Emulsion type fracturing fluid resistance reducing agent and preparation method thereof

A drag-reducing agent and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low drag-reducing efficiency, high formation damage, and expensive imported drag-reducing agents, and achieve reduction Wear resistance, short production process time, good anti-interference effect of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

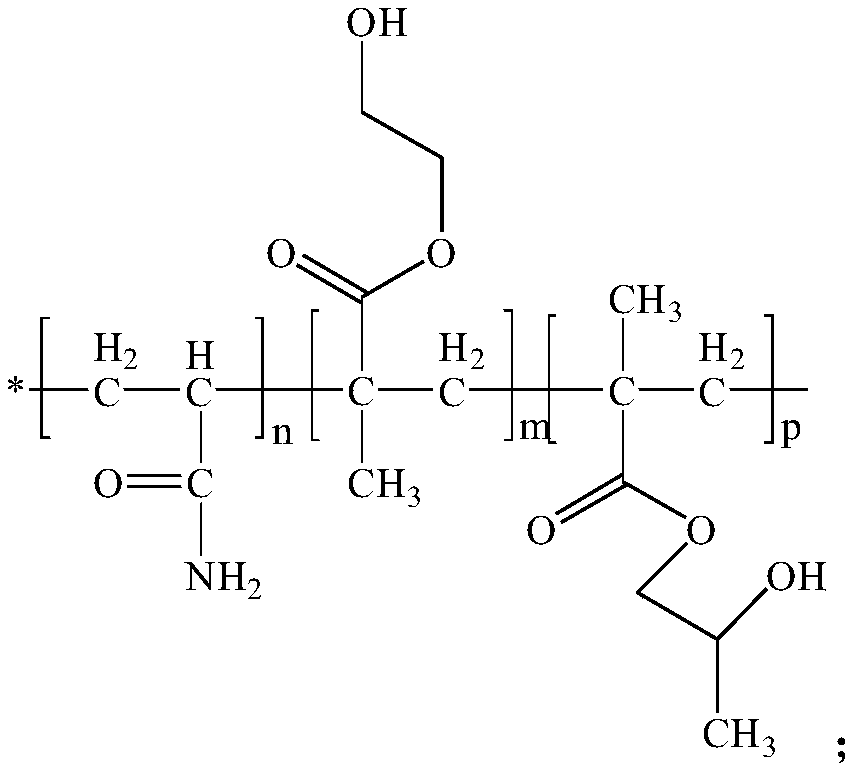

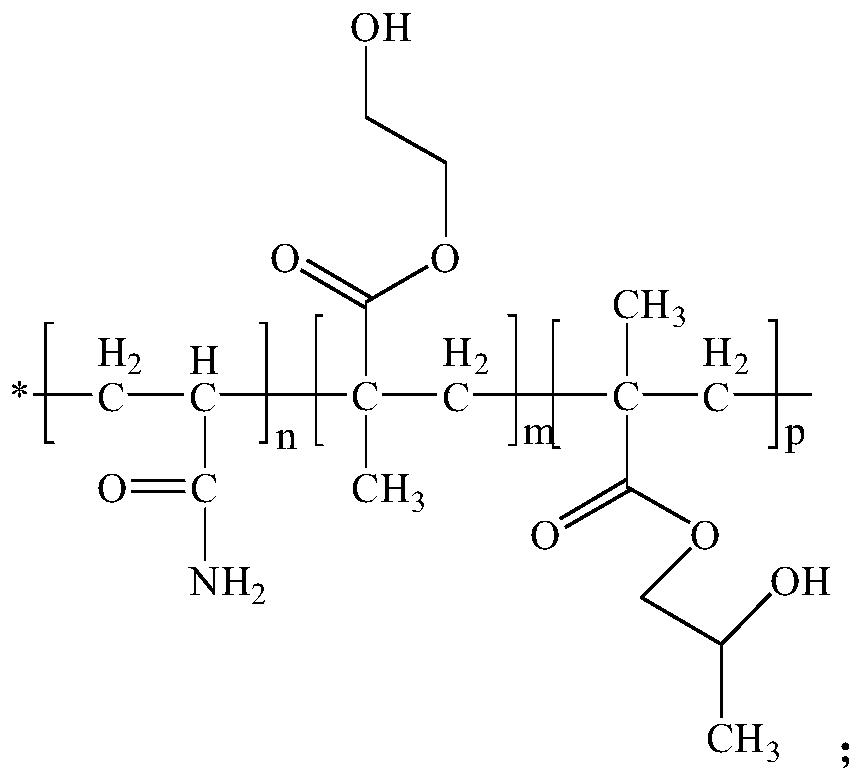

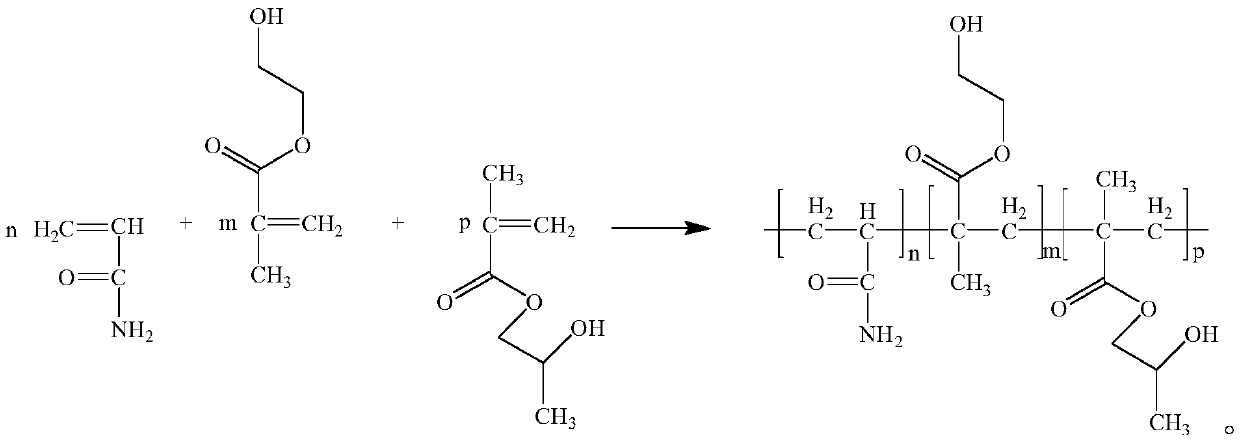

[0040] The invention provides a preparation method of an emulsion type fracturing fluid drag reducer, the specific preparation method is as follows:

[0041] (1) Preparation of water phase

[0042] Add acrylamide, hydroxyethyl methacrylate and 2-hydroxypropyl methacrylate in turn to the beaker, then add water, the heating temperature is 30°C, and the stirring speed is 200rpm. After it is completely dissolved, add urea and ethylene glycol Disodium amine tetraacetate, after stirring for 10 minutes, adjust the pH of the aqueous solution to 6.5 with sodium hydroxide solution, and finally lower it to room temperature to form an aqueous phase.

[0043] (2) Preparation of oil phase

[0044] Add ethyl distearate hydroxyethyl methyl ammonium methylsulfate and kerosene into a three-necked flask, stir at a speed of 300, and stir to dissolve evenly to form an oil phase.

[0045] (3) Preparation of emulsion type fracturing fluid drag reducer

[0046] At room temperature, the stirring sp...

Embodiment 2

[0057] The invention provides a preparation method of an emulsion type fracturing fluid drag reducer, the specific preparation method is as follows:

[0058] (1) Preparation of water phase

[0059] Add acrylamide, hydroxyethyl methacrylate and 2-hydroxypropyl methacrylate in sequence in the beaker, followed by adding water, the heating temperature is 35°C, the stirring speed is 320rpm, after it is completely dissolved, add urea and ethylene glycol Disodium amine tetraacetate, after stirring for 12 minutes, adjust the pH of the aqueous solution to 7.0 with sodium hydroxide solution, and finally lower it to room temperature to form an aqueous phase.

[0060] (2) Preparation of oil phase

[0061] Add ethyl distearate hydroxyethyl methyl ammonium methylsulfate and kerosene into a three-necked flask at a stirring speed of 350 rpm, and stir to make it dissolve evenly to form an oil phase.

[0062] (3) Preparation of emulsion type fracturing fluid drag reducer

[0063] At room tem...

Embodiment 3

[0074] The invention provides a preparation method of an emulsion type fracturing fluid drag reducer, the specific preparation method is as follows:

[0075] (1) Preparation of water phase

[0076] Add acrylamide, hydroxyethyl methacrylate and 2-hydroxypropyl methacrylate in turn to the beaker, then add water, the heating temperature is 42°C, the stirring speed is 280rpm, after it is completely dissolved, add urea and ethylene glycol Disodium amine tetraacetate, after stirring for 18 minutes, adjust the pH of the aqueous solution to 7.5 with sodium hydroxide solution, and finally lower it to room temperature to form an aqueous phase.

[0077] (2) Preparation of oil phase

[0078] Add ethyl distearyl hydroxyethyl methyl ammonium methylsulfate and diesel oil into a three-necked flask at a stirring rate of 420 rpm, and stir to make it dissolve evenly to form an oil phase.

[0079] (3) Preparation of emulsion type fracturing fluid drag reducer

[0080] At room temperature, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com