Preparation method of terpolymer doped polyaniline super-hydrophobic composite anticorrosive paint

A terpolymer, anti-corrosion coating technology, applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor water resistance and anti-corrosion performance, improve anti-corrosion performance, improve compatibility and weather resistance The effect of solving the problem of poor water resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

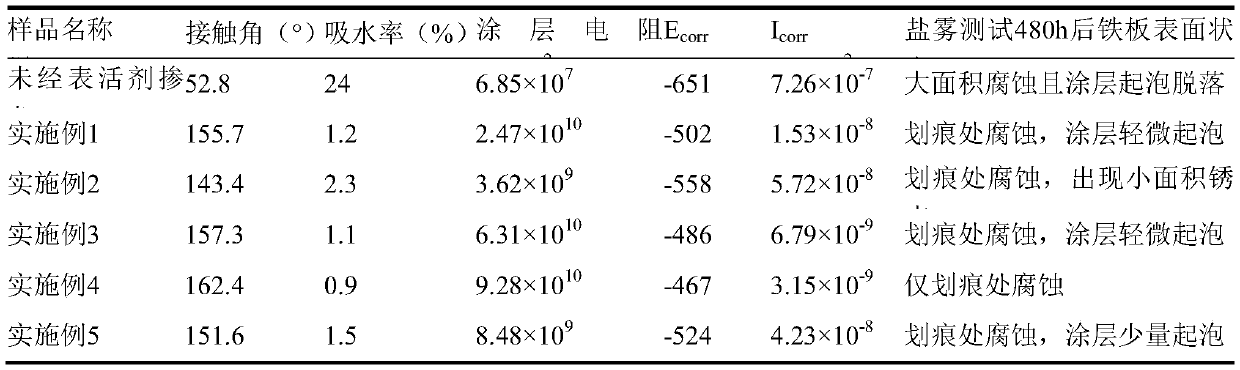

Examples

preparation example Construction

[0023] A preparation method of a terpolymer-doped polyaniline super-hydrophobic composite anti-corrosion coating of the present invention comprises the following steps:

[0024] 1) In parts by weight, mix 10-20 parts of hydrophilic vinyl monomers and 12-24 parts of fluorine-containing acrylate monomers in 20-40 parts of N,N-dimethylformamide and heat up to After stirring at 80-90°C for 1-2 hours, a uniformly mixed mixed solution A was obtained.

[0025] 2) Add 0.4-0.8 parts of an oil-soluble initiator to the mixed solution A, and react at 80-90° C. for 0.5-2 hours to obtain component B.

[0026] 3) Add the third monomer, 0.1-0.5 part of functional acrylic monomer or 0.2-1 part of long-chain acrylate monomer dropwise into component B and continue to react for 3-4 hours to obtain fluorine-containing terpolymer Surfactant.

[0027] 4) 2.5-3.5 parts of fluorine-containing terpolymer surfactant, 4-4.8 parts of aniline monomer, and 40-60 parts of water are uniformly mixed and reac...

Embodiment 1

[0039] 1) In parts by weight, 10 parts of 2-acrylamide-2-methylpropanesulfonic acid and 12 parts of trifluoroethyl acrylate were mixed in 20 parts of N,N-dimethylformamide, and the temperature was raised to 80°C and stirred. After 1 h, a uniformly mixed mixed solution A was obtained.

[0040] 2) Add 0.4 part of benzoyl peroxide to mixed solution A, and react at 80° C. for 0.5 h to obtain component B.

[0041] 3) The third monomer, 0.1 part of glycidyl acrylate, was added dropwise to component B, and the reaction was continued for 3 hours to obtain a fluorine-containing terpolymer surfactant.

[0042] 4) 2.5 parts of fluorine-containing terpolymer surfactant, 4 parts of aniline monomer, and 40 parts of water are uniformly mixed and reacted at room temperature for 1 hour to obtain a milky white mixed solution C.

[0043] 5) Slowly add 9.8 parts of an aqueous solution of ferric chloride into the mixed solution C dropwise, continue to react for 12 hours, filter, wash and dry to o...

Embodiment 2

[0046] 1) In parts by weight, 20 parts of 2-methacrylamide dodecyl sulfonic acid, 24 parts of hexafluorobutyl acrylate were mixed in 40 parts of N,N-dimethylformamide, and the temperature was raised to 90 ° C and stirred After 2 h, a uniformly mixed mixed solution A was obtained.

[0047] 2) Add 0.8 part of azobisisoheptanenitrile to mixed solution A, and react at 90° C. for 2 h to obtain component B.

[0048] 3) Add the third monomer, 1 part of n-octyl acrylate dropwise into component B and continue to react for 4h to obtain a fluorine-containing terpolymer surfactant.

[0049] 4) 3.5 parts of fluorine-containing terpolymer surfactant, 4.8 parts of aniline monomer, and 60 parts of water are uniformly mixed and reacted at room temperature for 2 hours to obtain a milky white mixed solution C.

[0050] 5) Slowly add 11.8 parts of an aqueous solution of potassium dichromate dropwise to the mixed solution C, continue to react for 24 hours, filter, wash and dry to obtain superhydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com