A curved shear wall formwork support to strengthen the main flute and its construction method

A formwork support and shear wall technology, applied in formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc. Accuracy requirements, the difficulty of accurate positioning and measurement of the arc-shaped inclined wall shape, and the inability of the tensile strength of steel bars to achieve the effect of reducing the deformation of the section, improving the arc line, and making it easy to obtain materials on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

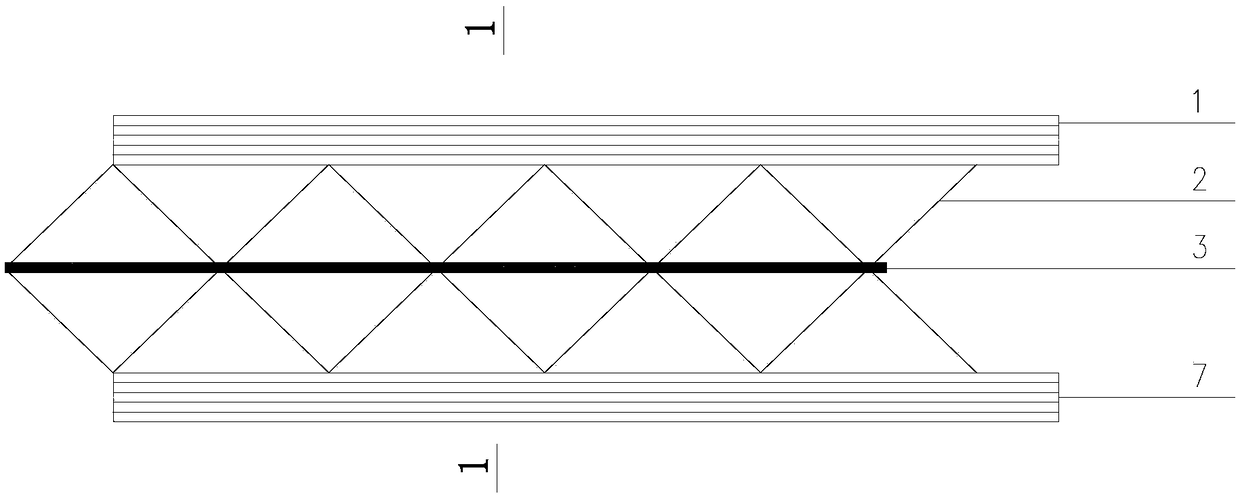

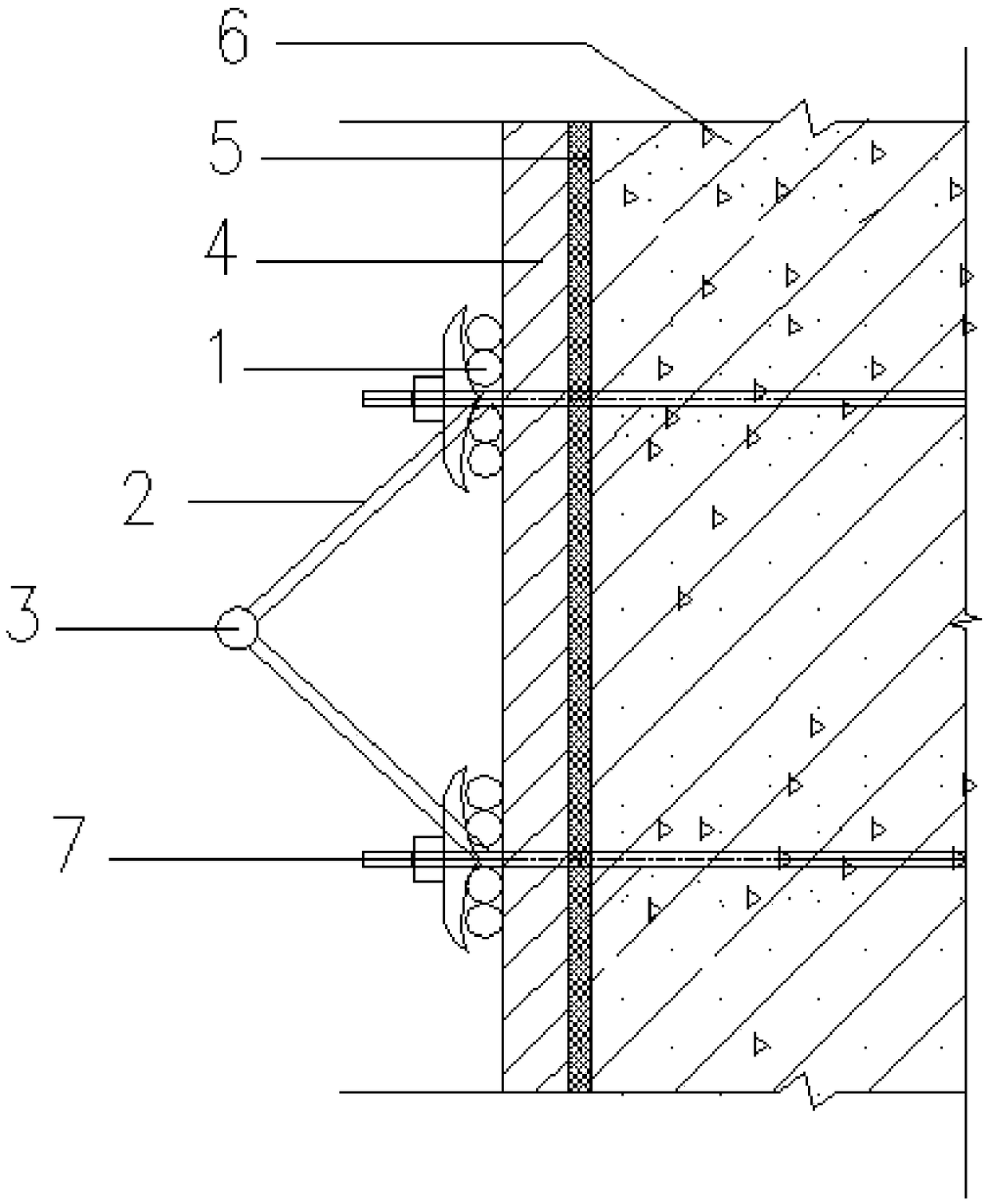

[0017] Such as figure 1 and figure 2 As shown, a curved shear wall formwork supports and strengthens the main flute, including a formwork 5 arranged on the outside of the shear wall 6, a secondary flute 4 for supporting and reinforcing the formwork 5, and passing through the secondary flute 4, formwork 5, The shear wall 6 and realizes the parallel tension screw 7 fixed on both sides of the shear wall. The outer side of the secondary corrugation 4 is provided with up and down parallel inner horizontal steel bars 1 on the upper and lower sides of the double tension screw 7. The inner horizontal steel bar There are two on the upper and lower sides of the pull screw, and four inner horizontal steel bars 1 that are close to the second corrugation form a steel bar group to reinforce the second corrugation. The Yamagata card on the outer side of the second lenght.

[0018] In addition, the outer side of the formwork is provided with a steel bar truss main flute fixed to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com