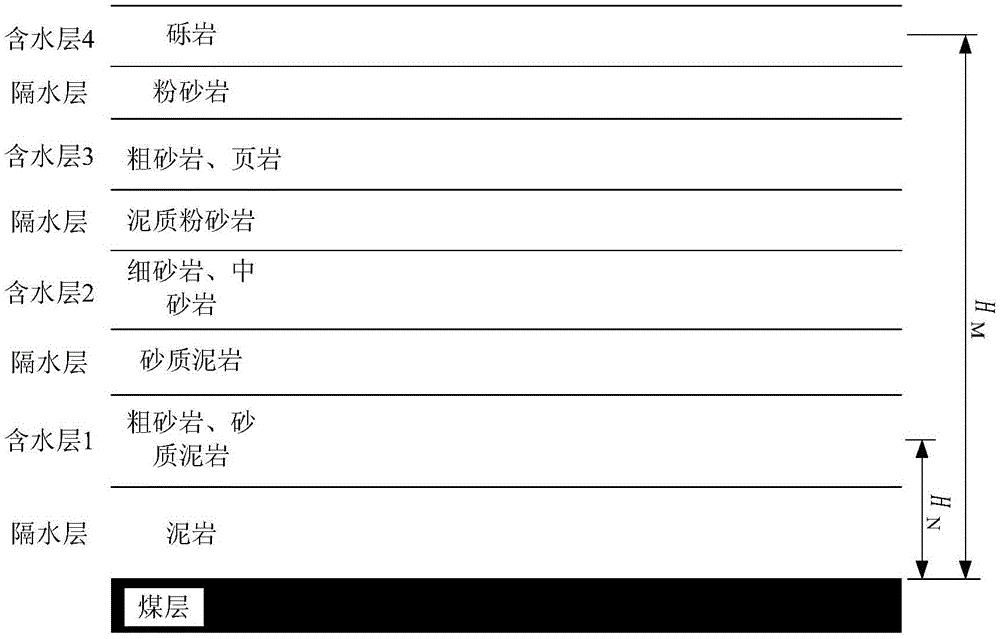

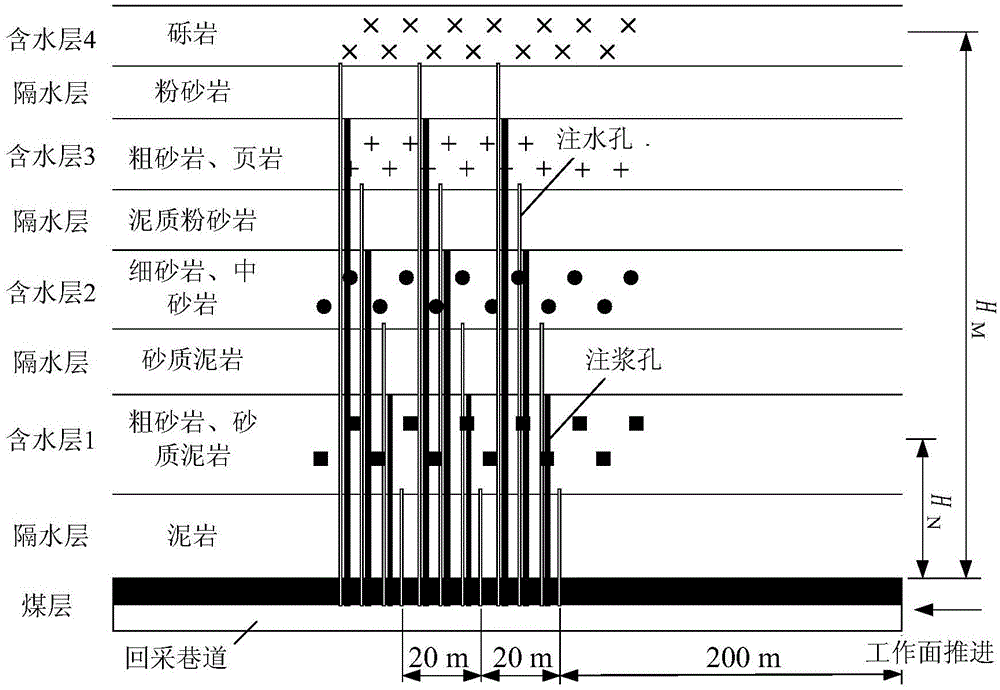

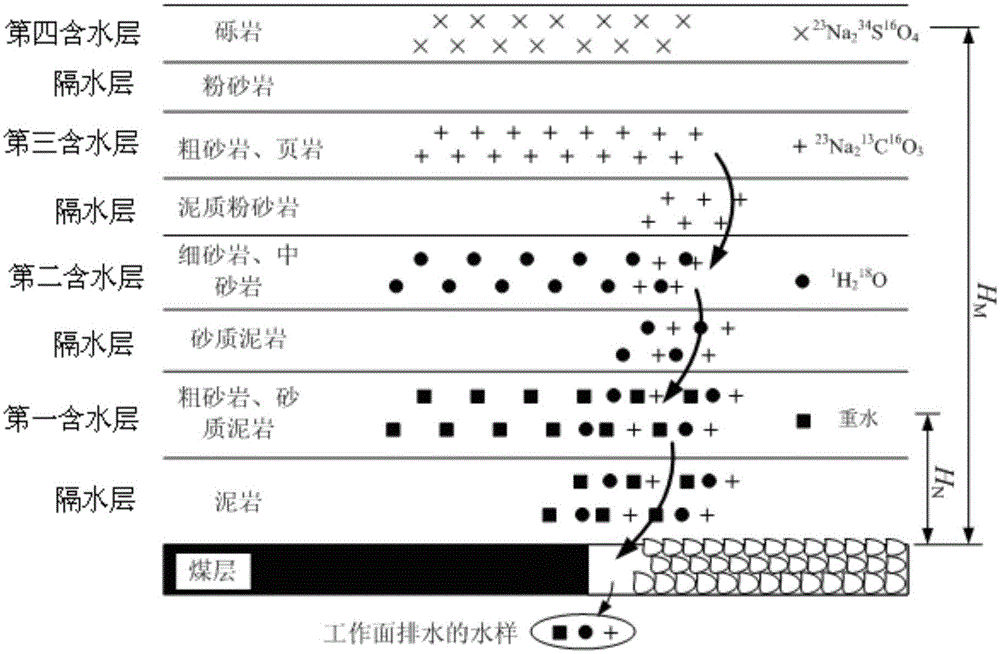

Method for detecting conduction of overlying rock strata crack based on isotope identification

The invention discloses a method for detecting the conduction of an overlying rock strata crack based on isotope identification. Different aquifer water is effectively identified by adding different isotope identifier, Conduction of water into working faces is determined by millesimal discrepancy of identifying isotopes in drained water of each aquifer and working face, and the conduction of overlying rock strata crack is determined according to conduction of water of each aquifer into the working face. The method overcomes the defects of conventional indirect method, eliminates error of this type, and provides accurate basis for flood damage control of a working face.

Owner:SHANDONG UNIV OF SCI & TECH

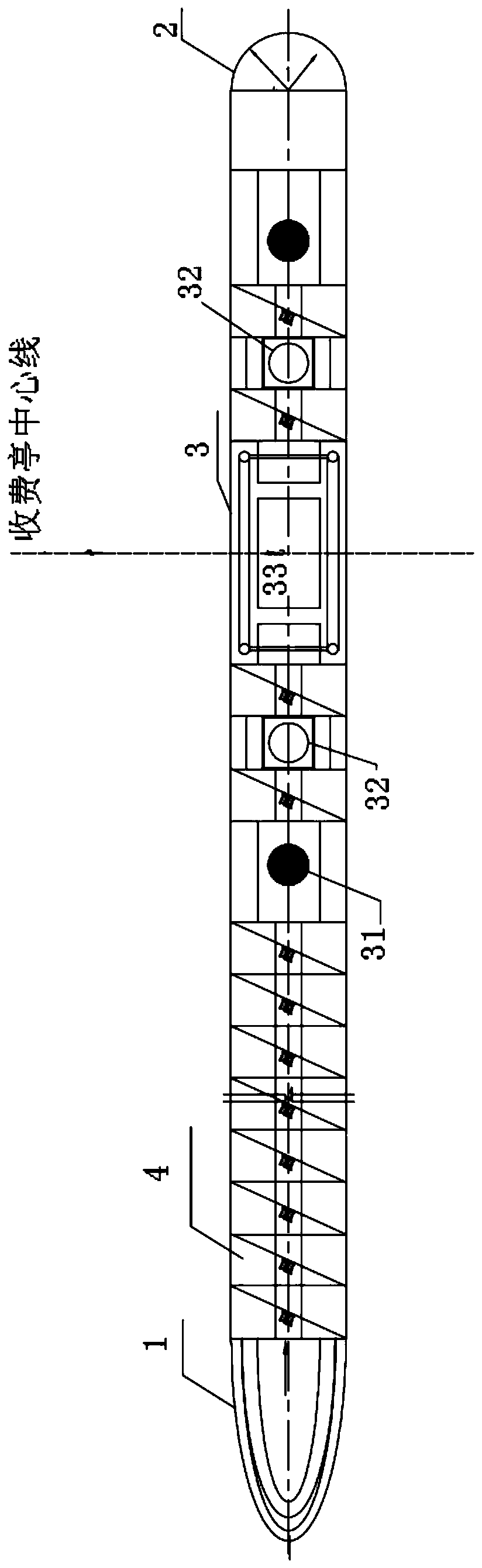

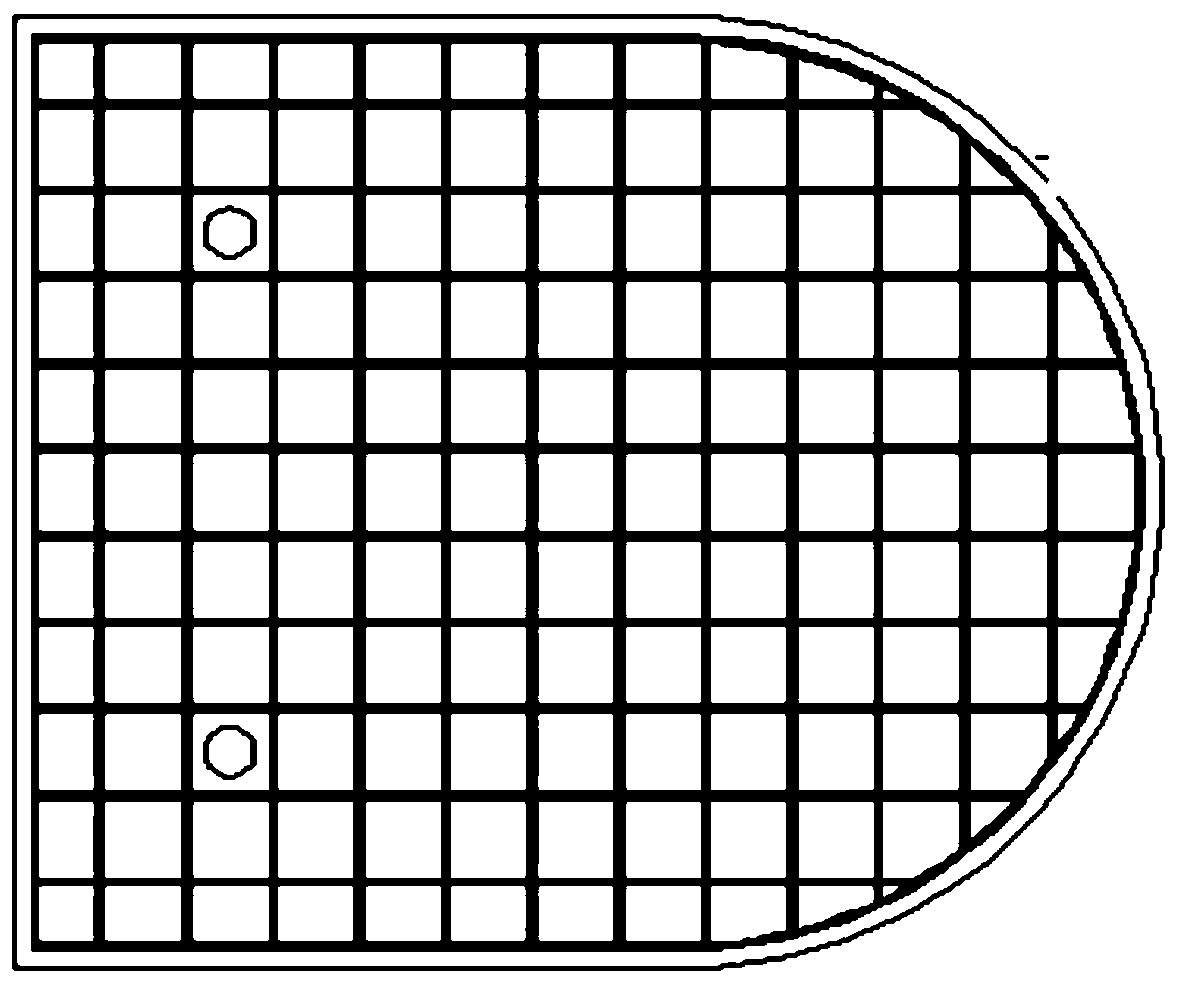

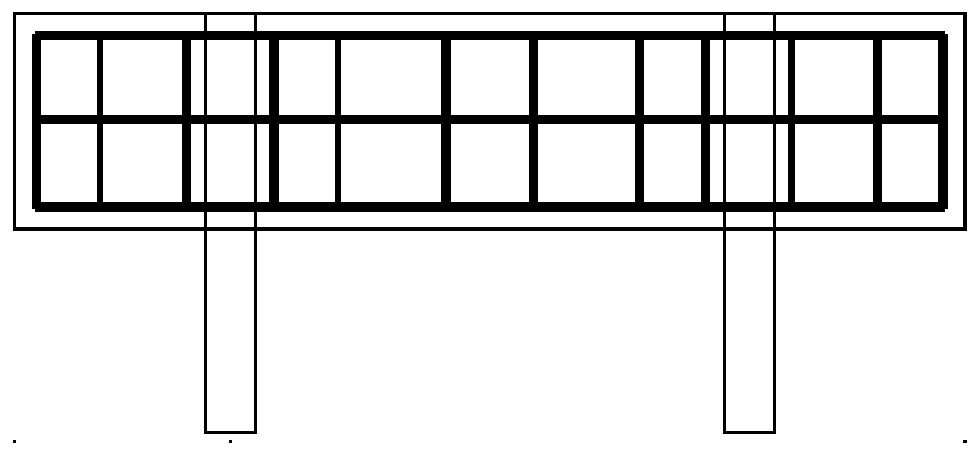

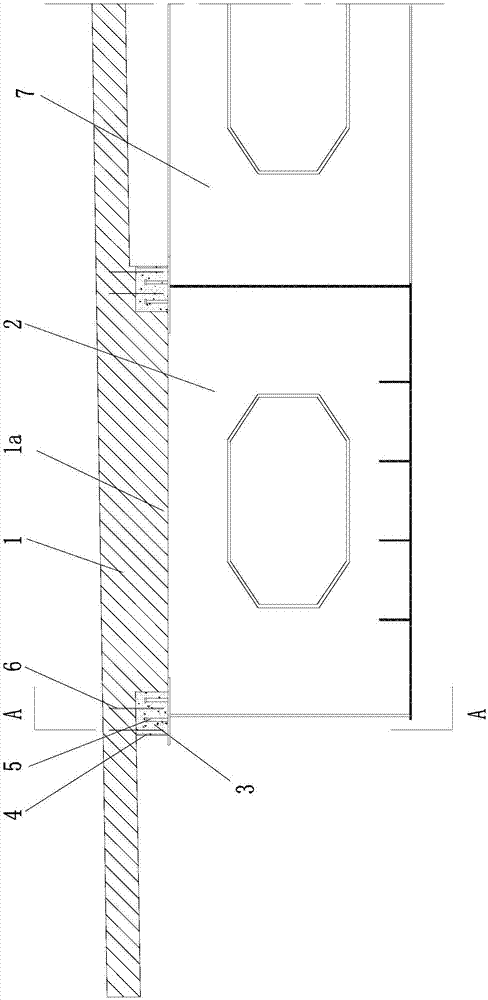

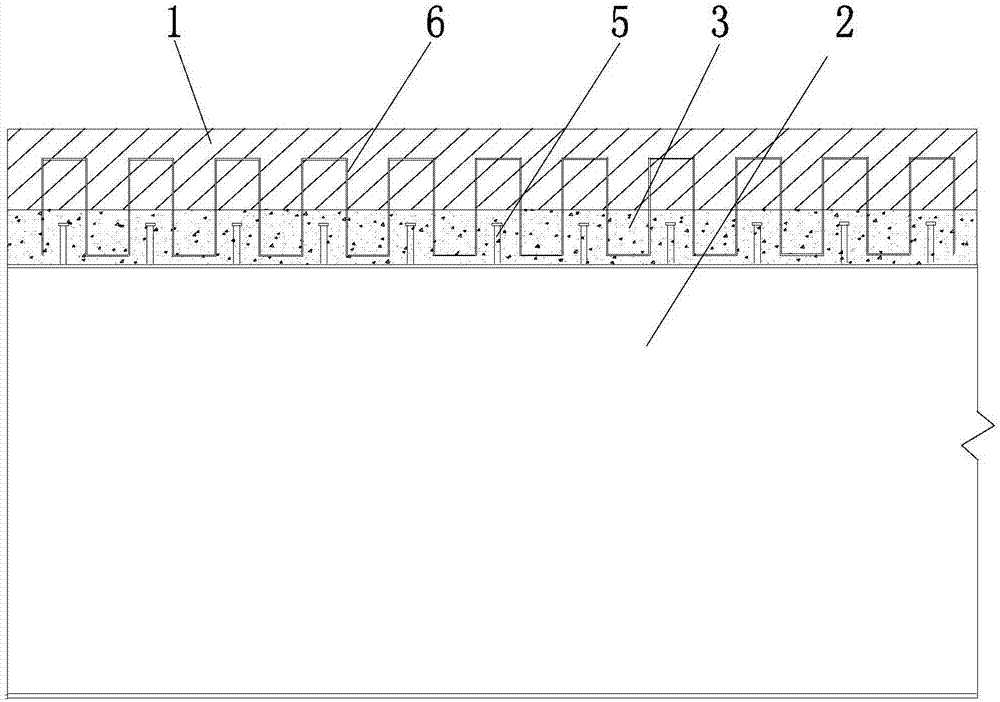

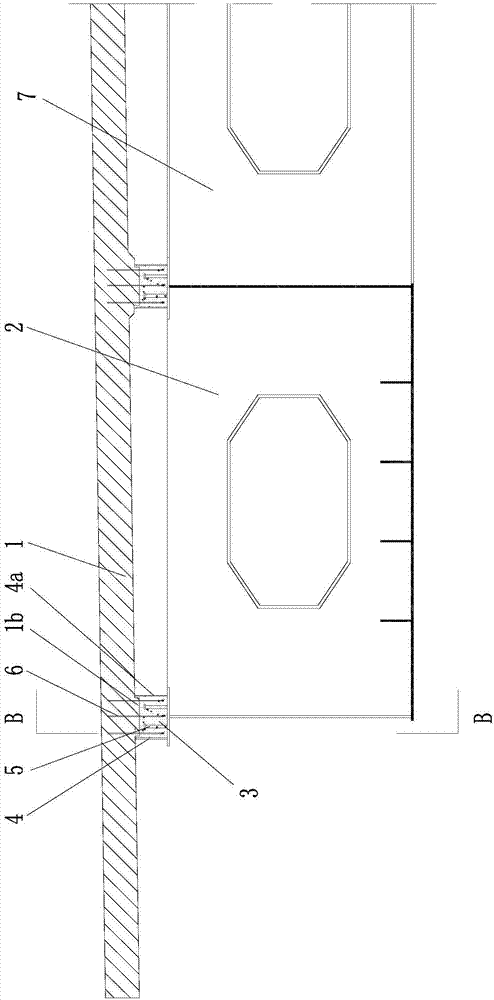

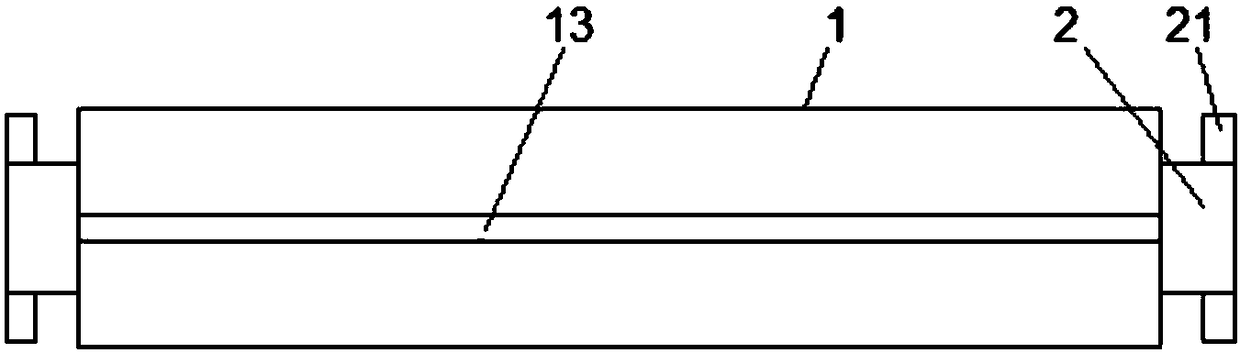

Prefabricated installation anchoring system and method for road toll island

PendingCN109826114ASimplify the assembly processSimplify on-site construction processRefuge islandsRoadway safety arrangementsRoad surfacePrefabrication

The invention provides a prefabricated installation anchoring system and method for a road toll island, wherein the system comprises a plurality of toll island unit concrete prefabricated components;each toll island unit concrete prefabricated component is anchored to a road surface through an anchoring installation unit (5); and each toll island unit concrete prefabricated component comprises atoll island head concrete prefabricated component (1), a toll island tail concrete prefabricated component (2), a toll booth foundation concrete prefabricated component (3) and a plurality of toll island body standard section concrete prefabricated components (4). The system has the advantages that (1) the prefabricated components are quickly installed on site, so that the site construction periodof the toll island is greatly shortened; (2) the prefabricated components of the toll island are prefabricated and maintained on a uniform mold in a factory for prefabrication, swelling does not occur, which is beneficial for protection of the finished product, and the construction quality of the concrete components is improved.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

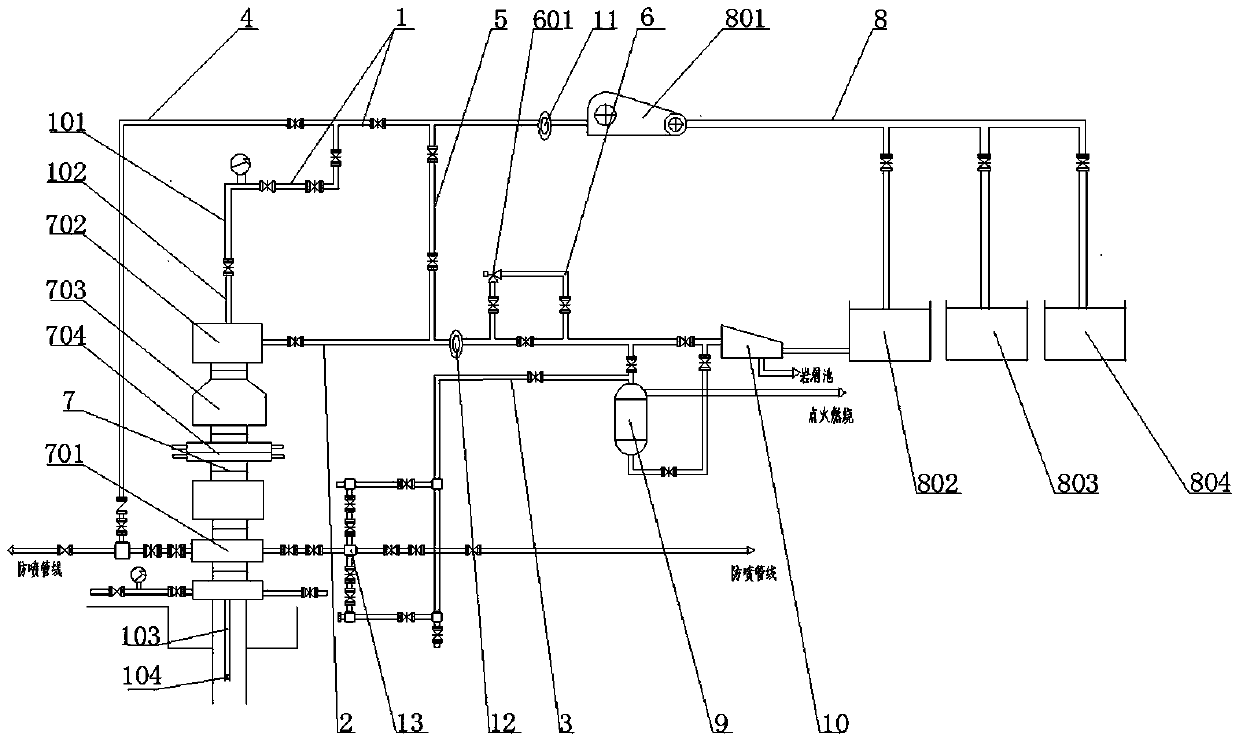

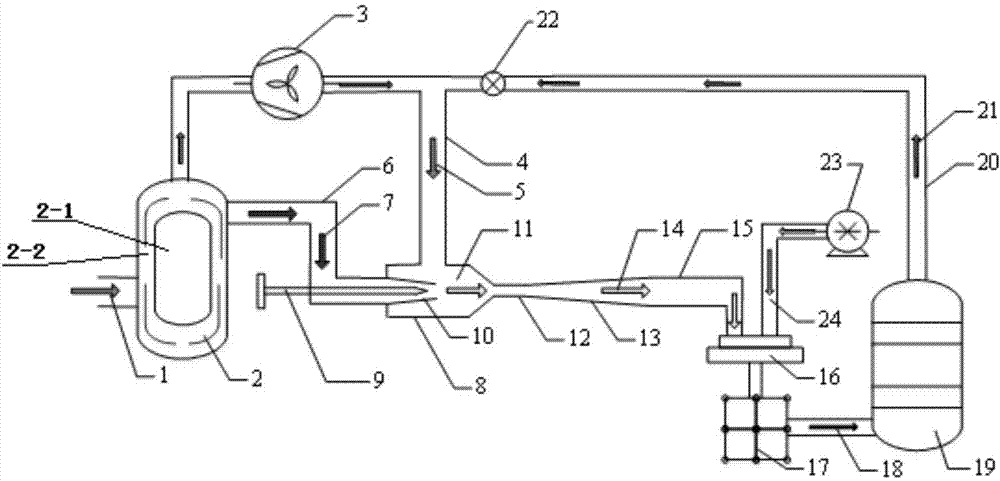

Flue gas resource utilizing system of oil field stream-injecting boiler based on steam injection and application thereof

InactiveCN104763397AAchieving zero emissionsRealize profile control and pluggingFluid removalWorking fluidCombustion

The invention discloses a flue gas resource utilizing system of an oil field stream-injecting boiler based on steam injection. The flue gas resource utilizing system comprises a steam injection system, a stream-injecting boiler system, a thickened oil production system, a produced liquid separating system and a foam generating system. The stream-injecting boiler system and the steam injection system are arranged in series connection and closed loop modes. The steam injection system, the thickened oil production system and the produced liquid separating system are arranged in series connection and closed loop modes. The foam generating system is arranged on the thickened oil production system. According to the flue gas resource utilizing system of the oil field stream-injecting boiler based on steam injection, the steam injection technology is adopted, high temperature and high pressure steam is used for injecting flue gas, and high pressure steam-flue gas mixed fluid is formed; the high temperature and high pressure steam generated by the boiler is used as working fluid of a steam injector, and the flue gas generated by boiler fuel combustion is used as injecting fluid of the steam injector. The flue gas in the produced liquid is separated and injected back into the steam injector, so that flue gas zero emission is realized. By the adoption of the system and the application thereof, profile control plugging of formation heterogeneity can be achieved, and the anti-corrosion requirement of an injection tubular column can further be met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

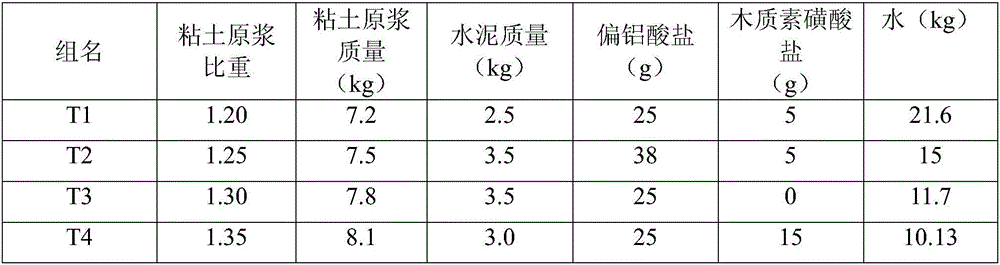

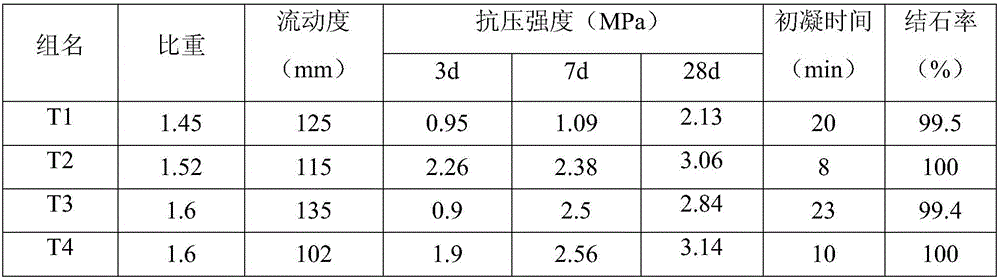

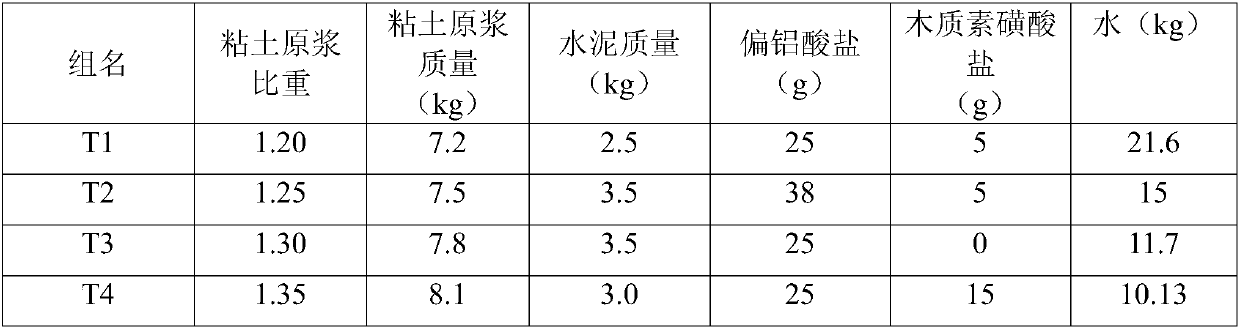

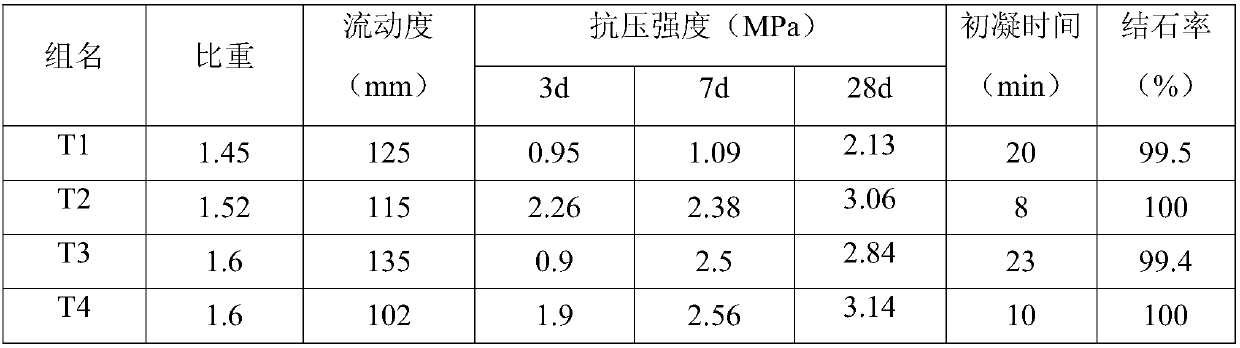

Filling paste slurry suitable for tunnel construction goaf

The invention discloses a filling paste slurry suitable for a tunnel construction goaf. The filling paste slurry is mainly prepared from a clay mud, a cement and water; the clay mud is prepared by stirring clay and water, a modifier is added in the filling paste slurry, the modifier comprises meta-aluminate and lignosulfonate, the mixing amount of the meta-aluminate is 0.5-1.5% of the mass of the cement, and the mixing amount of the lignosulfonate is 0.2-0.4% of the mass of the cement. The filling paste slurry is high in stone rate, has a good filling effect, and is environmentally friendly, convenient to prepare, and suitable for filling the tunnel construction goaf, the raw materials are cheap and easy to get, the setting time is controllable, the on-site construction operation is simple, and then a tunnel safely goes through the goaf.

Owner:CENT SOUTH UNIV +1

Low-fluorescence oil-base pipe-freeing agent and preparation method thereof

The invention discloses a low-fluorescence oil-base pipe-freeing agent and a preparation method thereof. The invention aims at providing the pipe-freeing agent with low filtration loss, good fluidity, good pipe-freeing performance, low solidifying point, and good stability, and a preparation method thereof. The agent is composed of a pipe-freeing liquid and a rapid penetration agent. The pipe-freeing liquid comprises, by weight: 30-40% of diesel oil, 30-40% of engine oil, 4-5% of polyamide, 4-5% of organic earth, 1.5-2% of oil-soluble yellow, and 6-8% of water. The addition amount of the rapid penetration agent is 1.5-2% of the weight of the pipe-freeing liquid. When the pipe-freeing agent provided by the invention is used for treating a pipe-stuck situation, the penetration performance is high, soil cake falling speed is high, and wetting performance is good. A soaking time is commonly 1-2h. A field construction process is simple, pipe-freeing comprehensive cost is low, and pipe-stuck accident can be rapidly and effectively solved.

Owner:天津市宏科泥浆助剂厂(普通合伙)

A high-temperature resistant solid-free microfoam drilling fluid or completion fluid

ActiveCN104046342BHigh temperature resistanceReduce harmDrilling compositionFoaming agentWell drilling

The invention discloses a high temperature-resistant and solid-free micro-foam drilling fluid or completion fluid. The drilling fluid is prepared from the following raw materials by weight: (1) 0.5-1 part of a high temperature-resistant tackifier; (2) 0.5-1 part of a high temperature-resistant foaming agent; (3) 0.2-0.3 part of a high temperature-resistant protective agent; (4) 2-3 parts of a high temperature-resistant fluid loss additive; (5) 0.6-1 part of a high temperature-resistant flow type conditioning agent; (6) 0.2-0.3 part of soda ash; and (7) 100 parts of water. The preparation method includes: adding the above (1)-(6) components into the component (7) according to the content sequentially under the conditions of normal pressure and temperature and mechanical stirring in a usual way, and then conducting stirring for 2-6h. The drilling fluid or completion fluid provided by the invention has the advantages of excellent rheological properties, good fluid loss reducing performance, good stability and high temperature resistant ability, and can be applied to well drilling or completion construction in high temperature, low pressure and likely leaking stratums.

Owner:CHINA PETROCHEMICAL CORP +1

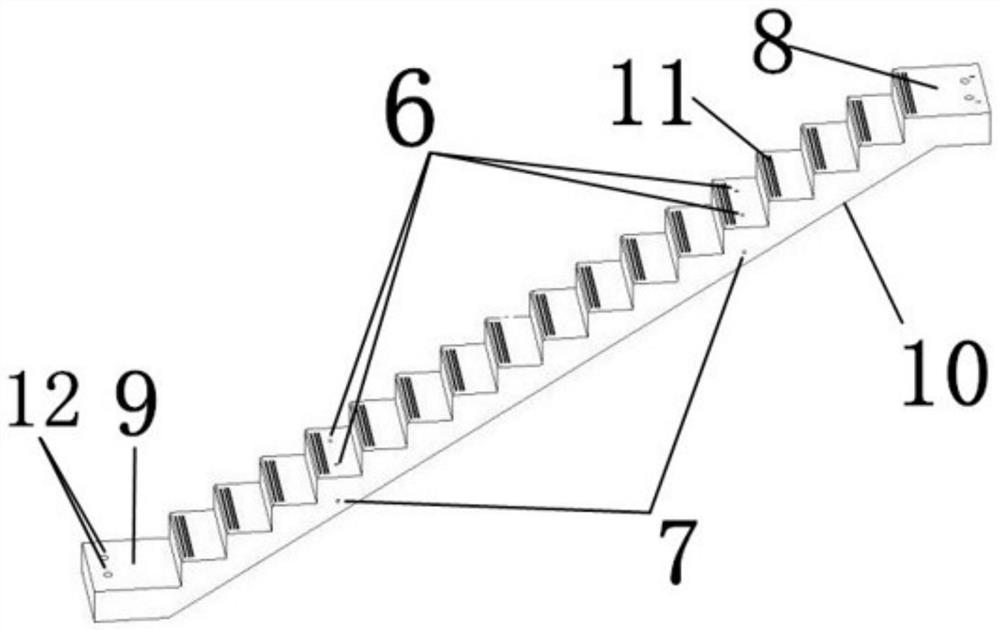

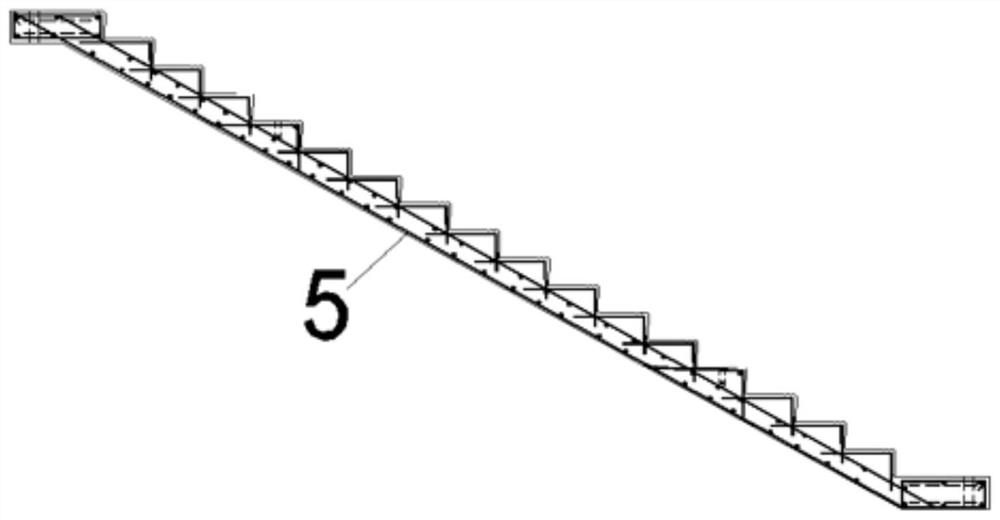

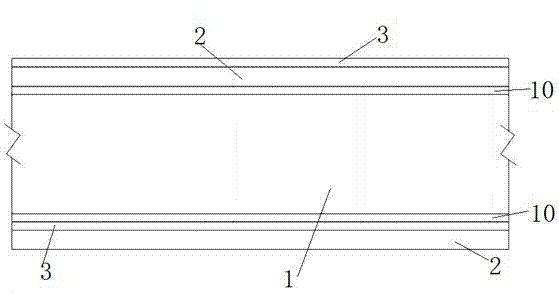

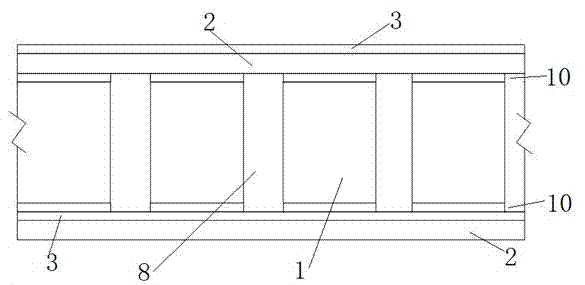

Separated precast prestressed concrete slab type stairway and production process thereof

PendingCN111958815AQuick demolitionAchieve thinningMouldsStairwaysPre stressArchitectural engineering

The invention relates to the technical field of prefabricated buildings, in particular to a separated precast prestressed concrete slab type stairway and a production process thereof. An existing slabtype stairway is large in dead weight and complicated in production process. The separated precast prestressed concrete slab type stairway comprises a stairway body, wherein the stairway body sequentially comprises an upper platform plate, stair section plates and a lower platform plate from top to bottom; prestressed reinforcing steel bars are arranged on the lower part in the stairway body along the length direction; reserved installation holes and reserved hole reinforcing ribs are respectively arranged on the surfaces of the upper platform plate and the lower platform plate; the stair section plates are provided with hoisting points and demoulding hoisting points; and the prestressed reinforcing steel bars are provided with reserved prestressed reinforcing steel bar plugging slots atreinforcing steel bar outlet holes of flat planels. Compared with a traditional precast stairway, 20 percent of concrete can be saved, 30 percent of reinforcing steel bars can be saved, the dead weight is light, fast production can be realized, and the separated precast prestressed concrete slab type stairway and the production process thereof have a favorable development prospect in the technicalfield of prefabricated buildings.

Owner:河南清水建设科技有限公司 +1

A managed pressure drilling system and a managed pressure drilling method using a managed pressure drilling automatic diversion manifold

The invention discloses a pressure-control drilling system utilizing an automatic shunt manifold for pressure-control drilling and a corresponding pressure-control drilling method. The pressure-control drilling system comprises a drilling spool, a rotary control head, a drilling column, an automatic shunt manifold, an automatic throttle manifold and a throttle manifold; the drilling spool, the rotary control head and the drilling column are arranged at a wellhead at the upper part of a mineshaft; and the automatic shunt manifold, the automatic throttle manifold and the throttle manifold respectively communicate with the drilling column, a by-pass pipeline of the rotary control head and a by-pass pipeline in the blowout direction of the drilling spool. Due to the arrangement ways of all the manifolds and the mutual opening / closing matching between hydromatic valves and check valves arranged on all the manifolds and the utilization of a drilling fluid pump equipped for a drilling crew at present, the pressure-control drilling operation is realized; and through controlling the automatic shunt manifold for pressure-control drilling in connection making and tripping processes, the fluctuation of bottom hole pressure can be reduced, the control capacity for the bottom hole pressure can be improved, the no-drilling time can be shortened, the drilling cost can be reduced, and the operation incapability caused by a fault of a pressure return pump can be avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

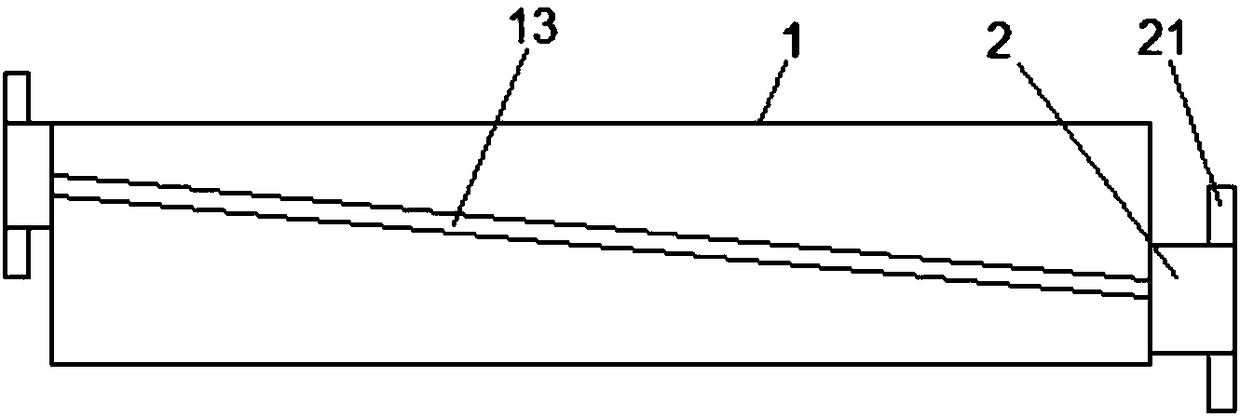

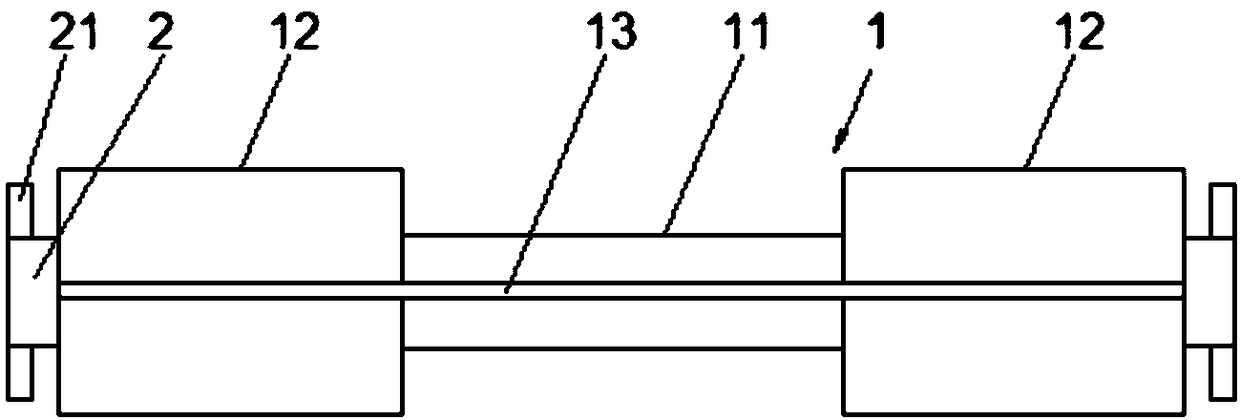

PCSC shear joint structure of plate girder overall assembly type composite beam bridge

ActiveCN107964875AReduce the risk of diseaseSimplify on-site construction processBridge erection/assemblyBridge materialsEngineeringPlate girder

The invention discloses a PCSC shear joint structure of a plate girder overall assembly type composite beam bridge. A steel beam is provided with a longitudinal side baffle. A precast concrete bridgechannel plate is located behind the steel beam and is located on the top of the longitudinal side baffle. A longitudinal perfusion space is formed between the precast concrete bridge channel plate andthe steel beam. The precast concrete bridge channel plate is fixedly connected with the steel beam by using a shear joint structure in a longitudinal perfusion mode between the precast concrete bridge channel plate and the steel beam. According to the PCSC shear joint structure of the plate girder overall assembly type composite beam bridge, by using pressure perfusion, a longitudinal perfusion space is formed and the longitudinal perfusion space is combined with concrete to form steel-concrete composite beams, and then all the steel-concrete composite beams are pushed to the corresponding bridge piers to be in position in the longitudinal direction, and assembly type combination of an overall precast concrete bridge channel plate unit and an overall steel beam unit is achieved. An assembly type industrialization bridge construction method that the steel-concrete composite beams are constructed in a factory and the fact that all the steel-concrete composite beams are pushed to the corresponding bridge piers to be in position in the longitudinal direction can be achieved. All the advantages of the PCSC shear joint structure are achieved. The three problems of the high working amount of welding on a site, extremely high accuracy requirements of adaptation of manufacture and poor fatigue resistance of inconel weld are overcome.

Owner:CHONGQING JIAOTONG UNIVERSITY

Special mortar for micro pile pouring, and preparation method and application thereof

The invention relates to special mortar for micro pile pouring, and a preparation method and an application thereof. The special mortar material for micro pile pouring is a mixed powder of ordinary Portland cement, quartz sands, a mineral powder or fly ash admixture and additives, the additives comprise a polycarboxylate superplasticizer, an expanding agent, a plastic expanding agent, a defoamingagent and a tackifier, and the tackifier is one or a combination of more of cellulose ether, polysaccharide, polyacrylamide and flaky silicate. The special mortar has the advantages of stability in the pouring process without layering or bleeding, low viscosity after being mixed, good fluidity, easiness in pumping, low air content, guaranteed strength, small shrinkage amount after being cured, suitableness for pouring micro piles, realization of one-time grouting without mortar supplementation, and guaranteeing of the integrity of the pile body. The mortar is not only suitable for the micro pile pouring, but also suitable for grouting construction of large-slenderness-ratio components such as anchor rods and soil nails and structural reinforcement of damaged concrete components, so the mortar has good practical application values.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Stress component, fiber grating sensor, intelligent cable and manufacturing method

PendingCN108507714AEasy to install and connectImprove protectionControlSubsonic/sonic/ultrasonic wave measurementGratingPigtail

The invention discloses a stress component, a fiber grating sensor, an intelligent cable and a manufacturing method. The stress component comprises a measuring segment used for being deformed same asa to-be-tested component, a groove for containing fiber gratings is formed in the measuring segment and extends in the stress direction of the to-be-tested component, and fixing parts for fixing the fiber gratings are further arranged at both ends of the measuring segment. Since the groove is formed in the measuring segment of the stress component and extends in the stress direction of the to-be-tested component, when the fiber gratings are placed in the groove, the groove can position the fiber gratings; at the same time, the groove increases the contact area between the fiber gratings and the measuring segment, and by combining with the fixing parts at both ends of the measuring segment for fixes pigtails at both ends of the fiber gratings, an integral structure is formed. The stress component facilitates installation and connection of the fiber gratings. Moreover, the fiber gratings can be better protected, and damage of the fiber gratings is avoided.

Owner:GUANGXI UNIV

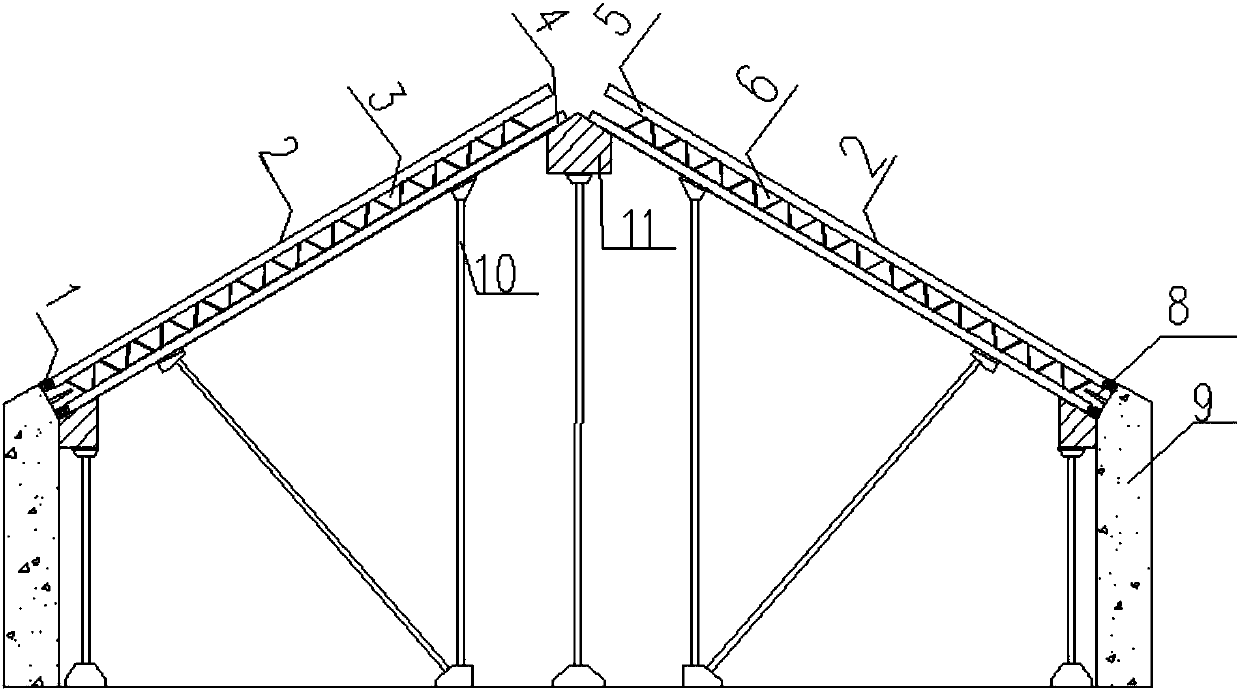

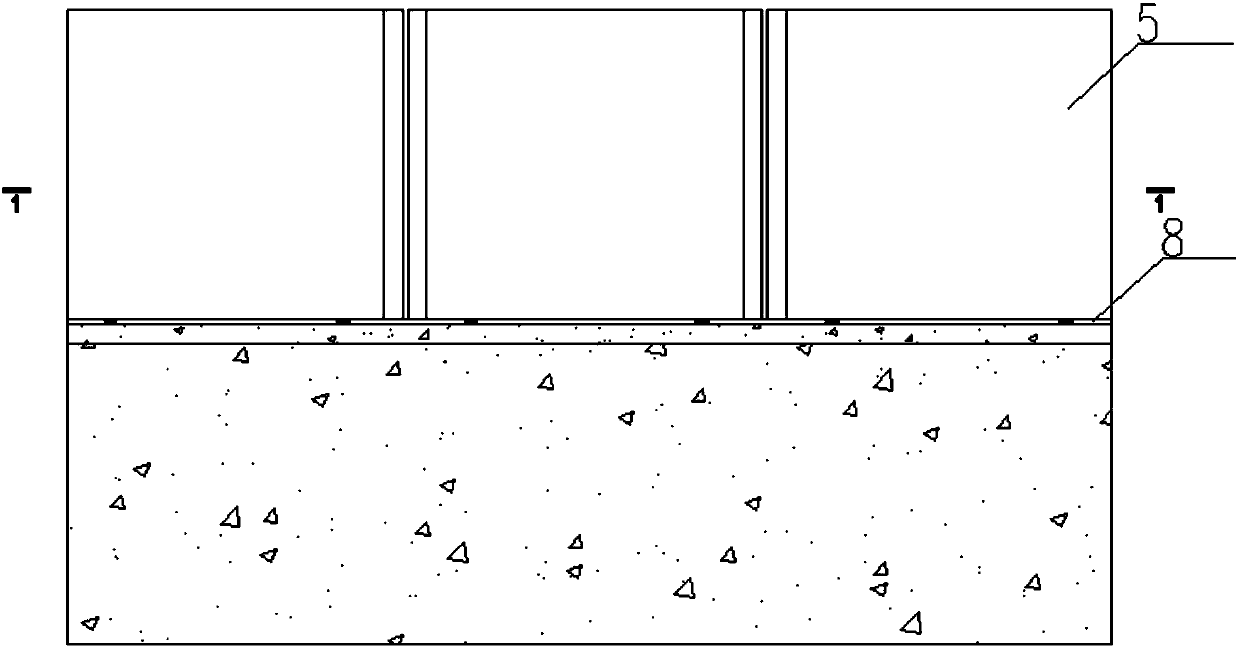

Prefabricated laminated wallboard sloping roof system and installing method thereof

PendingCN107663917ASolving Difficult-to-Pour ProblemsReduce on-site construction proceduresBuilding roofsArchitectural engineeringRebar

The invention relates to a prefabricated laminated wallboard sloping roof system, which comprises a roof sloping surface structure, inclined supporters, a wood pad block, a gasket and a water stop steel plate, wherein the roof sloping surface structure is formed by splicing a plurality of prefabricated lamination wall boards; each prefabricated lamination wall board comprises an outer prefabricated wall board and an inner prefabricated wall board; the inner and outer prefabricated wall boards are connected through truss bars; a certain gap is formed between the adjacent outer prefabricated wall boards and forms a clamp opening; the clamp opening is a cast-in-place inlet or one of the cast-in-place inlets; the wood pad block is arranged at the lower part of the slope top position of the prefabricated lamination wall boards; a vertical support rod is arranged under the wood pad block; the inclined supporters are arranged at the lower part of the slope surfaces of the prefabricated lamination wall boards; the vertical supporter, the inclined supporters and the base plane are connected and fixed; the gasket is clamped between the prefabricated lamination wall boards and the wall body,is used as a supporting point of the prefabricated lamination wall board and can be used for regulating the installation errors of the prefabricated lamination wall board.

Owner:SHANGHAI BAOYUE RESIDENTIAL IND CO LTD

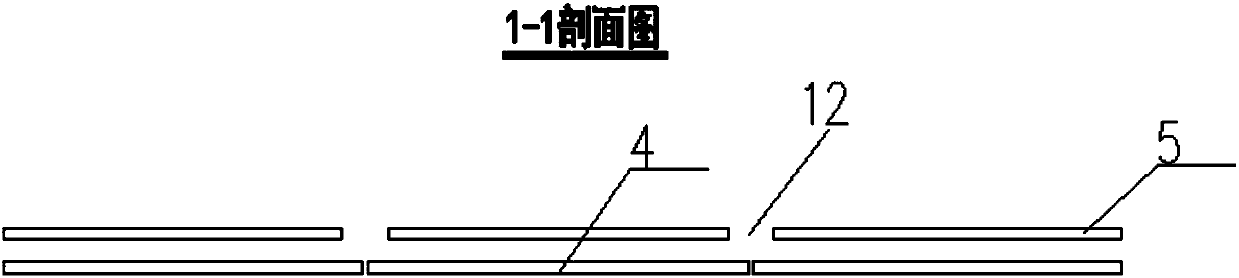

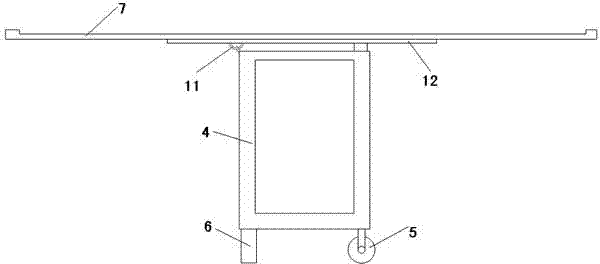

Formwork for cast-in-place assembly type filler wall and construction method

ActiveCN103306475BImprove integrityImprove seismic performanceForms/shuttering/falseworksBuilding material handlingBrickFloor slab

The invention provides a formwork for a cast-in-place assembly type filler wall and a construction method, wherein the formwork comprises a bracket (4), the left upper end of the bracket (4) is connected with a bottom formwork (12) through a separable suspension type semicircle hinge (11), a soffit formwork (7) is arranged above the bottom formwork (12), a fixing foot (6) is arranged at the left lower end of the bracket (4), and a moving wheel (5) is arranged at the right lower end of the bracket (4). A cast-in-place wallboard (1) takes a quick setting material (2) as a base material, a movable and turnable formwork (3) is used to conduct cast-in-place and rapid setting and forming, and then the quick setting material is fixed on floors at the upper and lower ends or a beam through moving and turning in place. According to the invention, the comprehensive economic indicator and the construction period are superior to those of the conventional aerated concrete brick filler wall and a hollow internal-model metal mesh cement internal parting wall, the advantages of quick construction, low cost and simple site operation process are achieved, and the defects of the prior art are made up.

Owner:盐城市双新建设投资有限公司

pcsc shear force coupled structure of integrally assembled composite girder bridge with slab girder

ActiveCN107964875BReduce the risk of diseaseSimplify on-site construction processBridge erection/assemblyBridge materialsPlate girderPrecast concrete

The invention discloses a PCSC shear joint structure of a plate girder overall assembly type composite beam bridge. A steel beam is provided with a longitudinal side baffle. A precast concrete bridgechannel plate is located behind the steel beam and is located on the top of the longitudinal side baffle. A longitudinal perfusion space is formed between the precast concrete bridge channel plate andthe steel beam. The precast concrete bridge channel plate is fixedly connected with the steel beam by using a shear joint structure in a longitudinal perfusion mode between the precast concrete bridge channel plate and the steel beam. According to the PCSC shear joint structure of the plate girder overall assembly type composite beam bridge, by using pressure perfusion, a longitudinal perfusion space is formed and the longitudinal perfusion space is combined with concrete to form steel-concrete composite beams, and then all the steel-concrete composite beams are pushed to the corresponding bridge piers to be in position in the longitudinal direction, and assembly type combination of an overall precast concrete bridge channel plate unit and an overall steel beam unit is achieved. An assembly type industrialization bridge construction method that the steel-concrete composite beams are constructed in a factory and the fact that all the steel-concrete composite beams are pushed to the corresponding bridge piers to be in position in the longitudinal direction can be achieved. All the advantages of the PCSC shear joint structure are achieved. The three problems of the high working amount of welding on a site, extremely high accuracy requirements of adaptation of manufacture and poor fatigue resistance of inconel weld are overcome.

Owner:CHONGQING JIAOTONG UNIVERSITY

Connection structure and construction technology of artificial dam body and coal pillar dam body of underground reservoir

The invention discloses an underground reservoir artificial dam body and coal pillar dam body connecting structure and further discloses a construction technology of the underground reservoir artificial dam body and coal pillar dam body connecting structure. The underground reservoir artificial dam body and coal pillar dam body connecting structure comprises an artificial dam body and a coal pillar dam body. A dam body groove is formed in the coal pillar dam body and provided with a groove oblique surface, and an acute angle is formed between the extending directions of the groove oblique surface and the artificial dam body. Anchor rod drill holes are formed in the groove oblique surface, and the extending directions of the anchor rod drill holes are perpendicular to the extending direction of the groove oblique surface. An inverted-hook-type grouted anchor rod is fastened in each anchor rod drill hole, and a plurality of reinforcement framework beams are arranged in the artificial dambody. The two ends of each reinforcement framework beam are in fastening connection with the ends of the inverted-hook-type grouted anchor rods on the two sides of the reinforcement framework beam correspondingly. According to the underground reservoir artificial dam body and coal pillar dam body connecting structure and the construction technology thereof, the connecting strength and stability are improved, and the construction technology is further simplified.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A kind of filling paste slurry suitable for goaf in tunnel construction

Owner:CENT SOUTH UNIV +1

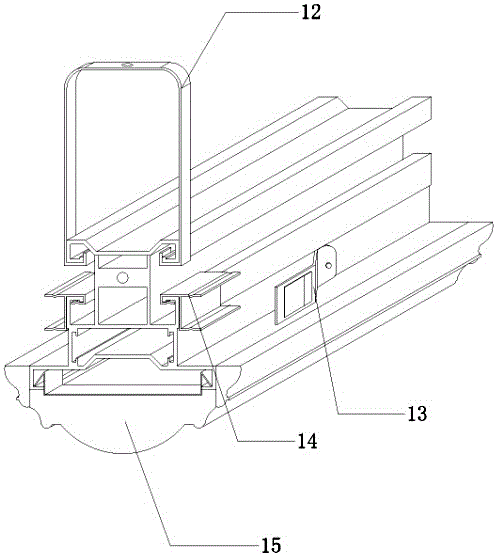

A ceiling-mounted keel

The invention relates to a ceiling hanging keel, which includes a keel body, and the keel body sequentially includes a first installation part, a connecting block, a cavity and a second installation part from top to bottom; the upper left and right sides of the keel body are provided with There is a first installation part, and the first installation part is used to connect with the large keel hanger; the connection block includes a vertical connection block and a horizontal connection block, and the horizontal connection block is provided with an installation hole; the connection block The lower part is provided with a cavity for threading, and the left and right sides of the upper part of the cavity are provided with hanging arms for connecting with decorative pendants; the left and right sides of the cavity are provided with mounting grooves for installing buffer pieces; The left and right sides of the lower part of the keel body are provided with second installation parts for connecting the decorative panels; the upper part of the second installation part is provided with a support surface for supporting heavy panels. The keel of the invention is formed by extruding light steel, not only has few components, but also has excellent mechanical properties, and can bear ceiling decorative panels of different weights.

Owner:ZHEJIANG WEILAIJIA E COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com