Construction process for reclamation by hydraulic filling of silt and device thereof

A technology of filling and filling silt and construction device, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of slow silt deposition and inability to follow-up construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

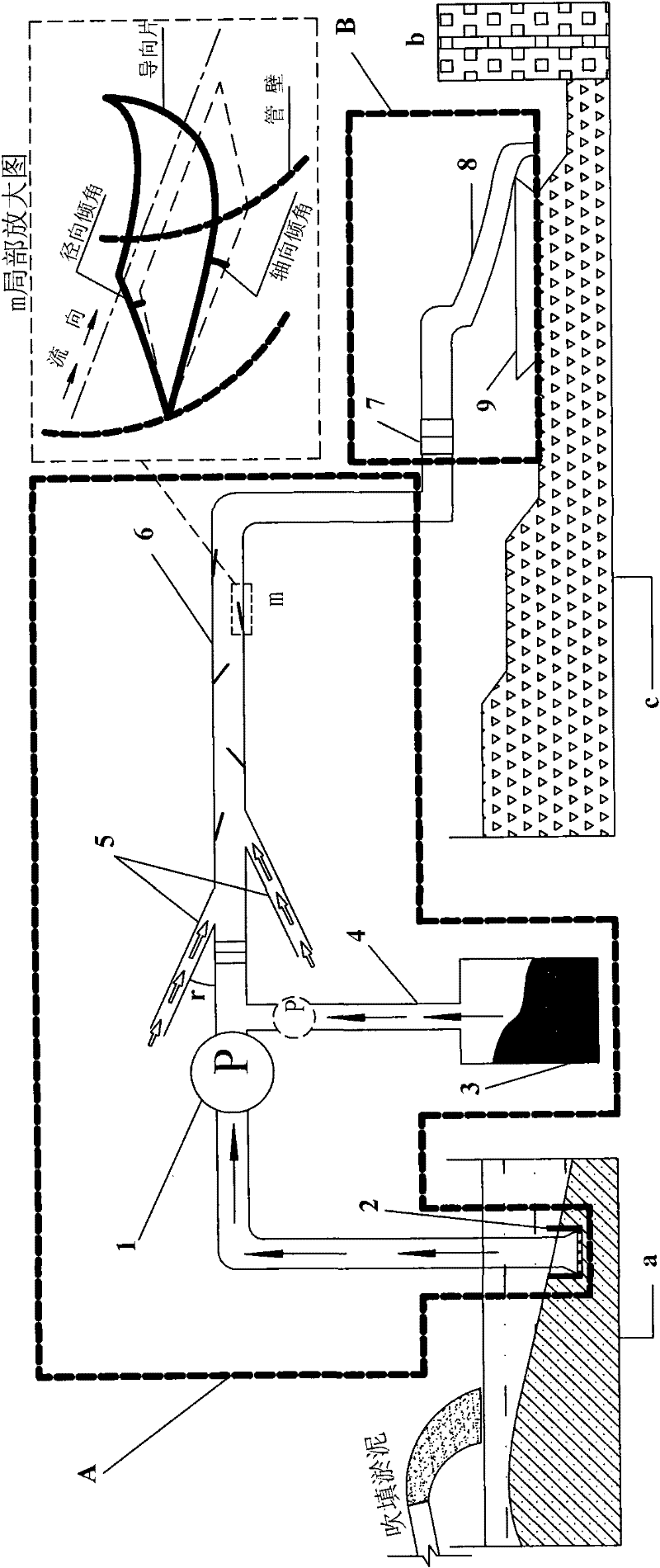

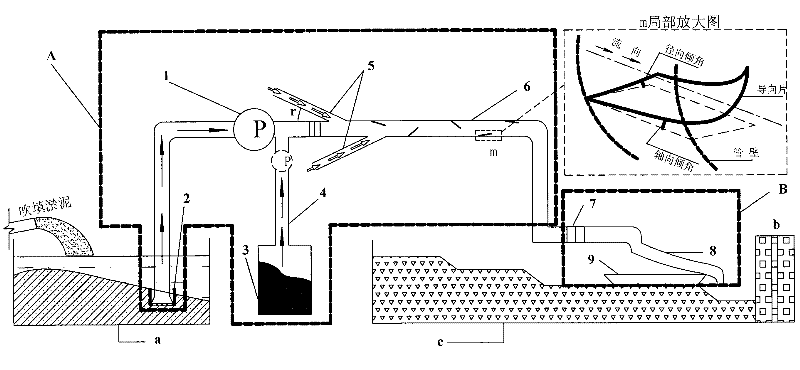

[0034] A seashore reclamation site uses the construction device for dredging silt reclaiming of the present invention. The specific devices and specifications of each device are as follows: Solidification treatment system A: Pumping device 1 includes mud pumps and inner diameters selected according to actual needs 80mm front and rear piping of the pump. The debris screening device 2 is a porous cuboid structure with a certain sieve aperture. The curing agent storage device 3 is 8m 3 The cylinder is used to store the slag cement. The curing agent delivery device 4 is a pipe with an inner diameter of 20 mm with a screw propeller on the inner wall, and the pipe is connected to the front pipe of the pump. The compressed air conveying device 5 includes an air compressor with a power of 2.5 kW and a compressed air conveying pipe with an inner diameter of 15 mm, which is located at the beginning of the mixed mud mixing conveying device 6. The mixed mud mixing and conveying device 6 ...

Embodiment 3

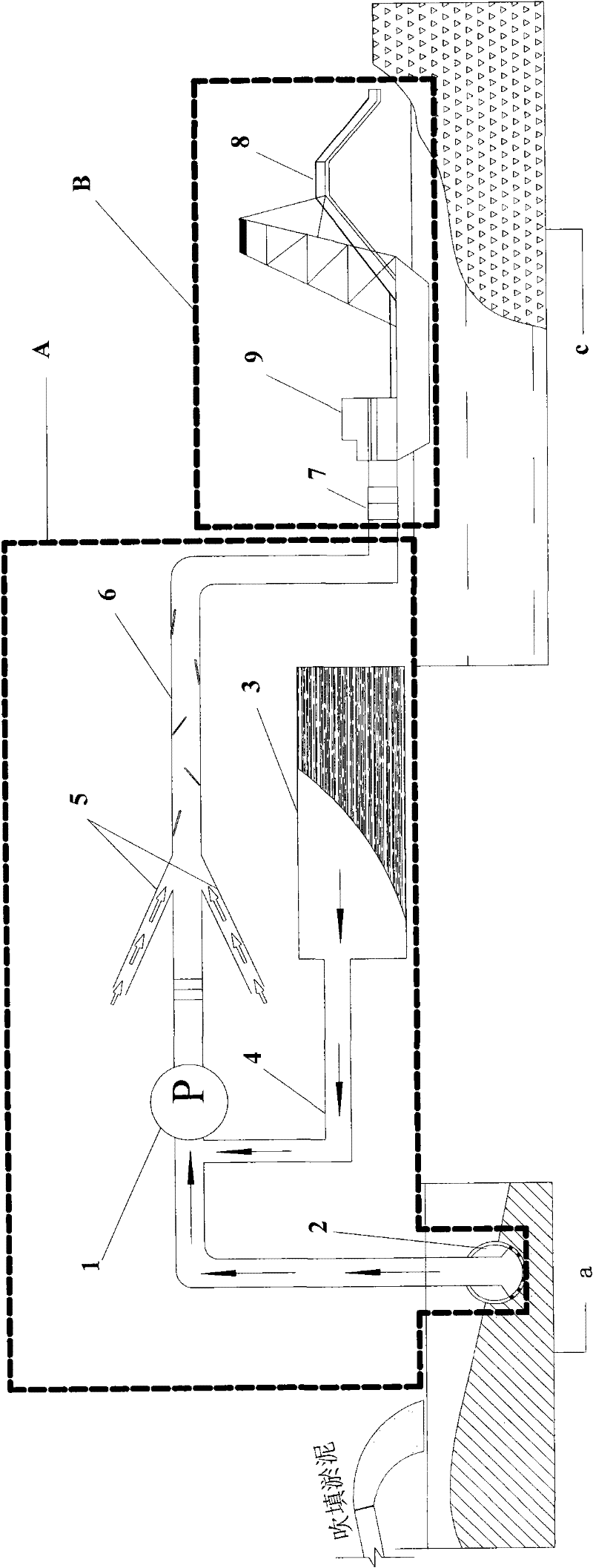

[0038] A coastal roadbed project uses the construction device for dredging and filling silt to make land of the present invention. The specific devices and specifications of each device are as follows: Solidification treatment system A: Pumping device 1 includes a slurry pump selected according to actual needs and an inner diameter of 150mm The pipeline before the pump and the pipeline after the pump. The debris screening device 2 is a porous spherical structure with a certain sieve aperture. The curing agent storage device 3 is 3×3×3m 3 The square tube is used to store ordinary silica cement and lime mixture. The curing agent delivery device 4 is a pipe with an inner diameter of 40 mm connected to the pipe before the pump, and a pump with a power of 3 kW is connected in the middle of the pipe. The compressed air delivery device 5 includes an air compressor with a power of 5 kW and three compressed air delivery pipes with an inner diameter of 10 mm. The mixed mud mixing and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com