Anchoring structure for liquid-injection corrosion-resistant anchor rod or anchor cable and construction method thereof

A technology for anchoring structures and bolts, which is applied in the direction of basic structure engineering, installation of bolts, earthwork drilling and mining, etc. It can solve problems such as water sealing, anti-corrosion problems, unsatisfactory support effects, and bolt corrosion. Achieve the effects of simple and reliable processing and manufacturing technology, superior cost performance, and good supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

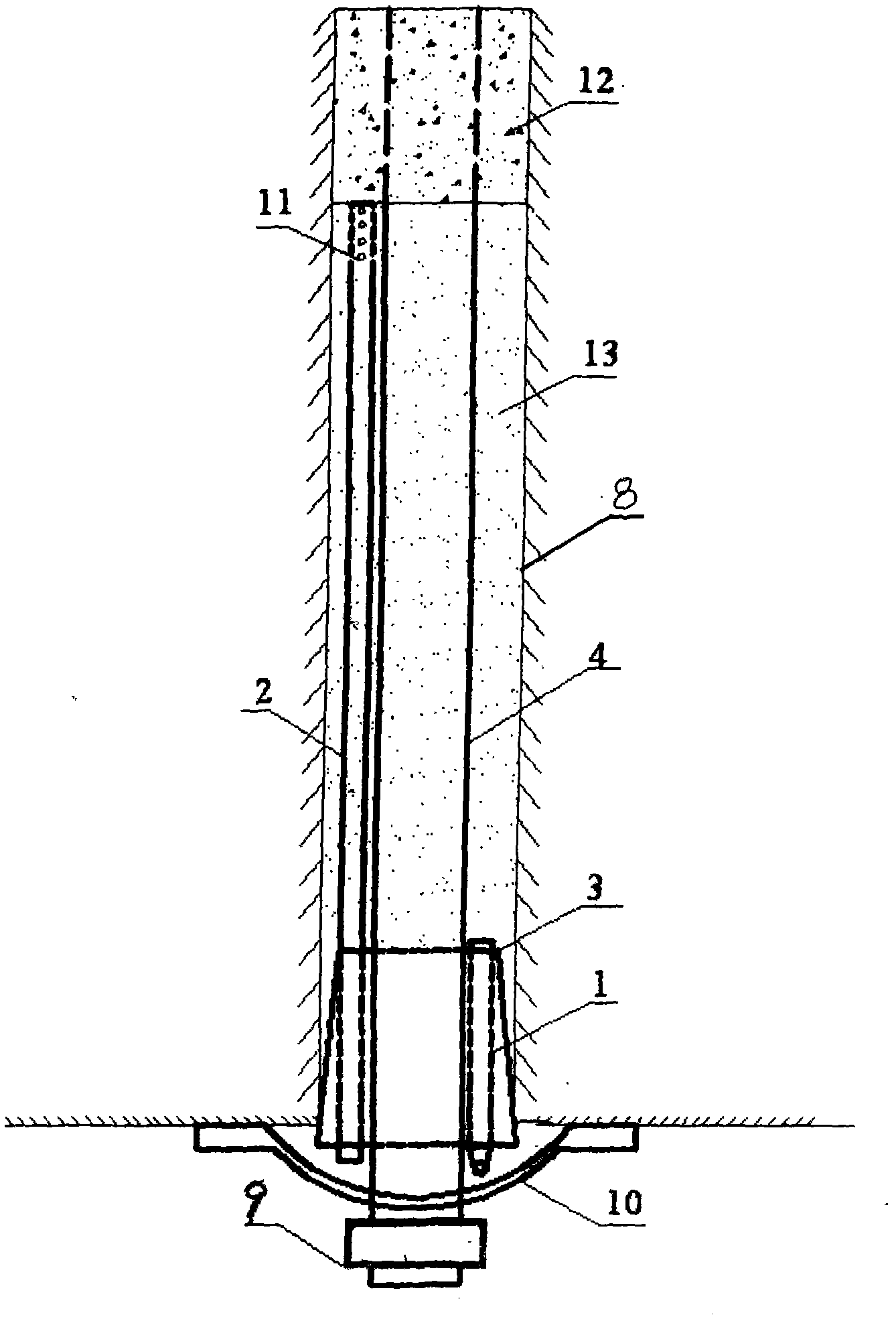

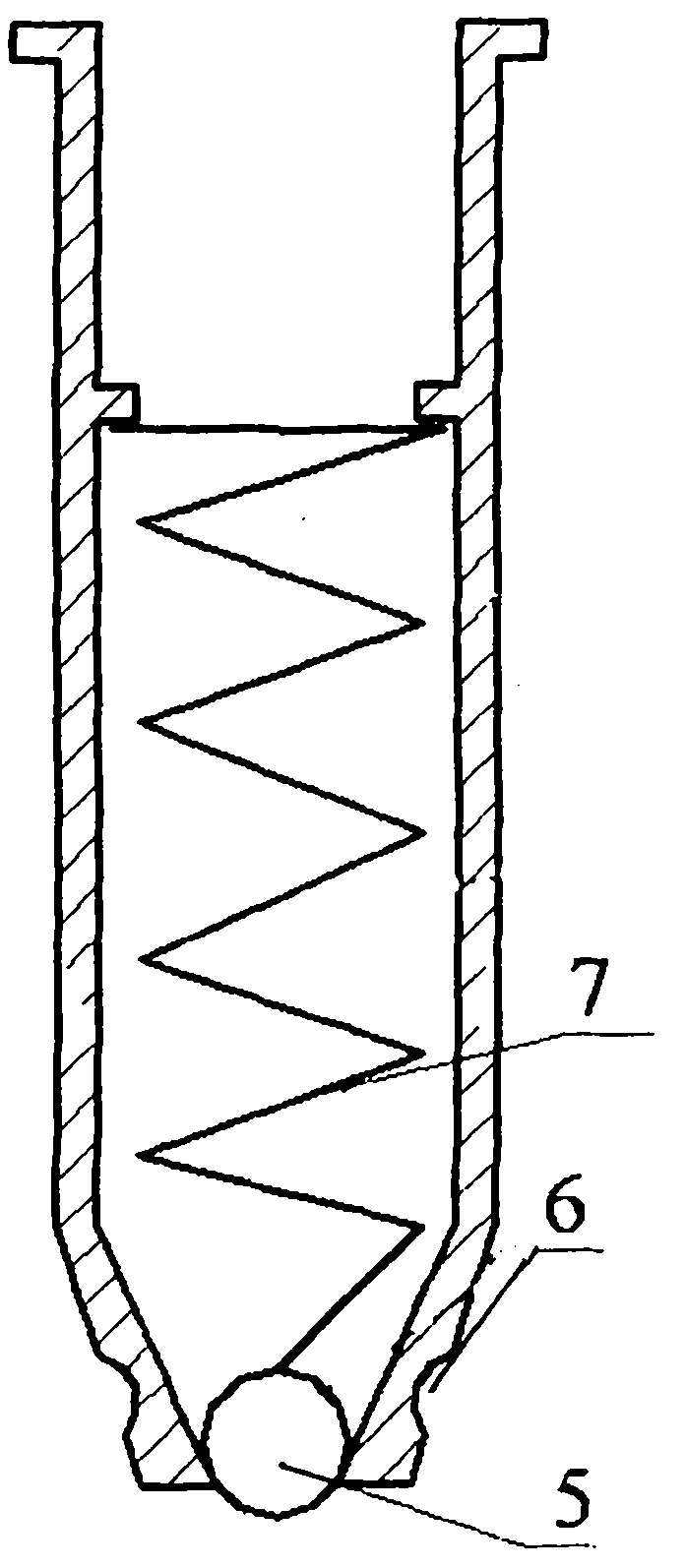

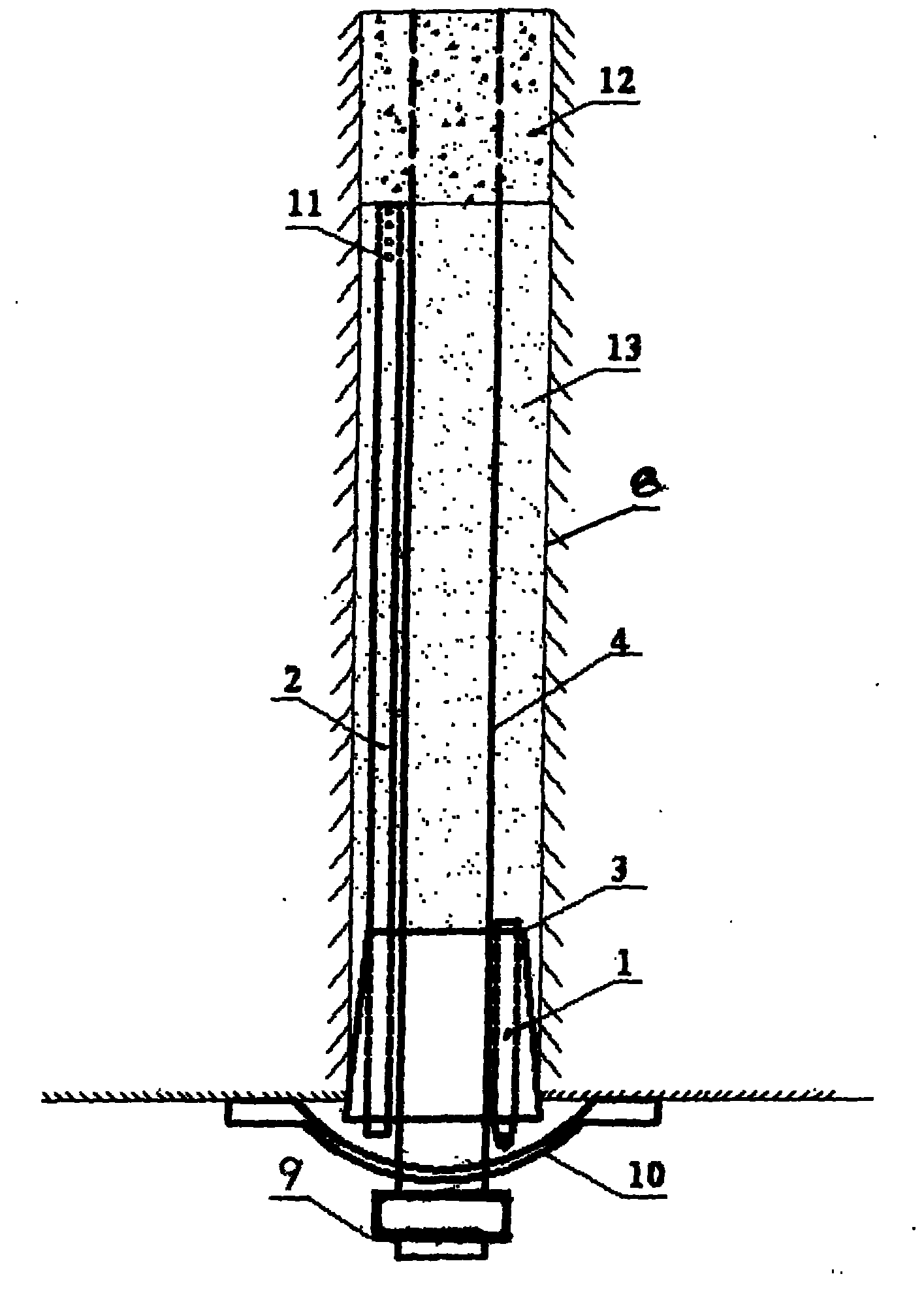

[0026] Such as figure 1 As shown, the anchoring structure of the full-length liquid injection anti-corrosion anchor rod of the present invention is that it includes a resin end-anchor anchor rod body 4 installed in the anchor hole 8, and a grout stopper 3 is also installed on the opening of the anchor hole 8 , the bolt head is exposed outside the anchor hole 8 from the socket of the grout stopper 3; two sockets are also processed on the grout stopper 3, and the liquid injection nozzle 1 is inserted into one of the sockets, and the liquid injection nozzle 1 Fill the anchor hole 8 with chemical slurry 13, and insert the exhaust pipe 2 with both ends open in the other socket; Vents 11 are arranged on the peripheral surface of the trachea 2 . Such as figure 2 As shown, the inlet of the liquid injection nozzle 1 is equipped with a check valve ball 5 and a return spring 7 , and the peripheral surface of the inlet end of the liquid injection nozzle 1 is provided with a card slot 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com