Formwork for cast-in-place assembly type filler wall and construction method

A construction method and filling wall technology, which is applied in the fields of formwork/formwork/working frame, preparation of building components on site, and processing of building materials, etc., which can solve the disadvantages of low strength of filling walls, increased cost of main structure, and complicated construction technology and other problems, to achieve the effect of fast wall formation, comprehensive cost reduction, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

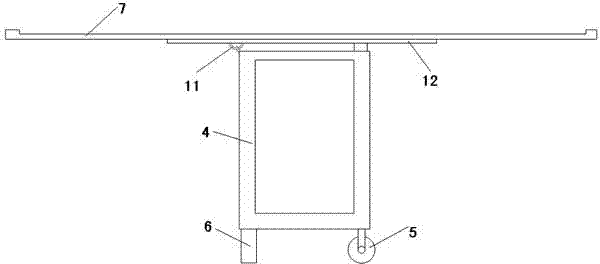

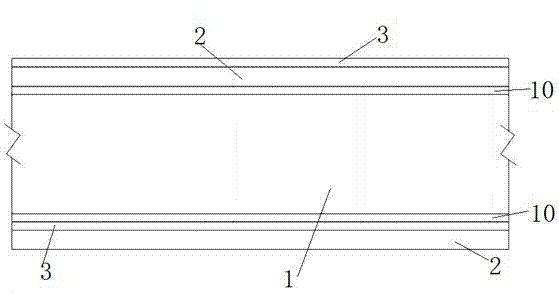

[0024] Such as figure 1 As shown, a formwork for cast-in-place assembled filling walls includes a rectangular support 4, the upper left end of the support 4 is connected to the bottom formwork 12 through a detachable suspension semicircular hinge 11, and the top of the bottom formwork 12 is Bottom template 7, the lower left end of support 4 is fixed foot 6, and the lower right end is mobile wheel 5. Figure 6 Be the perspective view of formwork, the left and right sides of support 4 lower ends are respectively a fixed pin 6 and 3 moving wheels 5, and support 4 upper end left side has 3 pairs of detachable suspension semicircle hinges 11 arranged in a row. Such as figure 2 As shown, the formwork needs to be poured into the floor of the partition wall when it arrives at the construction site, and the size of the bottom formwork 7 is adjusted to match the length and width of the partition wall. In the floor of the partition wall, it is laid horizontally and fixed on the bottom...

Embodiment 2

[0026] Such as figure 1 and figure 2 As shown, in the floor where the formwork is transported to the construction site and needs a partition wall, the size of the bottom formwork 7 is adjusted to match the length and width of the partition wall. The bottom formwork 7 adopts a steel formwork and is fixed on the bottom formwork 12. All the other methods of the block cast-in-place wallboard 1 are the same as in Embodiment 1. This example can be used for partition walls and general interior partition walls.

Embodiment 3

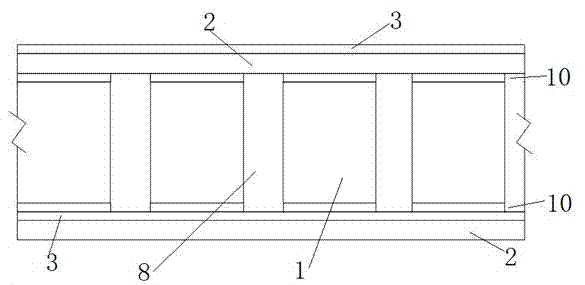

[0028] Such as figure 1 , image 3 and Figure 4 As shown, in the floor where the formwork arrives at the construction site and needs a partition wall, the partition wall is composed of a plurality of cast-in-place wall panels 1 with a width of 1200 mm. There are vertical ribs 8 between adjacent cast-in-place wall panels, and the vertical ribs 8 30mm wide. A paper tube with a diameter of 120 mm is laid on the bottom template 7 of the formwork as a core-pulling tubular inner mold with a center distance of 150 mm and a tube wall distance of about 40 mm from the bottom template 7. The bottom template 7 is a paper-faced gypsum board. Use quick-drying cement as the base material and mix with 70% sand (river sand) to mix and then cast-in-place on the bottom formwork 7 with a thickness of 200 mm. After 10 minutes, it solidifies and forms a hollow partition wall with a cavity 13. The cast-in-place wallboard is 1 pair The surface layer 9 on the side surface adopts phosphogypsum, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com