Screeding machine

A technology for punching tendons and pipes, which is applied in construction, building construction, etc. It can solve the problems that affect the progress of the project, it is not easy to control, and the waste of materials, etc., and achieve the effect of improving construction efficiency and quality, and easy leveling and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

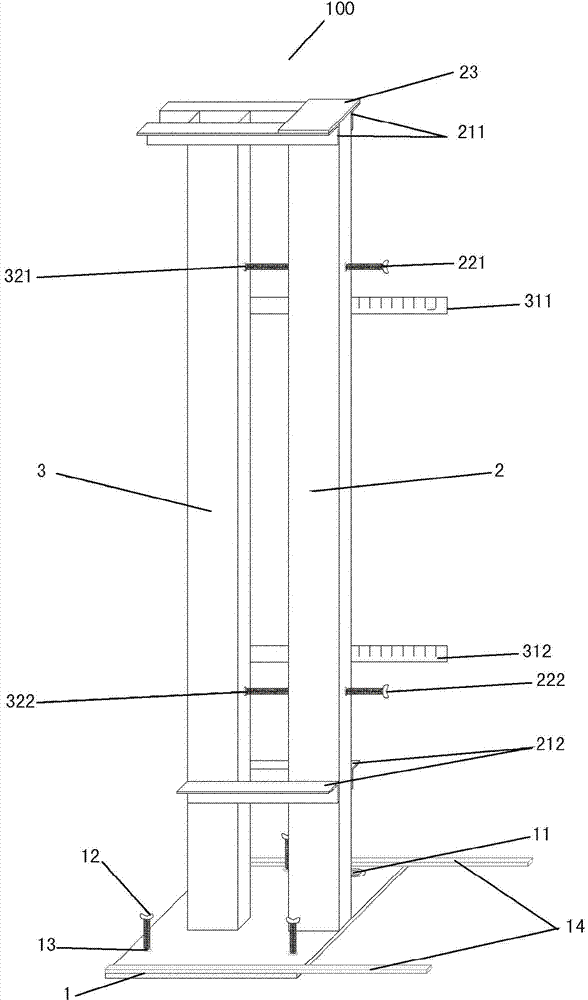

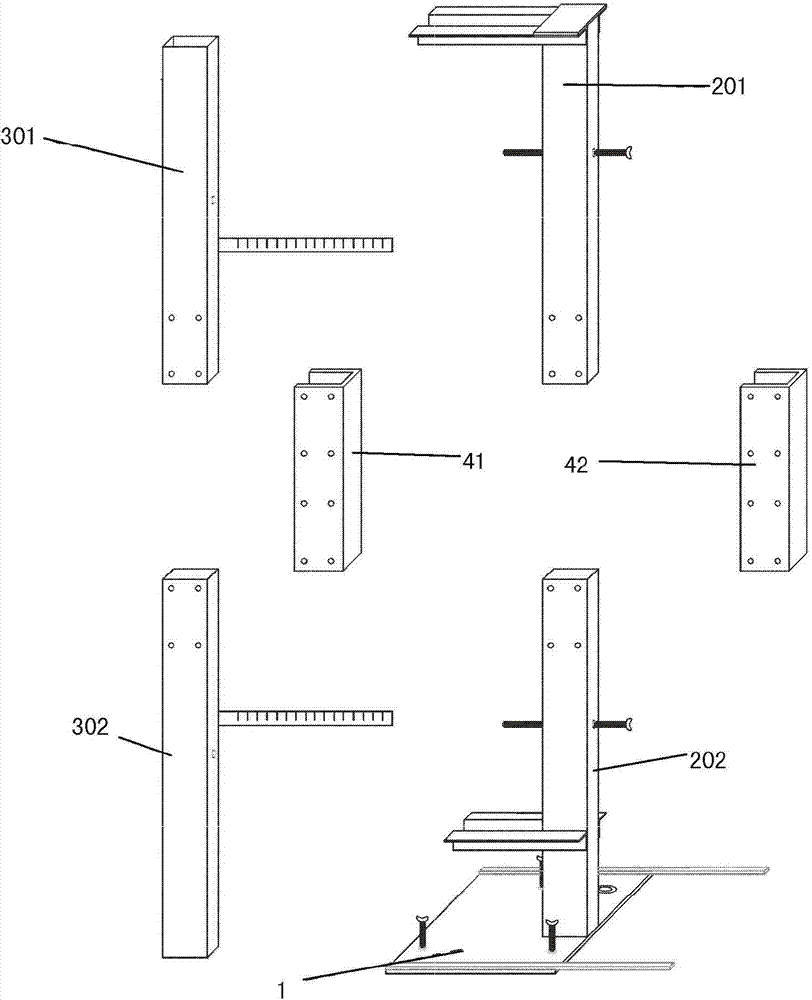

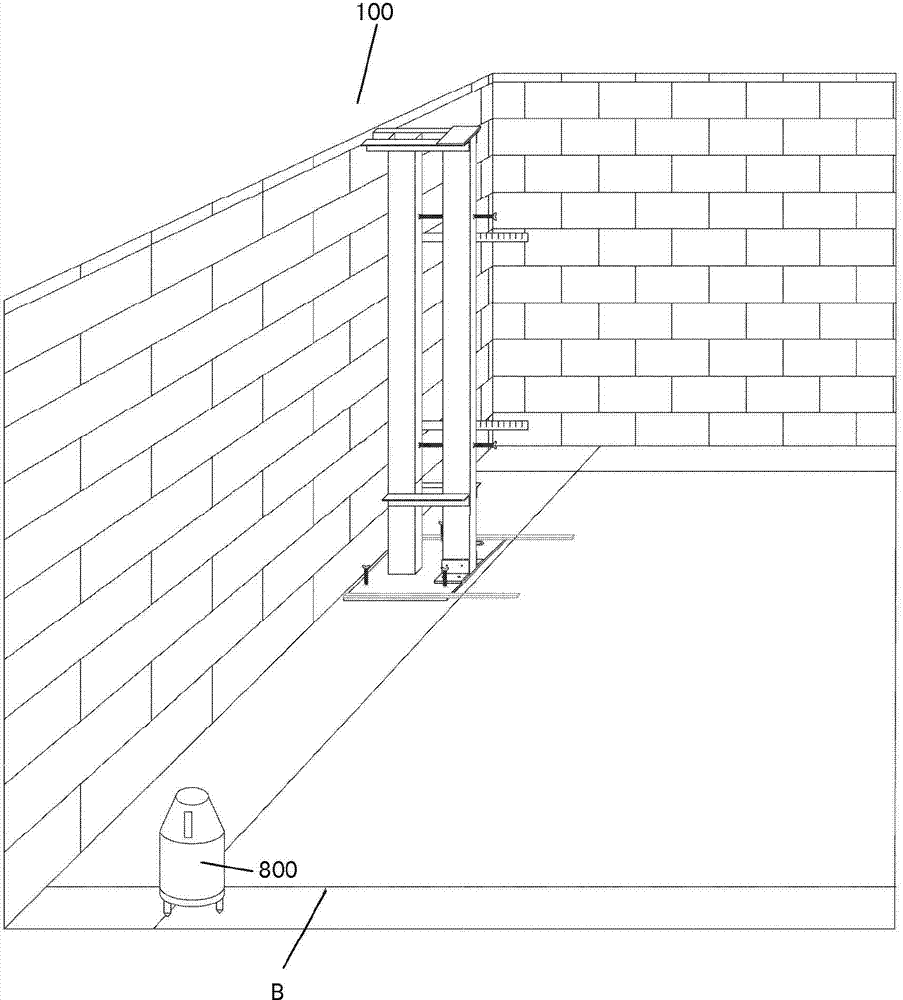

[0019] See figure 1 As shown, the bead puncher 100 of the present invention includes a bottom plate 1 , a fixed pipe 2 and a movable pipe 3 vertically installed on the bottom plate 1 .

[0020] A horizontal bubble 11, an adjustment screw 12 and a nut 13 are installed on the base plate 1, so that the whole bead puncher device is adjusted to a horizontal position on the ground. The scale 14 perpendicular to the base plate 1 is installed on the base plate 1 to ensure that the bead puncher and the control line are parallel.

[0021] The top of the fixed pipe 2 and the bottom near the bottom plate 1 are each provided with a pair of limiting angle fittings 211, 212, which are arranged to prevent the movable pipe 3 from tilting left and right and ensure that the movable pipe 3 moves in parallel accurately. An adjusting screw 221, 222 is respectively housed on the top and bottom of the fixed pipe material 2 so as to be connected with the movable pipe material 3. Rubber pad 23 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com