Hydrophobic and oleophilic-hydrophilic underwater oleophobic thin oil film as well as adjustment and control method, preparation process and application thereof

A film and super-oleophobic technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as poor emulsion separation effect, limited application range of oil-water separation membrane, and inability to complete controllable conversion of omentum membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

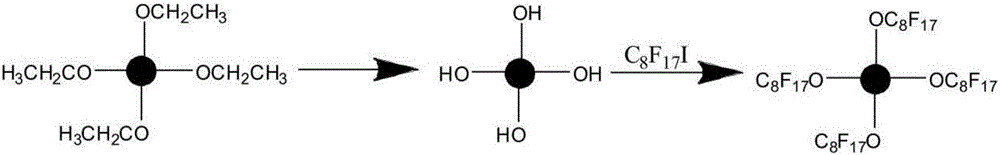

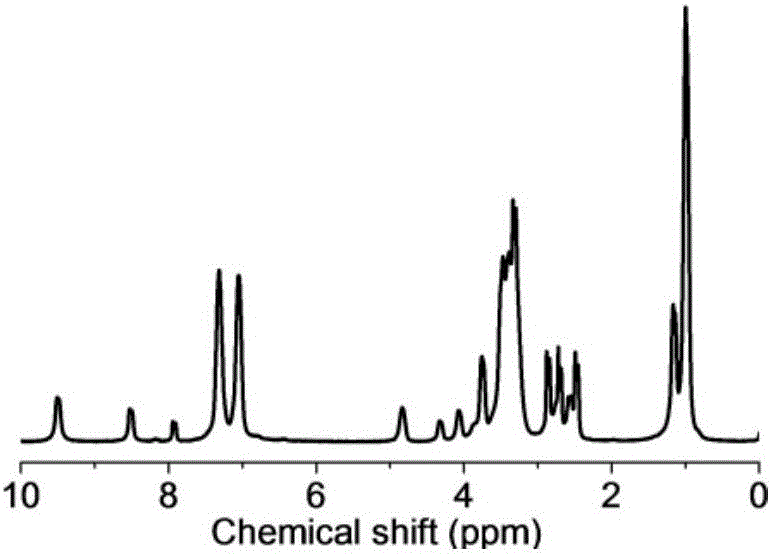

[0114] 1. Preparation of Polyurethane / SiO2 Nanoparticle Composite Film

[0115] 1.1 Preparation of polyurethane

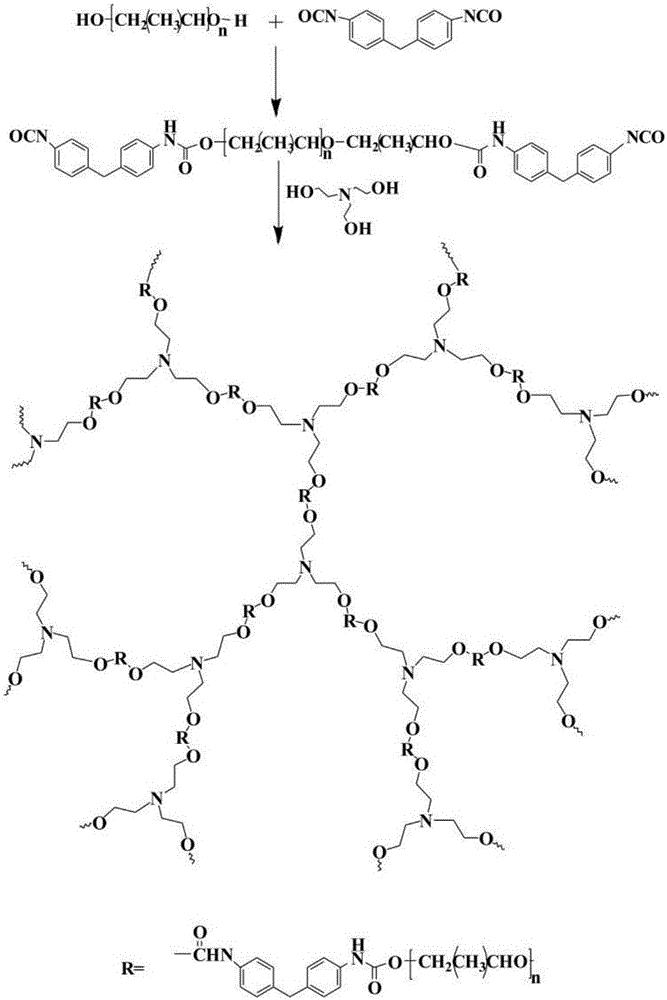

[0116] The synthesis of polyurethane is divided into two steps (such as figure 1 Shown): the first step is the synthesis of polyurethane prepolymer; the second step is the hyperbranched chain extension of polyurethane prepolymer by chain extender TEA.

[0117] (1) Synthesis of prepolymer

[0118] Weigh a certain amount of MDI into a three-necked flask, add an appropriate volume of DMF, and completely dissolve the MDI at room temperature under a nitrogen atmosphere. Then take a quantitative amount of PPG600 and add it dropwise into the reactor, and raise the temperature of the oil bath to 70-80°C. After the dropwise addition, the reaction continued for about 4 hours.

[0119] (2) TEA chain extension reaction

[0120] After the above-prepared isocyanate-terminated prepolymer, the metered chain extender TEA was slowly added dropwise to the three-necked reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com