Sand bag well point composite light well point deep rapid-draining dynamic consolidation method

A light-duty well point and dynamic consolidation technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problem that the dynamic compaction method is difficult to achieve the ideal effect and depth, and it is difficult to meet the needs of deep reinforcement of soft soil foundation , Ultra-static pore water pressure dissipates slowly and other issues, to achieve the effect of fast and controllable treatment, high cost performance, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific process steps of this construction method are as follows (dynamic consolidation takes dynamic compaction as an example):

[0024] Step 1. Arrange sandbag well points

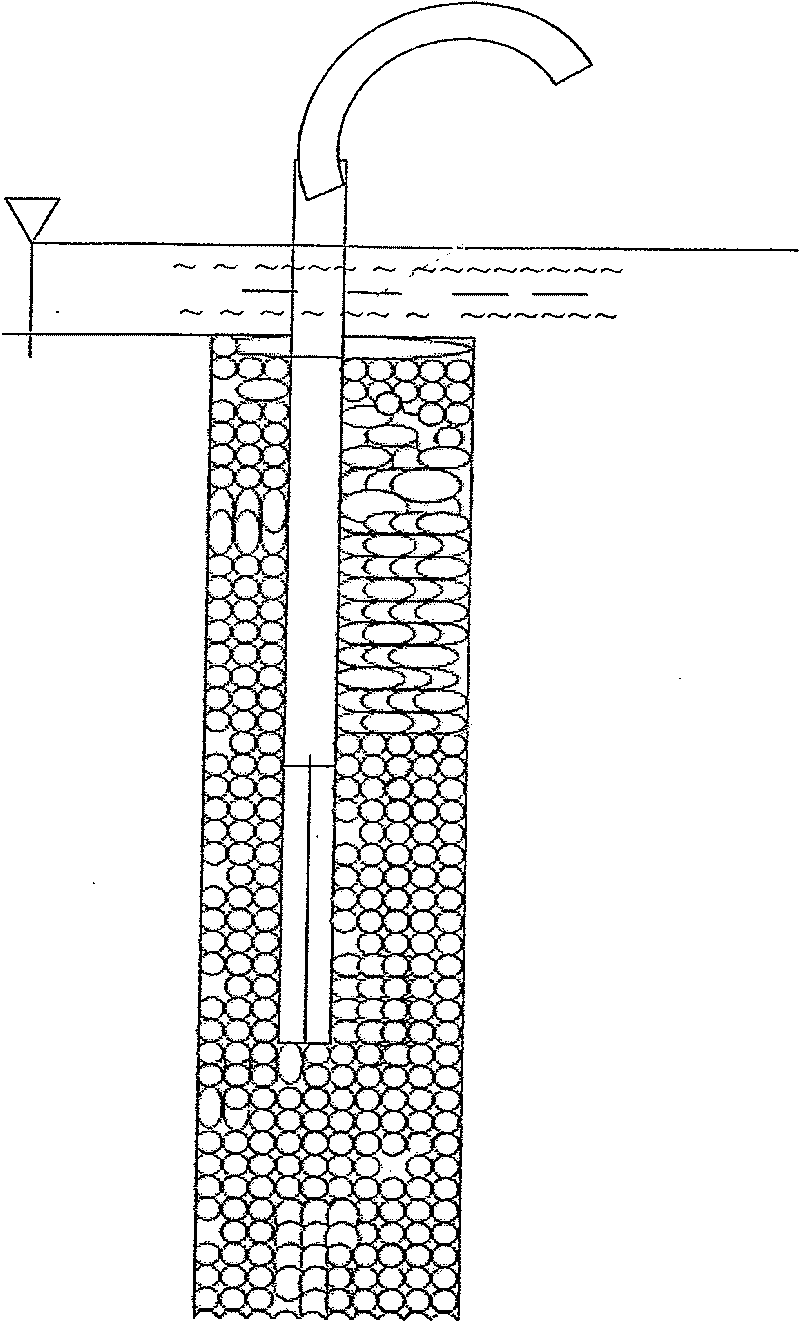

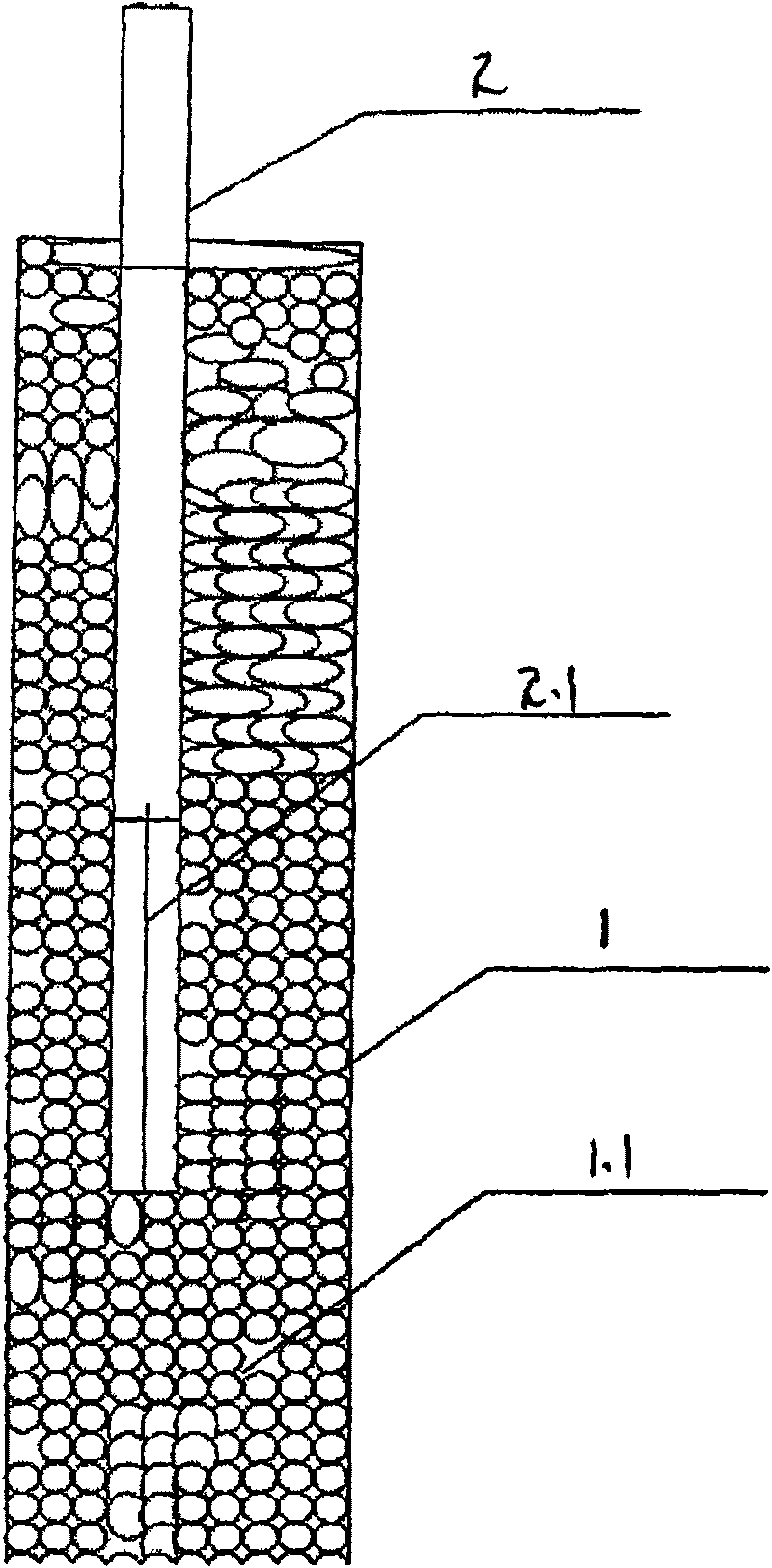

[0025] For the weak foundation that needs to be treated, according to the design requirements and geological conditions, use the "water flushing method" or "mechanical intubation method" to place sand bags into the weak foundation soil to be treated, arrange sand bag well points, and place sand bags at a distance of Below the surface of 0.5m, the surface layer shall be sealed with clay; figure 2 . The depth and spacing of sandbag well points are determined according to the required reinforcement depth.

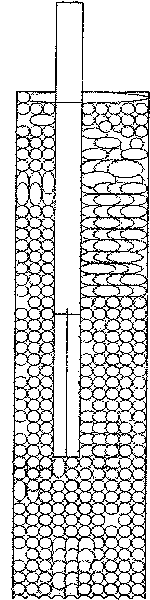

[0026] Step 2. Insert a light well point pipe in the sand bag well point, such as figure 1 , the length of the light well point pipe is 6m, and the light well point pipe is processed and manufactured according to the traditional light well point pipe. Light well point tubing connects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com