Patents

Literature

54results about How to "Fast construction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

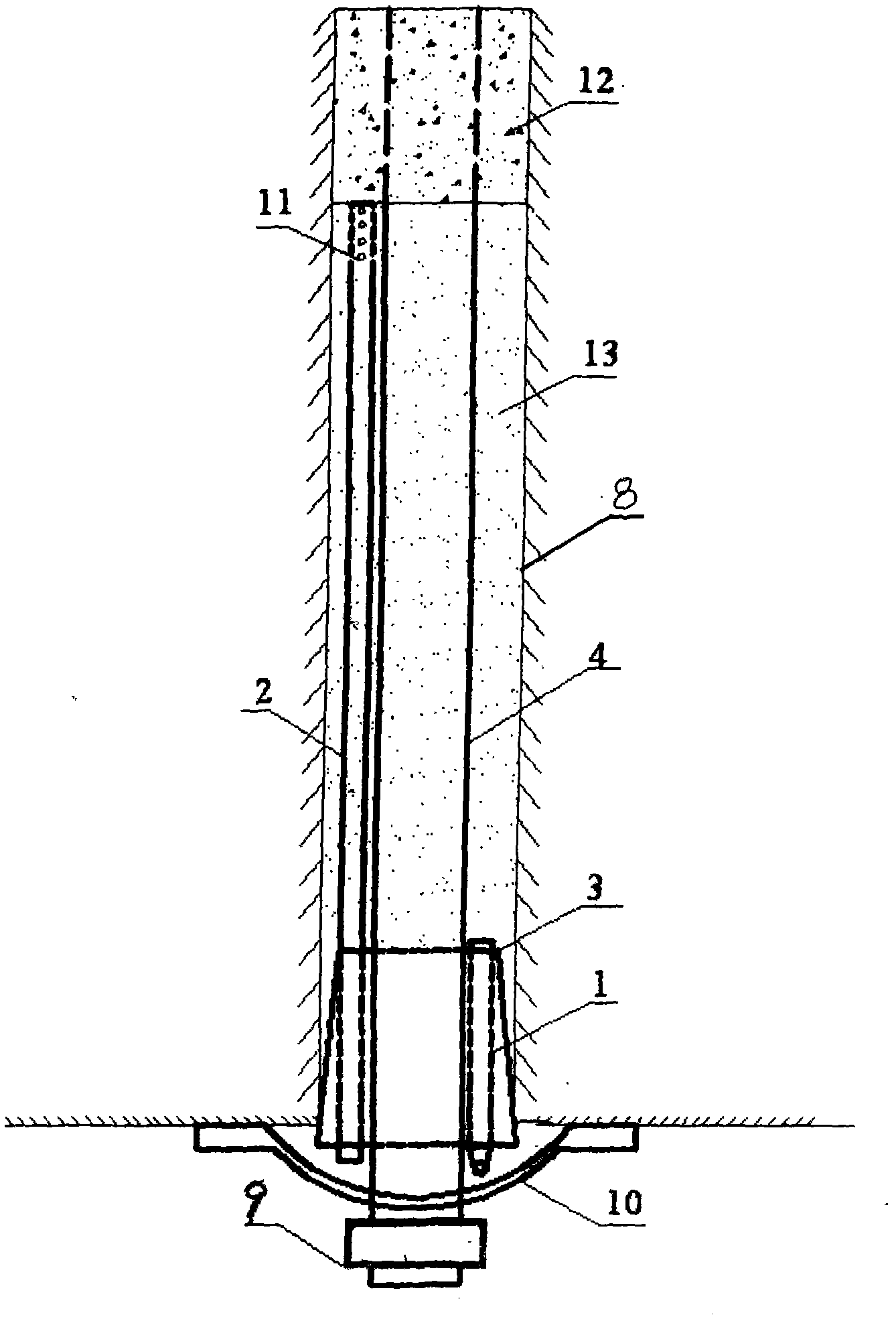

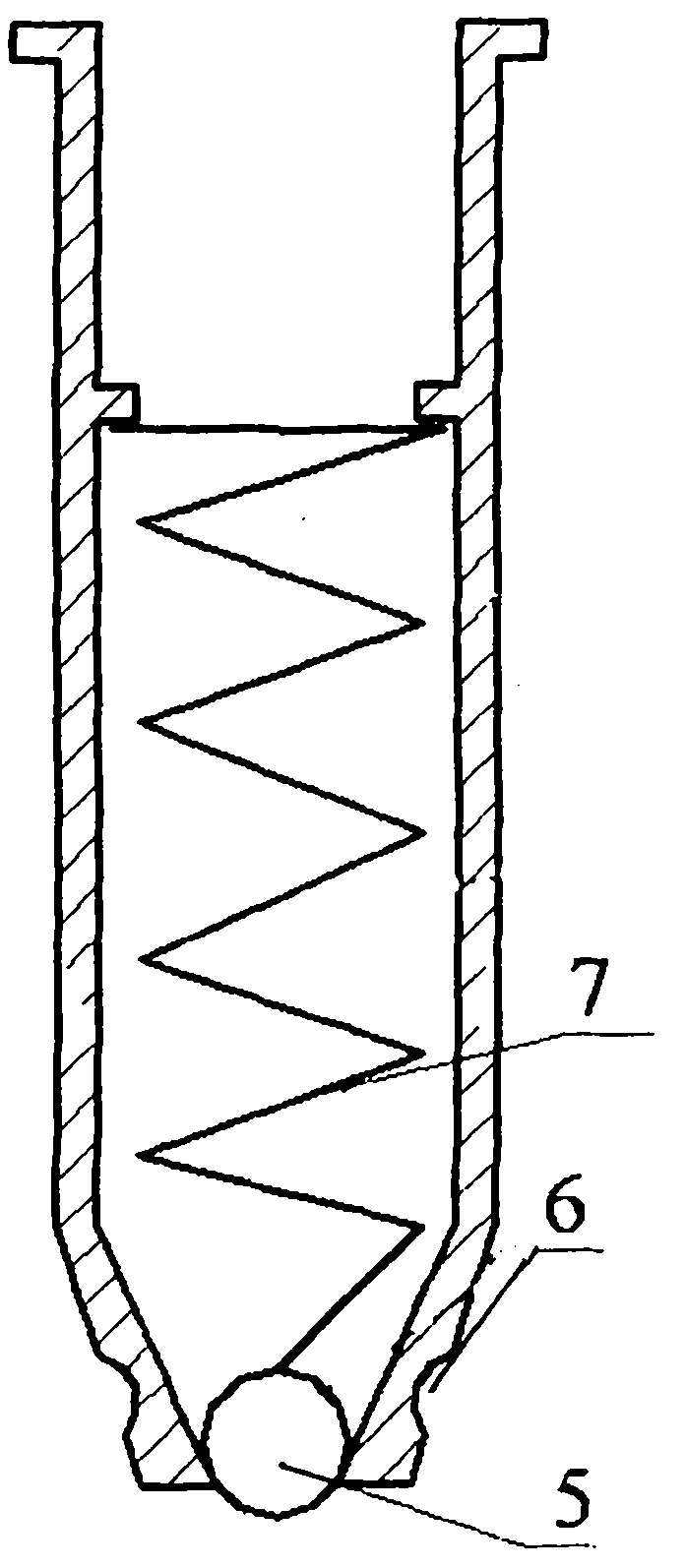

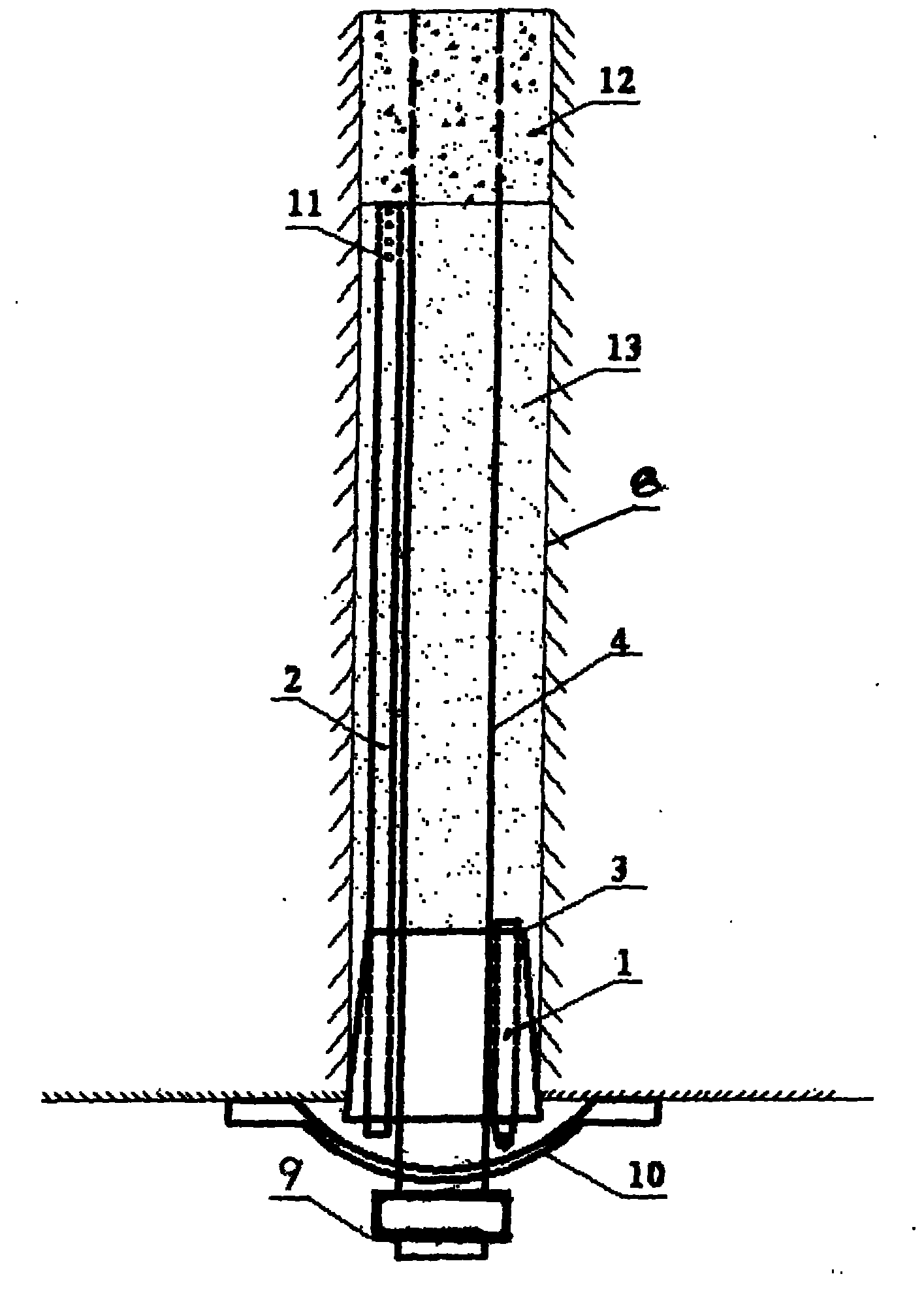

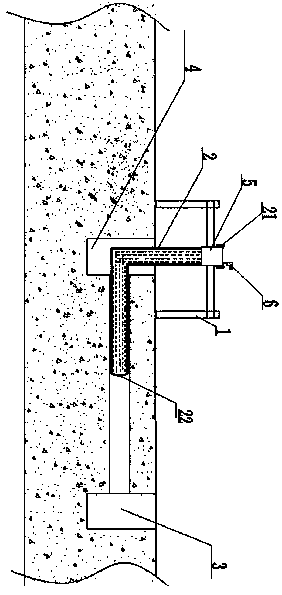

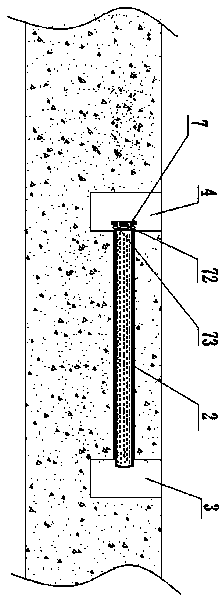

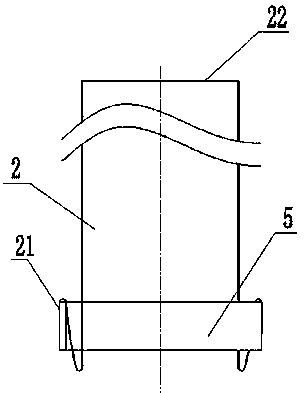

Anchoring structure for liquid-injection corrosion-resistant anchor rod or anchor cable and construction method thereof

InactiveCN102146673ASolve the sealing waterSolve corrosionAnchoring boltsBulkheads/pilesEngineeringSlurry

The invention discloses an anchoring structure for a liquid-injection corrosion-resistant anchor rod or anchor cable and a construction method thereof. The anchoring structure comprises a resin end-anchored anchor rod or anchor cable body arranged in an anchor hole, wherein a grouting-stop plug is also arranged at the opening of the anchor hole; an anchor rod head or an anchor cable head is exposed out of the anchor hole from the plug hole of the grouting-stop plug; the grouting-stop plug is also provided with two plug holes; a liquid injection nozzle is inserted into one plug hole and chemical grout is filled into the anchor hole through the liquid injection nozzle; an exhaust pipe with two open ends is inserted into the other plug hole; a check-valve ball and a return spring are arranged in the liquid injection nozzle; a locking slot connected with grouting equipment is reserved on the peripheral surface of the liquid injection nozzle; the length of the exhaust pipe is equivalent to that of the end-anchored anchor rod or anchor cable; and exhaust holes are reserved on the peripheral surface of the exhaust pipe close to the bottom of a drilled hole. The anchoring structure solves the problem of sealing water and preventing corrosion of anchor rod holes at the positions such as an arch part and the like, not only can serve as permanent support, but also can serve as temporary support.

Owner:SHANDONG UNIV OF SCI & TECH

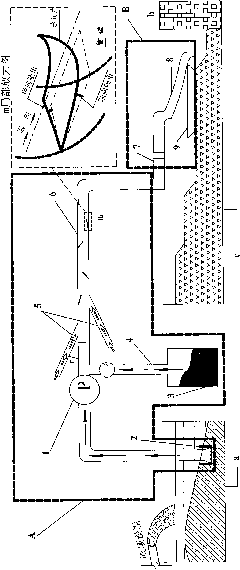

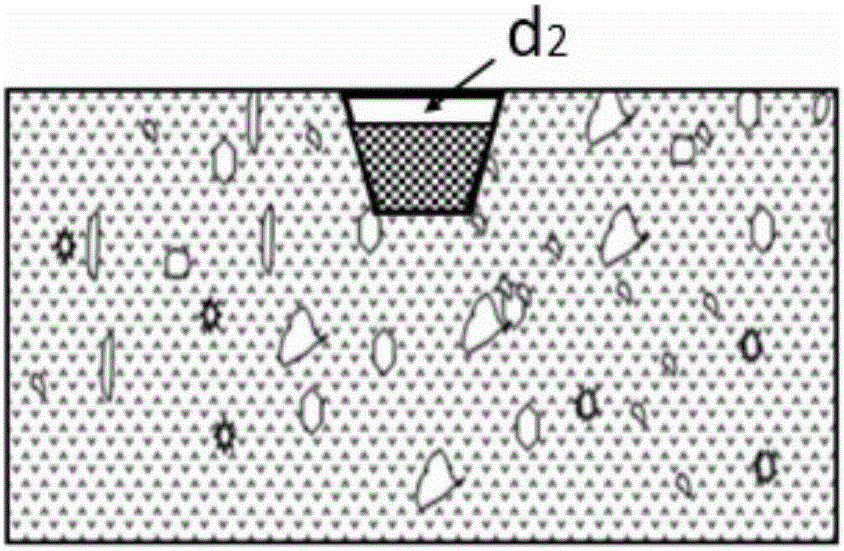

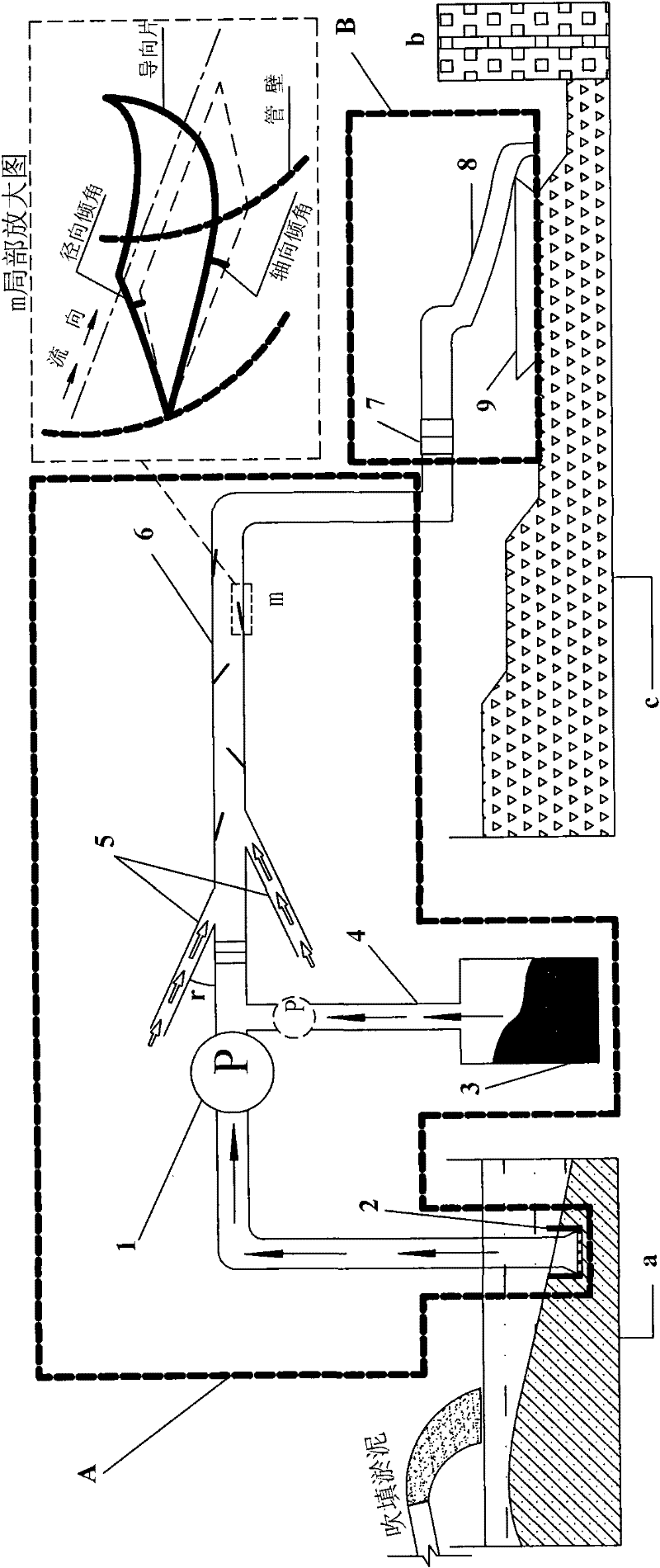

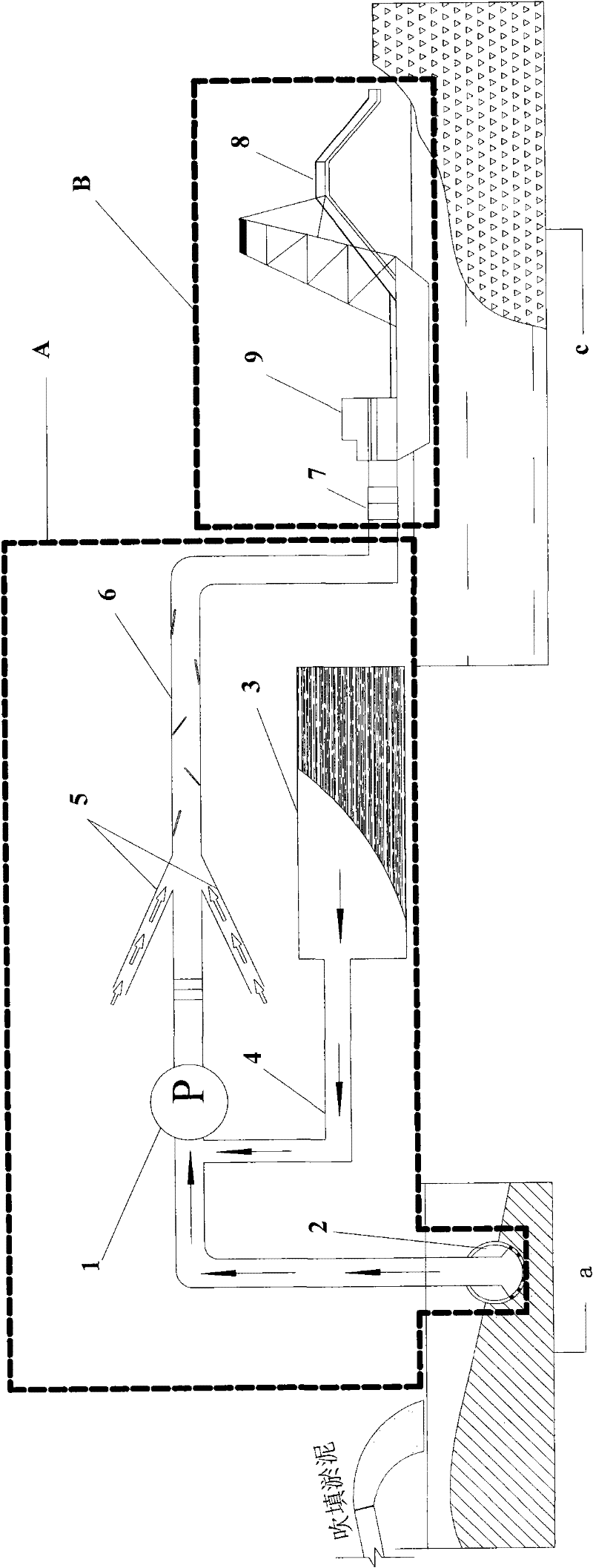

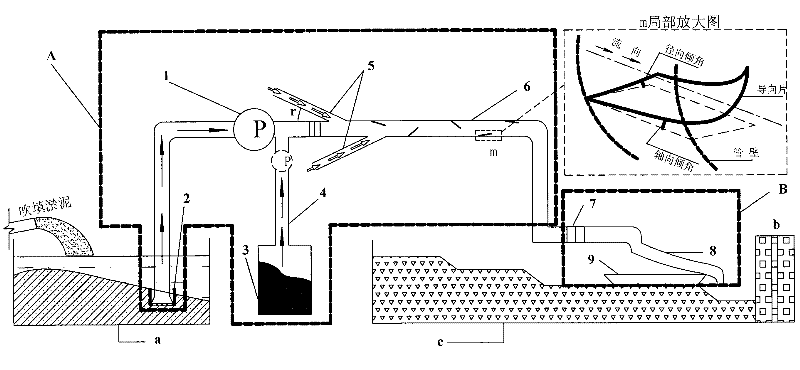

Construction process for reclamation by hydraulic filling of silt and device thereof

The invention discloses a construction process for the reclamation by the hydraulic filling of silt and a device thereof. The device comprises a solidification treatment system A and a paving system B for improved slurry, wherein the A comprises a pumping device, an impurity screening device, a solidification agent storage device, a solidification agent conveying device, a compressed air conveying device and a mixed slurry stirring and conveying device; the B comprises a connecting pipe section, a hose or belt conveyer and a bearing and moving device. The construction flow comprises the following steps of: (1) filling the silt slurry into a filling region or sedimentation tank so as to form a stacked layer of thick silt slurry; (2) pumping the thick silt slurry with the pumping device, conveying the solidification agent into the thick silt slurry at the same time, and mixing the thick silt slurry and the solidification agent in a pipe in front of or behind a pump so as to form the mixed slurry; (3) conveying the mixed slurry to the stirring and conveying device to form the improved slurry; (4) conveying the improved slurry out to the paving system B through the connecting pipe section; and (5) laying the improved slurry to specified thickness by the paving system B. The device is characterized by fast, high-efficiency, simple and convenient operation.

Owner:武汉华荣科技发展有限责任公司

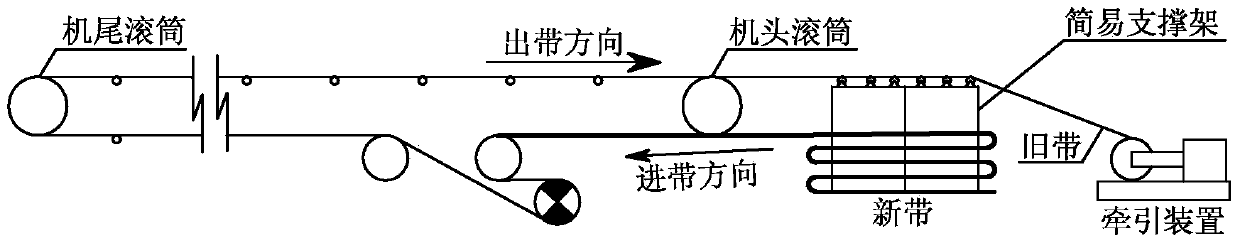

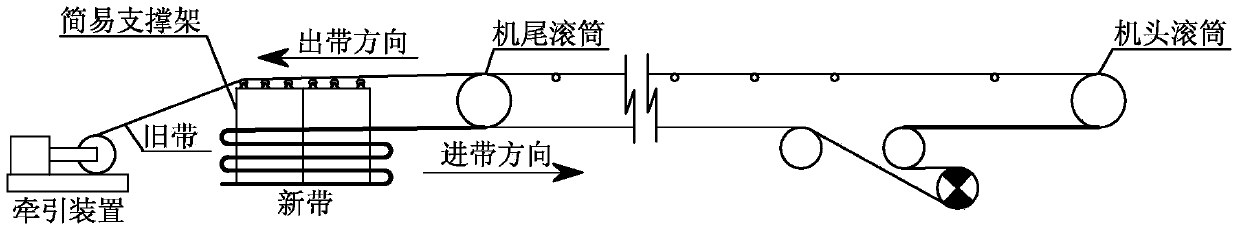

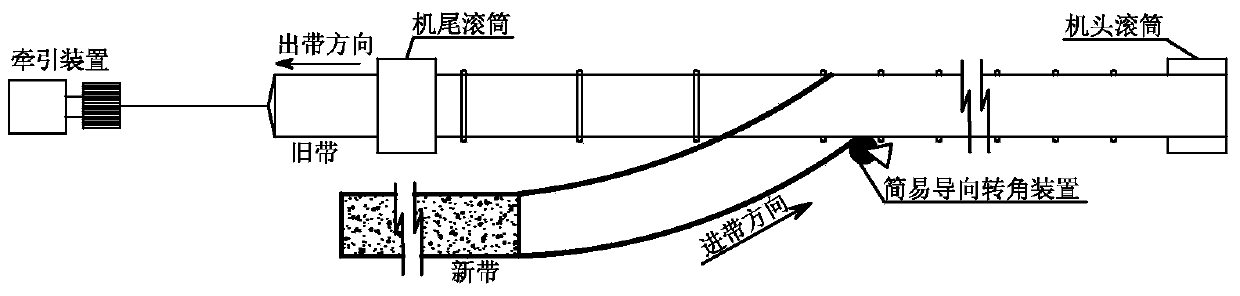

Conveying belt change method for conveyor

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

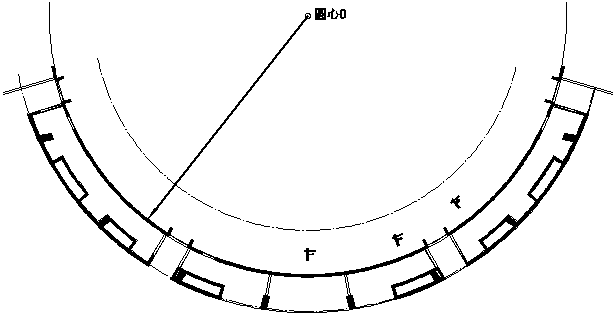

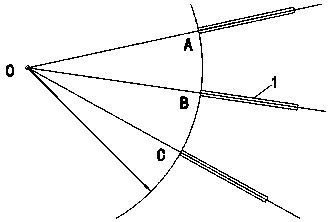

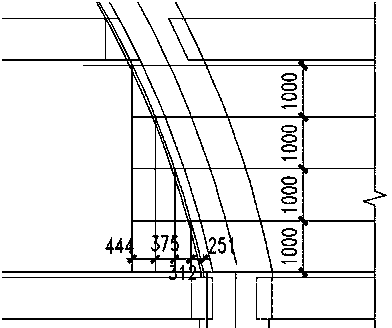

Space positioning control method of reverse arc wall template

ActiveCN104358410ASimple construction processShorten the construction periodForms/shuttering/falseworksEngineeringFlange

The invention discloses a space positioning control method of a reverse arc wall template. The method comprises the steps of determining a main ridge structure, wherein a main ridge is of a welded arc-shaped H section steel structure, a welded arc-shaped H section steel flange is parallel to a reverse arc wall, and the whole welded arc-shaped H section steel is bent to form an arc shape in the length direction and corresponds to an arc formed by the vertical section of the reverse arc wall; dividing the whole formed main ridge into a plurality of identical sections; fixedly mounting the lowermost sections of the main ridge on the outer side of the reverse arc wall at equal intervals on concrete ground; sequentially mounting a batten, a horizontal back ridge, a plywood and the like on an upper flange side of the main ridge; arranging a frame body on a lower flange side of the main ridge, and horizontally and vertically supporting the main ridge by virtue of connection between the frame body and the lower flange. According to the method, the strength can be guaranteed, the construction difficulty can be reduced, the cost is low, and therefore the three-dimensional space size of a pouring concrete reverse arc wall structure is guaranteed.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

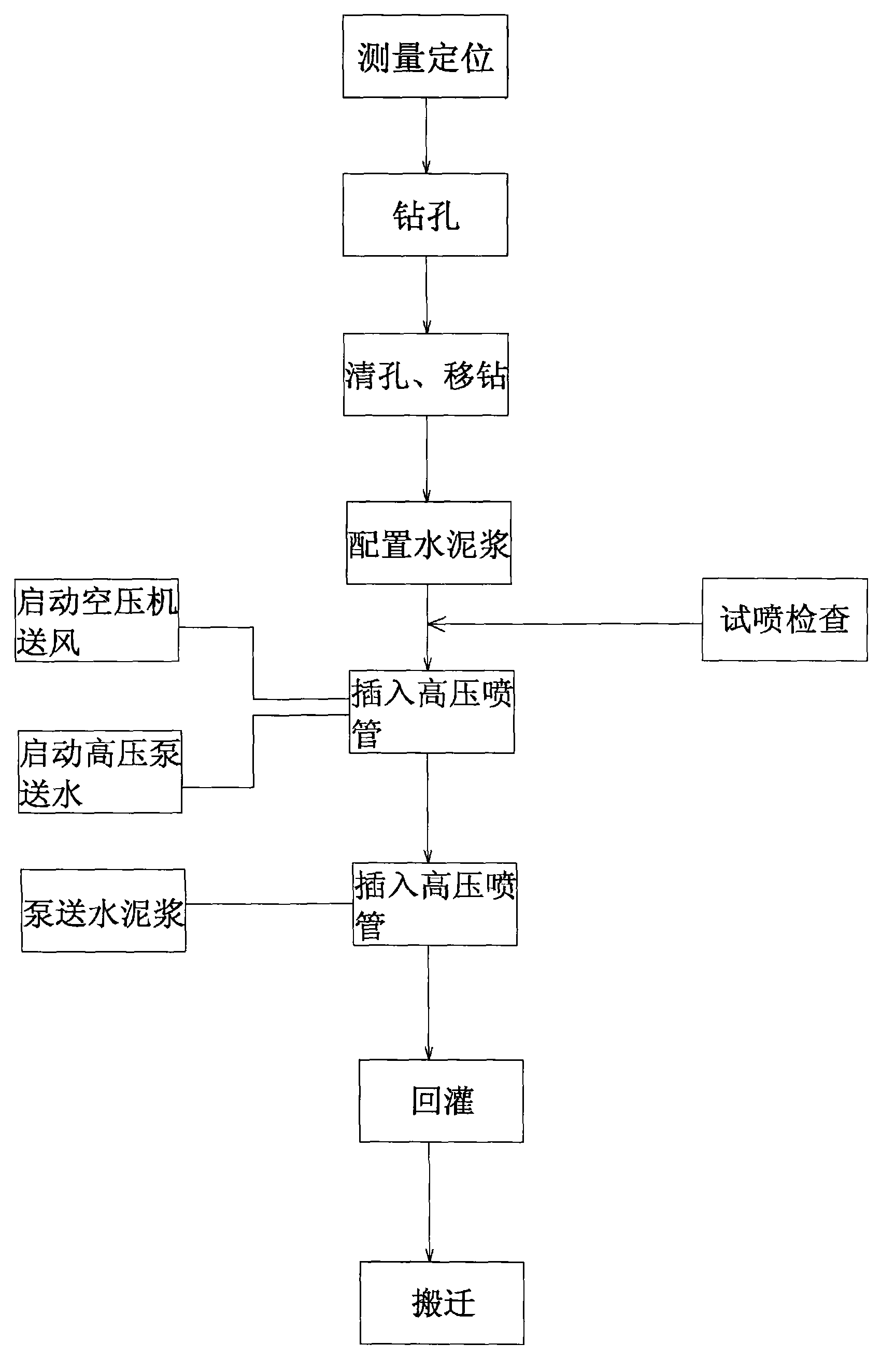

Novel construction technology of waterproof curtain

InactiveCN103806457AFast constructionFast construction processFoundation engineeringEngineeringHigh pressure water

The invention relates to a novel construction technology of a waterproof curtain. The novel construction technology includes the following processing steps: (1) carrying out measurement positioning, (2) enabling a hole leading drilling machine to be in place according to the marked position to carry out hole drilling, (3) cleaning a hole after hole drilling is completed, moving the hole leading drilling machine to a next hole position, and repeating the step (2) and the step (3), (4) preparing cement paste, (5) inserting a high-pressure spraying pipe into the hole, meanwhile, starting an air compressor to supply air, and starting a high-pressure water pump to supply water, (6) carrying out high-pressure jet grouting operation: forming the waterproof curtain by pumping the cement paste, and enabling the high-pressure spraying pipe to be lifted in a rotary mode, (7) carrying out recharging to enable the hole to be filled with the paste, and (8) carrying out movement: moving the high-pressure spraying pipe to the next hole position, repeating the step (5), the step (6) and the step (7), and finally completing construction of the whole waterproof curtain. The novel construction technology of the waterproof curtain has the advantages of being rapid in construction, good in waterproof effect, capable of keeping a soil layer structure stable and the like.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG

Supporting method for primary support of underground excavated chamber

ActiveCN103590841AAvoid water seepage hazardsReduce construction proceduresUnderground chambersTunnel liningReinforced concreteSteel frame

The invention discloses a supporting method for a primary support of an underground excavated chamber. The supporting method for the primary support of the underground excavated chamber comprises A, arranging rectangular steel pipes inside the underground excavated chamber, inserting profile steel into the rectangular steel pipes and connecting the rectangular steel pipes with a primary supporting steel frame through steel base plates; B, paving a water proof layer on a whole section of the primary support after sectional primary supports of the underground chamber section are formed into a cross-shaped temporary steel support; C, colligating secondary lining reinforcing bars, reserving construction space for a rear covered water proof layer on the peripheries of the rectangular steel pipes and pouring concrete to form into an underground chamber full-section reinforced concrete structure; D, pulling out the temporary supporting profile steel in the rectangular steel pipes, pouring concrete inside the steel pipes and covering the water proof layer; E, pouring concrete in the reserved construction space of the rear covered water proof layer. The supporting method for the primary support for the underground excavated chamber has the advantages of being few, rapid and simple in construction process and saving construction periods.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

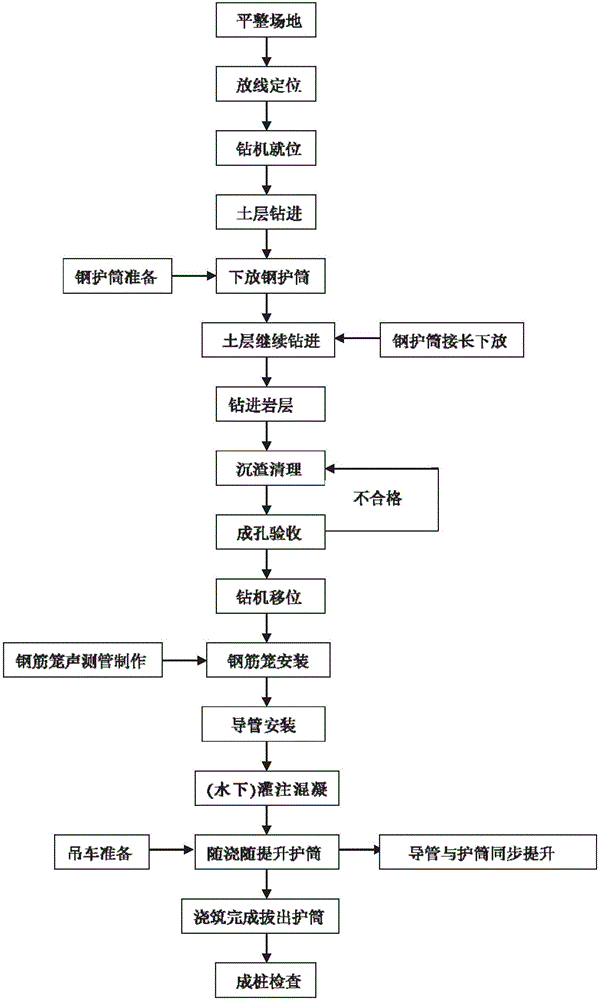

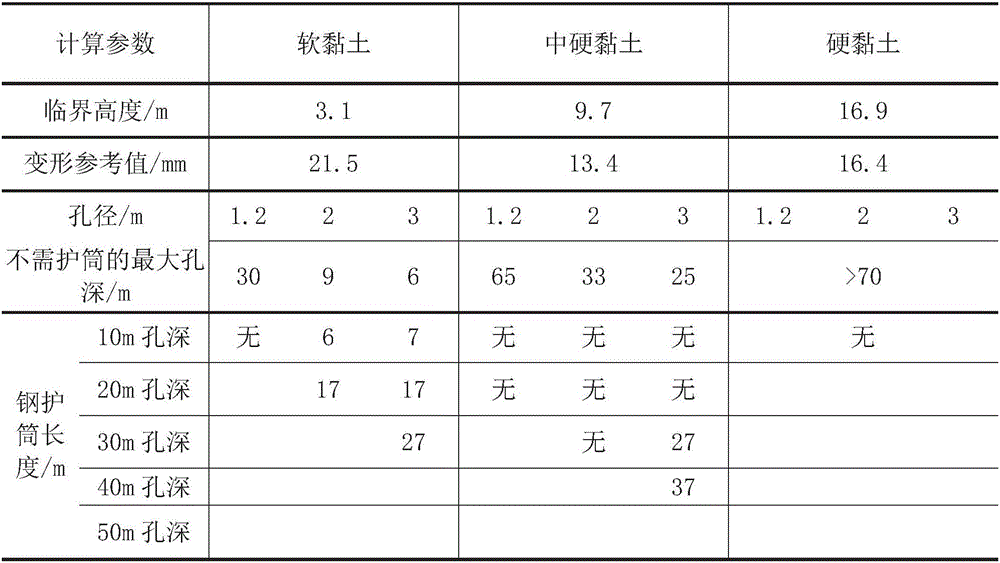

Construction method for forming pile through rotary digging of pile casing

InactiveCN106836206AAdaptableSimplify the construction processBulkheads/pilesStructural engineeringSediment

The invention provides a construction method for forming a pile through rotary digging of a pile casing. The construction method comprises the following construction processes of site leveling, pay-off locating, drilling machine placement, soil drilling, steel casing construction, further soil drilling, rock stratum drilling, sediment cleaning, pore-forming acceptance check, drilling machine displacement, reinforcement cage installation, conduit installation, concrete pouring, pile casing lifting while pouring, pulling out of the pile casing after pouring, and pile inspection. By adopting fully mechanized construction, the construction method has the advantages of being high in construction speed, low in construction cost, safe, reliable and stale in quality.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +2

Self-migration rust inhibitor and its preparation method

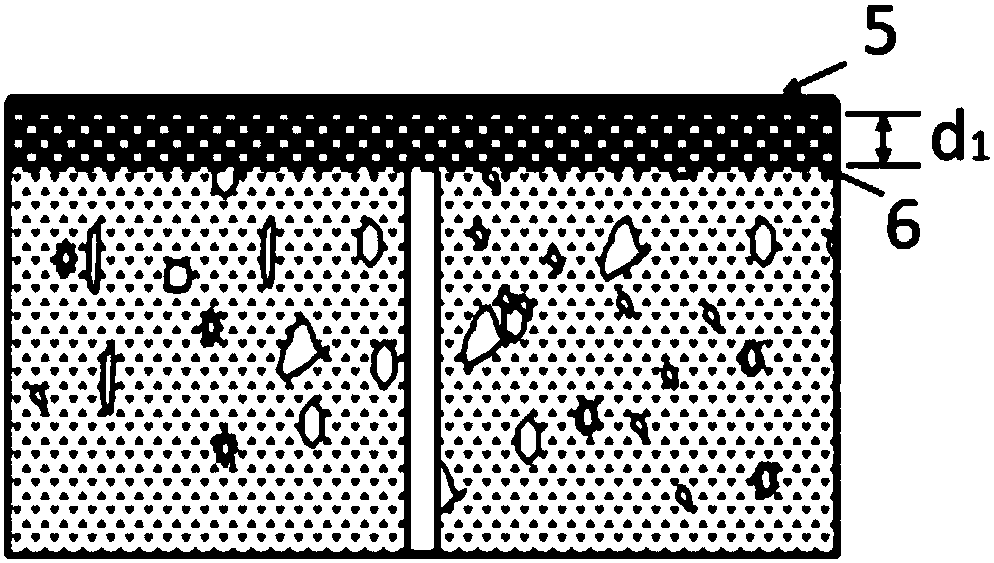

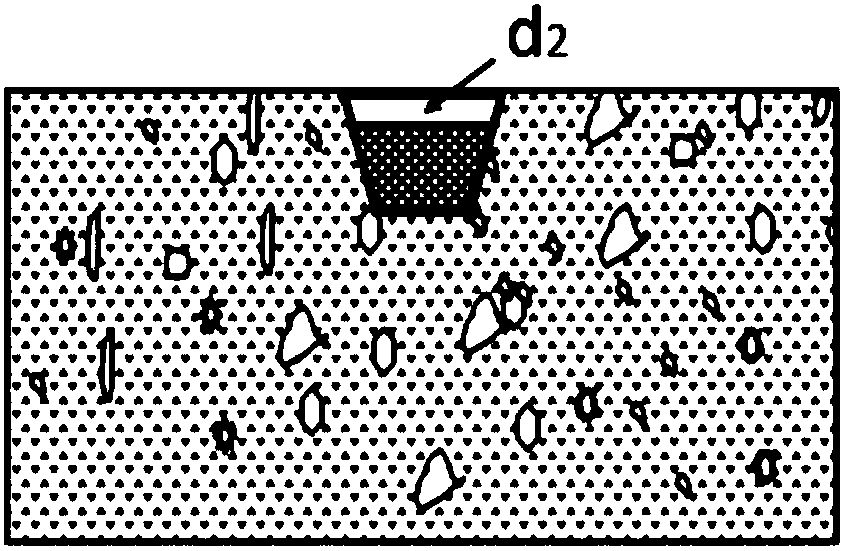

The invention relates to a self-migration rust inhibitor and its preparation method. The self-migration rust inhibitor, which is a novel rust inhibitor product developed by the inventor, has very strong penetration and migration capability, can migrate from the surface layer of asphalt concretes to the surface of steel bars inside cement concretes, and has remarkable rust-resistant effect. The main components of the self-migration rust inhibitor are sodium molybdate, diethylenetriamine and the like. The rust inhibitor for steel bars has no adverse impact on concrete properties, has high-efficient steel bar rust-resistant performance, and can be widely applied in new reinforced concrete structures of sea port engineering, coastal buildings, civil buildings and the like. By the usage of the self-migration rust inhibitor, the service life of steel bars can be substantially raised, the maintenance period of roads and bridges can be prolonged, and the engineering cost can be reduced.

Owner:北京新桥技术发展有限公司

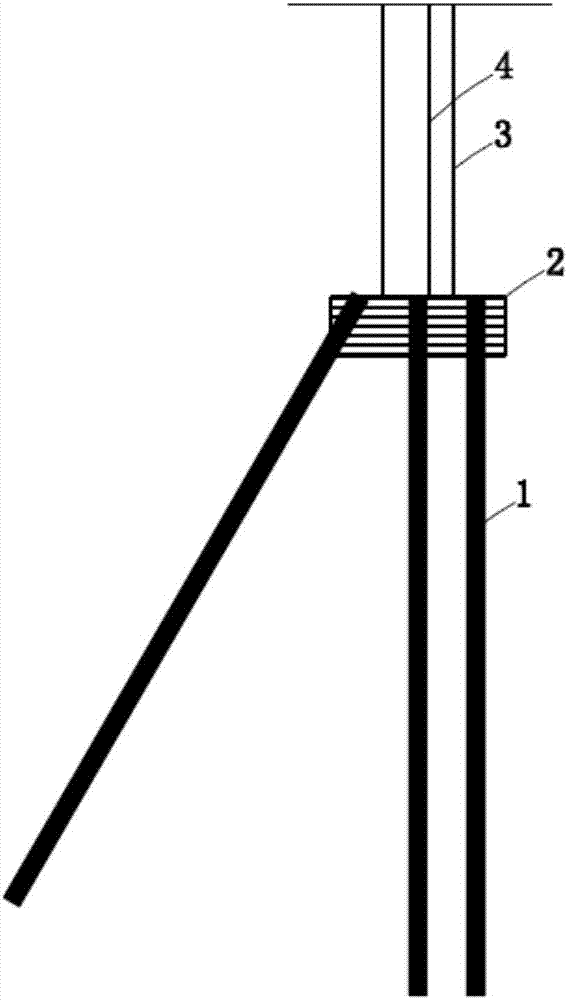

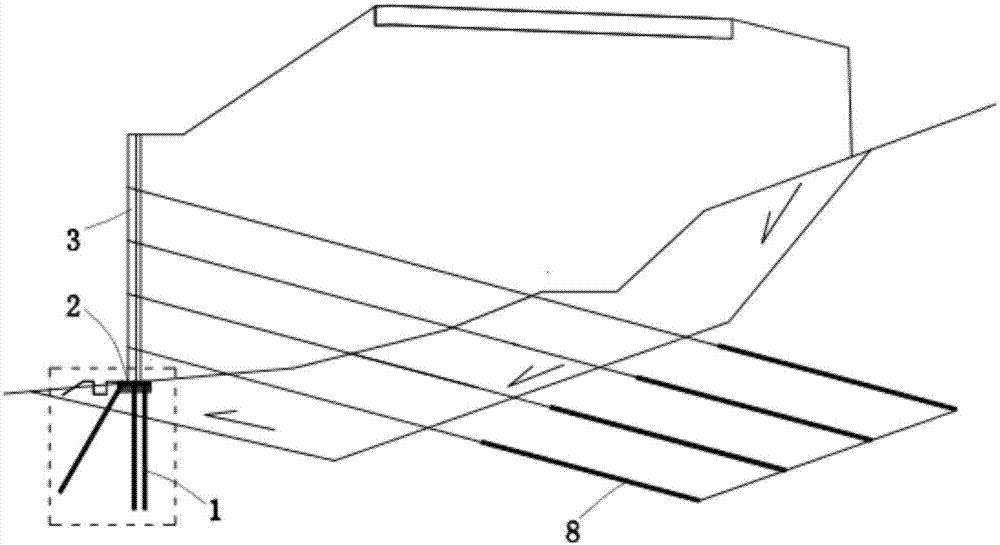

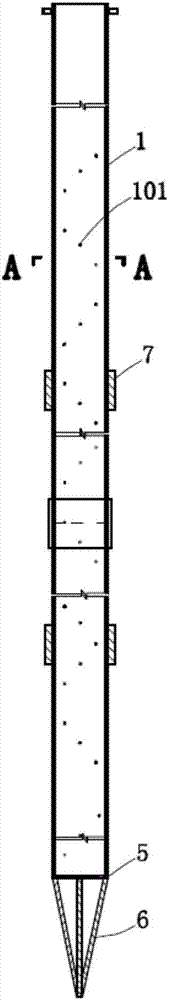

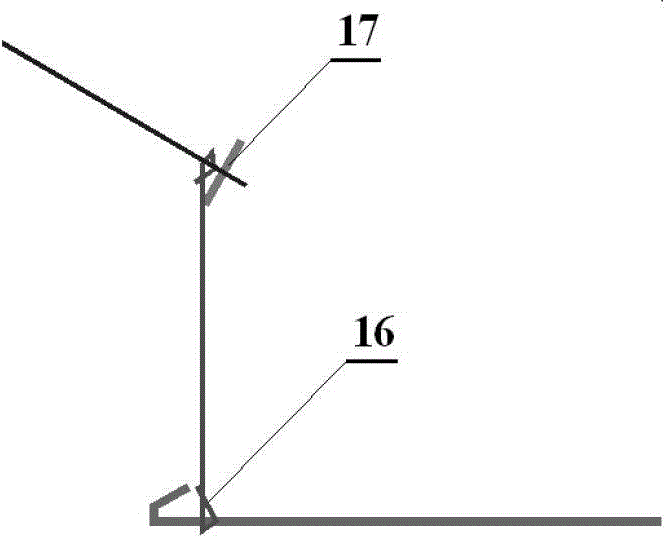

Vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure and construction method thereof

The invention relates to a vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure and a construction method thereof and belongs to the technical field of capital construction. The vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure comprises a steel perforated pipe drill hole formed in a slope, the steel perforated pipe drill hole is internally provided with a steel perforated pipe, and the steel perforated pipe is spirally provided with a plurality of secondary grouting holes; the bottom of the steel perforated pipe is provided with a blocking plate, and the side, away from the steel perforated pipe, of the blocking plate is fixedly connected with a triangular supporting frame; the steel perforated pipe drill hole is internally provided with a grouting body, a pipe opening of the steel perforated pipe is provided with a sealing cover, the position of the pipe opening of the steel perforated pipe is provided with a concrete supporting beam, the concrete supporting beam is internally provided with a steel bar structure, the steel bar structure is welded to the steel perforated pipe, and the concrete supporting beam is provided with a retaining wall. By means of the vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure, the technical problems that a traditional pile foundation technology is high in construction condition requirement, low in manual hole digging speed and high in comprehensive cost are solved, and the vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure is widely applied to slope reinforcement engineering, such as roads, railways, mines and municipal administration.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

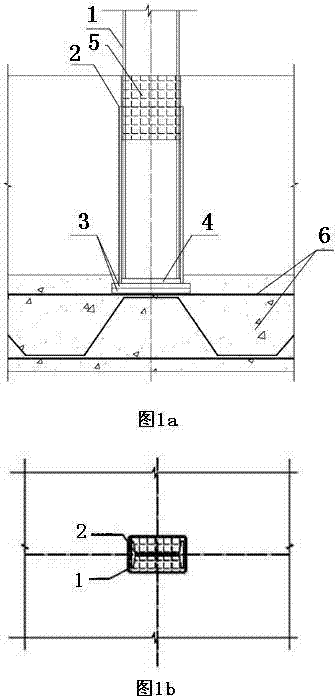

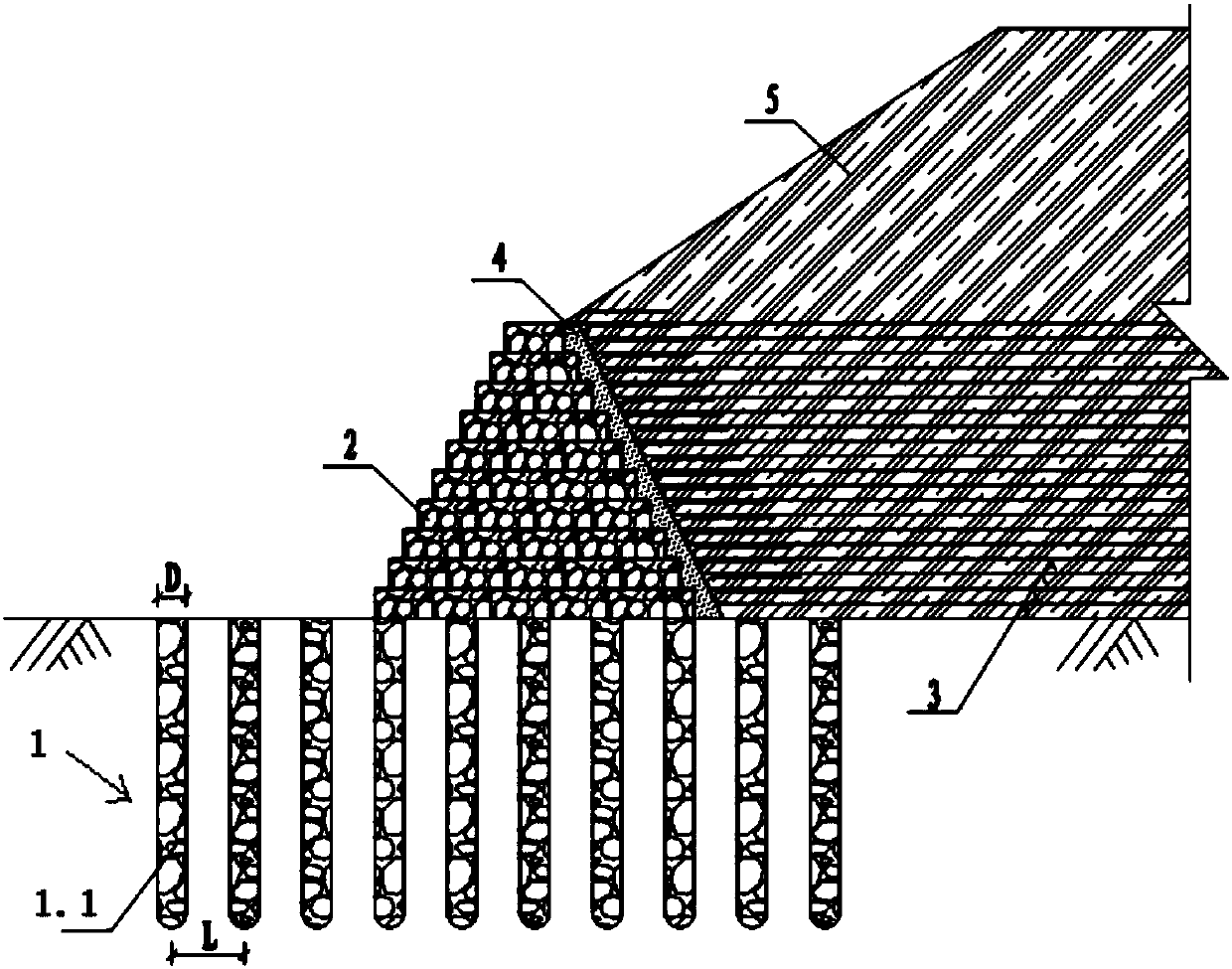

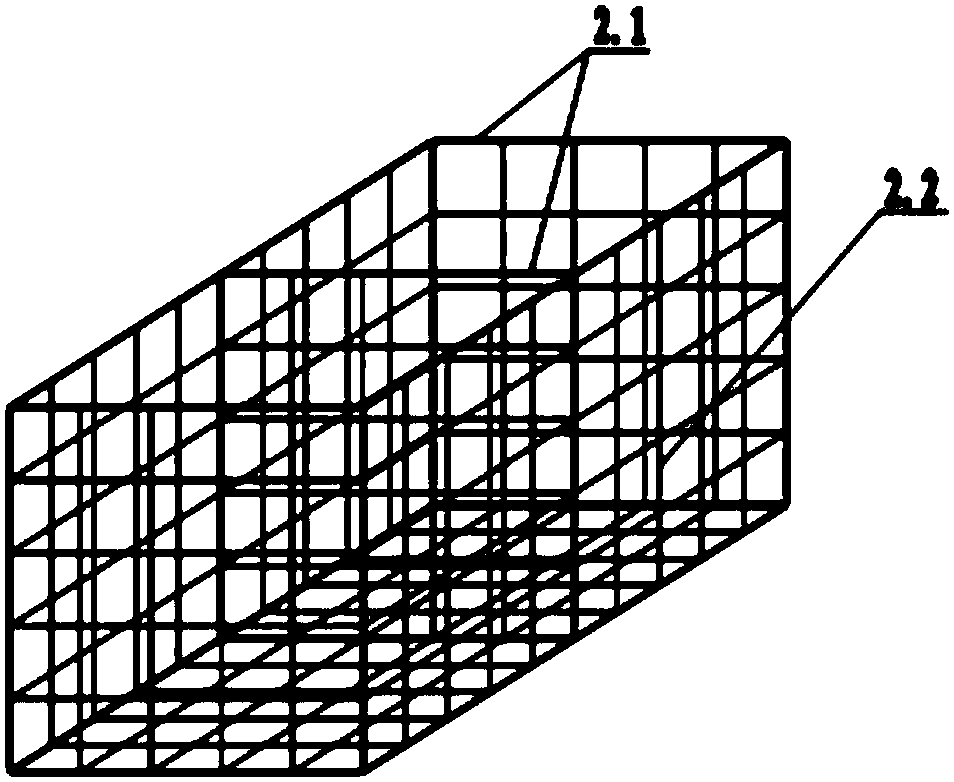

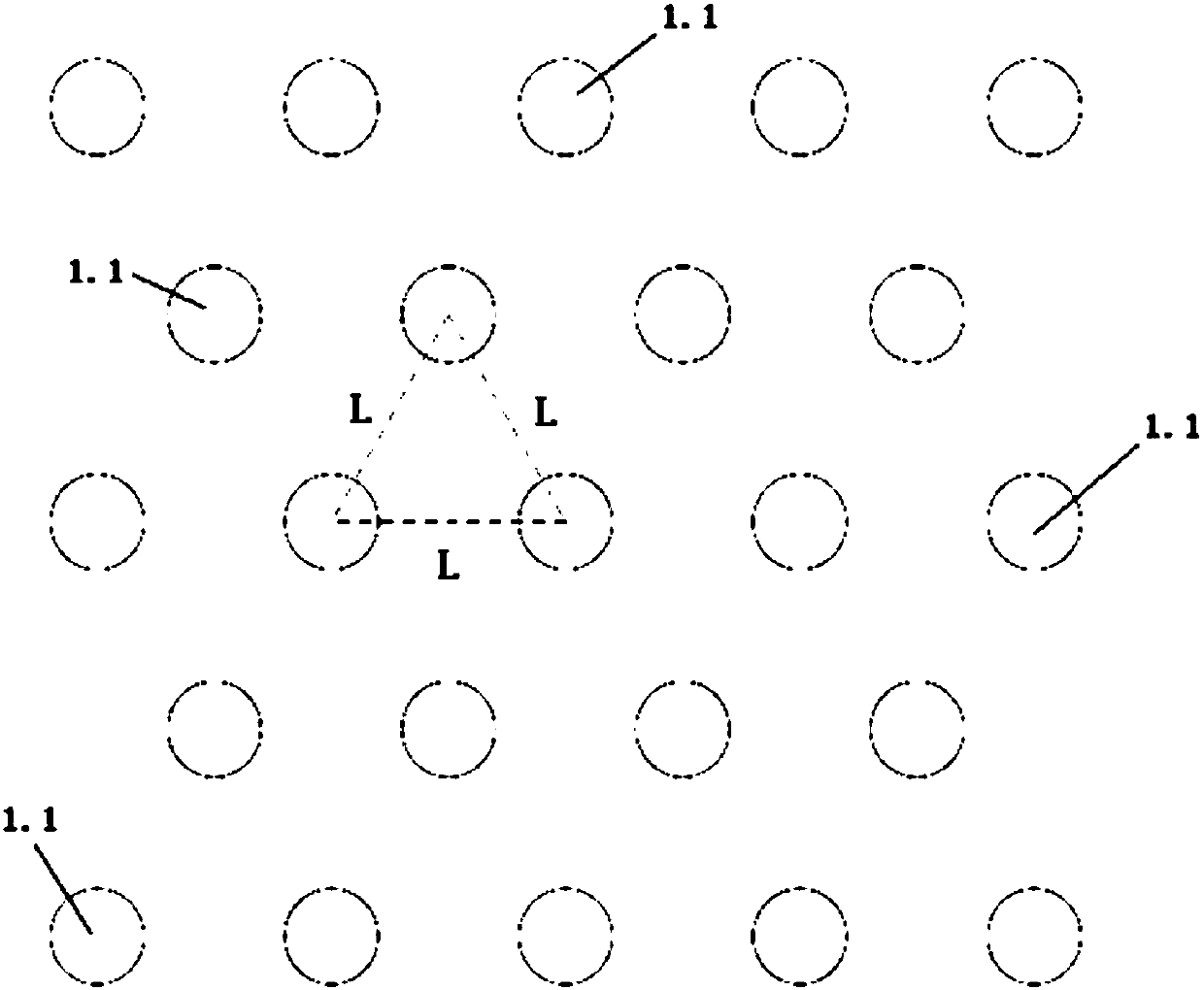

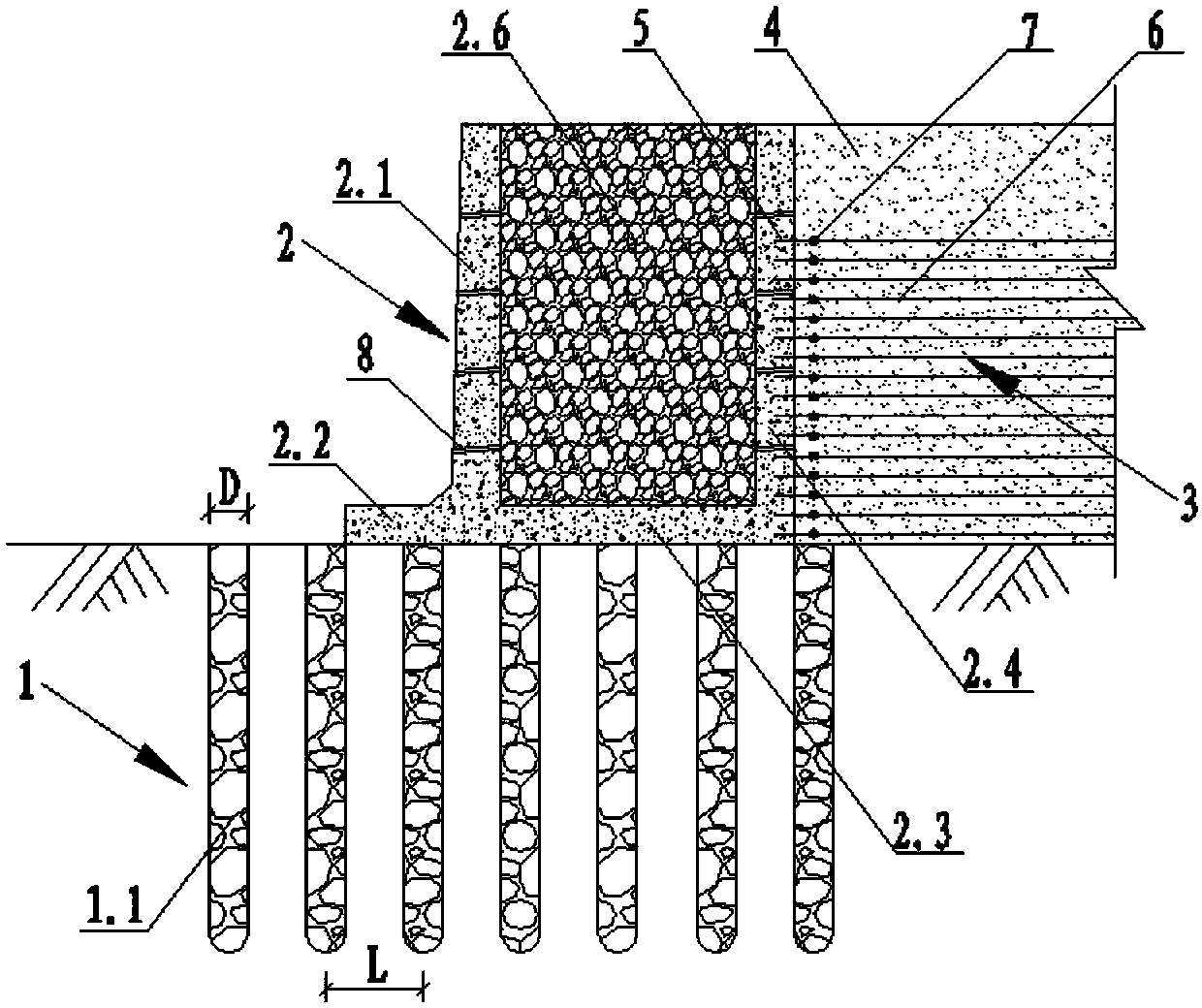

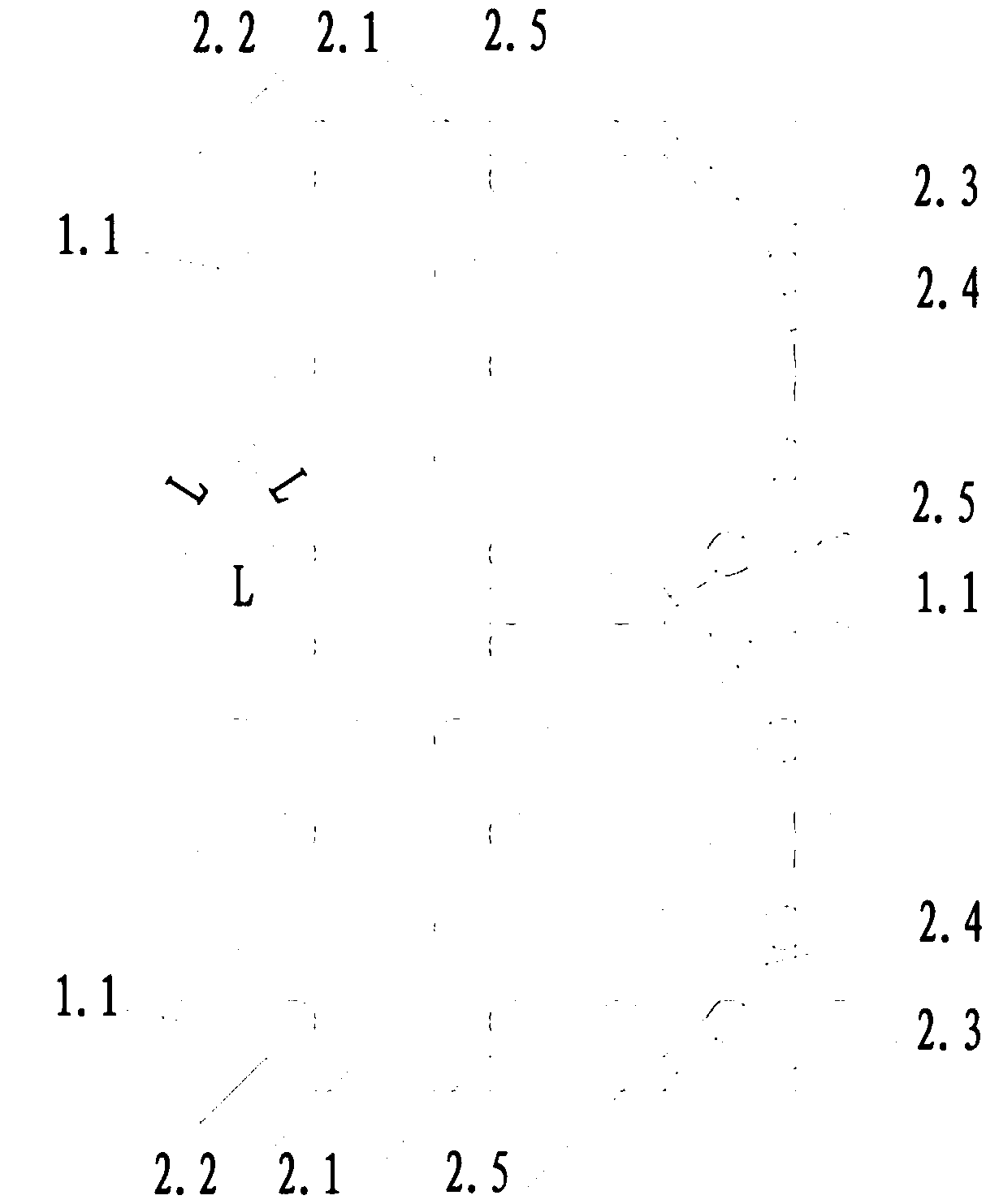

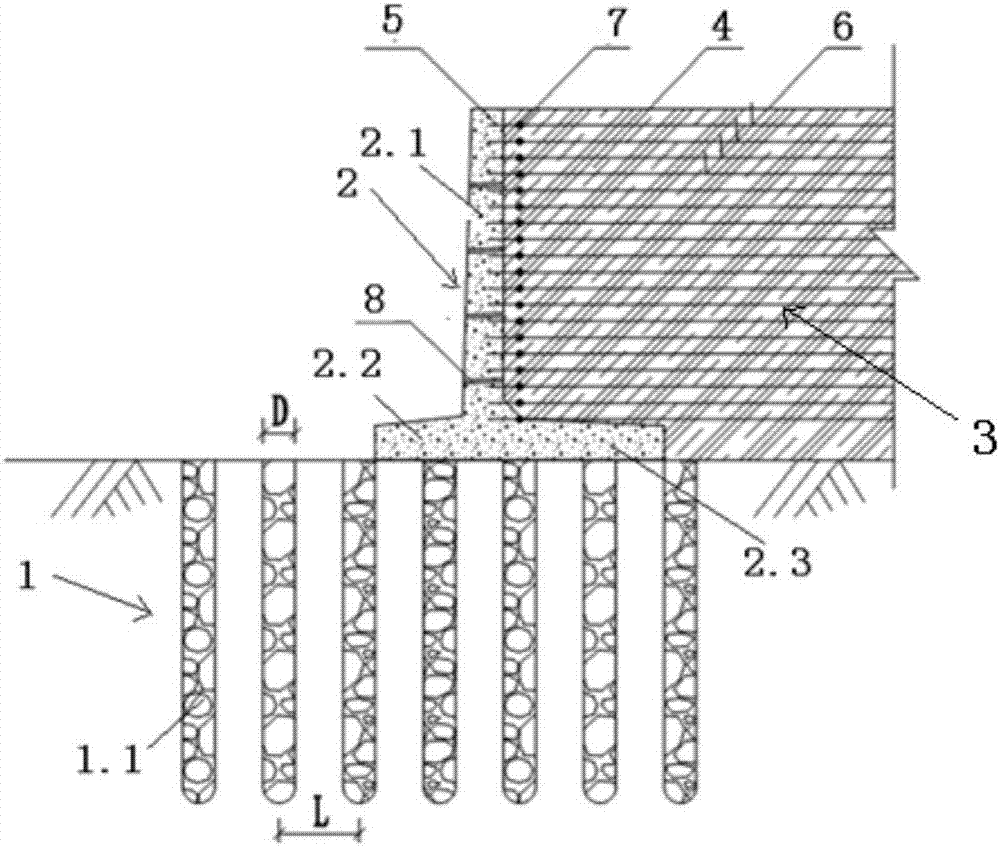

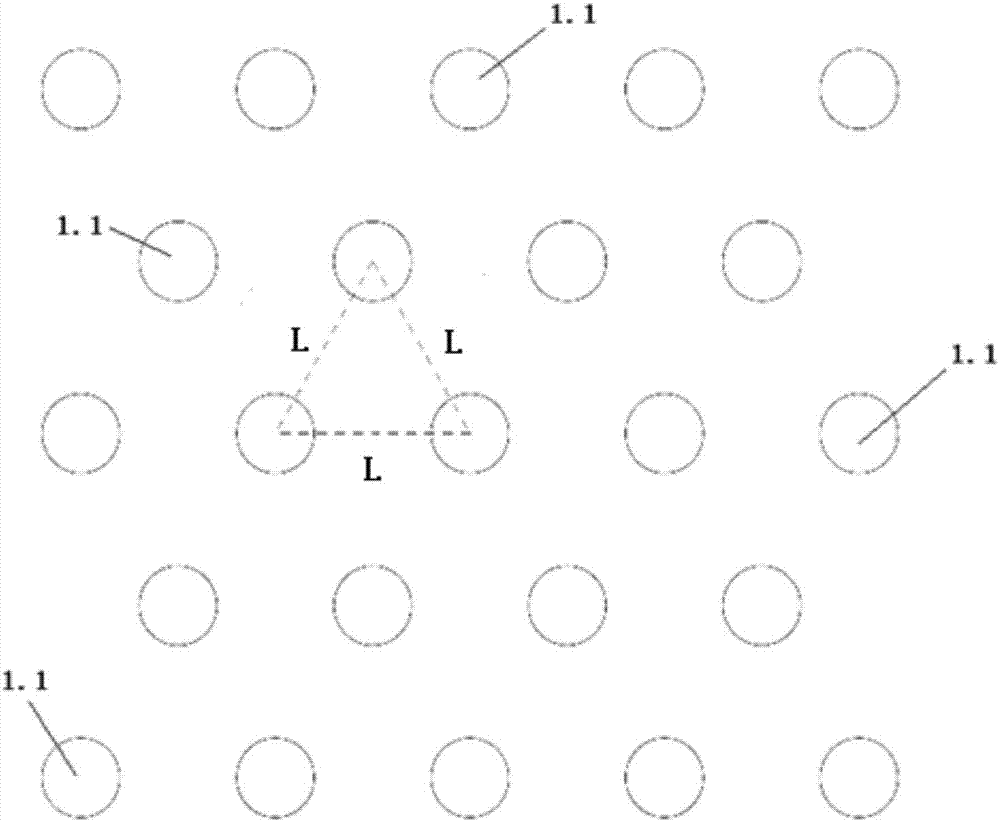

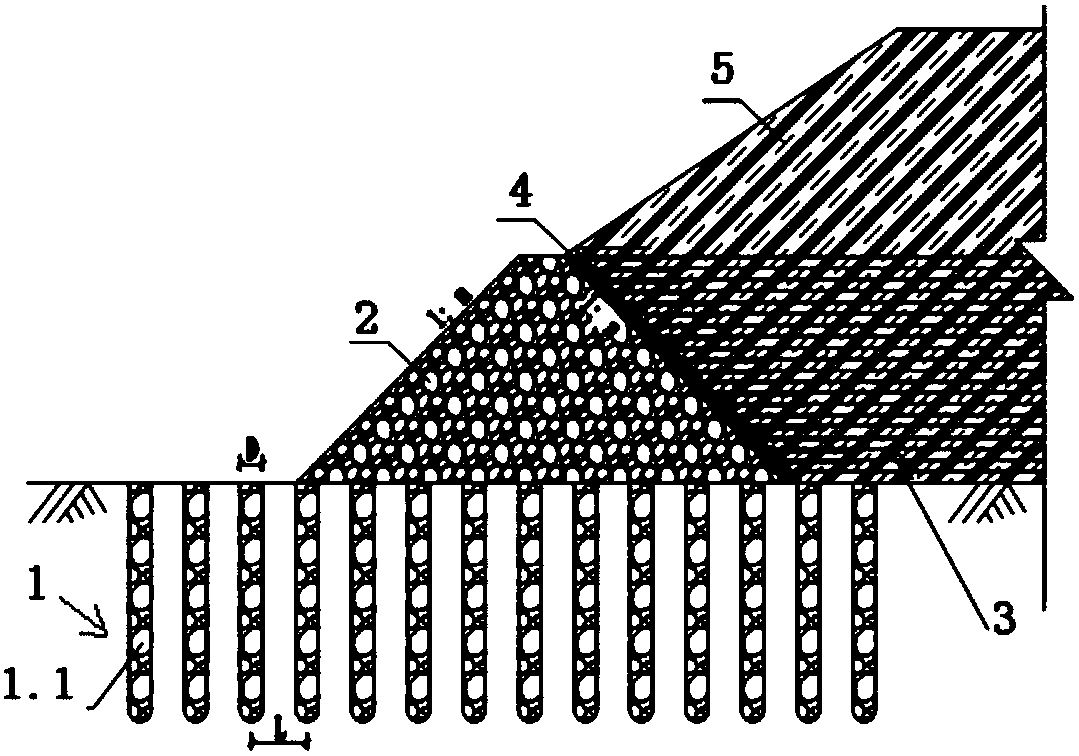

Retaining wall structure with composite foundation and reinforced gabions and construction method

The invention discloses a retaining wall structure with a composite foundation and reinforced gabions and a construction method. The retaining wall structure is composed of the composite foundation (1), the multiple reinforced gabions (2), a geogrid (3), inverted filter layers (4) and filling bodies (5). The composite foundation (1) is located underground and composed of a plurality of vibration blunt gravel piles (1.1), the multiple reinforced gabions (2) are stacked on the upper portion of the composite foundation (1), the filling bodies (5) are arranged on the inner sides of the reinforcedgabions (2), and the geogrid (3) is arranged on the lower portions of the filling bodies (5). The inverted filter layers (4) are arranged between the reinforced gabions (2) and the filling bodies (5).According to the retaining wall structure and the construction method, the defects that in the prior art, the bearing capacity of a foundation is low, and a retaining wall and filling bodies behind the wall greatly deform accordingly and are even instable to be damaged are overcome, and the retaining wall structure and the construction method have the advantages that construction is easy and convenient, the construction speed is high, and the wall body manufacturing cost is low.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

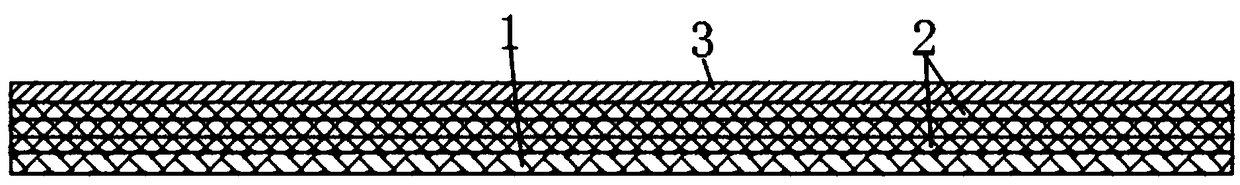

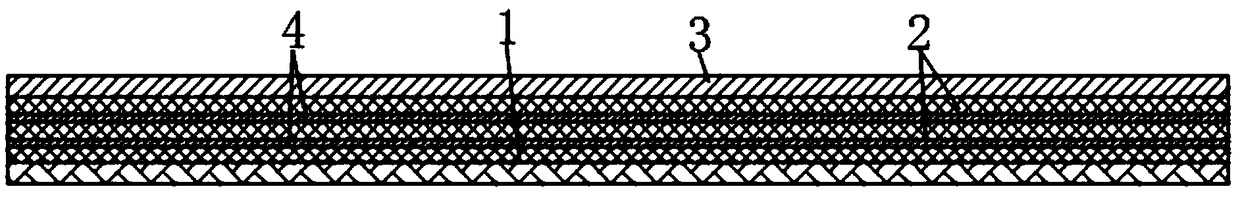

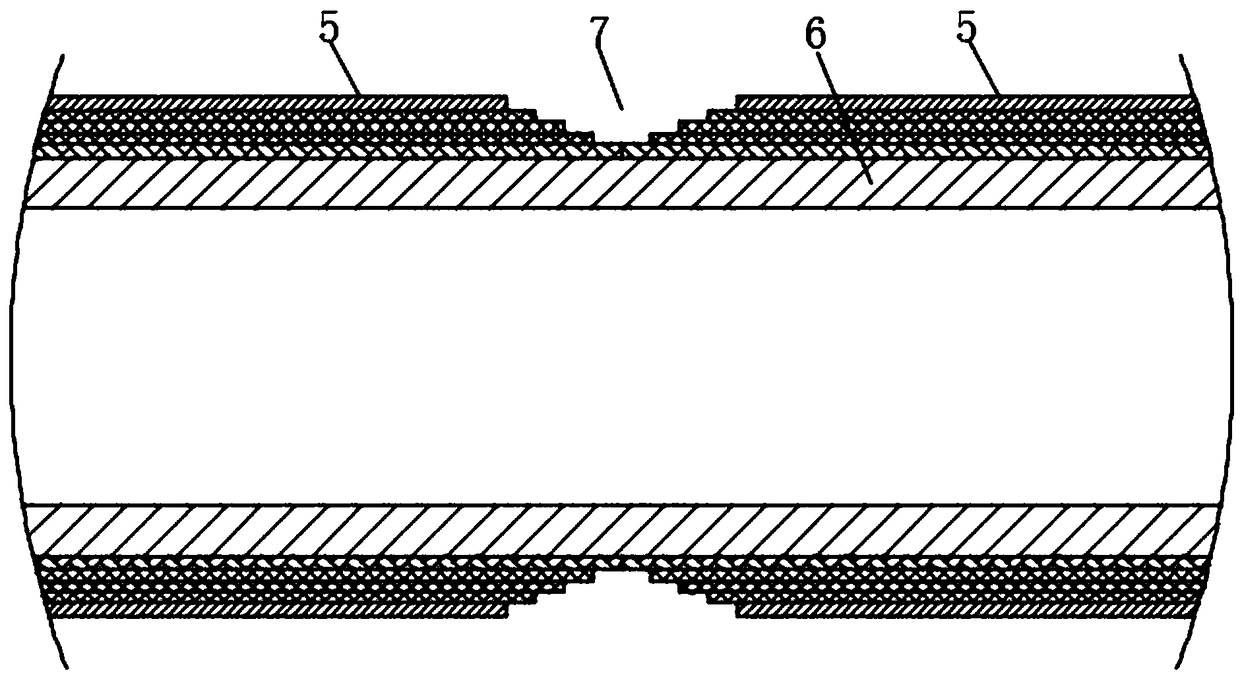

Aerogel insulation and protection integrated product and construction method of using the same to wrap pipe

InactiveCN108980525ASimple structureGood heat insulationThermal insulationLaminationArchitectural engineeringAerogel

The invention relates to an aerogel insulation and protection integrated product and a construction method of wrapping pipes. The aerogel insulation and protection integrated product comprises an inner liner, an aerogel layer and a bendable protective layer which are sequentially bonded from inside to outside. The construction method includes the steps of making pipe-wrapping slices, wrapping thepipes, making seam covering sheets and covering the seams. The aerogel insulation and protection integrated product has the advantages of simple structure, and good heat insulation and protection; theconstruction method has the advantages of convenient and fast construction, high construction efficiency and low cost.

Owner:SHENZHEN AEROGEL TECH CO LTD

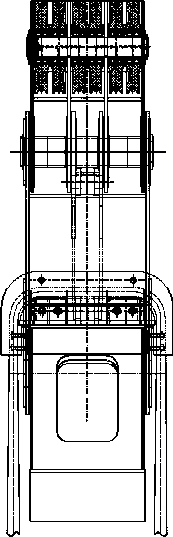

Screeding machine

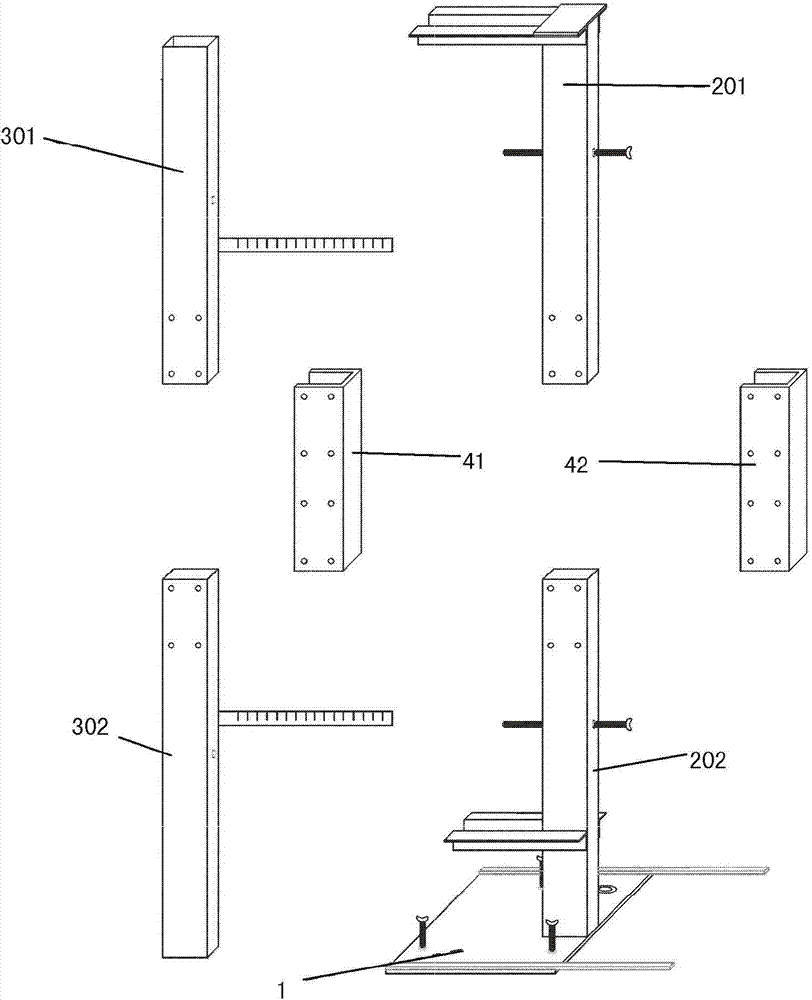

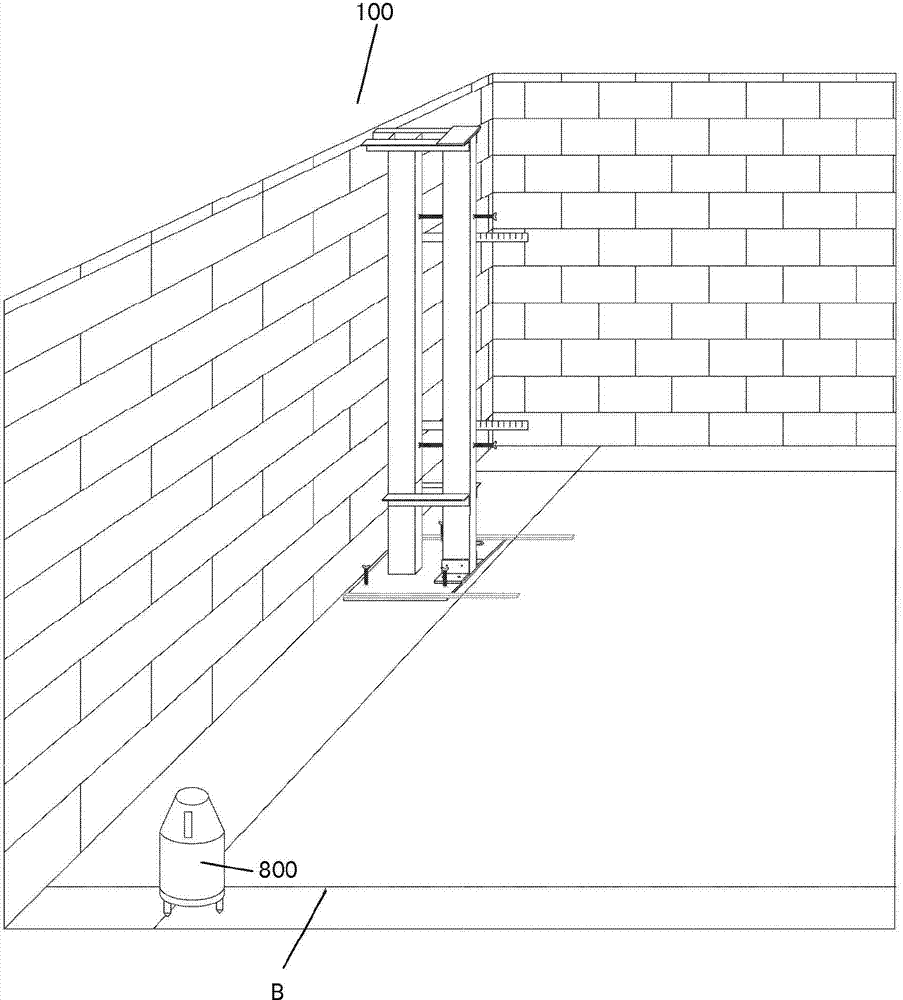

InactiveCN104514358ASimplify the construction processFast construction processBuilding constructionsHorizonEngineering

The invention discloses a screeding machine. The screeding machine is characterized by comprising a bottom plate, a fixed tubular product and a movable tubular product, wherein the bottom plate is provided with a horizon adjusting device and a length measuring tool; the fixed tubular product and movable tubular product are vertically arranged at the bottom plate, the upside and downside of the fixed tubular product are connected with the movable tubular product through horizontal adjusting devices, a telescopic measuring tool is arranged at each of the upper and lower ends of the movable tubular product, and the telescopic measuring tools are vertical to the movable tubular product. The screeding machine does not require high technology, and the screeding construction flow is easy and convenient to perform. The screeding machine omits a step of preparing a cement block and avoids accumulated error, the perpendicularity and flatness of the cement ribs of the wall are easy to unify, and the construction efficiency and quality are obviously improved.

Owner:王凯

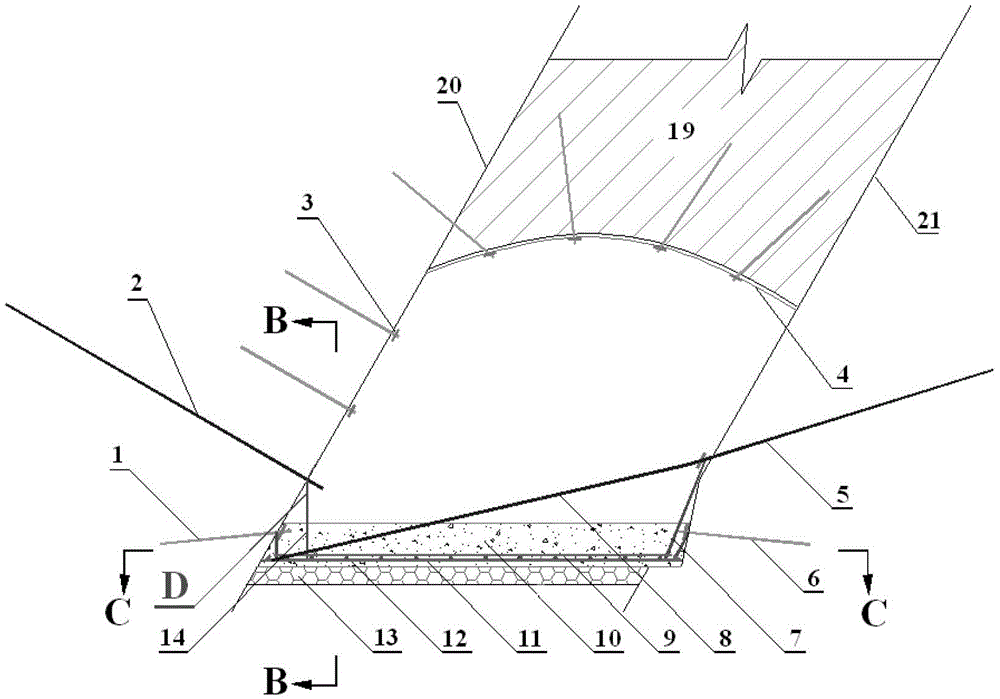

Composite foundation reinforced arch box retaining wall structure and construction method

PendingCN109653242ALow costSimple construction processArtificial islandsUnderwater structuresReinforced concreteCrushed stone

The invention relates to the technical field of retaining wall projects, in particular to a composite foundation reinforced arch box retaining wall structure and a construction method. The composite foundation reinforced arch box retaining wall structure comprises a composite foundation, an arch box retaining wall, a geogrid and a filling body, wherein the composite foundation is positioned belowthe ground and comprises a plurality of vibration crushed stone piles, the arch box retaining wall is positioned on the composite foundation, the filling body is arranged on the right side of a rear arch wall of the arch box retaining wall, and the geogrid is horizontally arranged in the filling body. A spongy soil foundation and a deep overburden foundation are reinforced by a vibro-replacement method, a wall body is provided with an arch box reinforced concrete structure, the geogrid is added into the filling body on the rear side of the retaining wall and connected with the rear arch wall,integrity and deformation resistance of the retaining wall and reinforcement can be improved, and the applicable wall height of the arch box retaining wall can be increased, so that project requirements are met.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

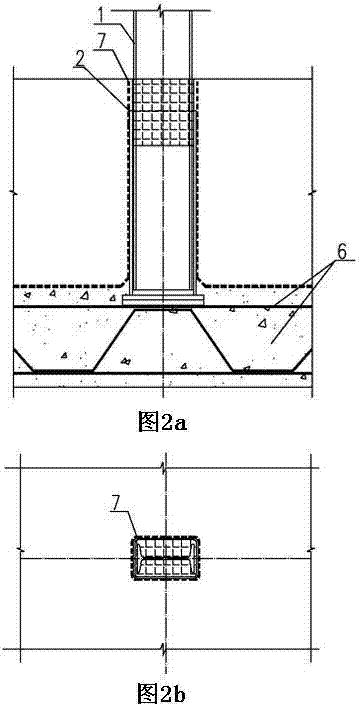

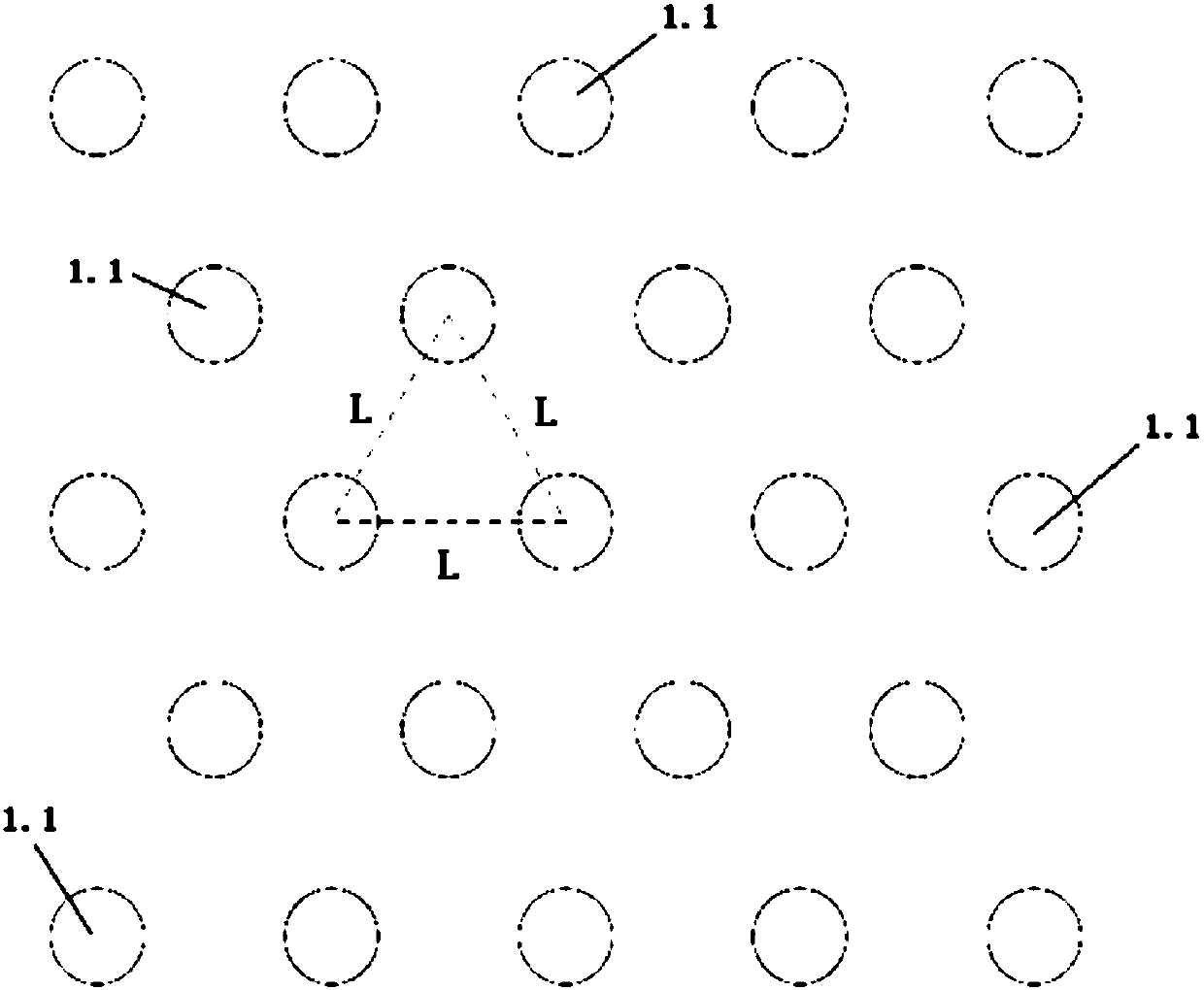

Composite foundation reinforced cantilever retaining wall structure and construction method thereof

PendingCN107514008ALow costReduce earth pressureArtificial islandsUnderwater structuresCrushed stoneEngineering

The invention discloses a composite foundation reinforced cantilever retaining wall structure and a construction method of the composite foundation reinforced cantilever retaining wall structure. The composite foundation reinforced cantilever retaining wall structure comprises a composite foundation (1), a cantilever retaining wall (2), a geogrid (3) and a filling body (4). The composite foundation (1) is located underground and composed of multiple vibro-replacement crushed stone piles (1.1). The cantilever retaining wall (2) is located above the composite foundation (1). The inner side of the cantilever retaining wall (2) is provided with the filling body (4). The geogrid (3) is transversely arranged on the lower portion of the filling body (4). The composite foundation reinforced cantilever retaining wall structure overcomes the defects that in the prior art, a traditional cantilever retaining wall structure cannot meet the stability requirements of the cantilever retaining wall structure and the filling body behind the wall and has the advantages that the construction technology is simple, convenient and rapid.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

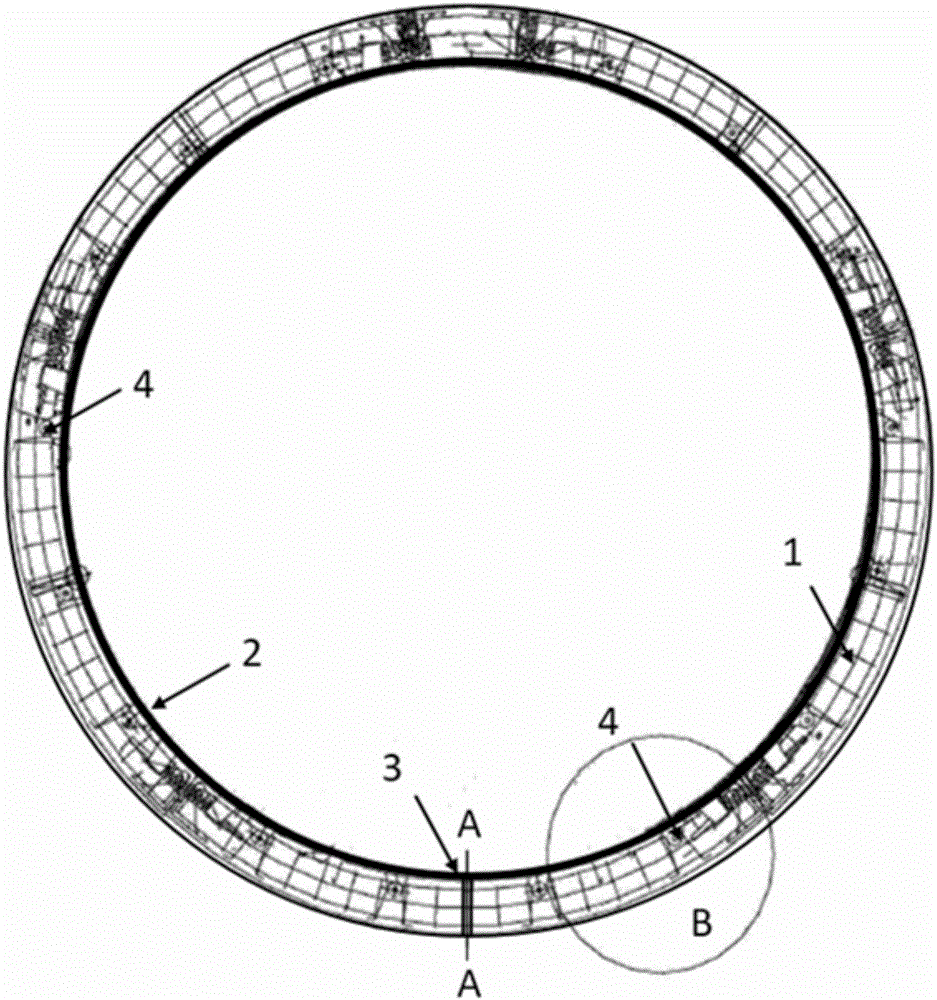

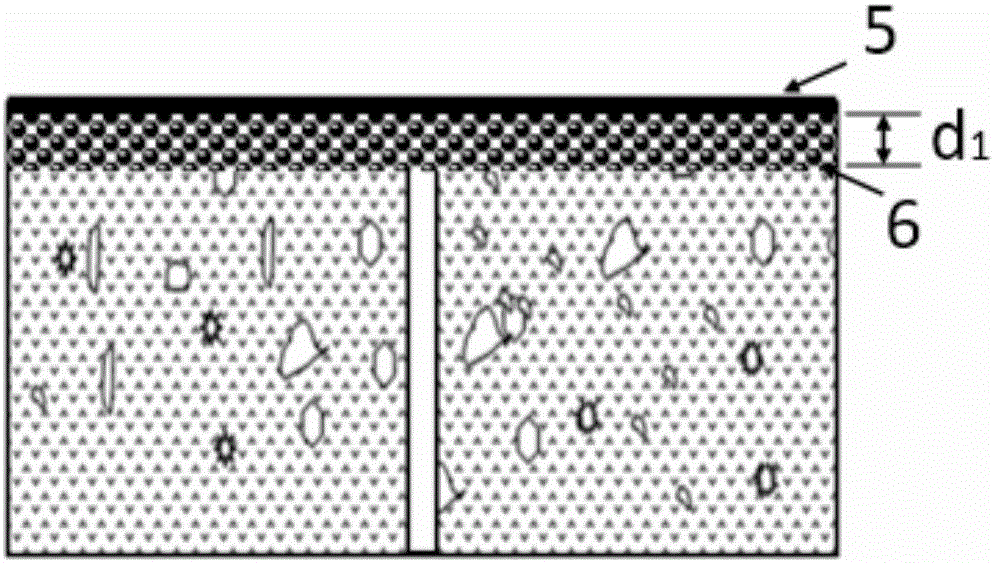

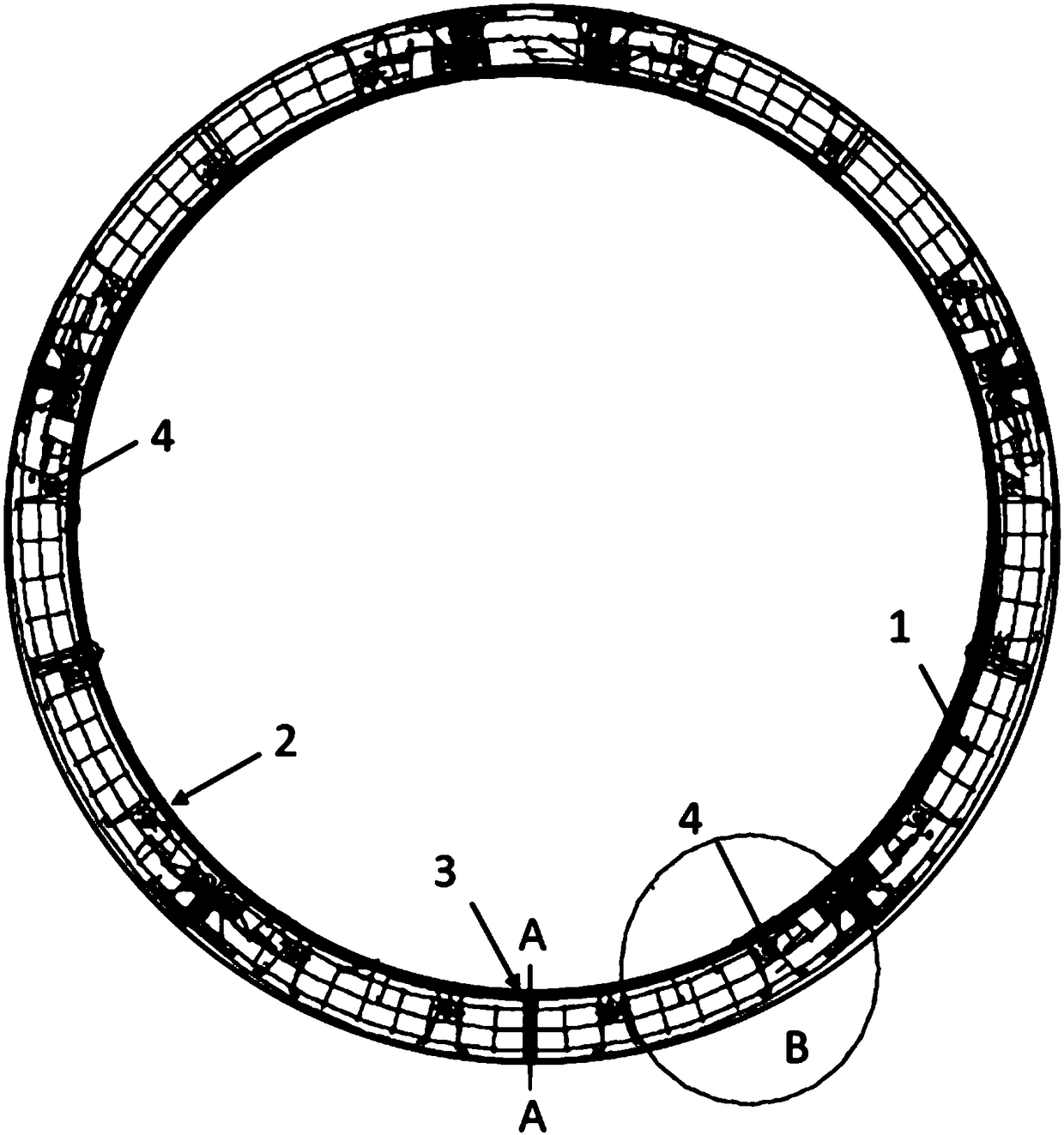

Construction method based on shield method for anti-seepage anticorrosion sewage pipe segment lining

The invention relates to a construction method based on a shield method for an anti-seepage anticorrosion sewage pipe segment lining. The method comprises the following steps that (a) holes in shield segments and gaps between the segments are blocked through epoxy resin; (b) the inner cambered faces of the shield segments are polished to expose inner pores of the shield segments; and (c) polyaniline / epoxy resin mixed coating is sprayed on the inner cambered faces of the shield segments and cured to form protecting coatings. Through the construction steps of epoxy resin blocking, shield segment inner cambered face polishing and protecting coating forming through curing, the construction process is more economical, simpler and rapider, the effective utilized area in pipes is increased, flow resistance of the coatings to sewage is smaller, and the pollution discharge speed is increased. In addition, the protecting coatings have excellent film-forming performance and corrosion resistance and can effectively resist corrosion of acid, alkali and salts in the sewage pipes to the reinforced concrete segments.

Owner:HOHAI UNIV

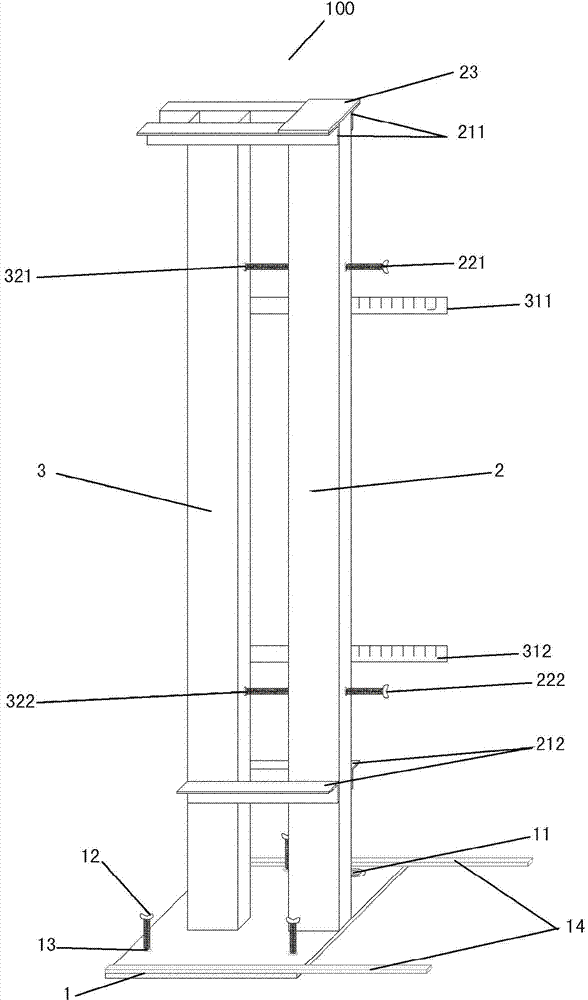

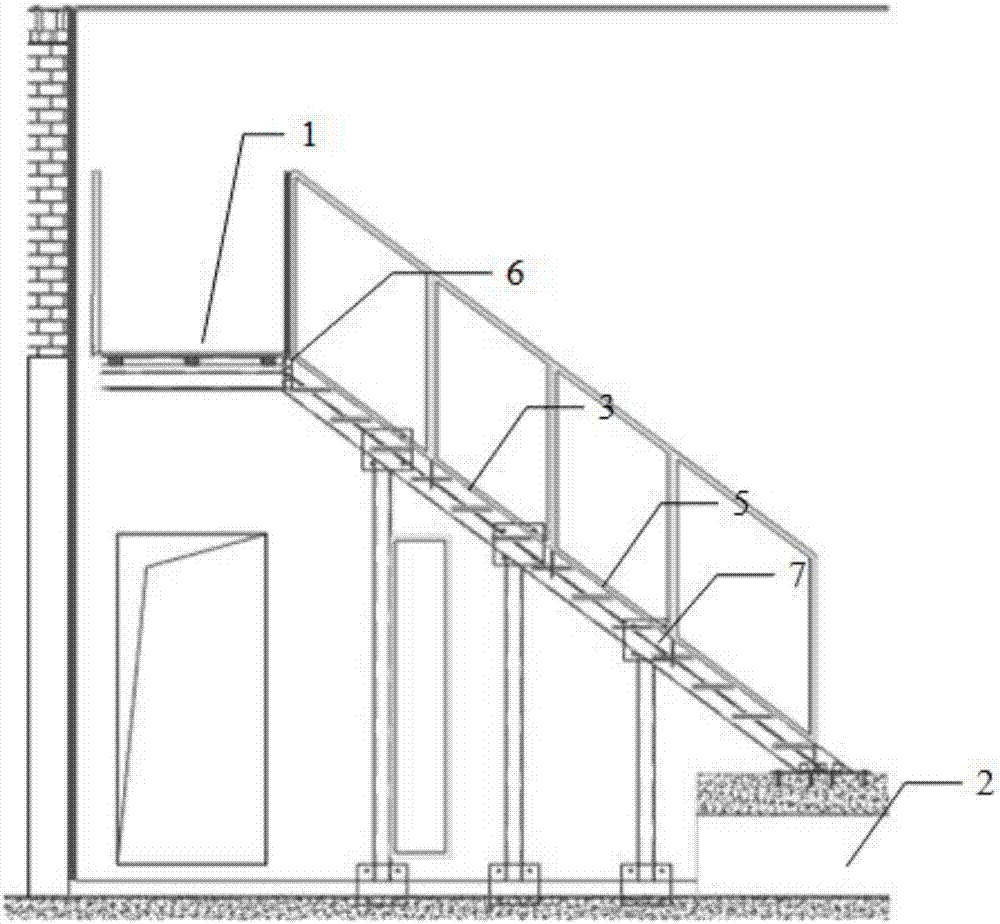

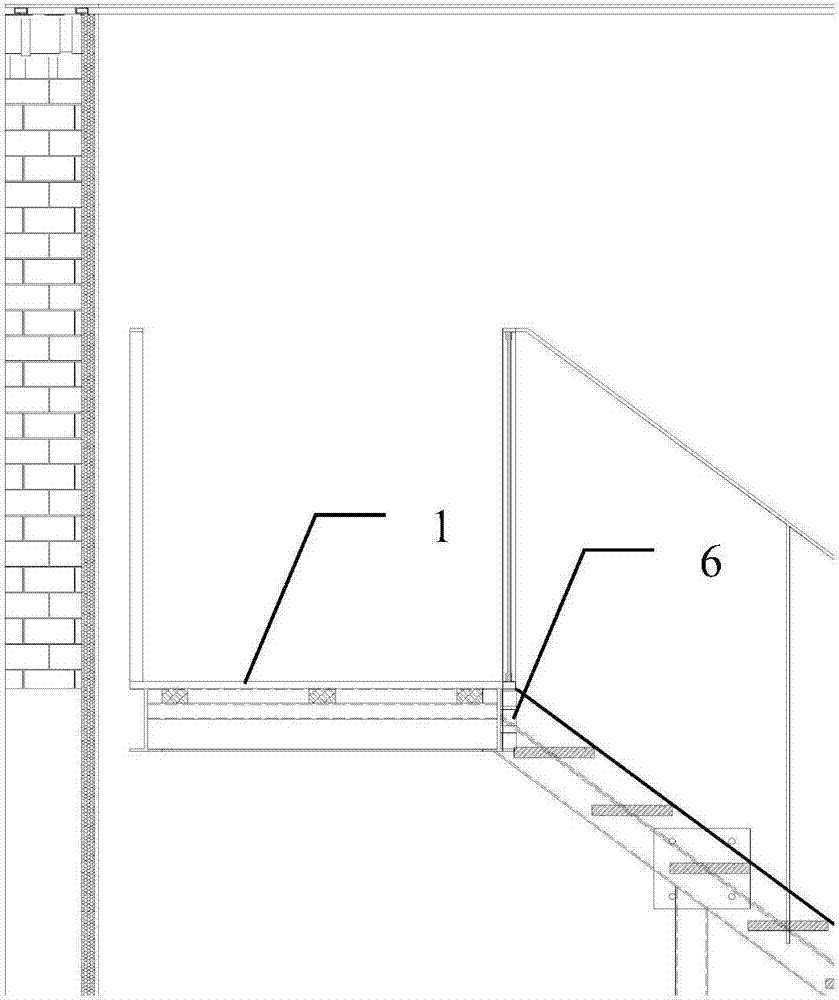

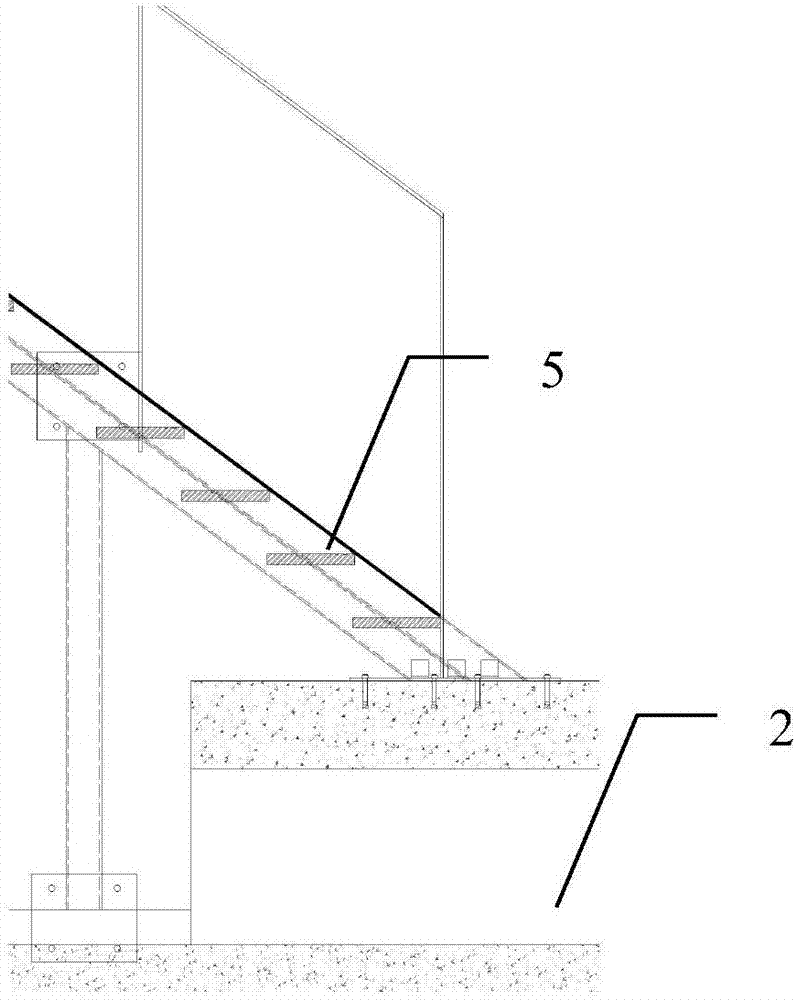

Simple steel staircase

The invention provides a simple steel staircase, which comprises four parts: a fulcrum structure, a main keel of the staircase, a reinforcement structure of the main keel of the staircase and steel plate steps of the staircase. The invention solves key problems such as fixing the fulcrum of the stair keel, mechanical interpretation and force transformation, so that the overall state of the stair can be optimized, so as to achieve the most basic structural safety and the most important aesthetic effect.

Owner:SHANDONG TIANYUAN DECORATION ENG

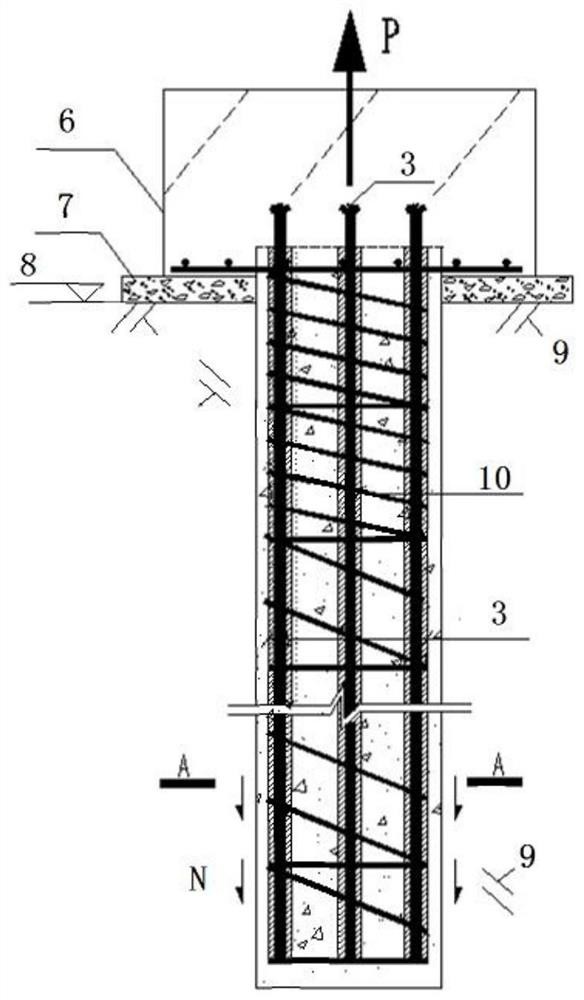

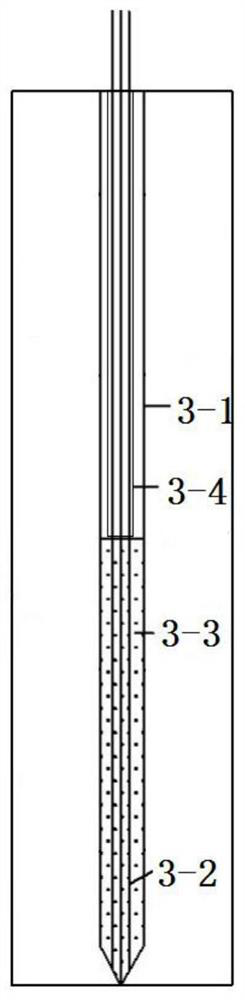

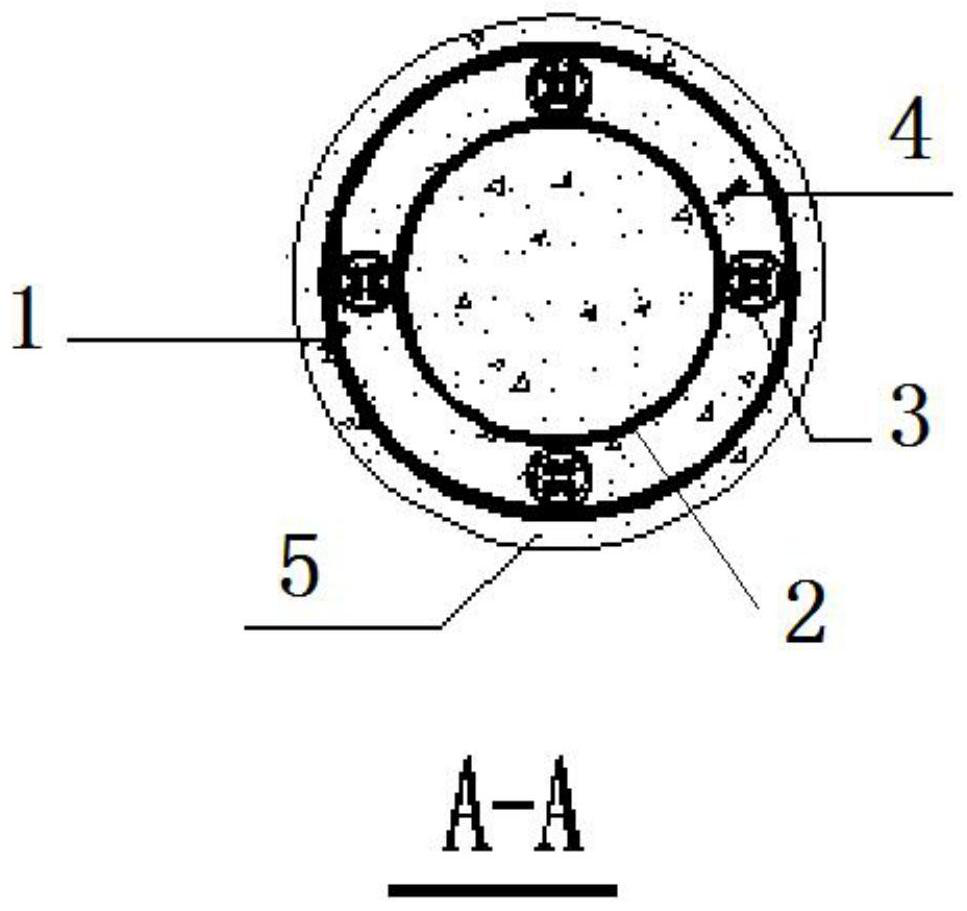

Prestressed post-inserted composite anchor cable uplift pile and preparation method thereof

The invention belongs to the field of underground construction, and particularly relates to a prestressed post-inserted composite anchor cable uplift pile and a preparation method thereof. The upliftpile comprises an uplift pile composite reinforcement cage, a composite anchor cable and a filler, wherein the uplift pile composite reinforcement cage comprises an uplift pile cage outer wall and anuplift pile cage inner wall; the composite anchor cable is arranged between the uplift pile cage outer wall and the uplift pile cage inner wall, and consists of an isolation body and an uplift anchorcable arranged in the isolation body; the isolation body isolates a corrosive from the uplift anchor cable; and a steel plate anchoring end is arranged at the lowermost side, and is connected with theisolation body. The uplift pile has the advantages of good overall performance, high bearing capacity, no mud pollution, low manufacturing cost, corrosion resistance and high construction speed; andthe upper part of a pile body is always located in a pressed state to prevent cracks.

Owner:CHINA BUILDING TECHN GROUP +1

Quick and low-cost artificial fake roof construction method for ground mine

ActiveCN103291305BImprove carrying capacityReduce construction costsUnderground miningSurface miningReinforced concreteStructure of the Earth

The invention discloses a quick and low-cost artificial fake roof construction method for a ground mine. Under an extreme smashing and exploring condition of ore rocks, an artificial fake roof is pre-constructed to form a safe protection layer by using a downward cemented filling mining method; according to an actual situation of the mine, under the combination of a cable-stayed bearing theory, a plate block theory and the like, a high-intensity plate block structure integrated with an anchor rope, an anchor rod and steel bar concrete is obtained; a safe and economical artificial fake roof structure is supplied to subsequent mining. Compared with the conventional artificial fake roof construction method, the quick and low-cost artificial fake roof construction method disclosed by the invention has the outstanding advantages of science, rationality, high bearing capacity, low construction cost, safety and reliability in use, quick construction technology, high efficiency and the like.

Owner:贵州开磷设计研究院有限责任公司 +1

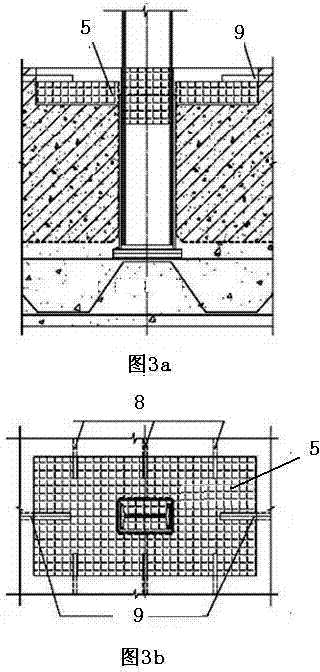

Ribbed rockfill retaining wall structure with compound foundation and construction method thereof

PendingCN107558490AEasy constructionFast constructionArtificial islandsUnderwater structuresEngineeringRetaining wall

The invention discloses a ribbed rockfill retaining wall structure with a compound foundation and a construction method thereof. The ribbed rockfill retaining wall structure comprises the compound foundation (1), a rockfill retaining wall (2), a geogrid (3), a reverse filtering layer (4) and a filling body (5), wherein the compound foundation (1) is located underground and composed of a pluralityof vibroflotation crushed stone piles (1.1); the rockfill retaining wall (2) is located above the compound foundation (1); the filling body (5) is arranged on the inner side of the rockfill retainingwall (2); the geogrid (3) is arranged on the lower portion of the filling body (5); and the reverse filtering layer (4) is arranged between the rockfill retaining wall (2) and the geogrid (3). By means of the ribbed rockfill retaining wall structure with the compound foundation and the construction method, the defect that a traditional retaining wall structure cannot meet the stability requirementof the retaining wall structure and a filling body behind a retaining wall in the prior art is overcome, and the ribbed rockfill retaining wall structure with the compound foundation and the construction method have the advantages of easy and convenient construction, high construction speed and low wall manufacturing cost.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

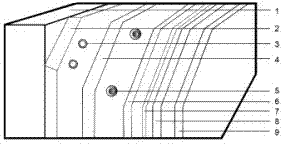

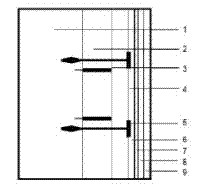

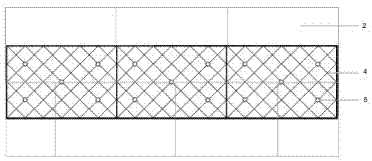

Thermal insulation structure for building

InactiveCN104775531AHigh tensile strengthImprove stabilityClimate change adaptationHeat proofingThermal insulationSlurry

The invention relates to a thermal insulation structure for a building and a construction technology. The construction technology comprises the steps that an insulating layer is nailed to a wall body basic layer, then a special reinforcing grid is supported by preset special buckles, the special reinforcing grid is pressed on and covers the insulating layer through the assisting of expansion anchor bolts, and the special reinforcing grid and the insulating layer are fixed to the wall body basic layer, so that all the loads of the insulating layer and the externally-hung special reinforcing grid are completely borne by the expansion anchor bolts and transmitted to the wall body basic layer; and scraping operation, covering operation and leveling operation are conducted on the externally-hung special reinforcing grid through thermal-insulating particle slurry. The thermal insulation structure for the building and the construction technology can effectively solve the technical problems that combination between a conventional exterior wall external insulation system and a basic layer wall body is poor, water seepage easily happens, and surface treatment is difficult. In addition, due to the fact that various materials adopted by the thermal insulation structure for the building and the construction technology are incombustible materials with the fireproof grade higher than A, the fire prevention hidden danger of a conventional exterior wall external insulation material is eliminated.

Owner:北京泰瑞通和科技有限公司

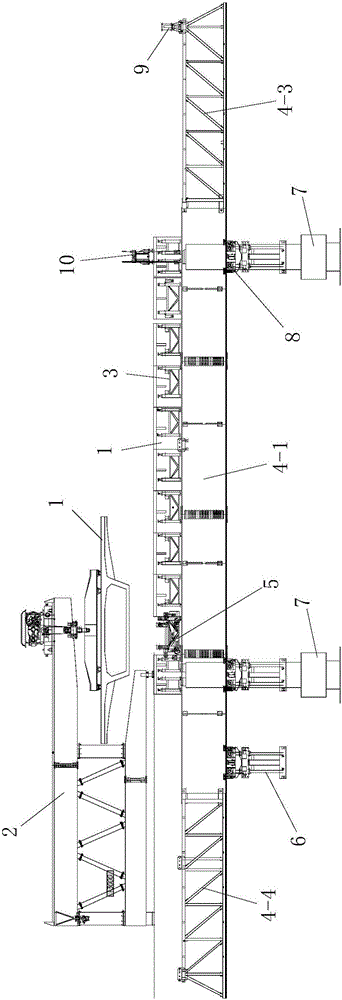

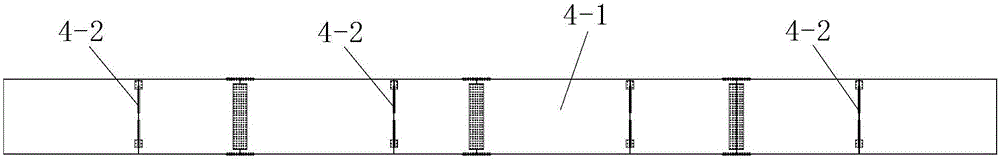

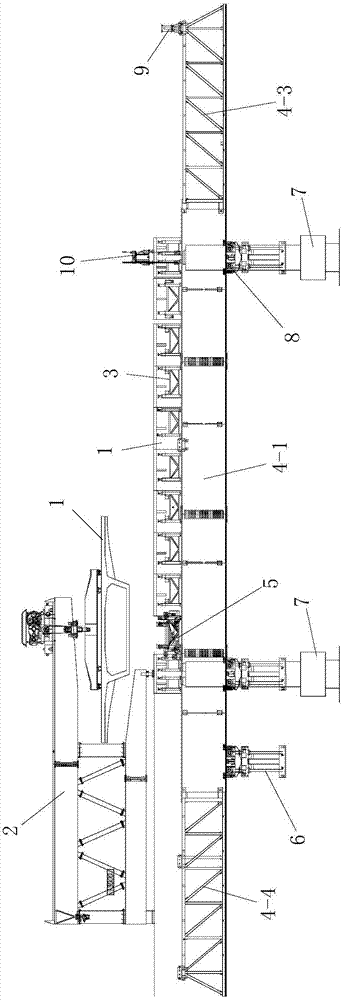

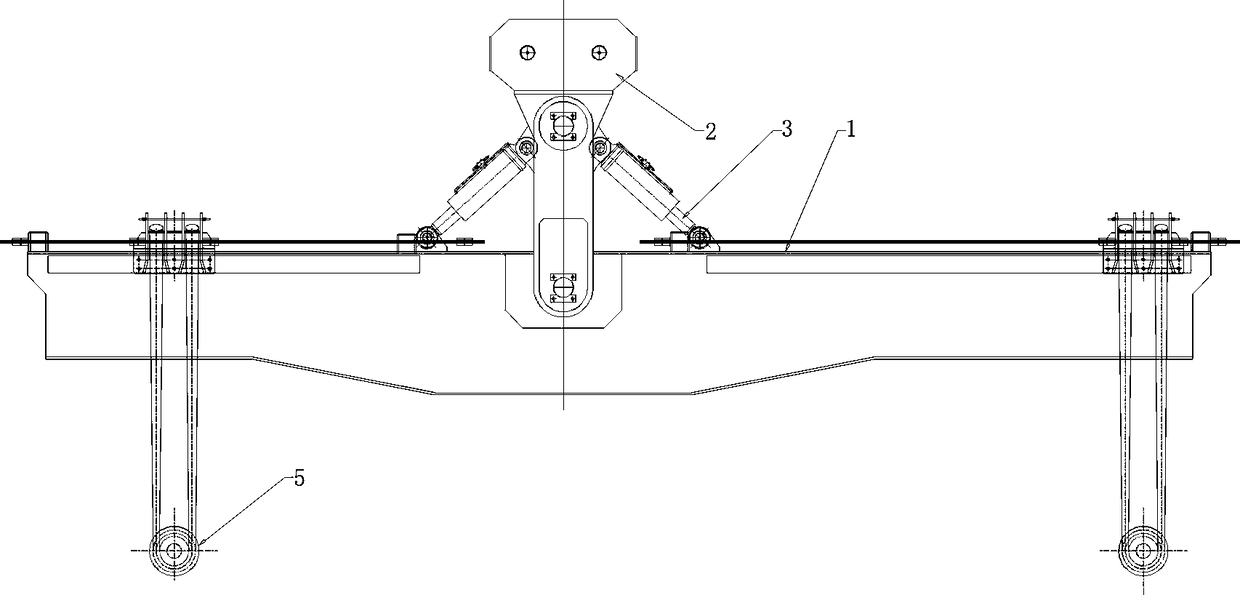

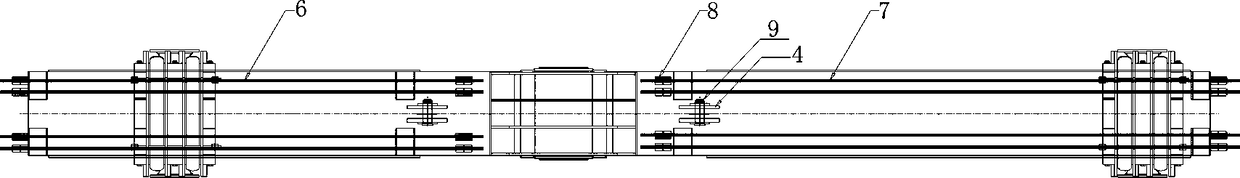

Segment splicing box girder erection and construction technology based on descending bridge girder erection machine

ActiveCN105839548AThe process steps are simpleReasonable designBridge erection/assemblySupporting systemCantilever

The invention discloses a segment splicing box girder erection and construction technology based on a descending bridge girder erection machine. The descending bridge girder erection machine is adopted for erecting and constructing a constructed box girder. The descending bridge girder erection machine comprises a bottom horizontal supporting system, a main girder system, a longitudinally-moving system, a cantilever crane, a splicing frame and a splicing trolley. When the constructed box girder is erected and constructed, each hole girder of the constructed box girder is erected and constructed from rear to front in the longitudinal bridge direction. The process includes the following steps that firstly, the first hole girder is erected and constructed, wherein a main structure of the bridge girder erection machine is installed, and box girder segments are lifted and spliced; secondly, the next hole girder is erected and constructed, wherein the main structure of the bridge girder erection machine is moved forwards to stride a hole, the cantilever crane is moved forwards, and the box girder segments are lifted and spliced; and thirdly, the second step is repeated till the process of erection and construction of the constructed box girder are finished. By the adoption of the technology, the technological steps are simple, design is reasonable, construction is easy and convenient, the construction process is easy to control, a use effect is good, the box girder erection and construction process can be easily, conveniently and rapidly completed, and the construction quality is easy to guarantee.

Owner:CHINA RAILWAY FIRST GRP CO LTD

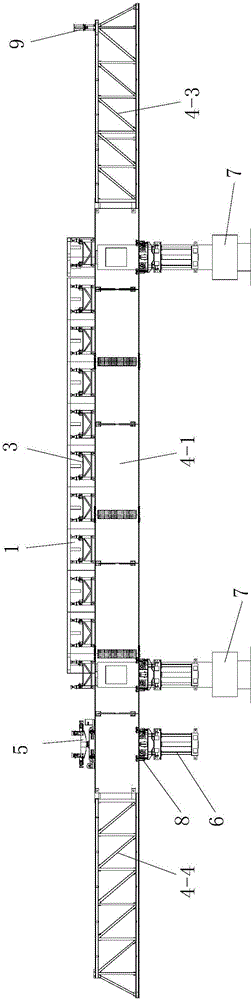

Construction process for reclamation by hydraulic filling of silt and device thereof

The invention discloses a construction process for the reclamation by the hydraulic filling of silt and a device thereof. The device comprises a solidification treatment system A and a paving system B for improved slurry, wherein the A comprises a pumping device, an impurity screening device, a solidification agent storage device, a solidification agent conveying device, a compressed air conveying device and a mixed slurry stirring and conveying device; the B comprises a connecting pipe section, a hose or belt conveyer and a bearing and moving device. The construction flow comprises the following steps of: (1) filling the silt slurry into a filling region or sedimentation tank so as to form a stacked layer of thick silt slurry; (2) pumping the thick silt slurry with the pumping device, conveying the solidification agent into the thick silt slurry at the same time, and mixing the thick silt slurry and the solidification agent in a pipe in front of or behind a pump so as to form the mixed slurry; (3) conveying the mixed slurry to the stirring and conveying device to form the improved slurry; (4) conveying the improved slurry out to the paving system B through the connecting pipe section; and (5) laying the improved slurry to specified thickness by the paving system B. The device is characterized by fast, high-efficiency, simple and convenient operation.

Owner:武汉华荣科技发展有限责任公司

Construction technology of section assembled box girder erection based on descending bridge erecting machine

ActiveCN105839548BThe process steps are simpleReasonable designBridge erection/assemblySupporting systemCantilever

The invention discloses a construction process for segmental assembled box girder erection based on a descending bridge erecting machine. The descending bridge erecting machine is used to erect the constructed box girder. The descending bridge erecting machine includes a bottom horizontal support system, a main girder System, longitudinal moving system, cantilever crane, assembly frame and assembly vehicle; during the construction of the box girder erection facilities, the construction of each hole beam of the constructed box girder is carried out along the longitudinal bridge direction from back to front. The process is as follows: 1. Construction of the first hole beam erection: installation of the main structure of the bridge erecting machine, hoisting of box girder segments and assembly of box girder segments; Second, construction of the next hole beam erection: the main structure of the bridge erecting machine moves forward to cross the hole, the cantilever crane moves forward, Box girder segment hoisting and box girder segment assembly; 3. Repeat step 2 until the erection process of the constructed box girder is completed. The invention has the advantages of simple process steps, reasonable design, convenient construction, easy control of the construction process, good use effect, simple and rapid completion of the box girder erection construction process, and easy guarantee of construction quality.

Owner:CHINA RAILWAY FIRST GRP CO LTD

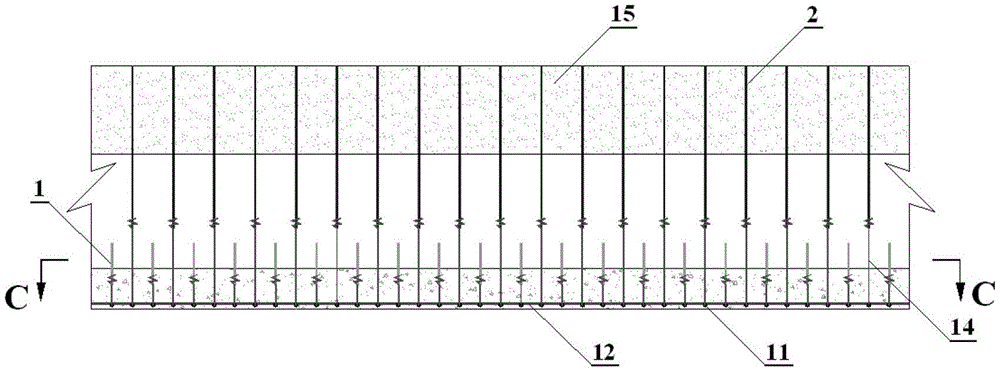

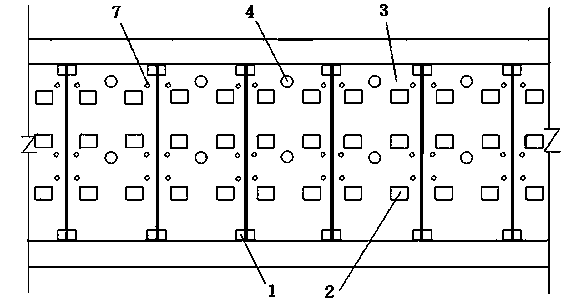

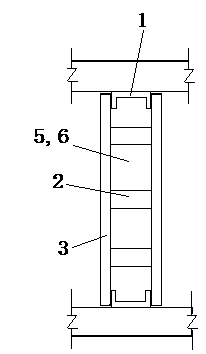

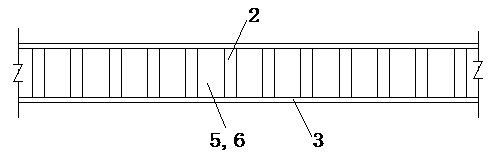

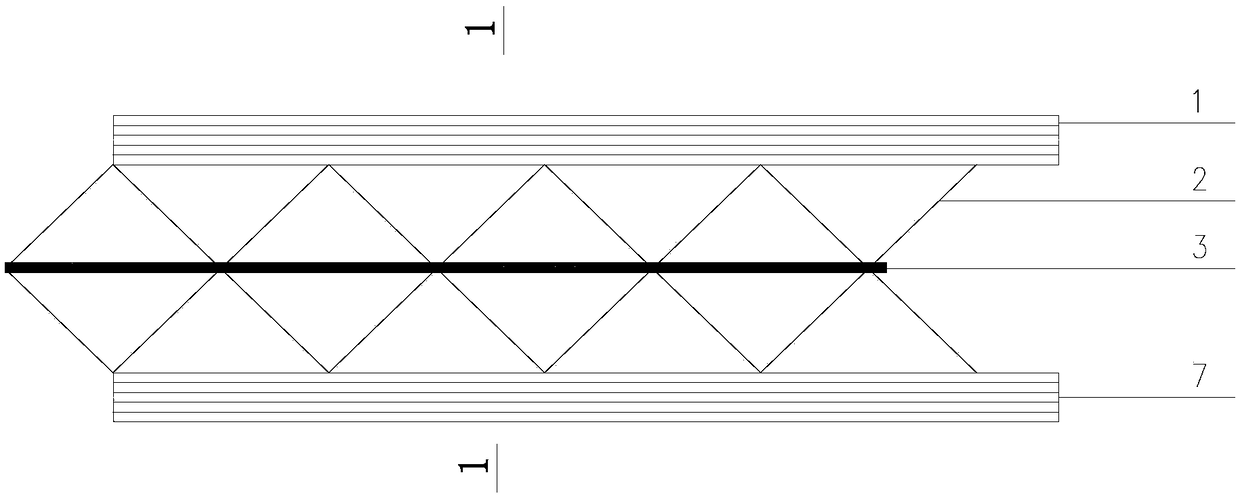

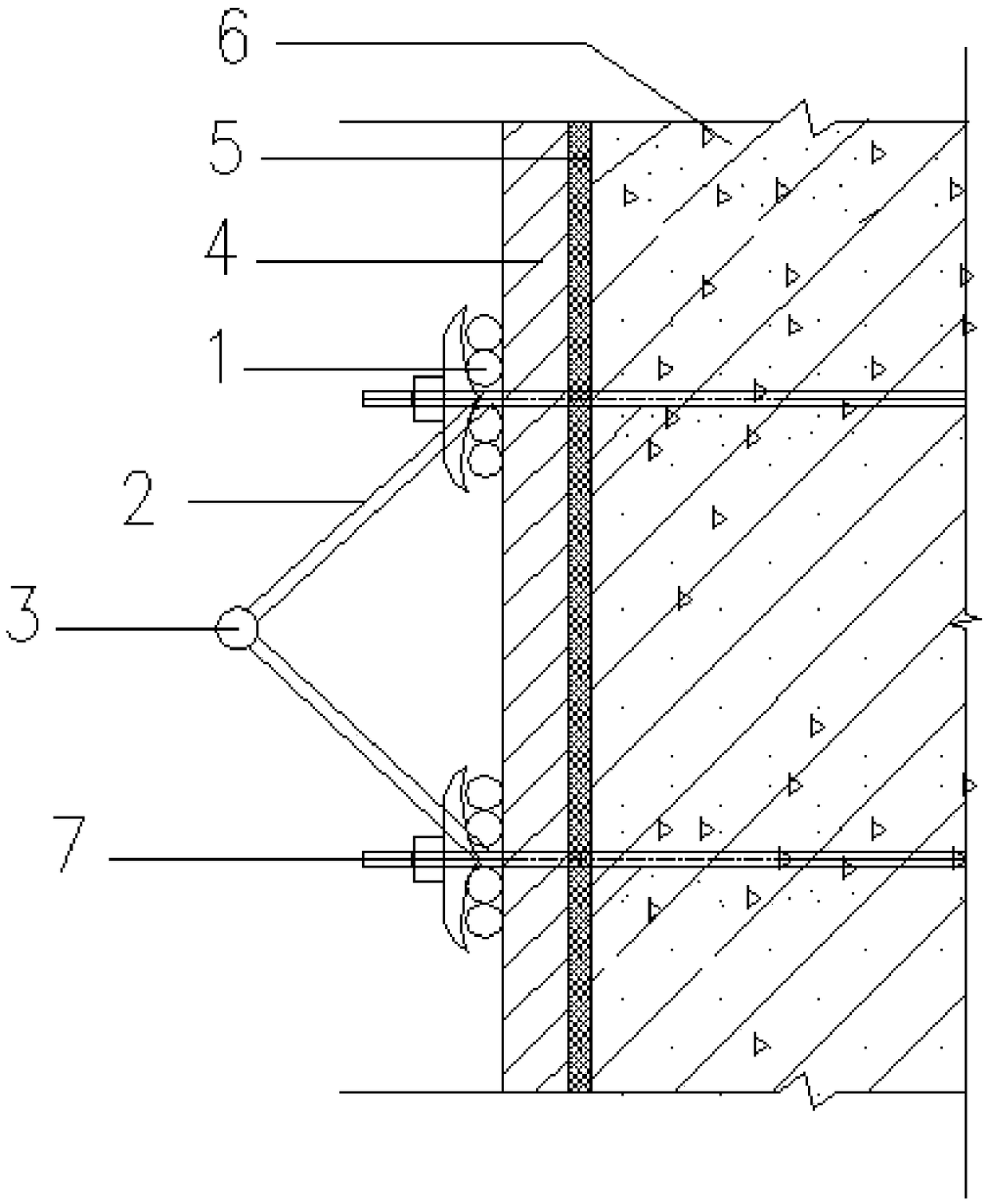

Formwork of self-balancing prefabricated face and cast-in-situ core infilled wall

ActiveCN103590516AImprove wear and tearImprove efficiencyWallsLogistics managementArchitectural engineering

The invention provides a formwork of a self-balancing prefabricated face and cast-in-situ core infilled wall. The formwork comprises positioning keys (1) arranged in the direction of an infilled wall body at intervals. The two sides of each positioning key (1) are prefabricated slabs (3) connected through connection keys (2), each prefabricated slab (3) is provided with a pulling connection hole (7), the middle and the upper end of each prefabricated slab are respectively provided with at least one pouring hole (4), and the outside of each prefabricated slab (3) is provided with a pressure applying device. The formwork has the advantages that materials used for the formwork are prefabricated in a large scale in a factory, requirements for core fillers of the wall body are low, the range of usable materials is wide, logistics cost of the materials is reduced, a construction formwork for wall face prefabrication is eliminated, external construction fixing measures of a cavity mold are eliminated, the construction process is simplified, prefabrication pressure is controllable and adjustable, the comprehensive economy index and the construction period of the formwork are superior to those of the prior art, and defects of the prior art are made up for.

Owner:盐城市双新建设投资有限公司

A construction method of anti-seepage and anti-corrosion sewage pipeline segment lining based on shield method

Owner:HOHAI UNIV

Self-adaptive steel truss girder gravity center and installation inclination angle change hoisting lifting appliance and construction method

PendingCN108275574ACost reduction measuresReduce installation difficultyBridge erection/assemblyLoad-engaging elementsArchitectural engineeringGravity center

The invention discloses a self-adaptive steel truss girder gravity center and installation inclination angle change hoisting lifting appliance and a construction method. The main structure comprises alifting appliance main beam, a movable pulley assembly, an oil cylinder, a fixed base, a suspender assembly, a high-strength finish rolling thread steel A, a high-strength finish rolling thread steelB, a high-strength finish rolling thread steel bar matching nut and a cotter pin; the lifting belt assembly is located on the lifting appliance main beam, and the movable pulley assembly is located on the lifting appliance main beam; the two sides of the movable pulley assembly are correspondingly provided with oil cylinders, the high-strength finish-rolled threaded steel A and the high-strengthfinish-rolled threaded steel B penetrate through the suspender assembly and the corresponding high-strength finish-rolled threaded steel rod matched nut correspondingly. According to the gravity center and the hoisting lifting appliance and the method, after being improved, the change of the center of gravity of the large-section hoisting of the structural object can be effectively applied, the lifting appliance is reduced, the measure cost is reduced, the construction process is simple and rapid, the installation difficulty is reduced, the total construction period is saved, and the measure cost is greatly reduced.

Owner:四川路桥华东建设有限责任公司

Method for repairing overall non-excavation sewage pipe through hot water overturning curing

InactiveCN110671576AThe traffic environment has no effectTraffic environment impactPipe elementsSewageSanitary sewer

The invention discloses a method for repairing an overall non-excavation sewage pipe through hot water overturning curing. The method comprises the steps that firstly, the sewage pipe is cleaned and detected, then a felt-made hose completely soaked in thermosetting resin is conveyed a to-be-repaired pipe which is thoroughly cleaned, and finally hot water is introduced for curing. By adopting a hotwater overturning curing technology, the hose is attached to the inner wall of the damaged sewage pipe, excavation is not needed during construction of the pipe, and no influence on the traffic environment of the city is caused. According to the method, the speed of the construction technology is high, the cost can be effectively lowered, and the construction period is shortened.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

A curved shear wall formwork support to strengthen the main flute and its construction method

ActiveCN106284977BEnsure reinforcementEnsure smoothForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksRebarShear wall

The invention discloses an arc-shaped shear wall formwork support and reinforcement main ridge and a method for constructing the same. The arc-shaped shear wall formwork support and reinforcement main ridge comprises a shear wall, a formwork, secondary ridges and opposite-pull screws. The formwork is arranged on the outer side of the shear wall, the secondary ridges are used for supporting and reinforcing the formwork, the opposite-pull screws sequentially penetrate the secondary ridges, the formwork and the shear wall and are fixed to two sides of the shear wall in an opposite-pull manner, inner-side horizontal reinforcing steel bars which are parallel to one another in the up-down directions are arranged on the outer sides of the secondary ridges and are positioned on the upper sides and the lower sides of the opposite-pull screws, and the opposite-pull screws are provided with E-shaped clamps for fixedly tensioning the inner-side horizontal reinforcing steel bars on the outer sides of the secondary ridges. The arc-shaped shear wall formwork support and reinforcement main ridge is characterized by further comprising a reinforcing steel bar truss main ridge; the reinforcing steel bar truss main ridge is fixed to the inner-side horizontal reinforcing steel bars and comprises a truss horizontal reinforcing steel bar, the truss horizontal reinforcing steel bar is separated from the secondary ridges by distances, the distances from the truss horizontal reinforcing steel bar to the inner-side horizontal reinforcing steel bars on the upper side and the lower side of the truss horizontal reinforcing steel bar are equal to one another, and truss diagonal bracing reinforcing steel bars are obliquely arranged between the truss horizontal reinforcing steel bar and the inner-side horizontal reinforcing steel bars on the upper side and the lower side of the truss horizontal reinforcing steel bar. The arc-shaped shear wall formwork support and reinforcement main ridge and the method have the advantages that the arc-shaped shear wall formwork support and reinforcement main ridge is simple in structural design, processes for constructing the arc-shaped shear wall formwork support and reinforcement main ridge can be easily and quickly implemented, and section deformation of the shear wall in construction procedures can be effectively diminished.

Owner:ZHONGTIAN CONSTR GROUP

River-crossing steel truss bridge closure method

ActiveCN113136803AMeet the Helong requirementsSuccessfully realized the cross-center cooperationTruss-type bridgeBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a river-crossing steel truss bridge closure method, which comprises the following steps of: respectively erecting steel truss main bodies to a closure gap from two bank sides to the center of a river, respectively and movably mounting a first steel truss, a second steel truss and the steel truss main bodies on the respective sides, temporarily arranging a closure steel truss on the second steel truss and enabling the closure steel truss to protrude by a part, adjusting the rotating angle of the first steel truss, connecting the first steel truss with one side of the closure steel truss, adjusting the position of the second steel truss, connecting the second steel truss with the other side of the closure steel truss, and locking the first steel truss, the second steel truss and the steel truss main bodies on the respective sides. The invention further discloses a river-crossing steel truss bridge closure device. The position and displacement of the first steel truss, the second steel truss and the closure steel truss can be adjusted to be matched with the closure opening according to the environmental influence, and the method has the advantages of being simple and rapid in construction procedure and high in closure precision.

Owner:CCCC THIRD HIGHWAY ENG

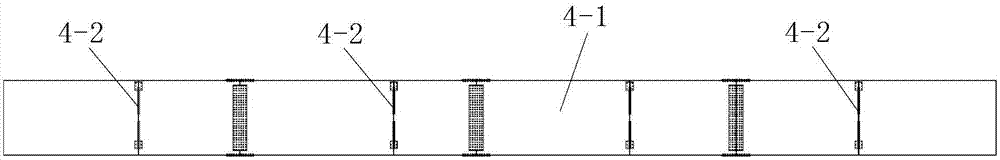

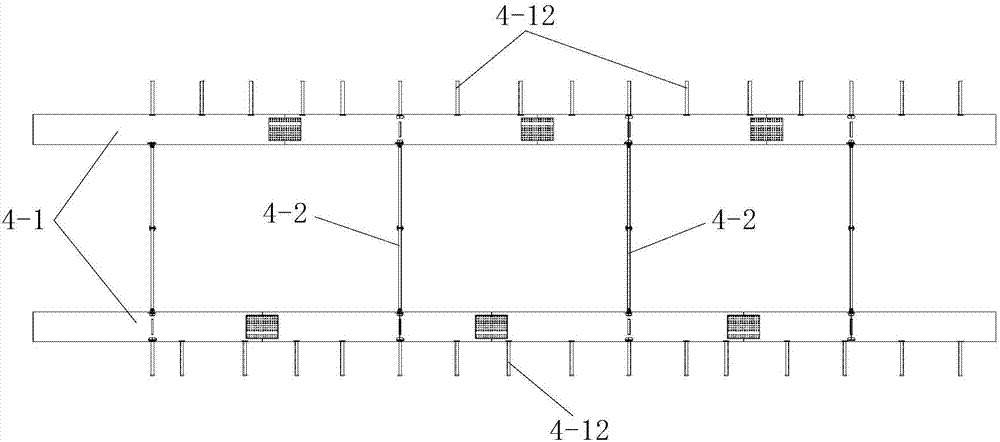

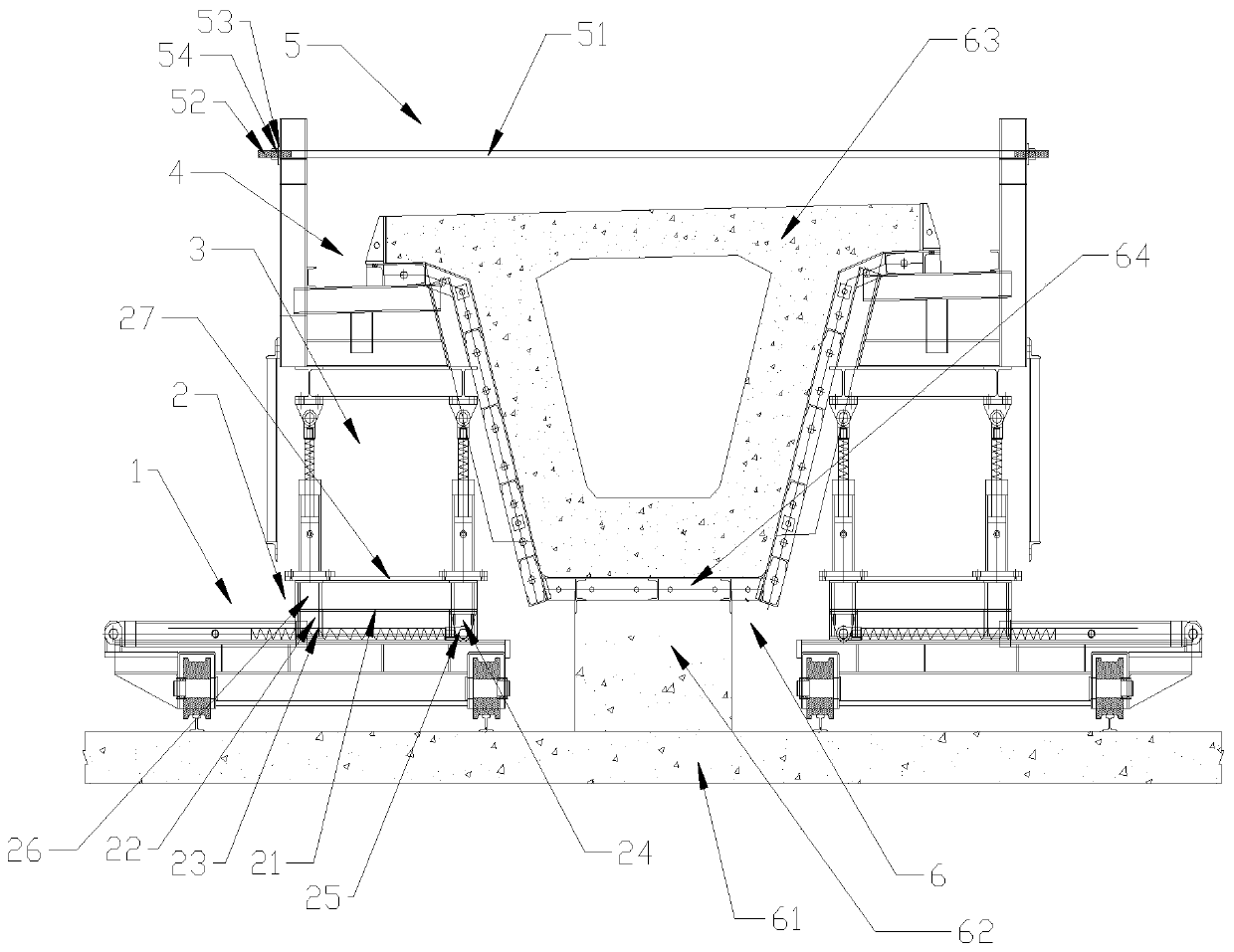

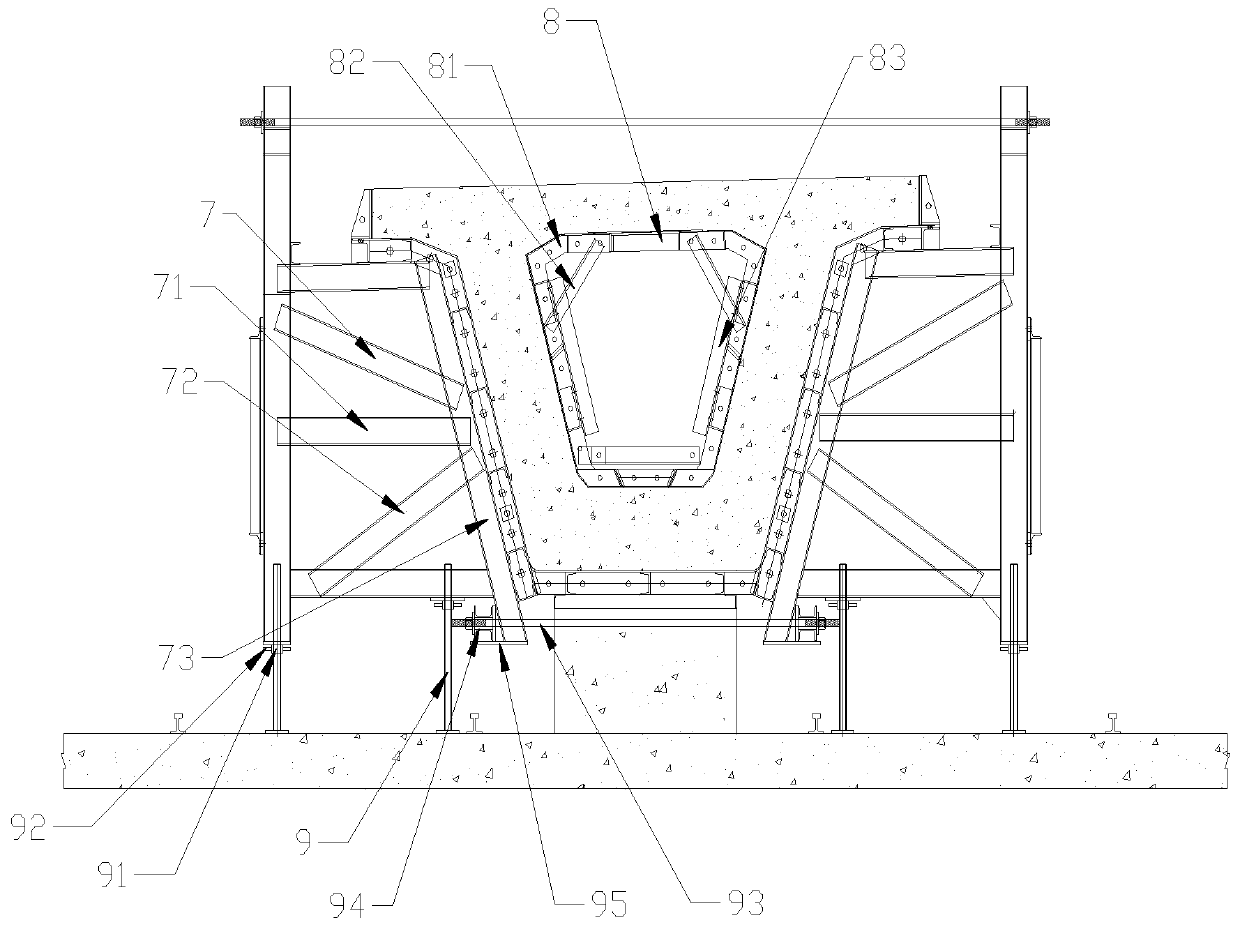

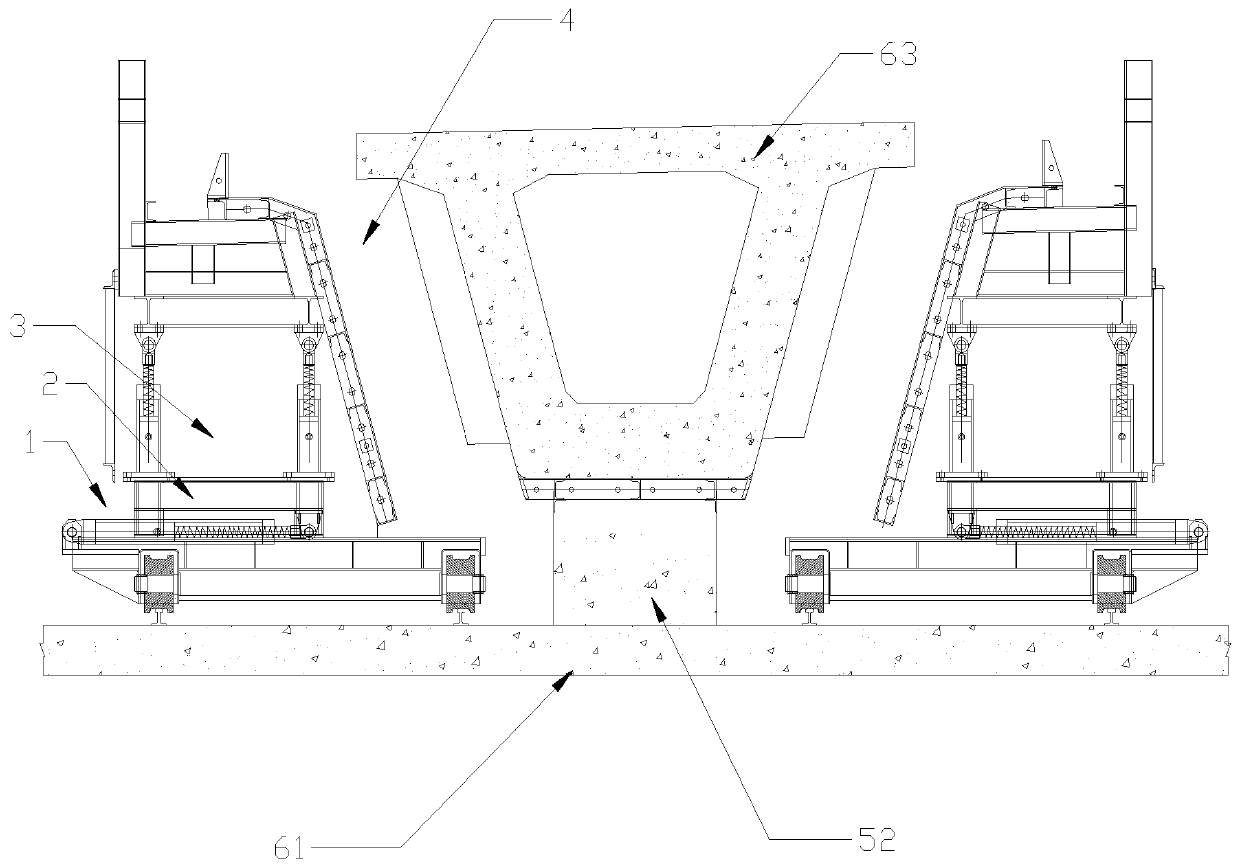

Prefabricated beam fast-dismounting type line production steel template

PendingCN110394886ALow costIncrease productivityMouldsAuxillary shaping apparatusTemplate securitySteel frame

The invention discloses a prefabricated beam fast-dismounting type line production steel template. The steel template comprises longitudinally-distributed longitudinal sliding mechanisms; transverse sliding mechanisms are arranged on one side above the longitudinal sliding mechanisms, vertical lifting mechanisms are arranged on the transverse sliding mechanisms; a prefabricated beam template supporting steel frame is arranged on each vertical lifting mechanism; a finish rolling threaded steel pair pull rod is jointly arranged on the prefabricated beam template supporting steel frame which is in mirror image distribution; the prefabricated beams are arranged between the longitudinal sliding mechanisms, the transverse sliding mechanisms, the vertical lifting mechanisms and the prefabricatedbeam template supporting steel frame which are mirror distributed. According to the prefabricated beam fast-dismounting type line production steel template, the whole template security and disassemblyprocess of the prefabricated beam fast-dismounting type line production steel template adopts conventional electric mechanization, so that a large amount of labor is saved, meanwhile, the productionefficiency and the safety are greatly improved, meanwhile, the single-sleeve template can meet the template requirements of all the pedestals of the through-length guide rail, the purchasing cost of the template is saved, the integrity of the template is good, repeated dismounting and mounting are not needed after the construction is started, and the construction process is compact and rapid.

Owner:THE FOURTH ENG CO LTD OF CCCC FIRST HIGHWAY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com