Patents

Literature

34results about How to "The processing technology is simple and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

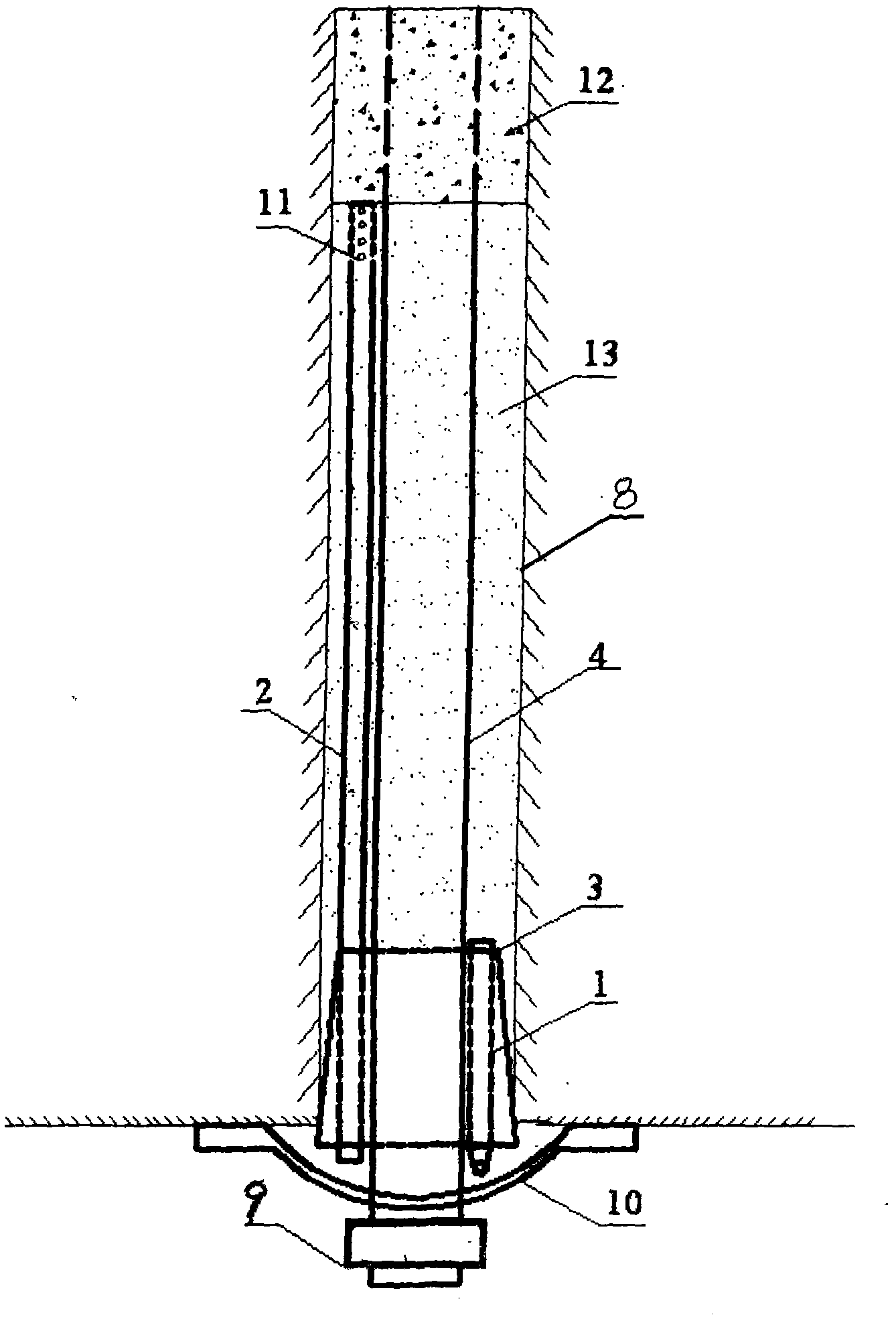

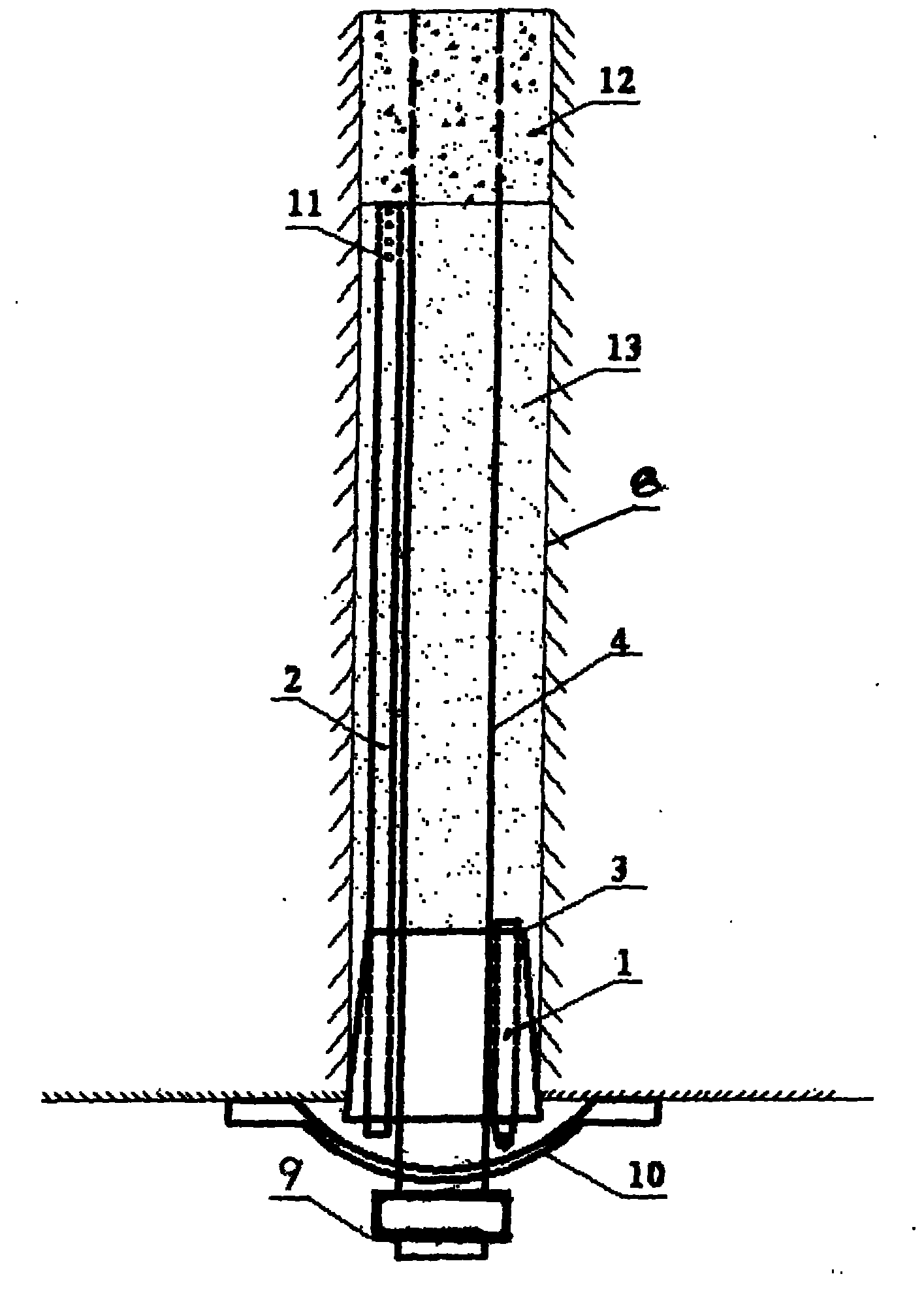

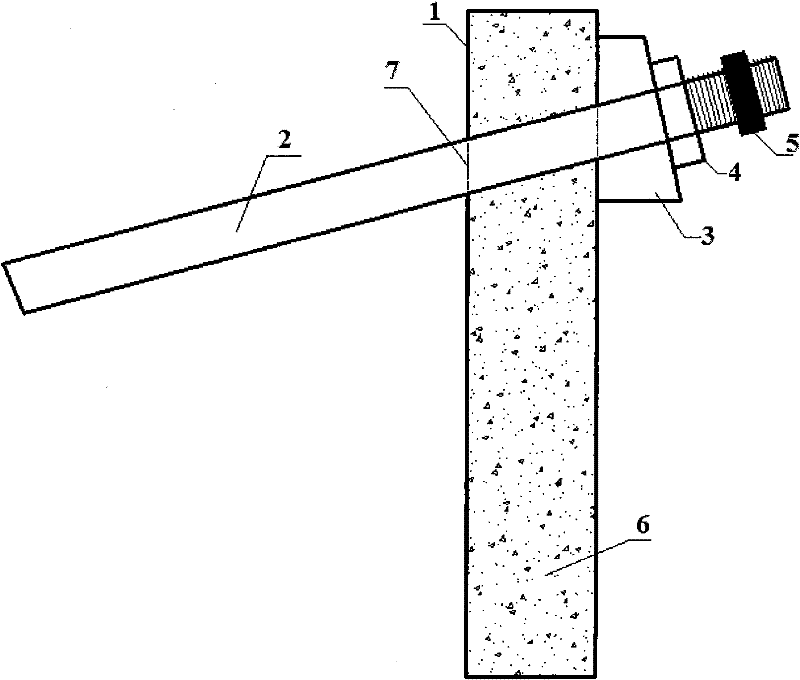

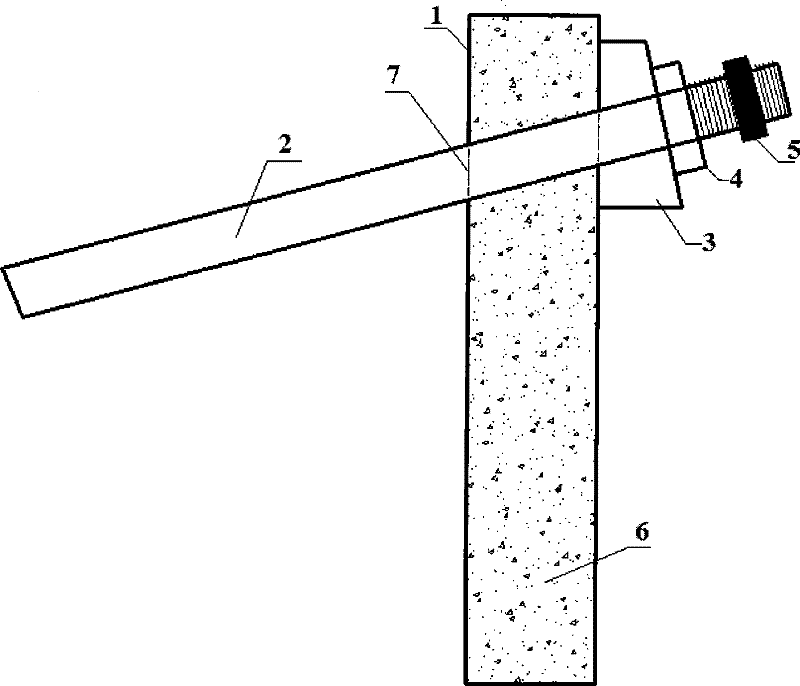

Anchoring structure for liquid-injection corrosion-resistant anchor rod or anchor cable and construction method thereof

InactiveCN102146673ASolve the sealing waterSolve corrosionAnchoring boltsBulkheads/pilesEngineeringSlurry

The invention discloses an anchoring structure for a liquid-injection corrosion-resistant anchor rod or anchor cable and a construction method thereof. The anchoring structure comprises a resin end-anchored anchor rod or anchor cable body arranged in an anchor hole, wherein a grouting-stop plug is also arranged at the opening of the anchor hole; an anchor rod head or an anchor cable head is exposed out of the anchor hole from the plug hole of the grouting-stop plug; the grouting-stop plug is also provided with two plug holes; a liquid injection nozzle is inserted into one plug hole and chemical grout is filled into the anchor hole through the liquid injection nozzle; an exhaust pipe with two open ends is inserted into the other plug hole; a check-valve ball and a return spring are arranged in the liquid injection nozzle; a locking slot connected with grouting equipment is reserved on the peripheral surface of the liquid injection nozzle; the length of the exhaust pipe is equivalent to that of the end-anchored anchor rod or anchor cable; and exhaust holes are reserved on the peripheral surface of the exhaust pipe close to the bottom of a drilled hole. The anchoring structure solves the problem of sealing water and preventing corrosion of anchor rod holes at the positions such as an arch part and the like, not only can serve as permanent support, but also can serve as temporary support.

Owner:SHANDONG UNIV OF SCI & TECH

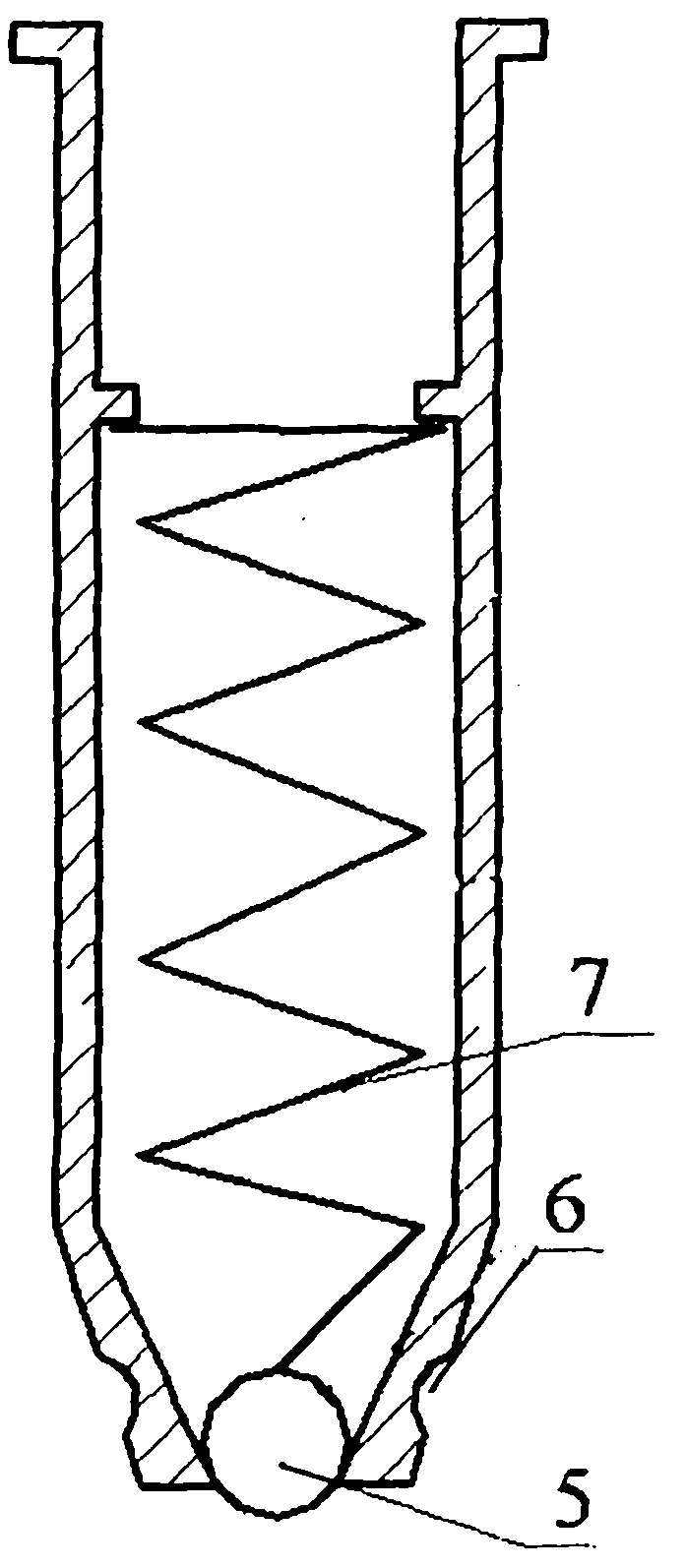

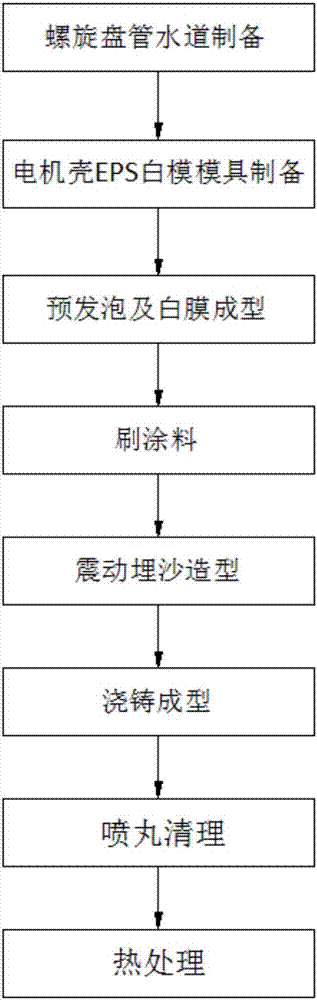

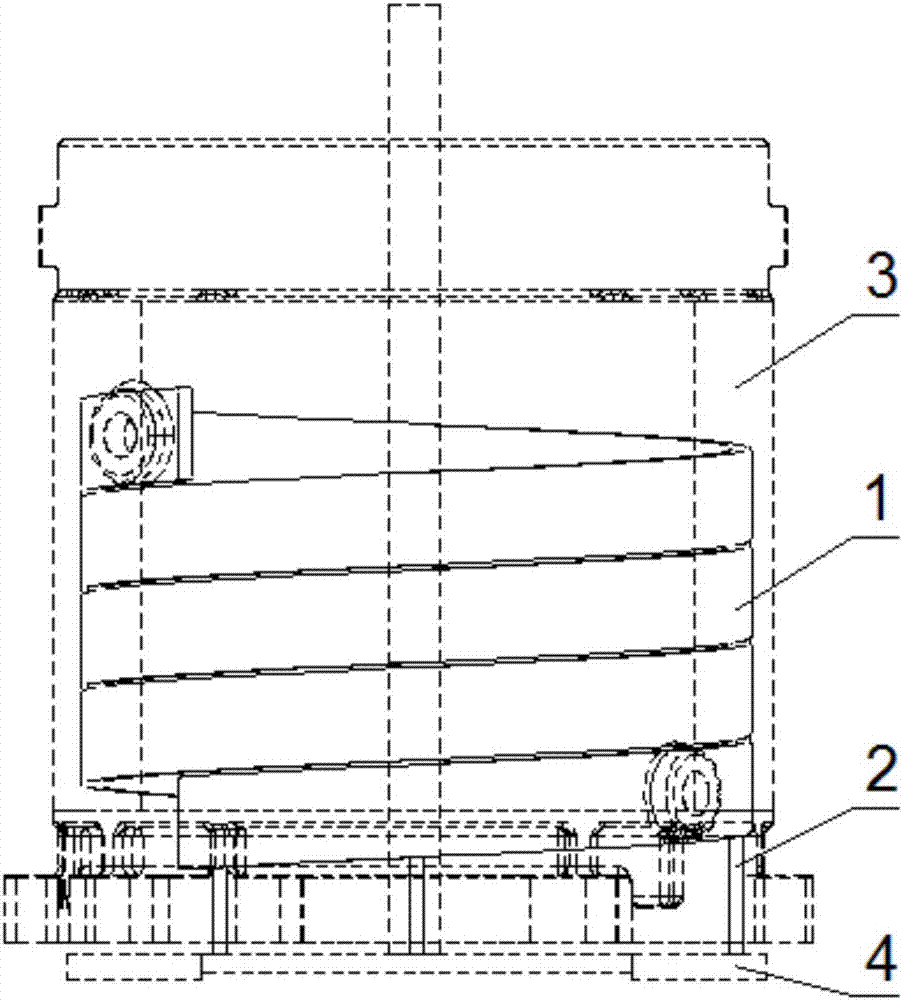

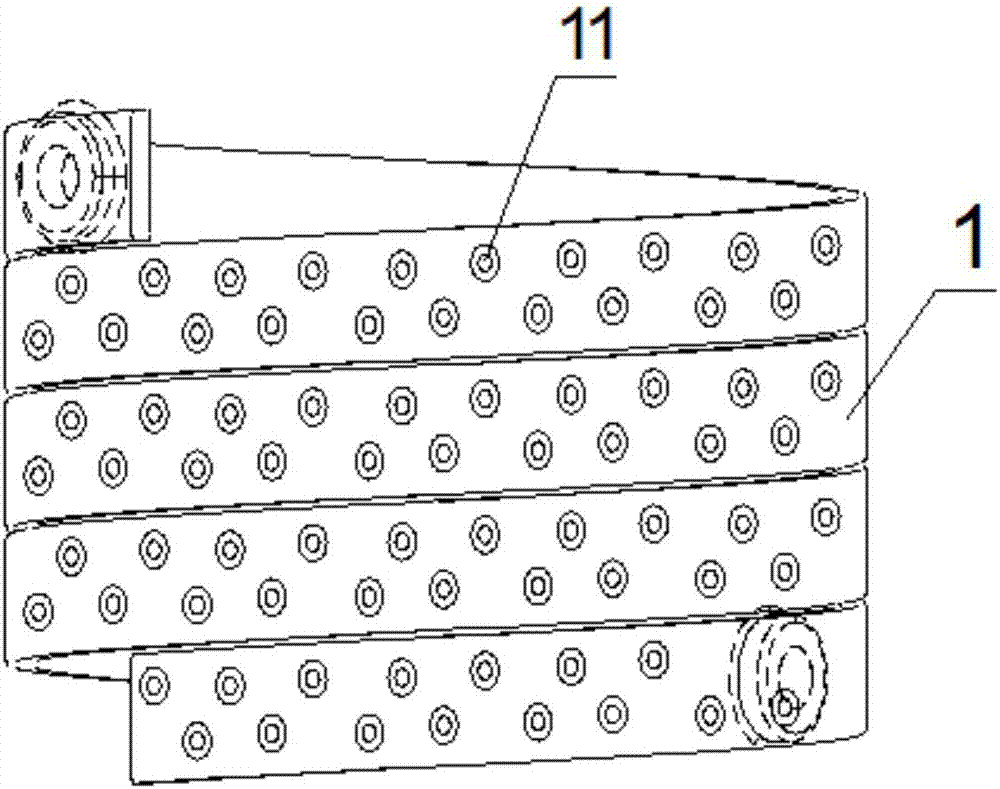

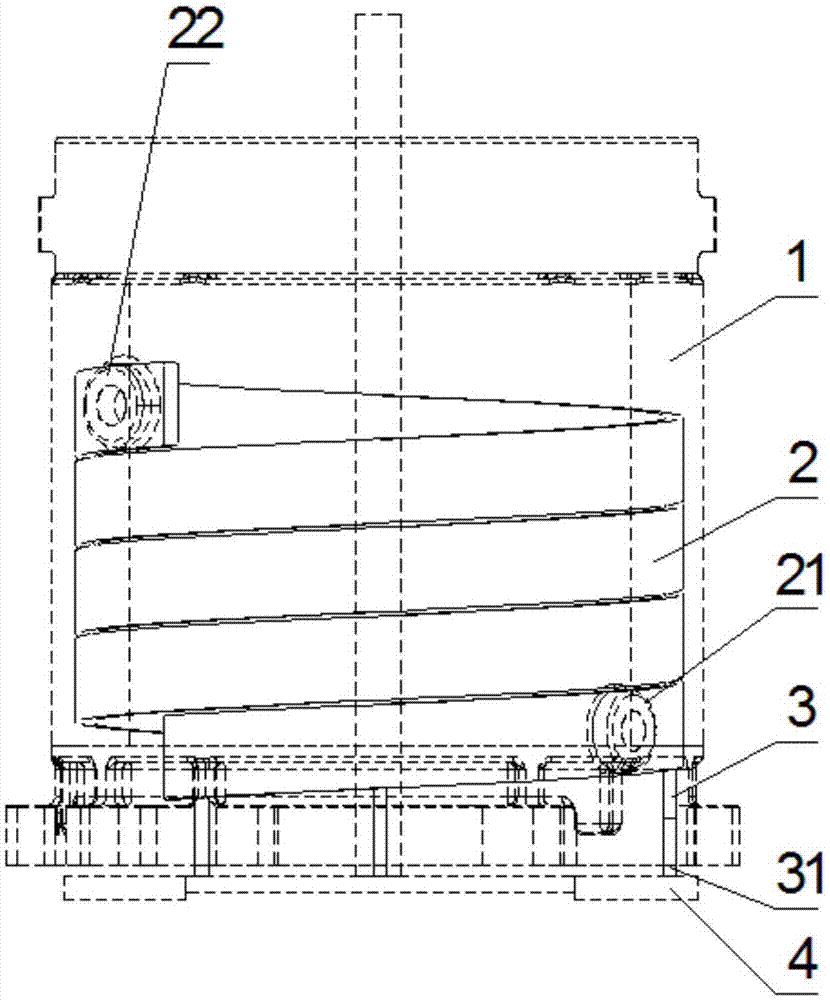

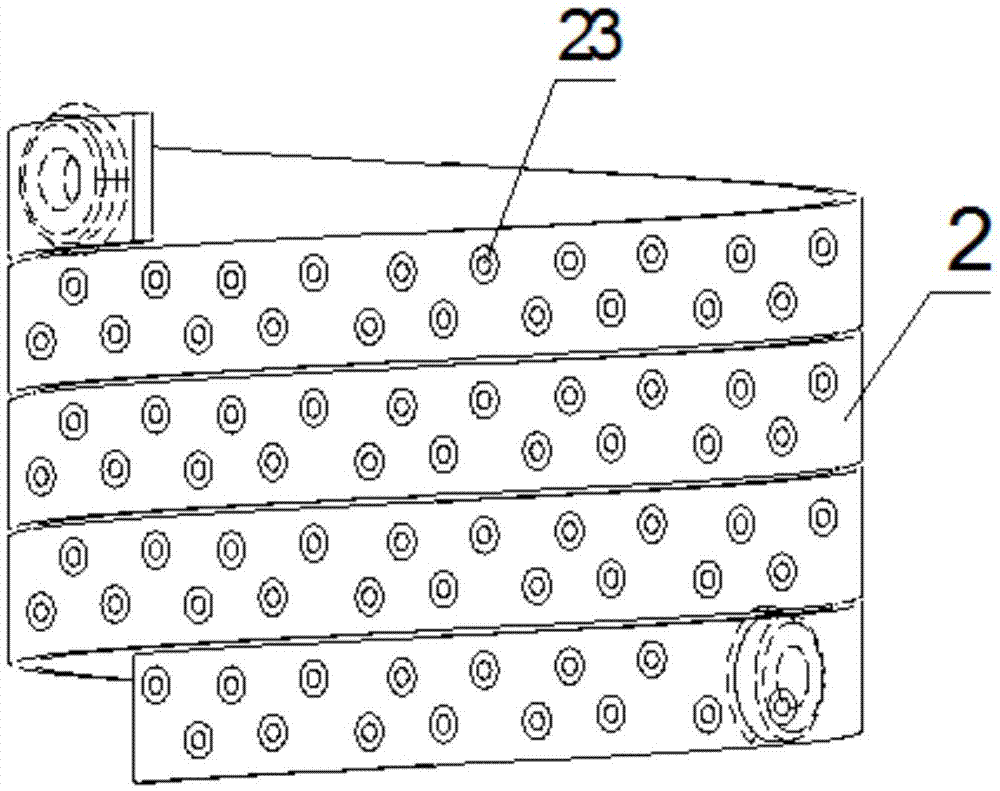

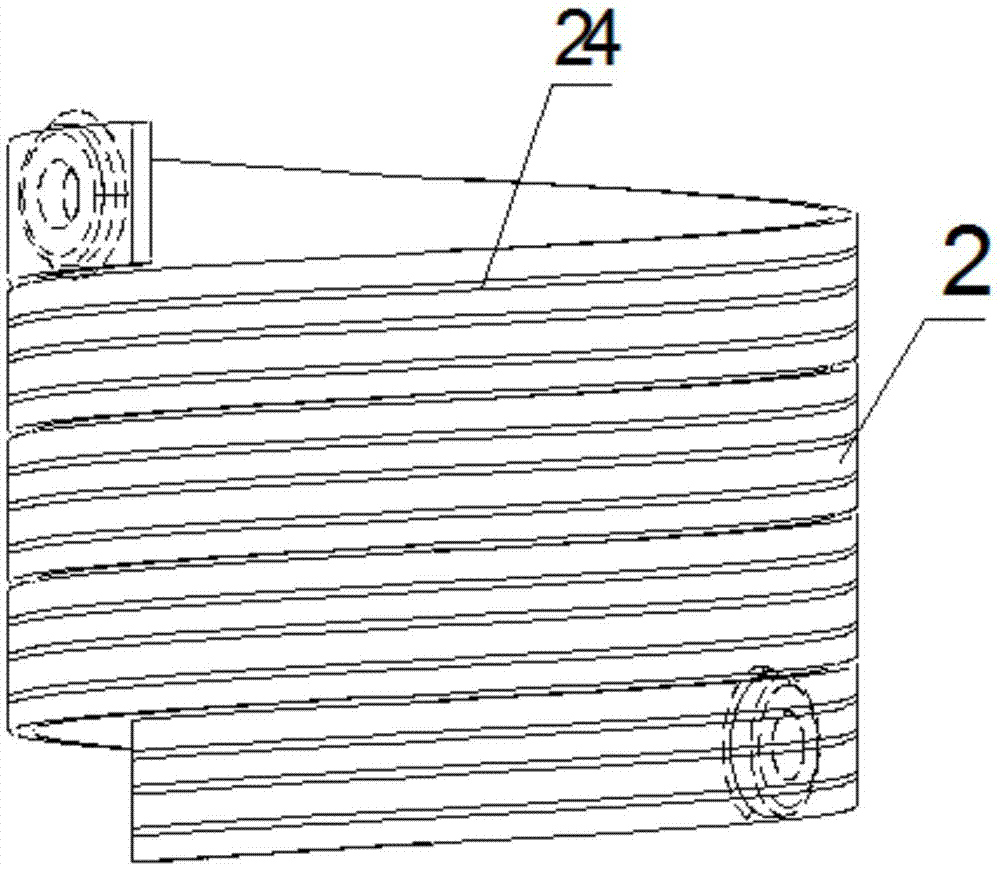

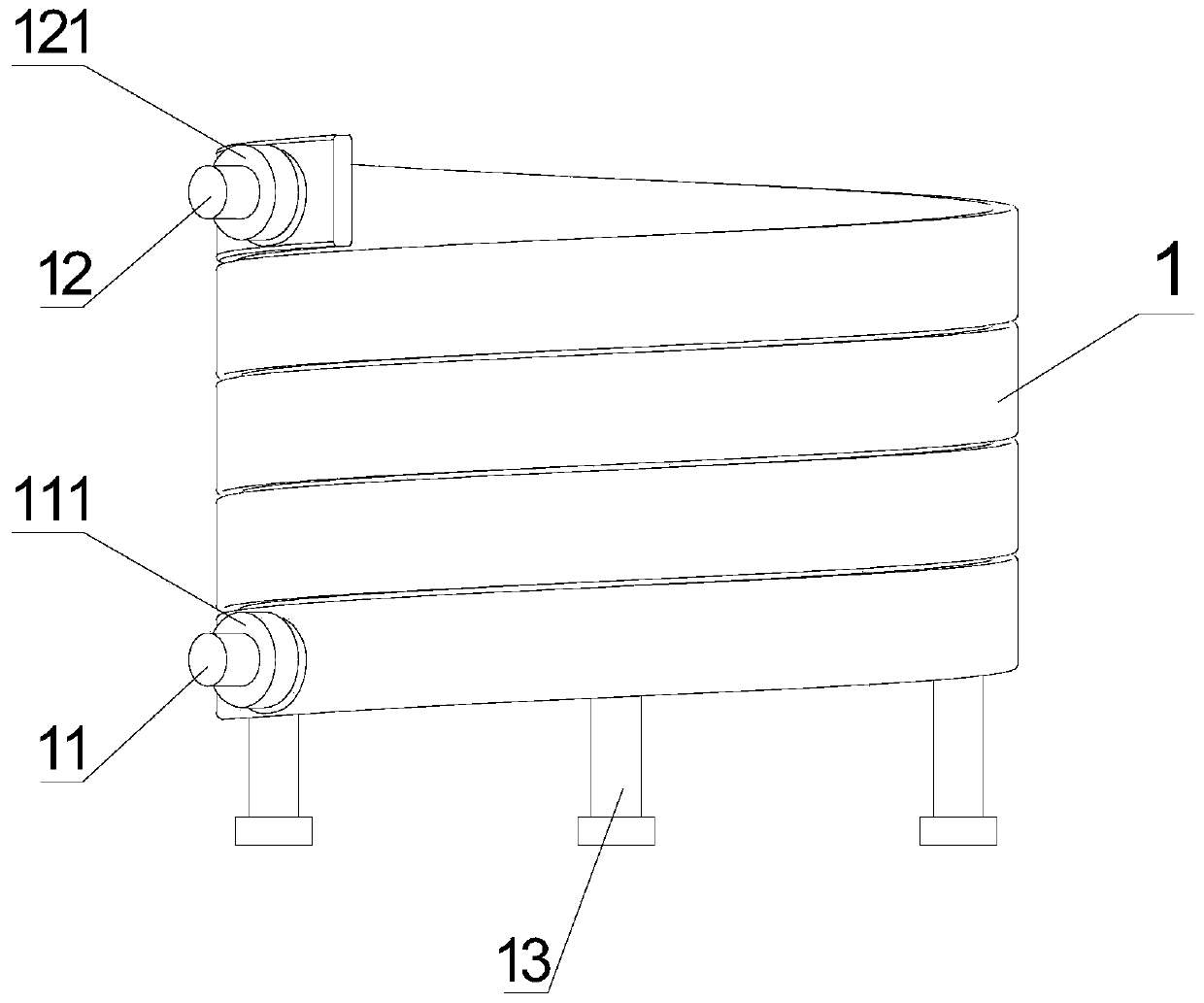

Expendable pattern casting technique for aluminum alloy internally provided with spiral coiled tube water passage

InactiveCN107282886ATightly boundReduce internal stressFoundry mouldsFoundry coresCooling effectCopper

The invention discloses an expendable pattern casting technique for an aluminum alloy internally provided with a spiral coiled tube water passage. According to the technique, the spiral coiled tube water passage made of stainless steel or copper is prefabricated firstly, and the upper end and the lower end of the spiral coiled tube water passage are provided with a water inlet and a water outlet which are capable of being exposed out of the column face of a motor shell correspondingly. A foaming mold is utilized for positioning and forming, an integrated motor shell EPS white mold internally comprising the prefabricated spiral coiled tube water passage can be machined through one-time forming, and then through the expendable pattern casting technique, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage in an embedded mode is casted. An auxiliary structure capable of being tightly combined with the casted aluminum alloy shell is arranged on the spiral coiled tube water passage, internal stress generated by cold-hot change is reduced, and the shell is prevented from cracking. The spiral coiled tube water passage is further connected with a casting technique supporting framework, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage can be stably and reliably casted on a large scale through an expendable pattern, the prefabricated spiral coiled tube water passage does not need to be filled with sand before casting, the water passage is smooth and not prone to being plugged, and it is ensured that the cooling effect is good.

Owner:FUJIAN JU NENG MACHINERY MFG CO LTD

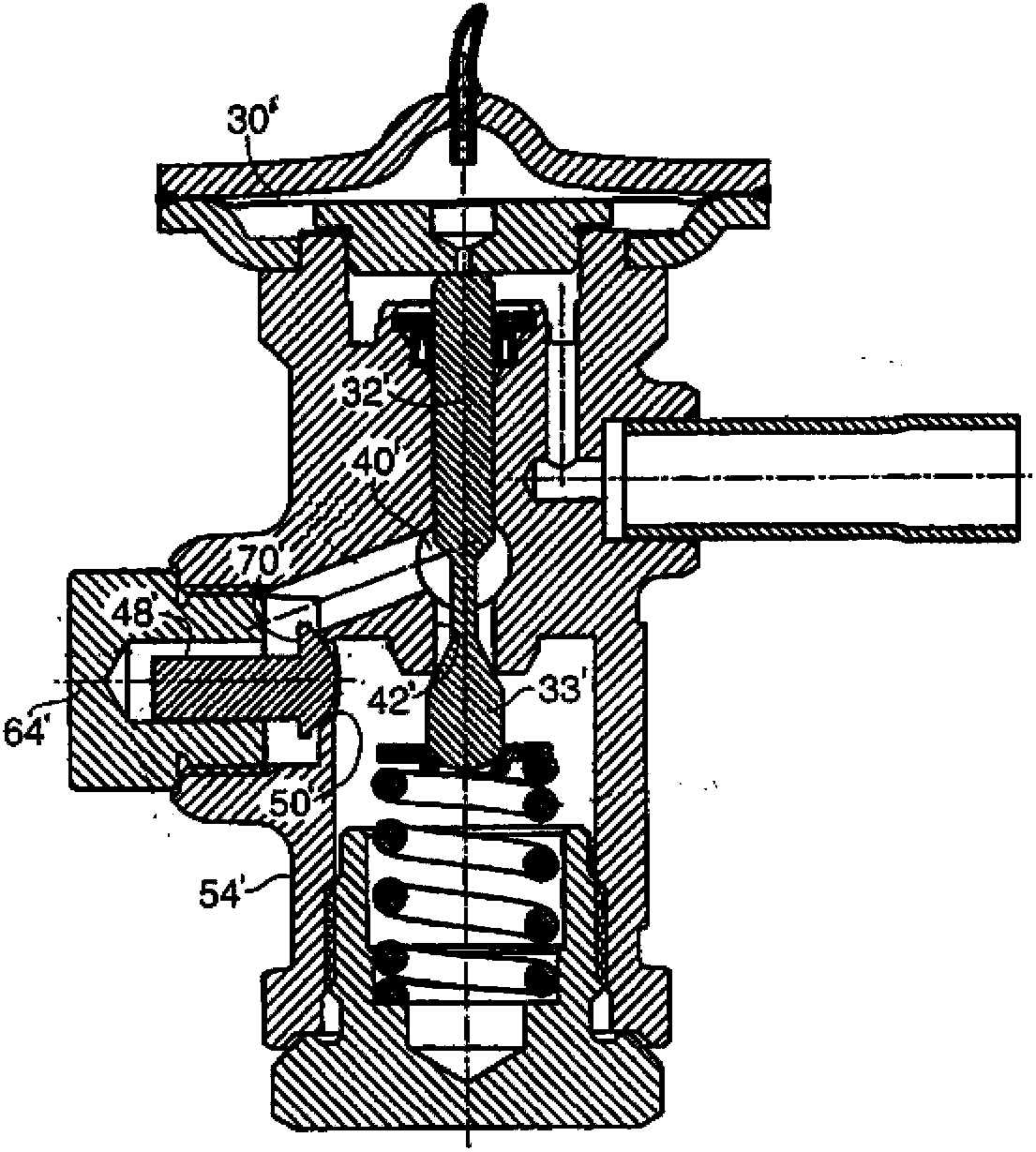

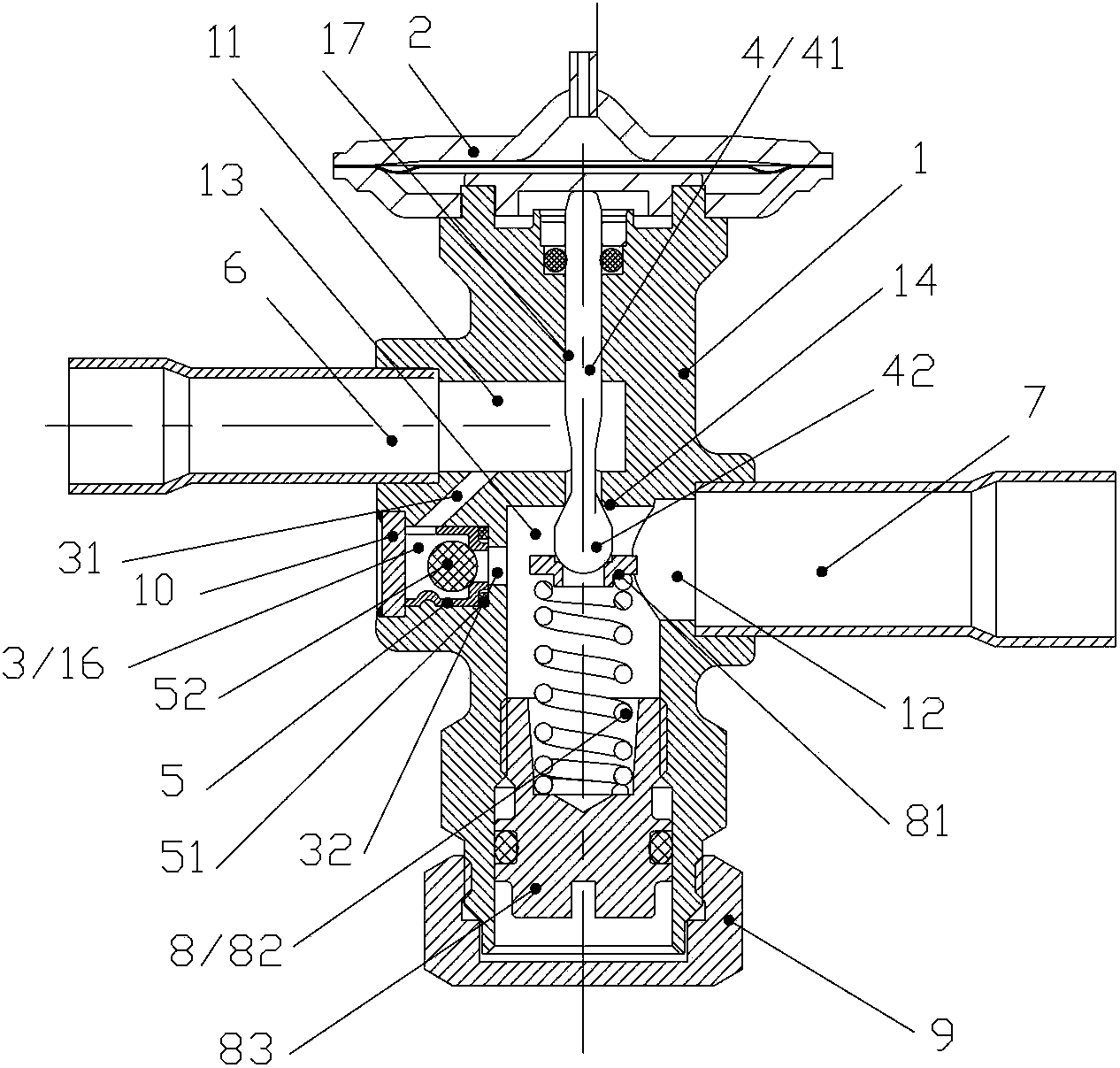

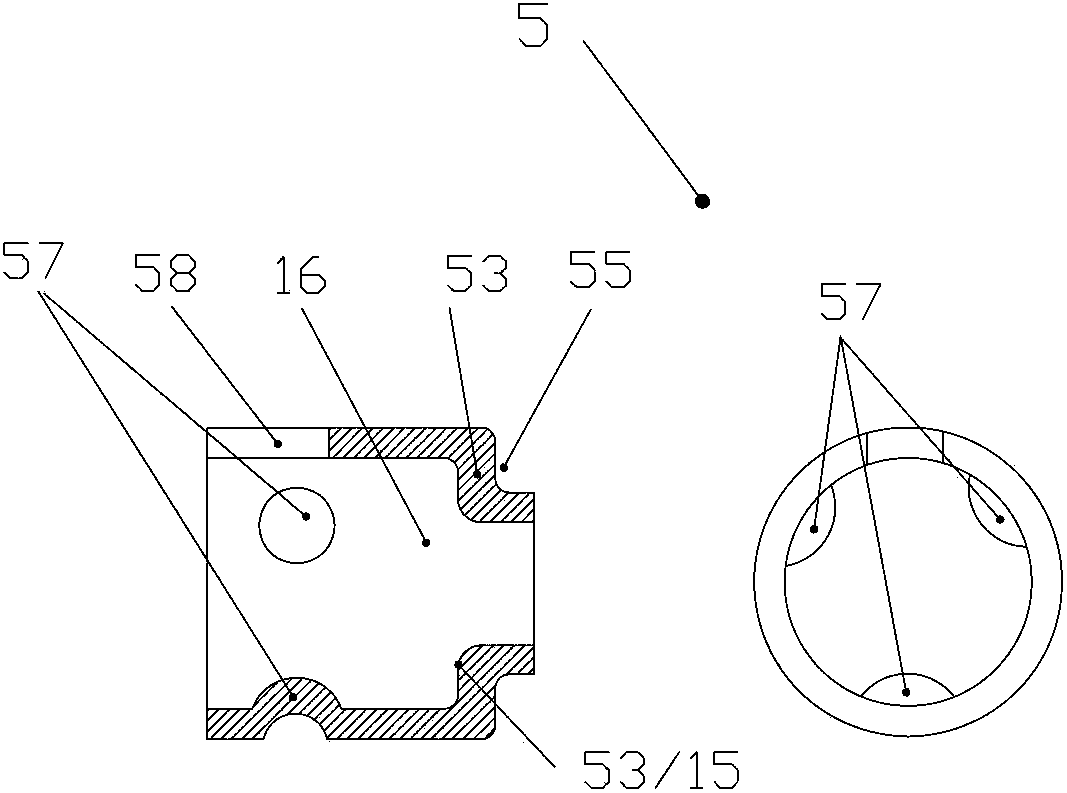

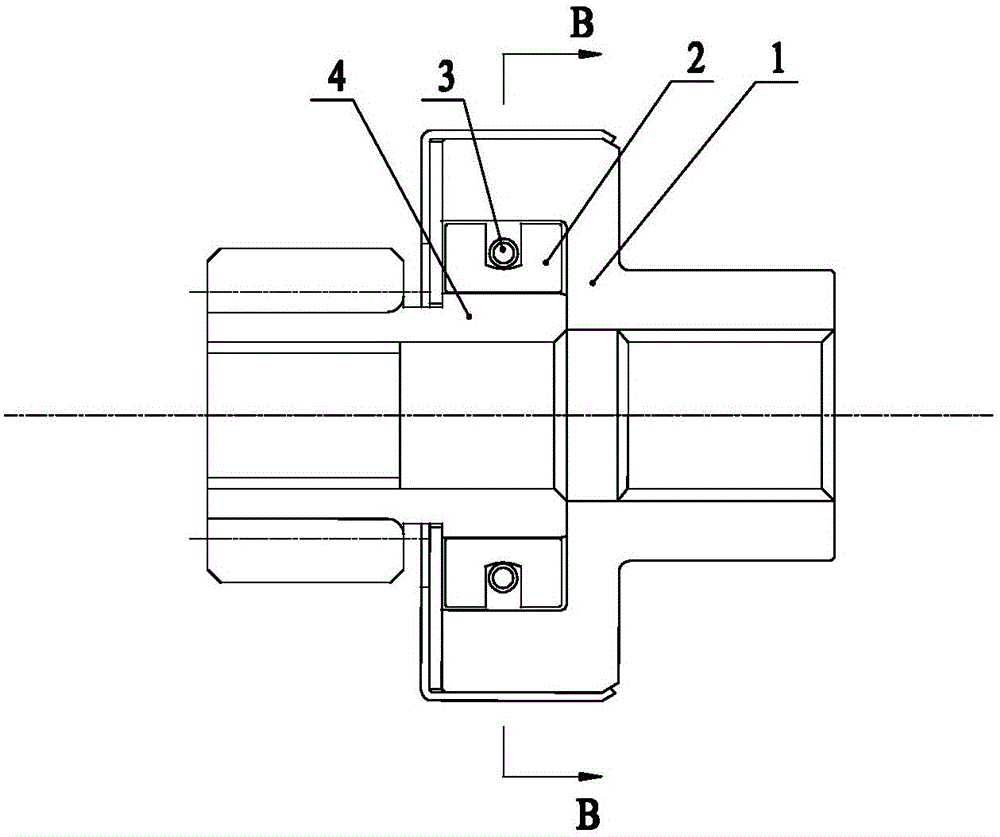

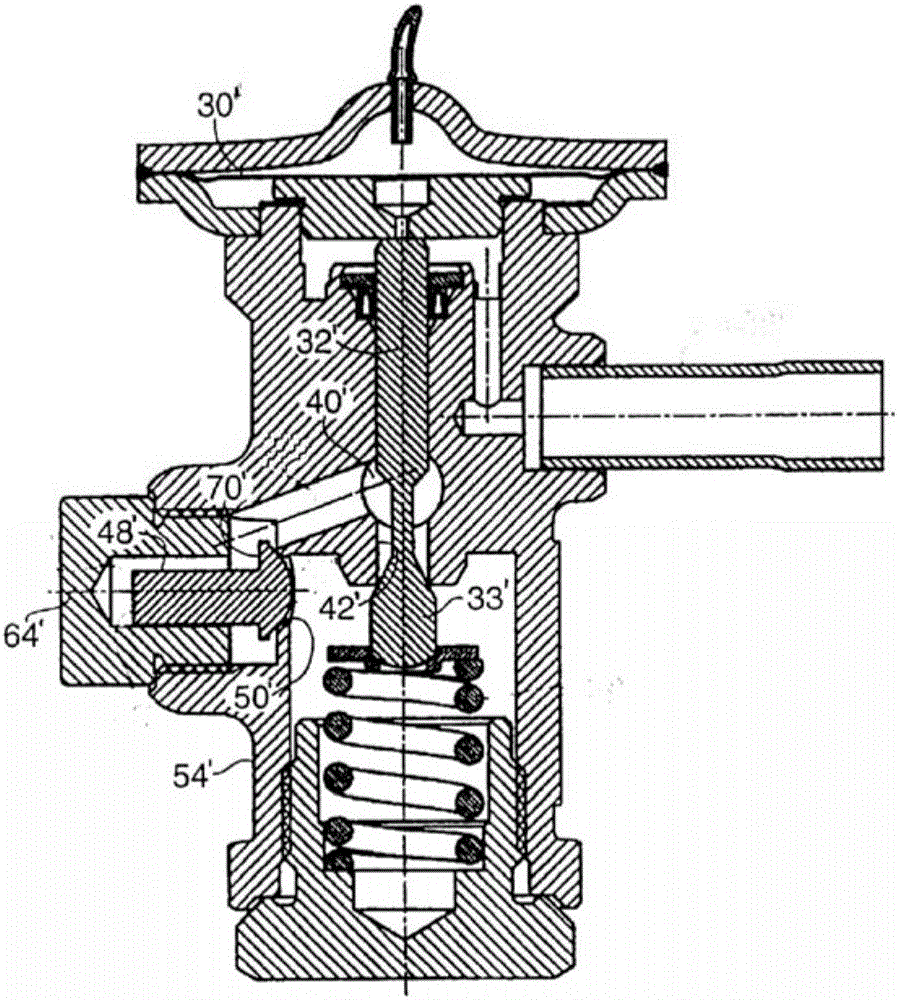

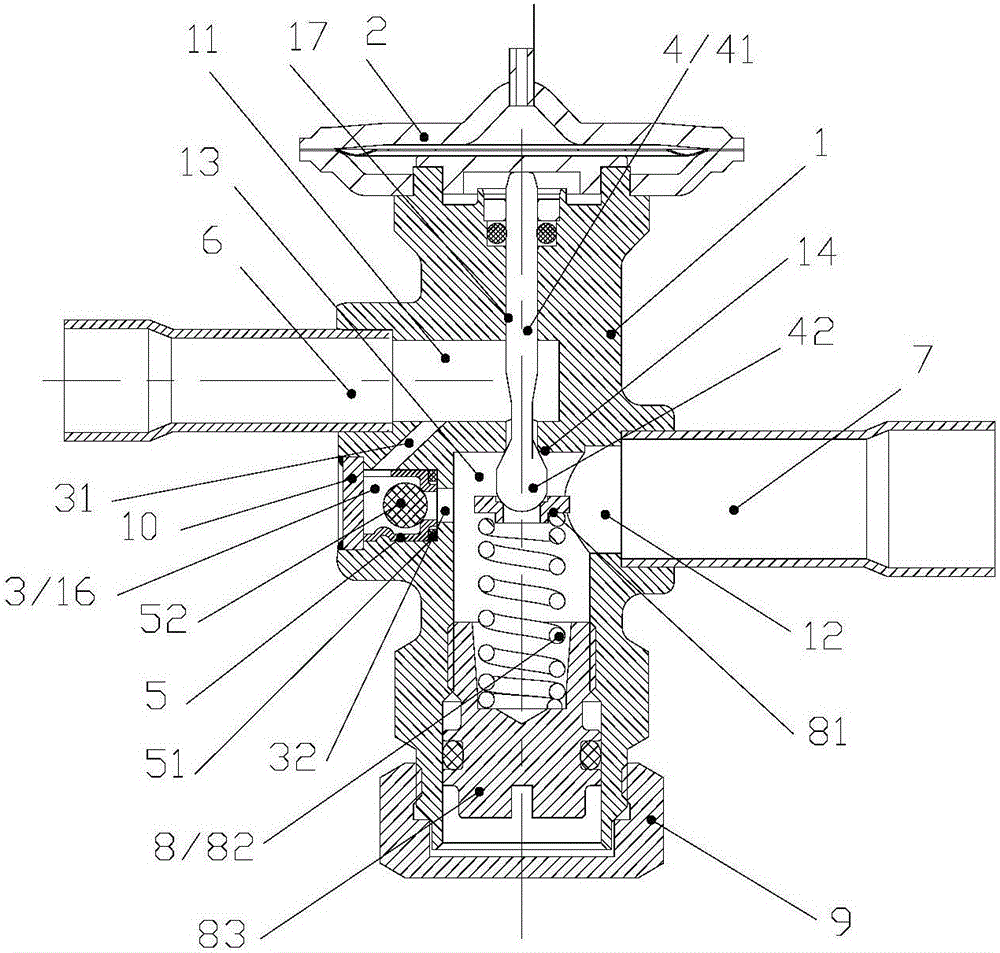

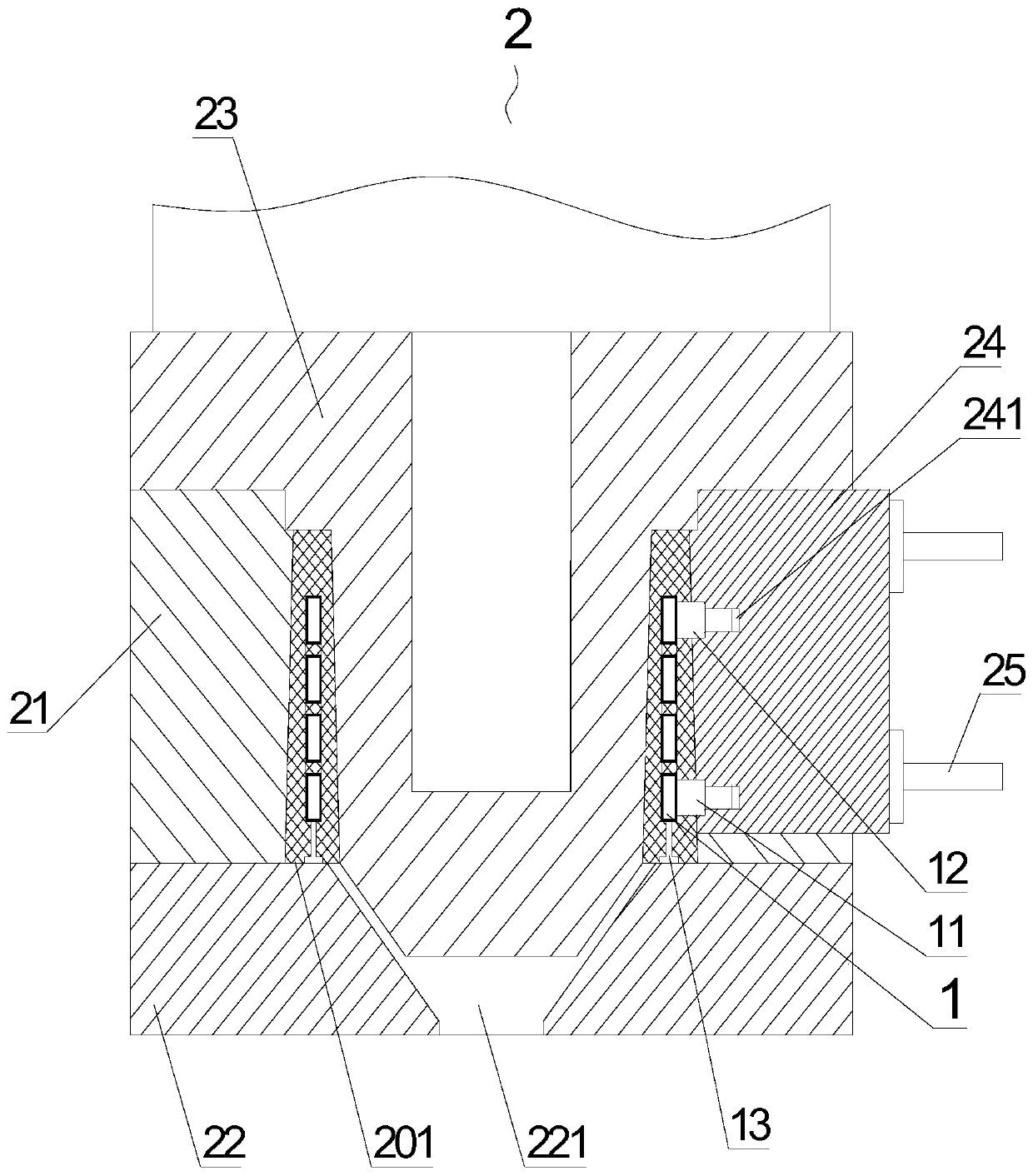

Thermal expansion valve

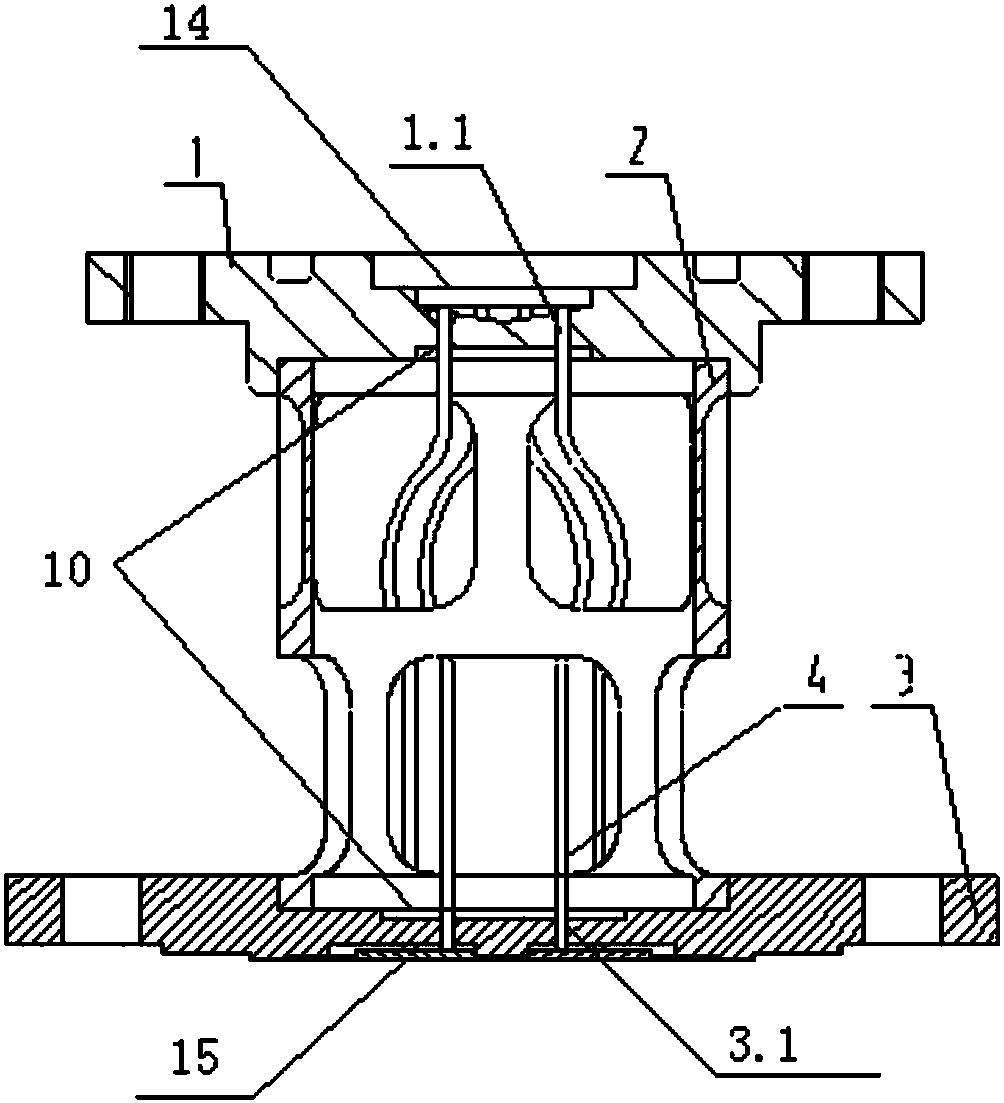

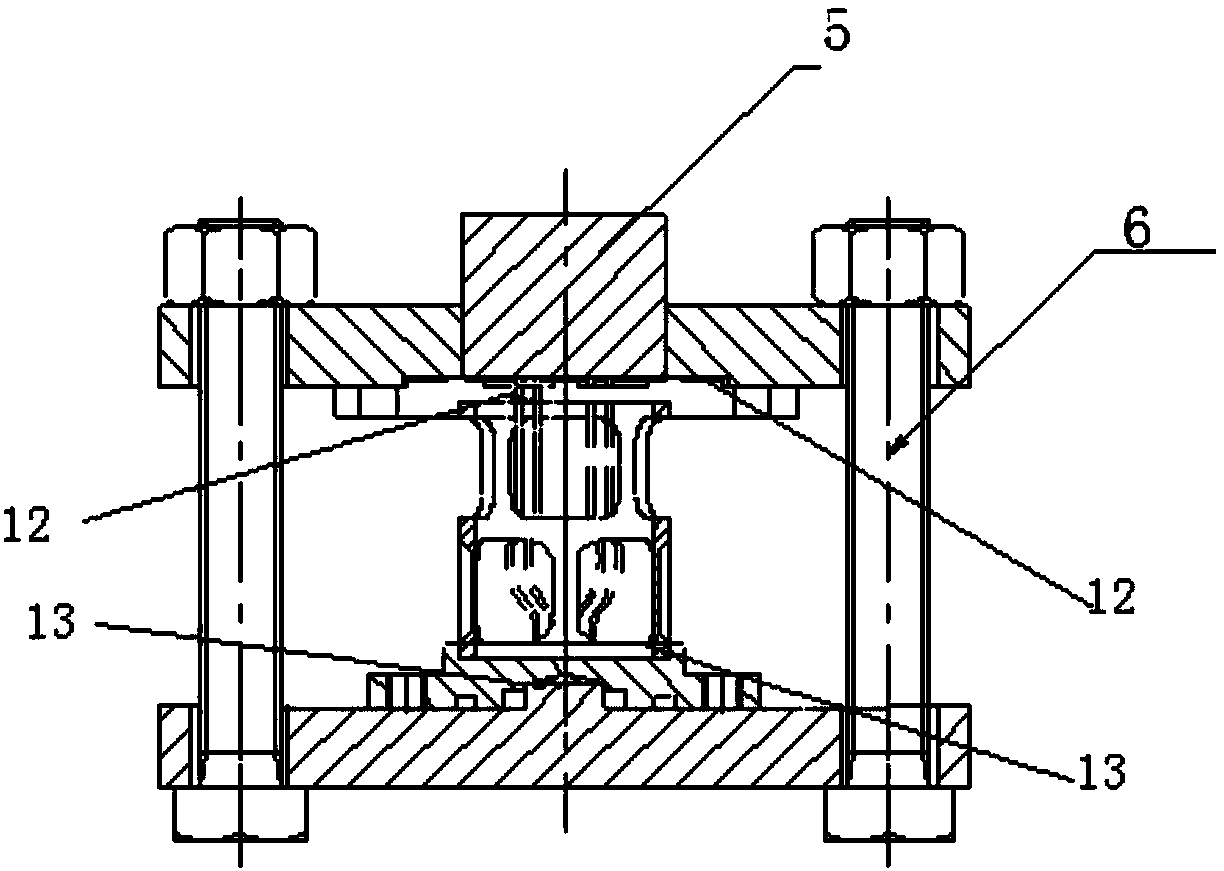

ActiveCN103423926ASimple processThe processing technology is simple and reliableMechanical apparatusFluid circulation arrangementInlet channelHigh volume manufacturing

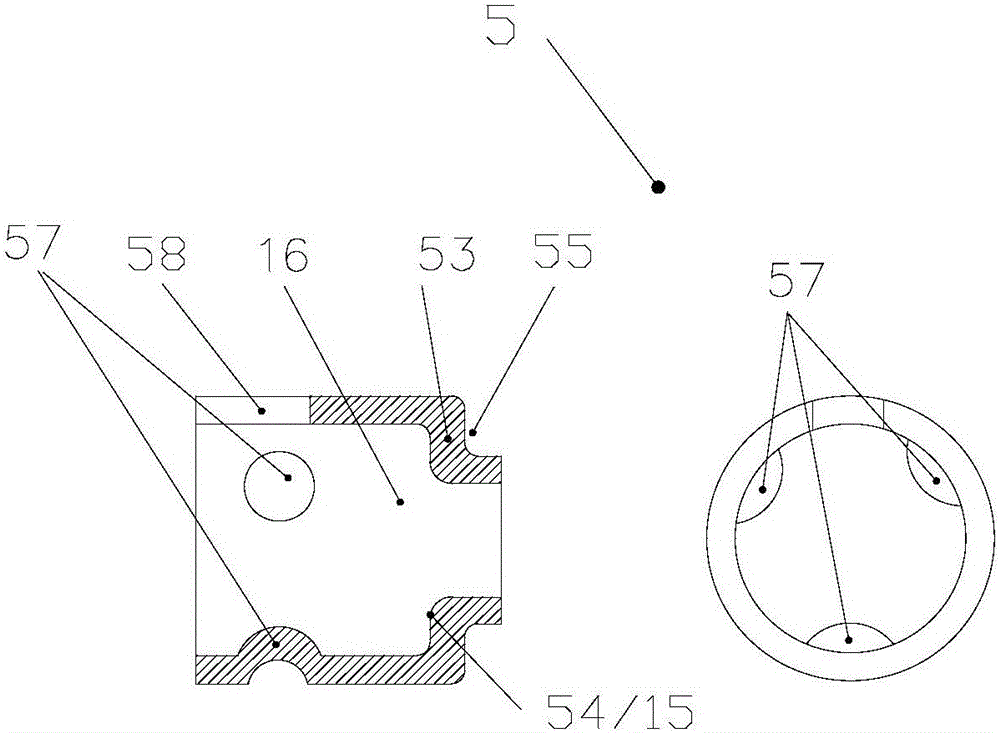

The invention discloses a thermal expansion valve with a unidirectional control function. The thermal expansion valve comprises a valve (1), a temperature sensing assembly (2) and a first valve element assembly (4). The valve (1) is provided with an inlet channel (11) and an outlet channel (12), the temperature sensing assembly (2) is arranged at one end of the valve (1), the first valve element assembly (4) is arranged in an inner cavity of the valve (1) and comprises a valve stem (41) and a first valve element (42), the valve stem (41) is abutted to the temperature sensing assembly (2), and the first valve element (42) is matched with a first valve port (14) arranged in the inner cavity (13), so that the flow of medium fluid which flows from the inlet channel (11) to the outlet channel (12) can be controlled. The thermal expansion valve is characterized in that the valve (1) is further provided with an accommodating portion, a cover (5) is arranged in the accommodating portion, and an inner hole (16) of the cover (5) is communicated with the inlet channel (11) and the inner cavity (13) to form auxiliary fluid channels. Compared with the prior art, the thermal expansion valve with the unidirectional control function has the advantages that the cover is arranged on the valve, so that a valve machining process is simplified; a valve port and a sealed position can be machined on the cover in the preferred scheme by means of drawing at one step, and a guide portion or limiting portion can be arranged on the cover by means of stamping, so that the machining process is simple and reliable, and the thermal expansion valve is suitable for mass production.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

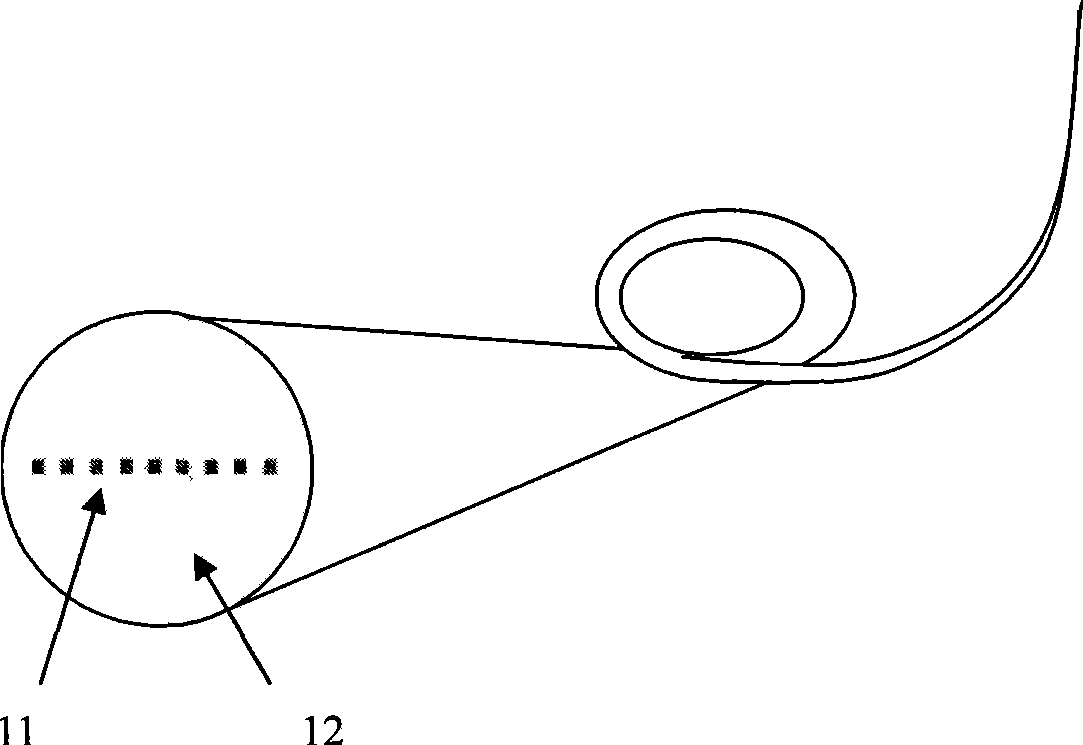

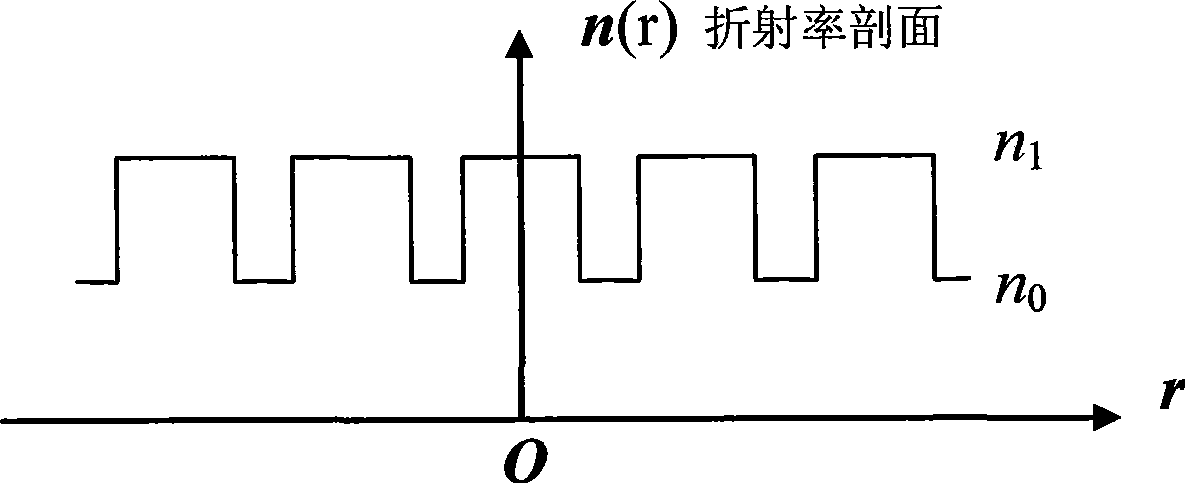

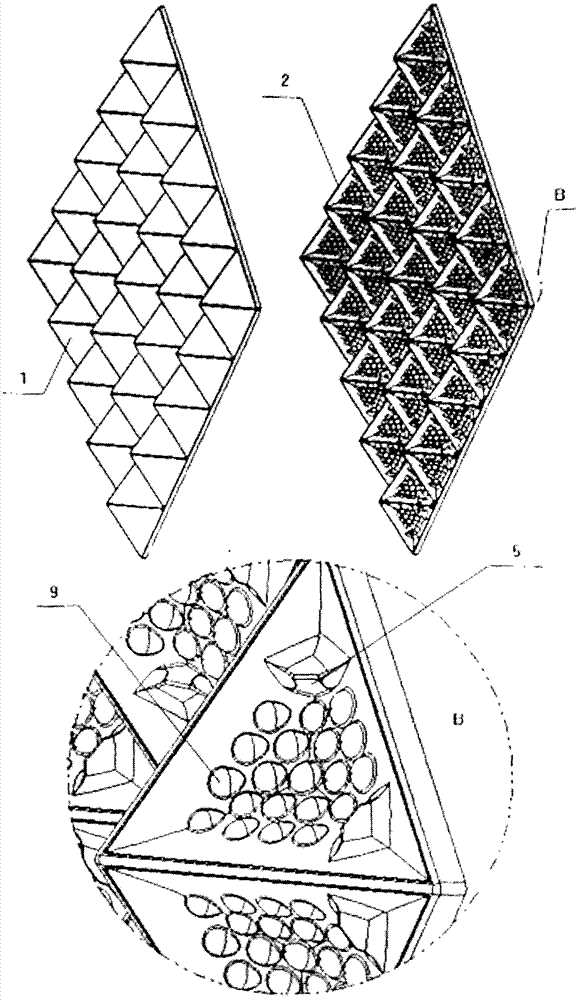

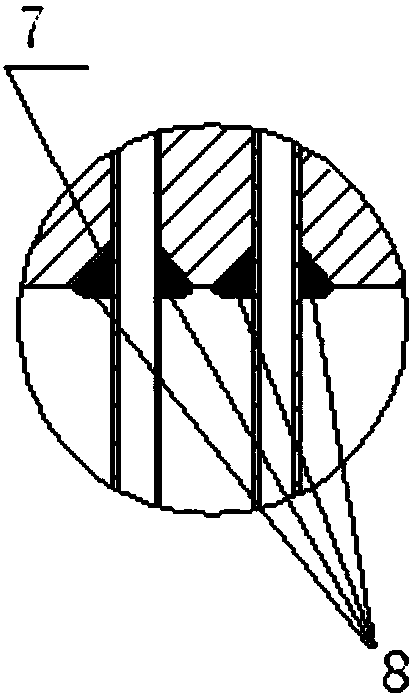

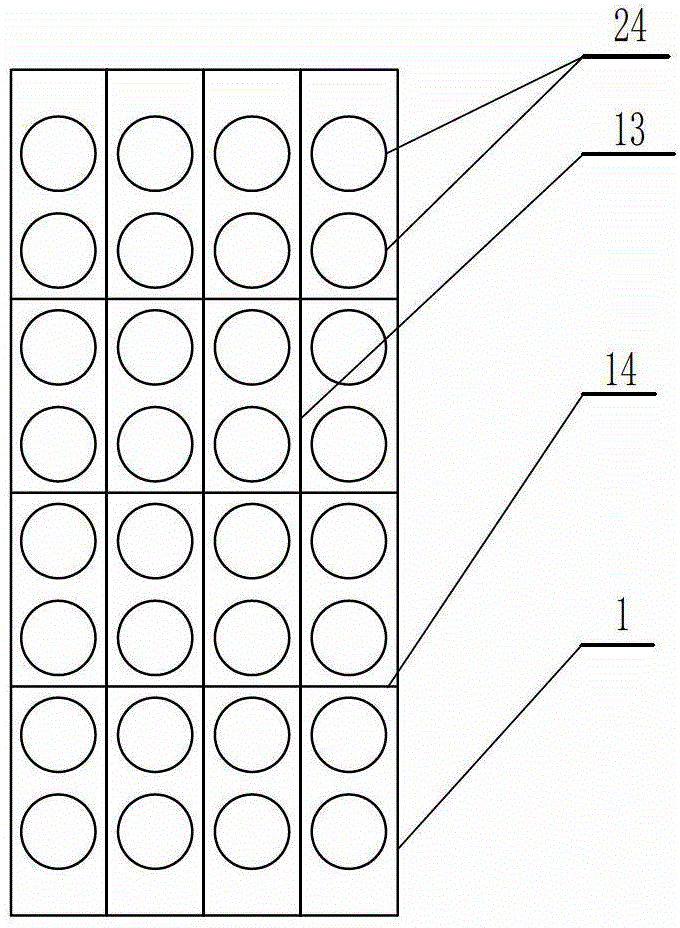

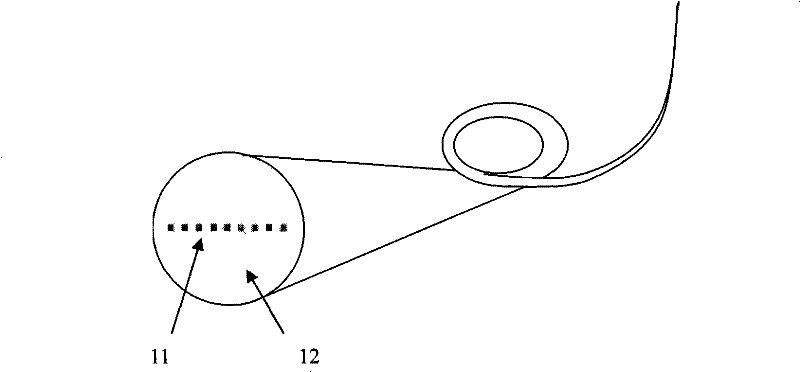

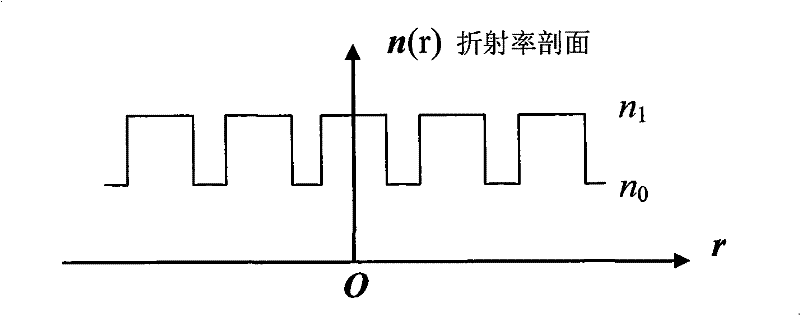

Parallel array multi-core fiber and preparation method thereof

InactiveCN101533124ASame optical performanceAvoid inconsistenciesGlass making apparatusOptical fibre with multilayer core/claddingParallel arrayOxyhydrogen

The invention provides a parallel array multi-core fiber and a preparation method thereof. Firstly, specially prepared fiber core filigree member is sectionally cut out according to certain length to obtain a group of fiber core filigrees with the same standard performance; the group of fiber core filigrees is tightly adjacent and is clamped between two high purity semi-column structure silica glass members, and is inserted into a high purity quartz outer sleeve after combination, so that a parallel array fiber core fiber preformed bar is formed; the group of the fiber core has the same axial direction with the quartz outer sleeve, and is positioned at the diameter position of the end face of the quartz outer sleeve; one end of the parallel array fiber core fiber preformed bar is sintered and sealed by high temperature oxyhydrogen flame, and then drawn into parallel array core fiber on a fiber wire-drawer-tower; in the process of fiber wire-drawing, a negative pressure is applied at the other end of the fiber preformed bar that is non-sintering end. The processing size is easy to control and the processing technology is simple and convenient, so the technology used for preparing the whole fiber preformed bar is simple, convenient and reliable, and has good economical efficiency.

Owner:HARBIN ENG UNIV

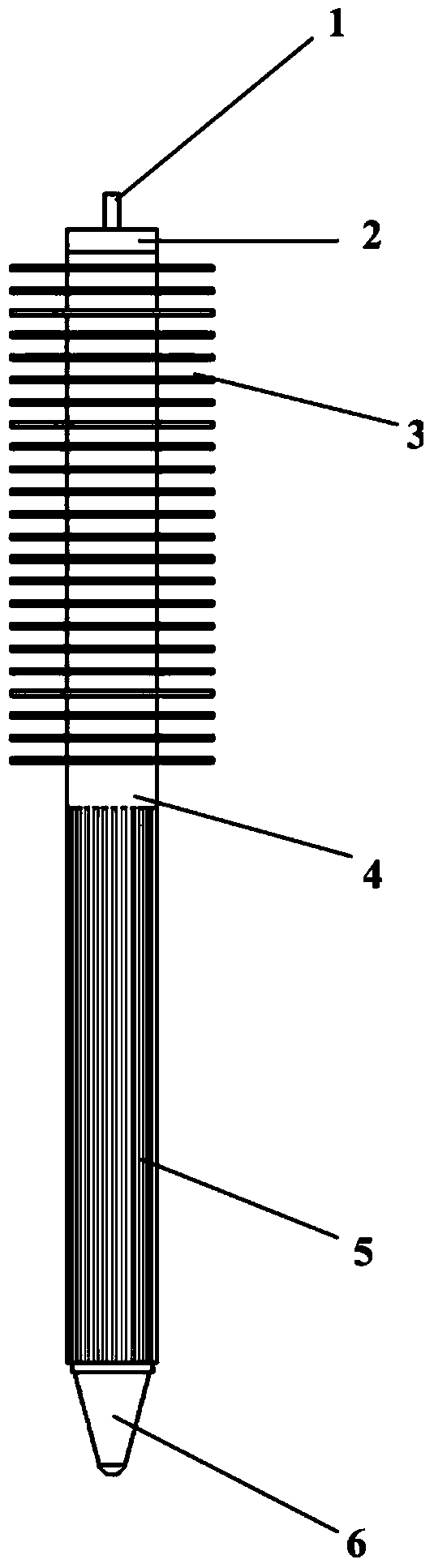

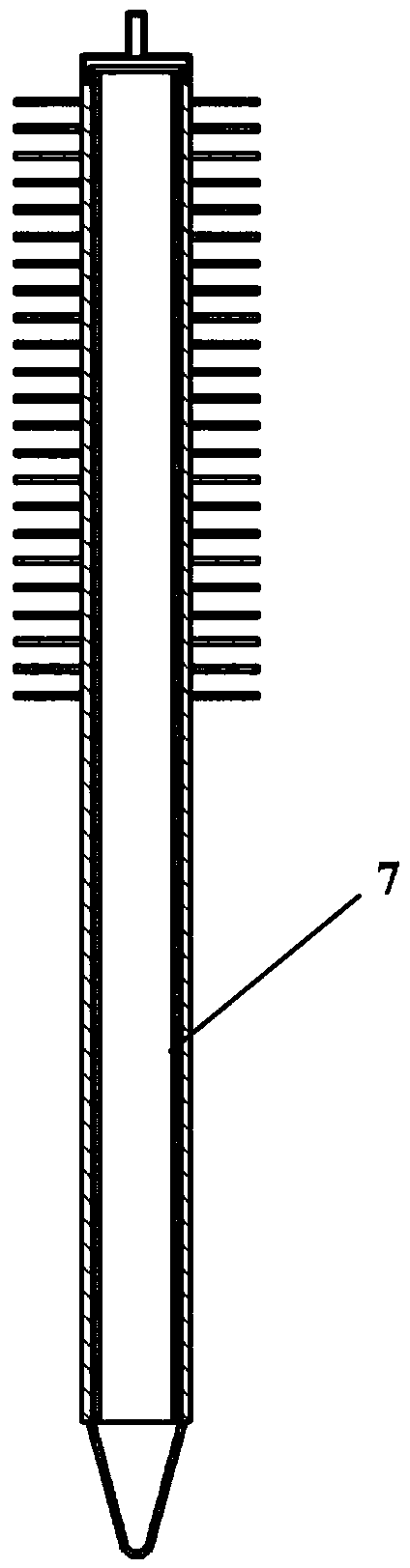

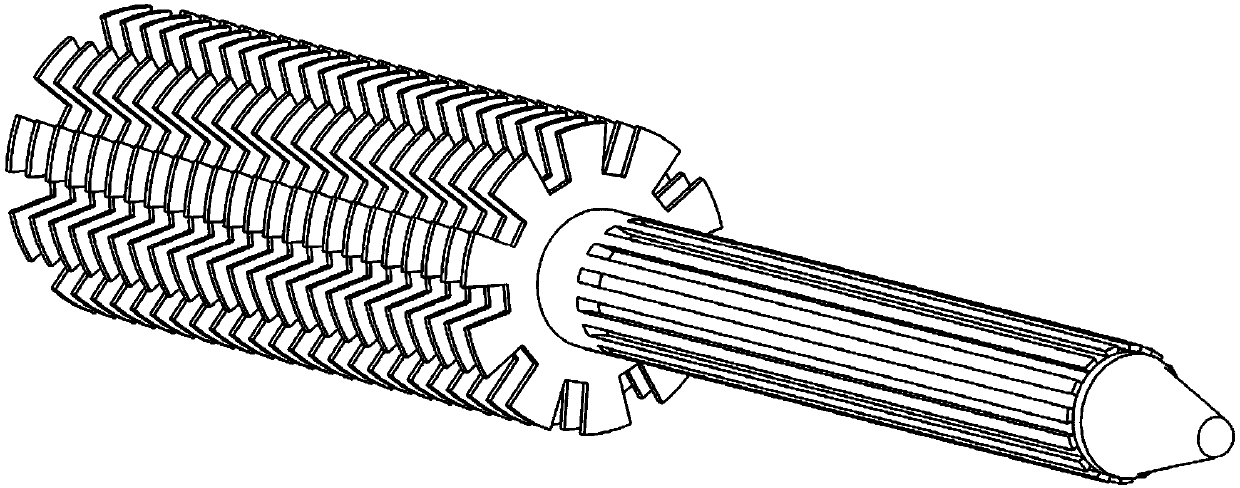

Combined exterior structural heat pipe for vertical heat-pipe condensers and manufacturing method thereof

InactiveCN103727823AEasy maintenanceThe processing technology is simple and reliableIndirect heat exchangersHeat pipeCivil engineering

The invention relates to a combined exterior structural heat pipe for vertical heat-pipe condensers. The combined exterior structural heat pipe for vertical heat-pipe condensers comprises a pipe body including a condensing segment and an evaporating segment. An exterior fin structure is arranged outside the pipe body, corresponding to the condensing segment, and an exterior grooved structure is arranged outside the pipe body, corresponding to the evaporating segment. The invention further relates to a manufacturing method of the combined exterior structural heat pipe for vertical heat-pipe condensers. The method includes the steps: manufacturing of the pipe body, manufacturing of an exterior fin unit, an upper end cover and a lower end cover, manufacturing of the exterior fin structure, and manufacturing and packaging of an absorbent core. The combined exterior structural heat pipe for vertical heat-pipe condensers and the manufacturing method thereof have the advantages that manufacturing process is simple and reliable, the combined exterior structural heat pipe provides a vertical heat-pipe condenser with good condensing effect and maintenance simplicity, and the combined exterior structural heat pipe and the manufacturing method thereof belong to the technical field of parts for condensers.

Owner:SOUTH CHINA UNIV OF TECH

LED light source, luminous ornament and illumination decorative lighting utilizing variable optical module to emit light

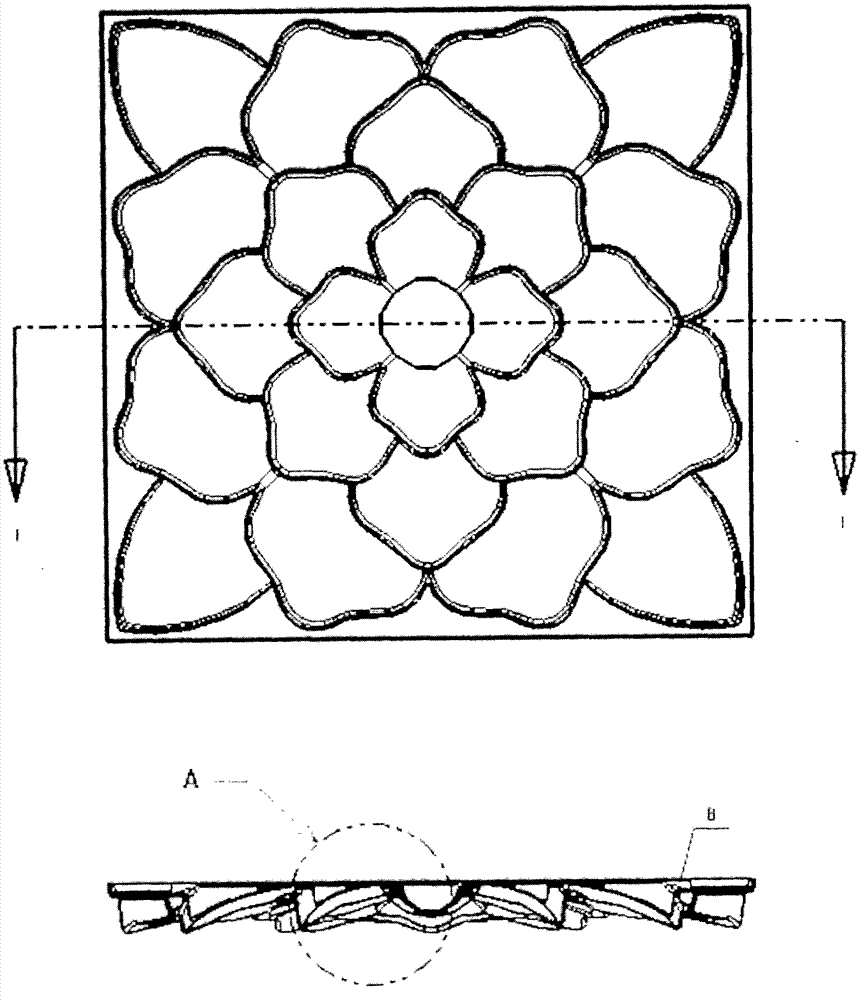

InactiveCN103363330AGood effectImprove reliabilityLighting heating/cooling arrangementsSpecial ornamental structuresOptical ModuleEffect light

The invention discloses an LED light source, a luminous ornament and an illumination decorative lighting utilizing a variable optical module to emit light. The variable optical module is composed of an inner shell, an outer shell and transparent media poured in a plurality of cavities between the inner shell and the outer shell. Usually, a layer of reflective film is arranged on the surface of the inner shell. The inner shell is provided with a plurality of small planes corresponding to luminous faces of an LED. The LED is pasted on the small planes on the inner side of the inner shell through transparent adhesive tape, light holes are formed in positions, corresponding to the LED, of the reflective film, and circuits and structural members of the LED are arrayed and fixed on the inner side of the inner shell. Light emitted by the LED forms various light effects and light shapes on the variable optical module after the light is subjected to optical variation. The LED optical variation light source can be made into various shapes like planes, curved faces, embossments and sculptures, and emit light wholly, and also can emit light in partial artistic shapes and artistic patterns. The LED optical variation light source can be used as a light source on the decorative lighting and can also be directly made into the luminous ornament or the illumination decorative lighting.

Owner:徐建国

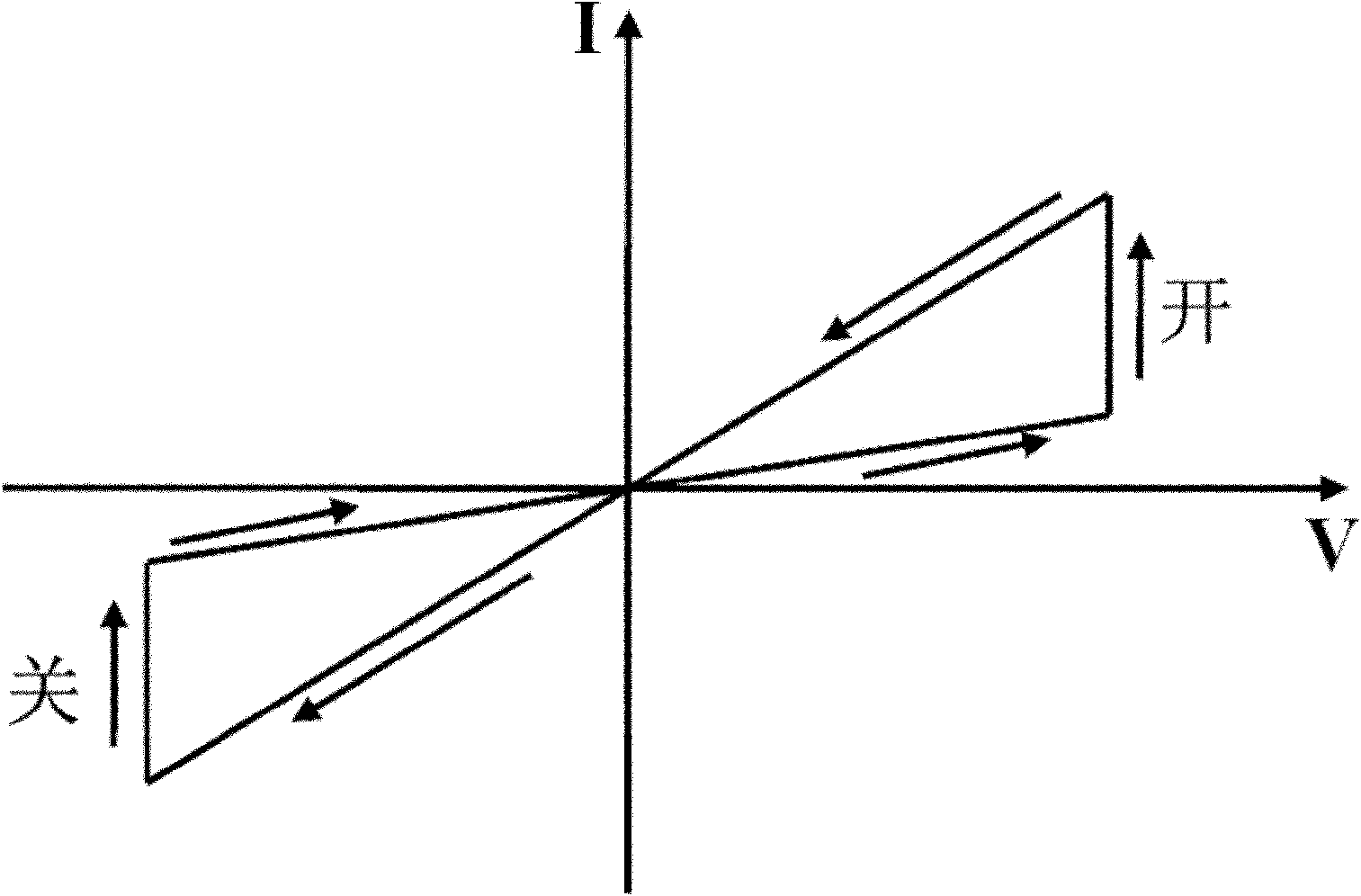

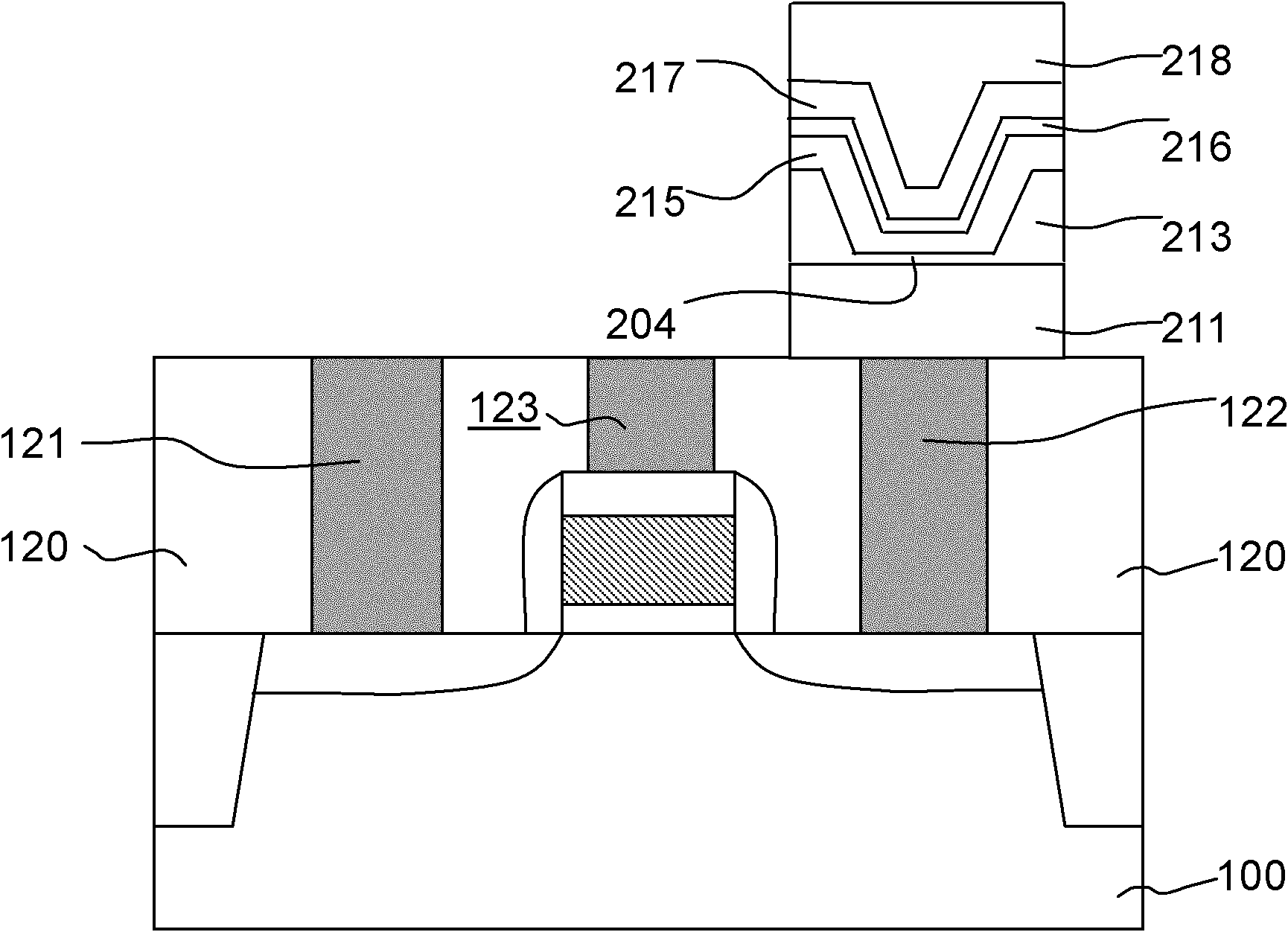

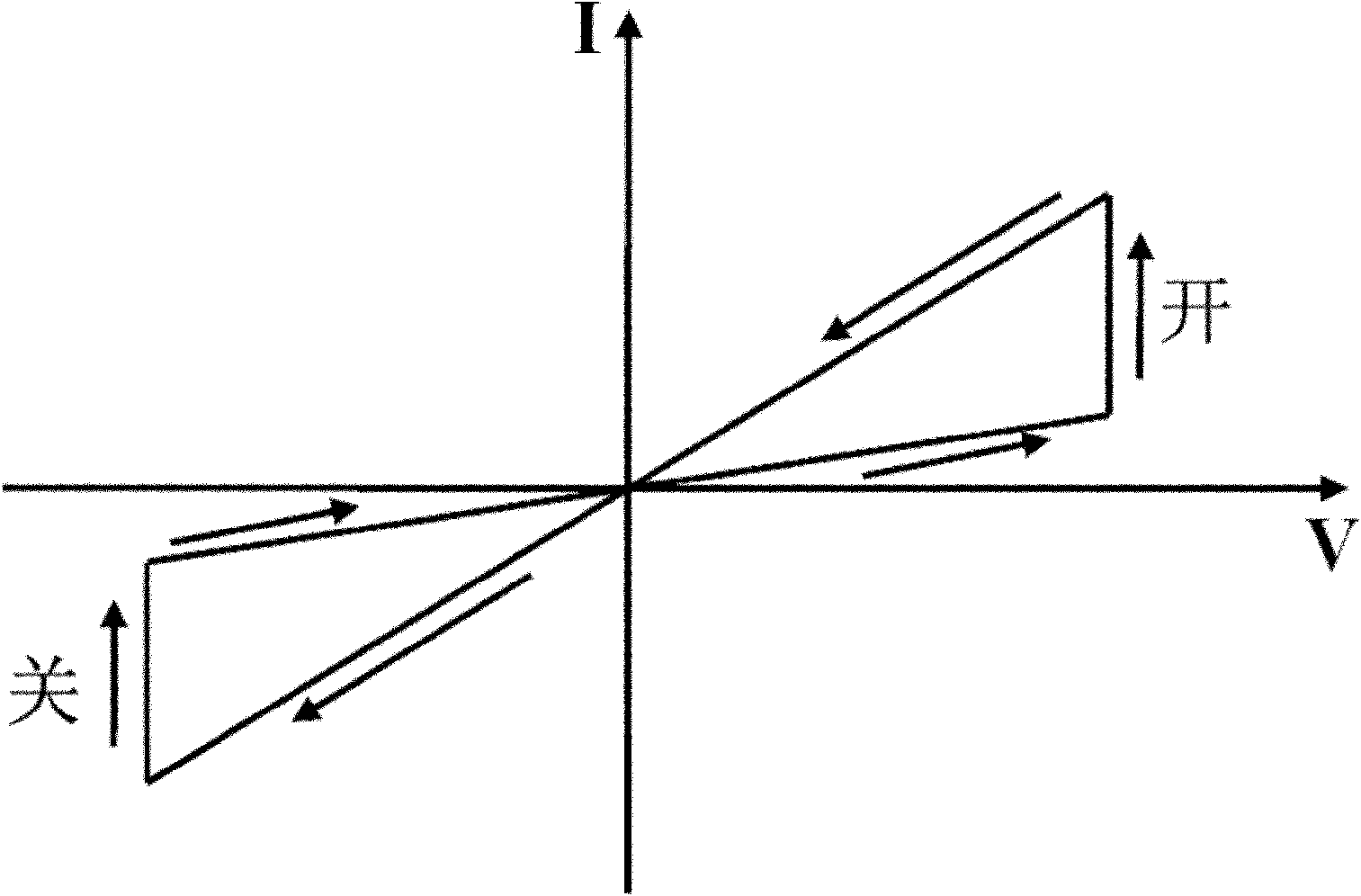

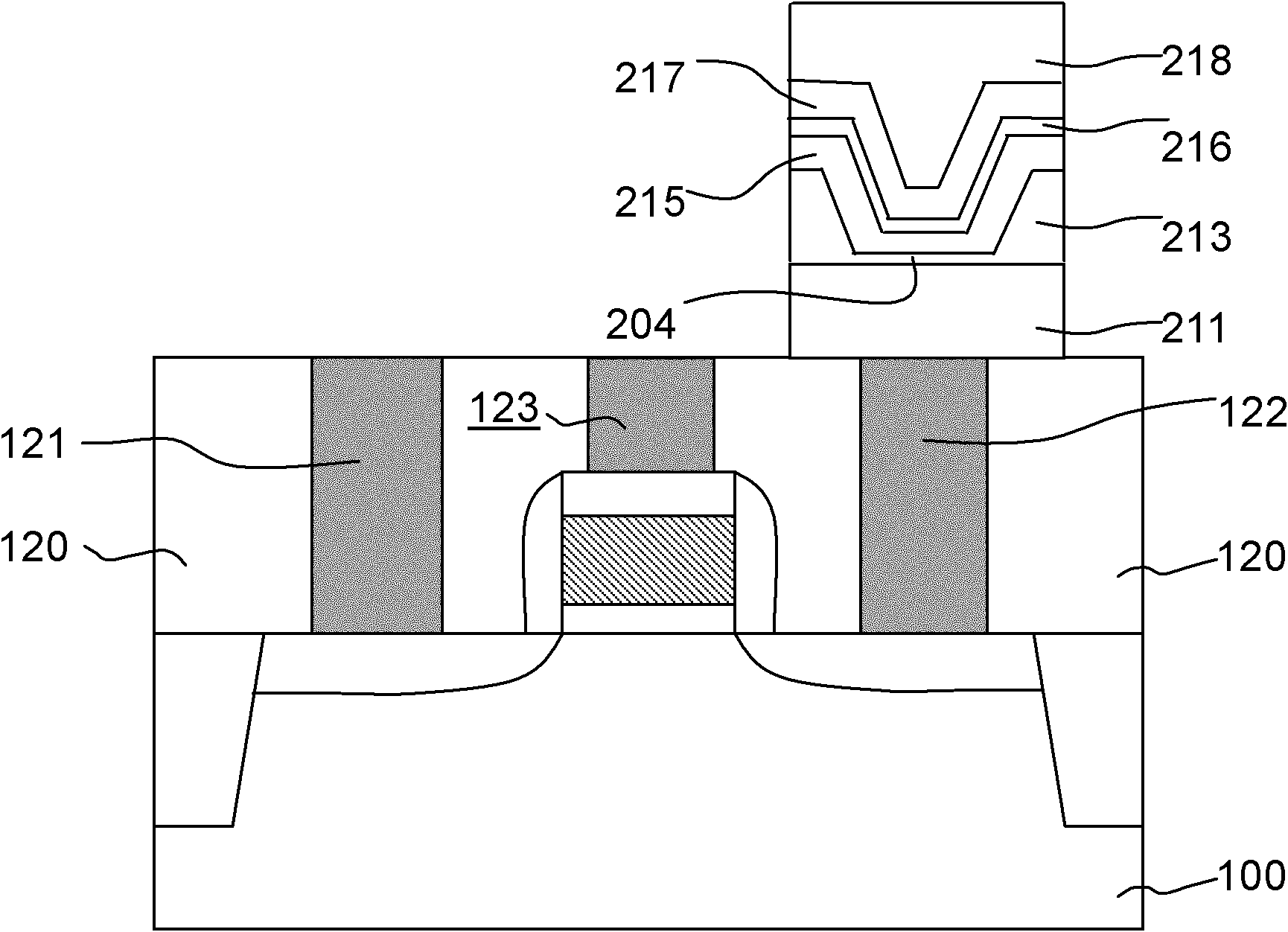

Nanoscale non-volatile resistive random access memory unit and preparation method thereof

ActiveCN102487123ASimple materialSimple processElectrical apparatusDigital storageElectrical resistance and conductanceHydrogen

The invention relates to the technical field of semiconductor memories, and discloses a nanoscale non-volatile resistive random access memory unit utilizing a hemi-spherical grain (HSG) electron beam resist and a preparation method thereof. The memory mainly comprises a first conductive electrode, a through-hole, a first resistive material, a second resistive material, a second metal nano layer, a third resistive material and a third conductive electrode, wherein the through-hole and the first resistive material are formed after a hydrogen silsequioxane (HSQ) electron beam resist is exposed and developed via electron beams. A part left after the HSQ electron beam resist is exposed and developed is utilized as the through-hole, the diameter of the through-hole can be as small as a nano magnitude, and the HSQ electron beam resist which is not completely developed at the bottom of the through-hole can be used as a part or the whole of the first resistive material. By utilizing the preparation method, the resistance changing memory which has the advantages of small device area, high yield and good performance can be obtained; and the semiconductor memory is apt to large-scale integration and practicality.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

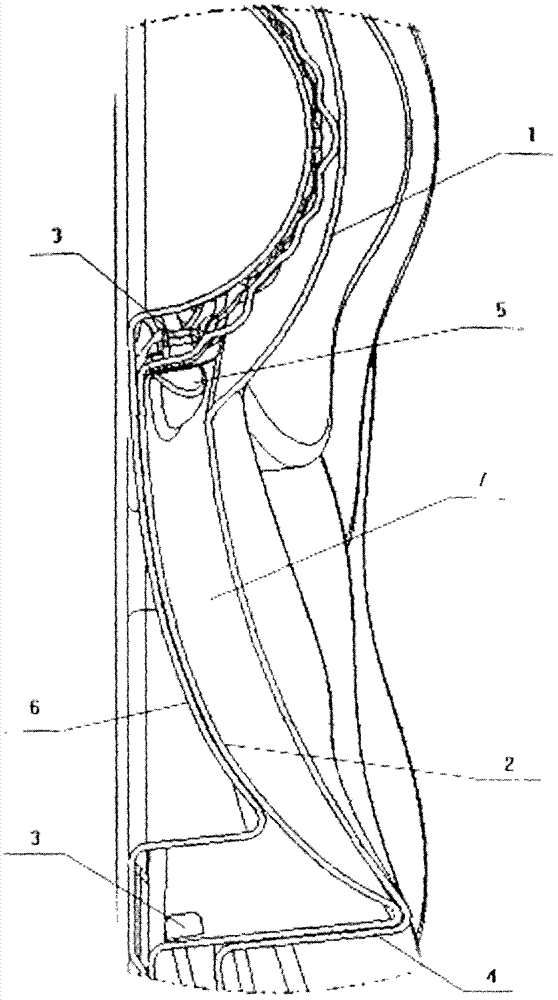

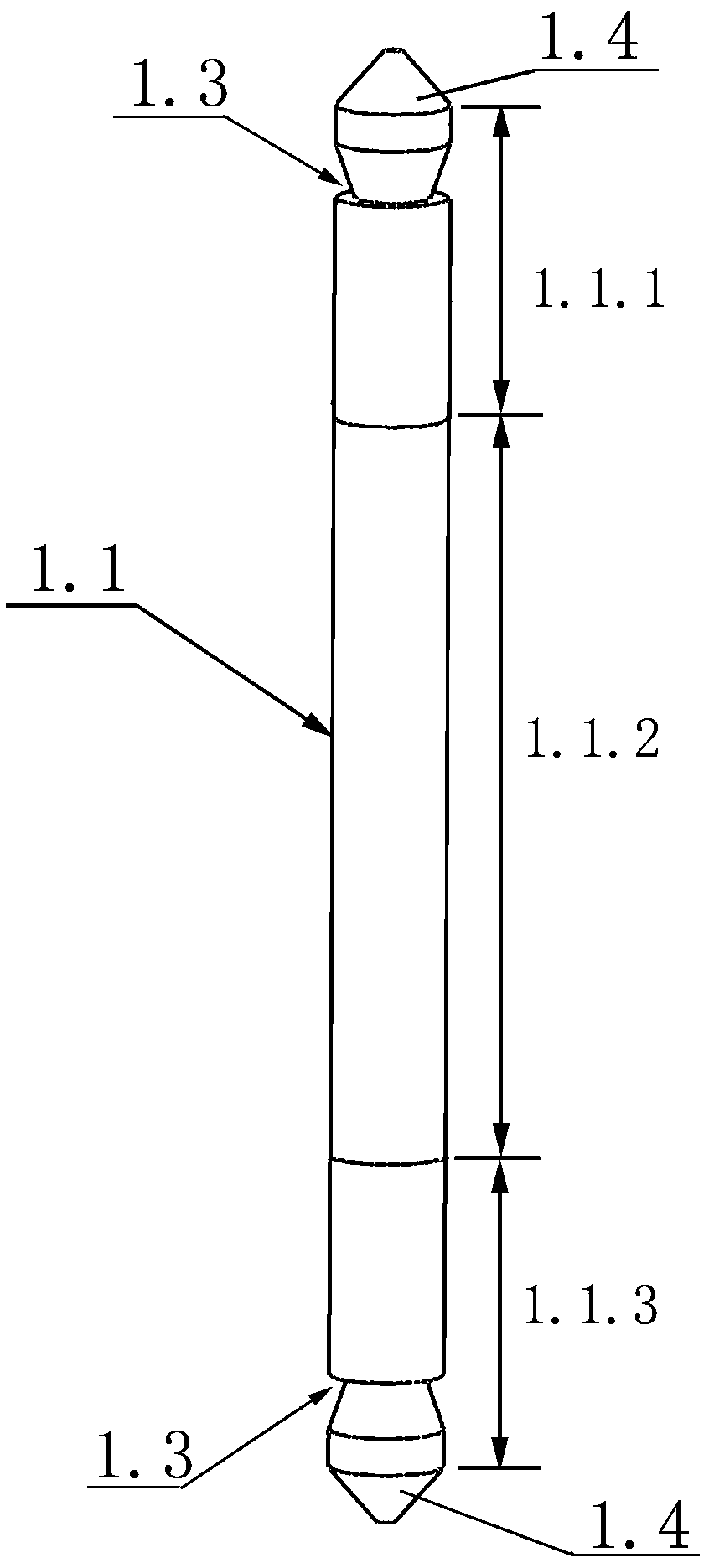

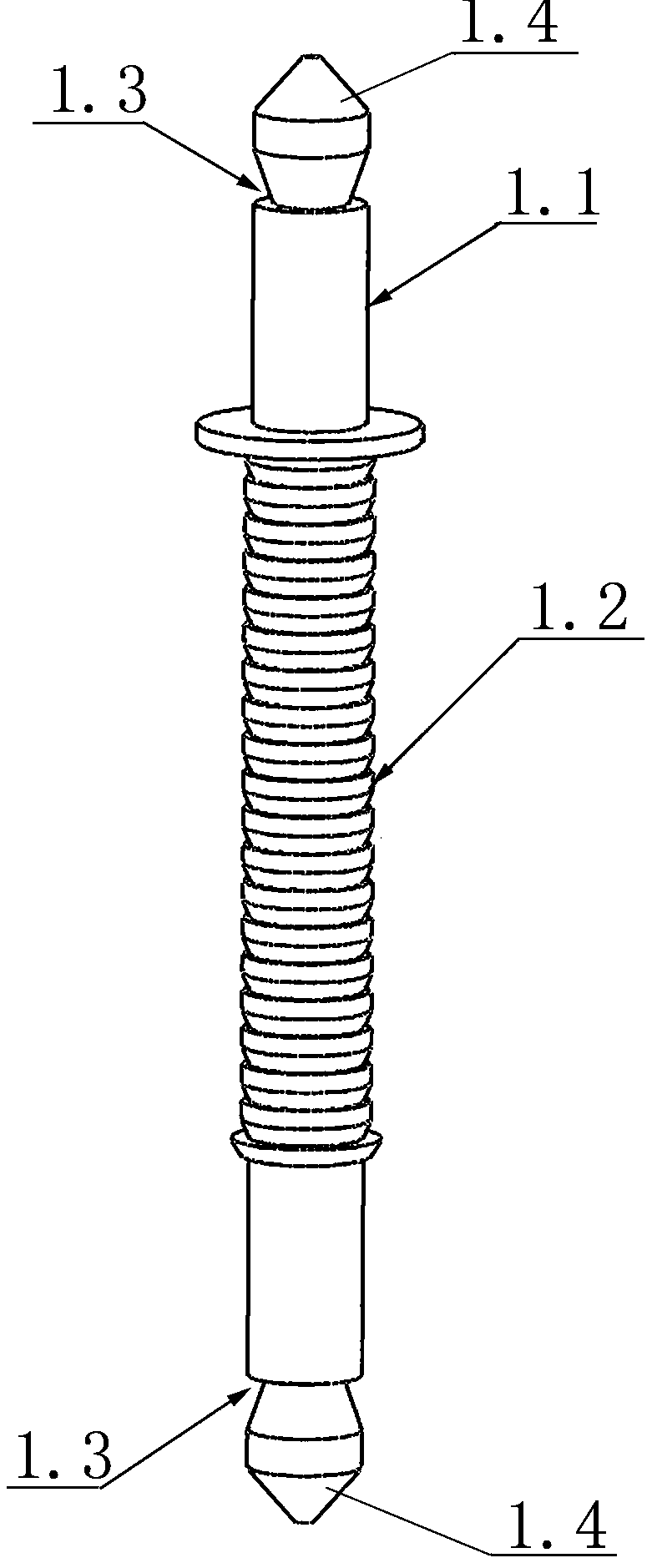

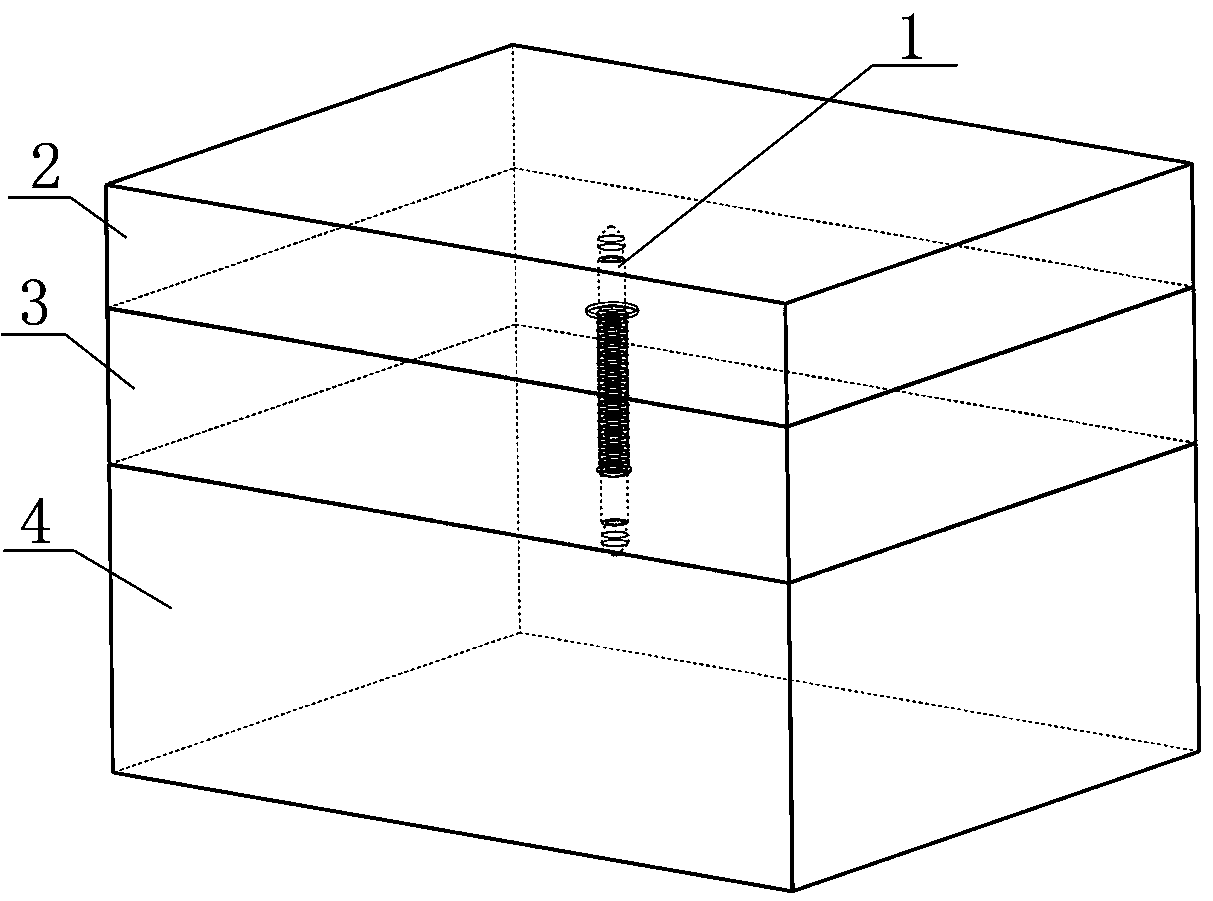

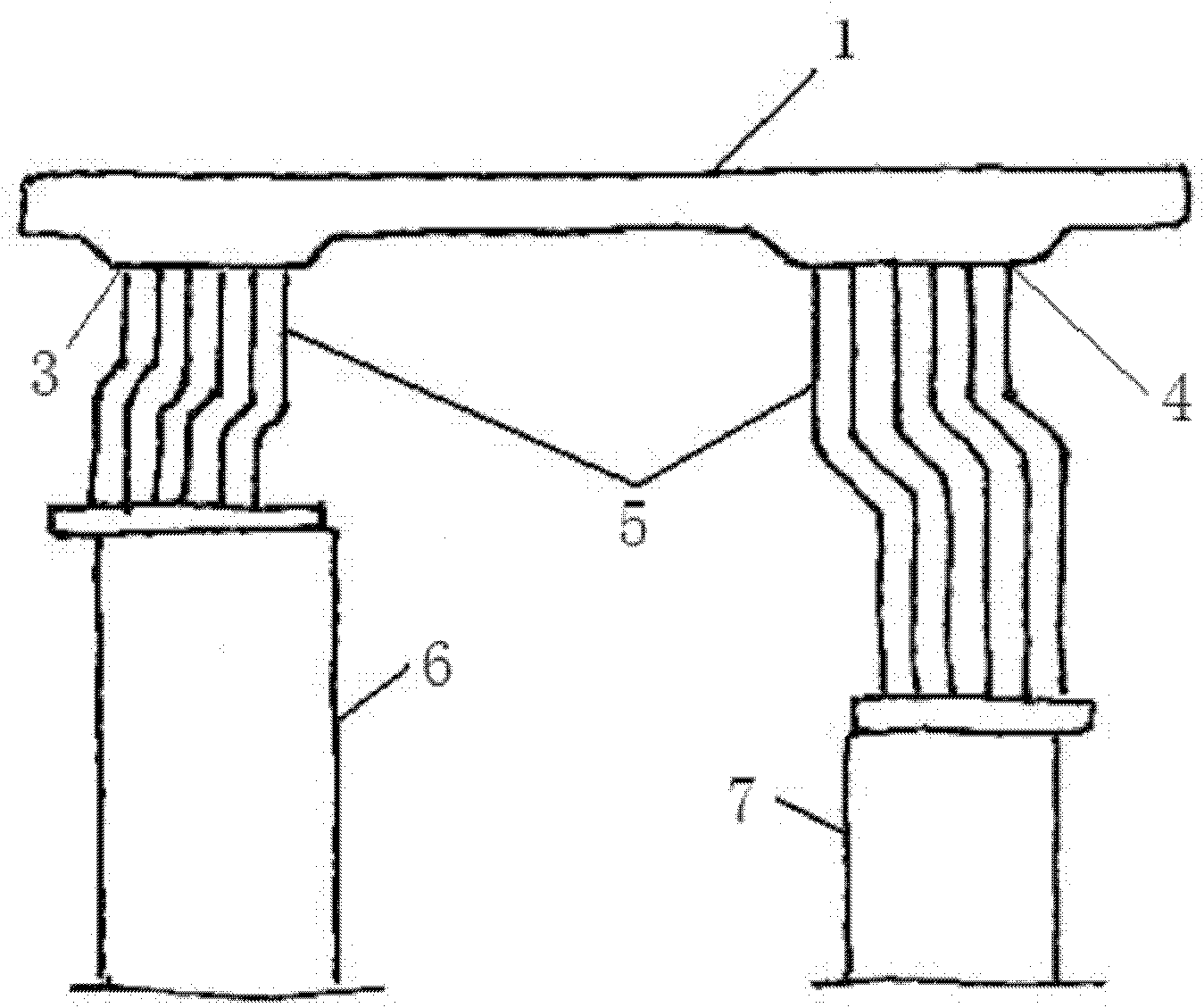

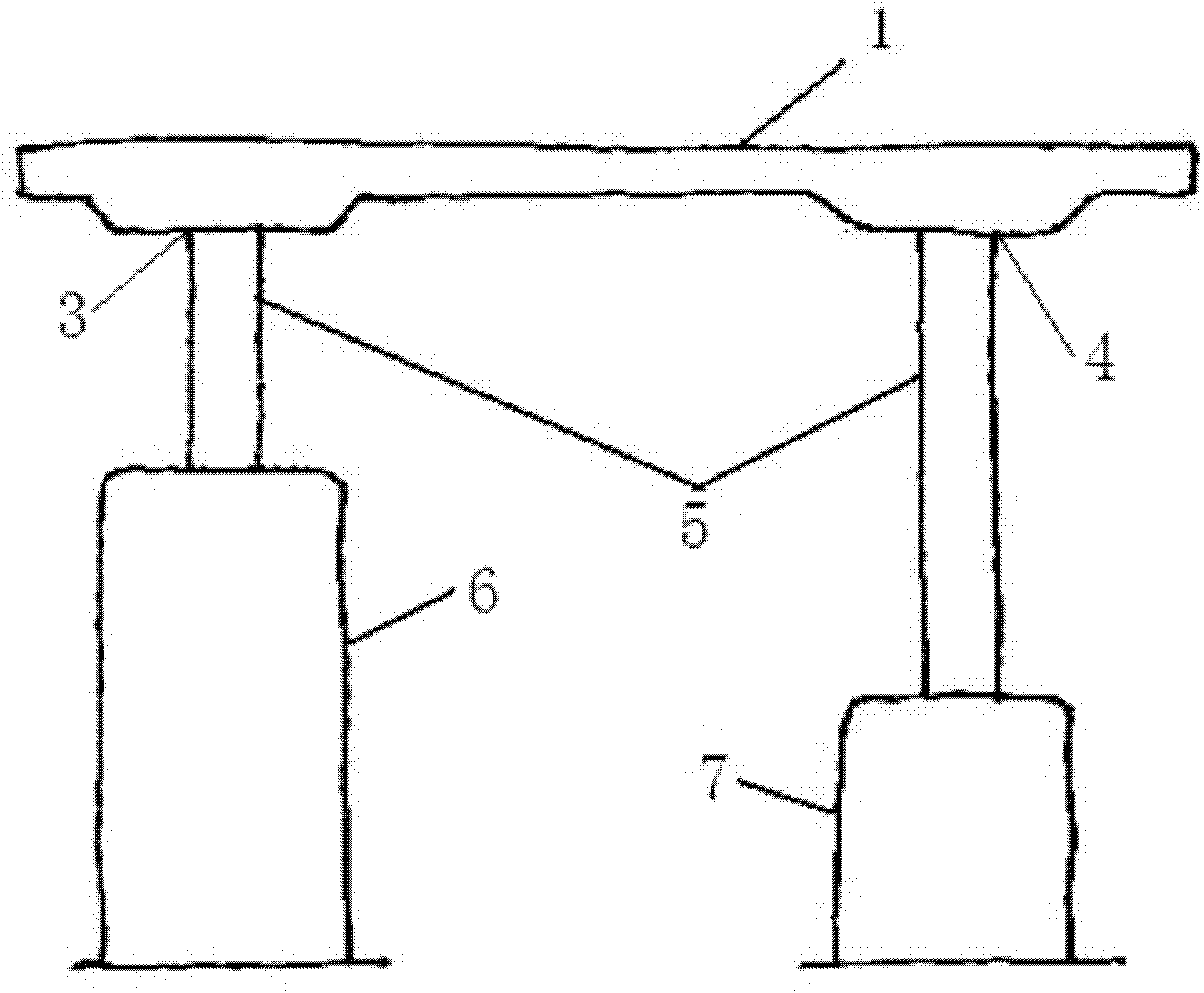

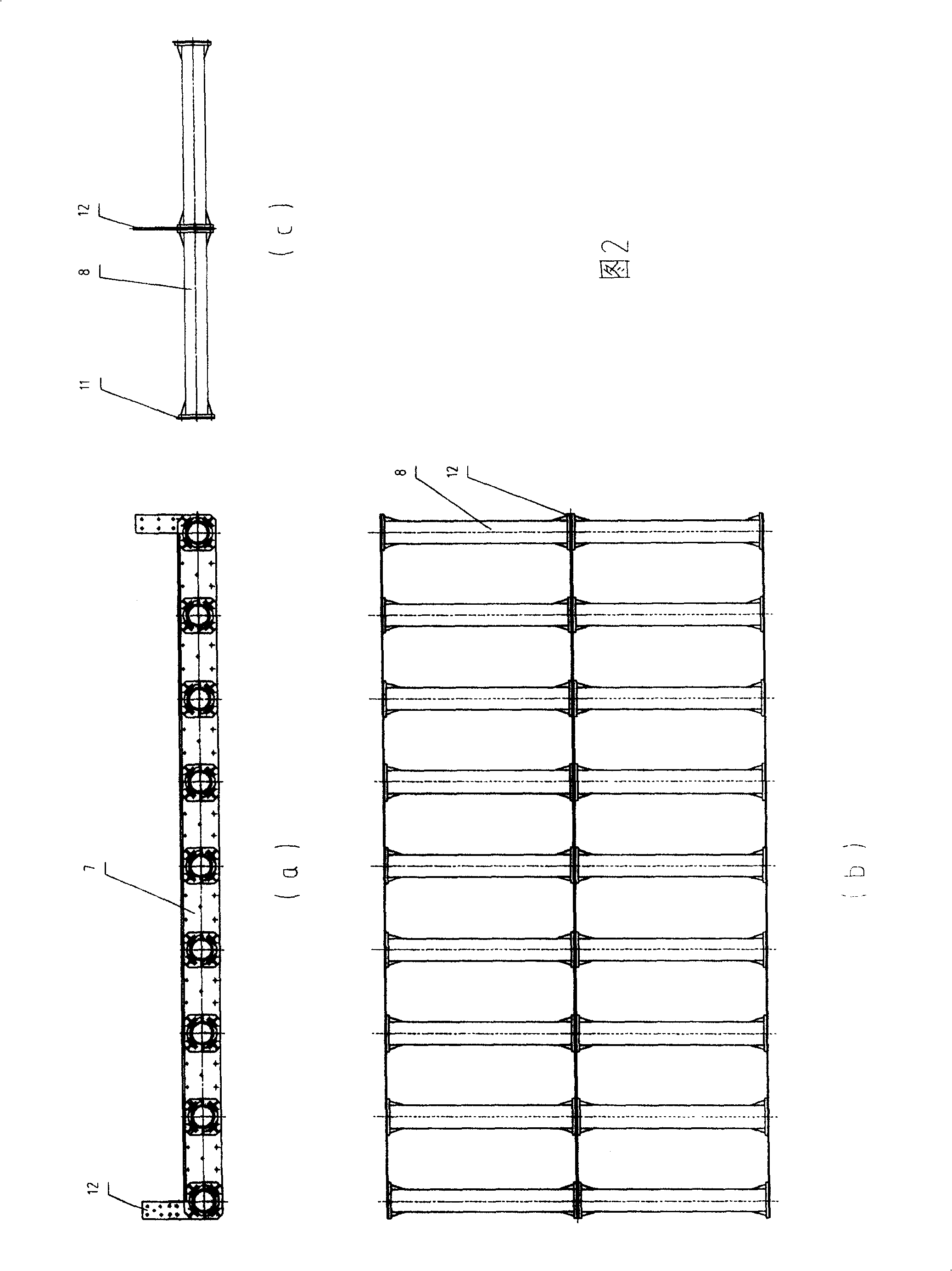

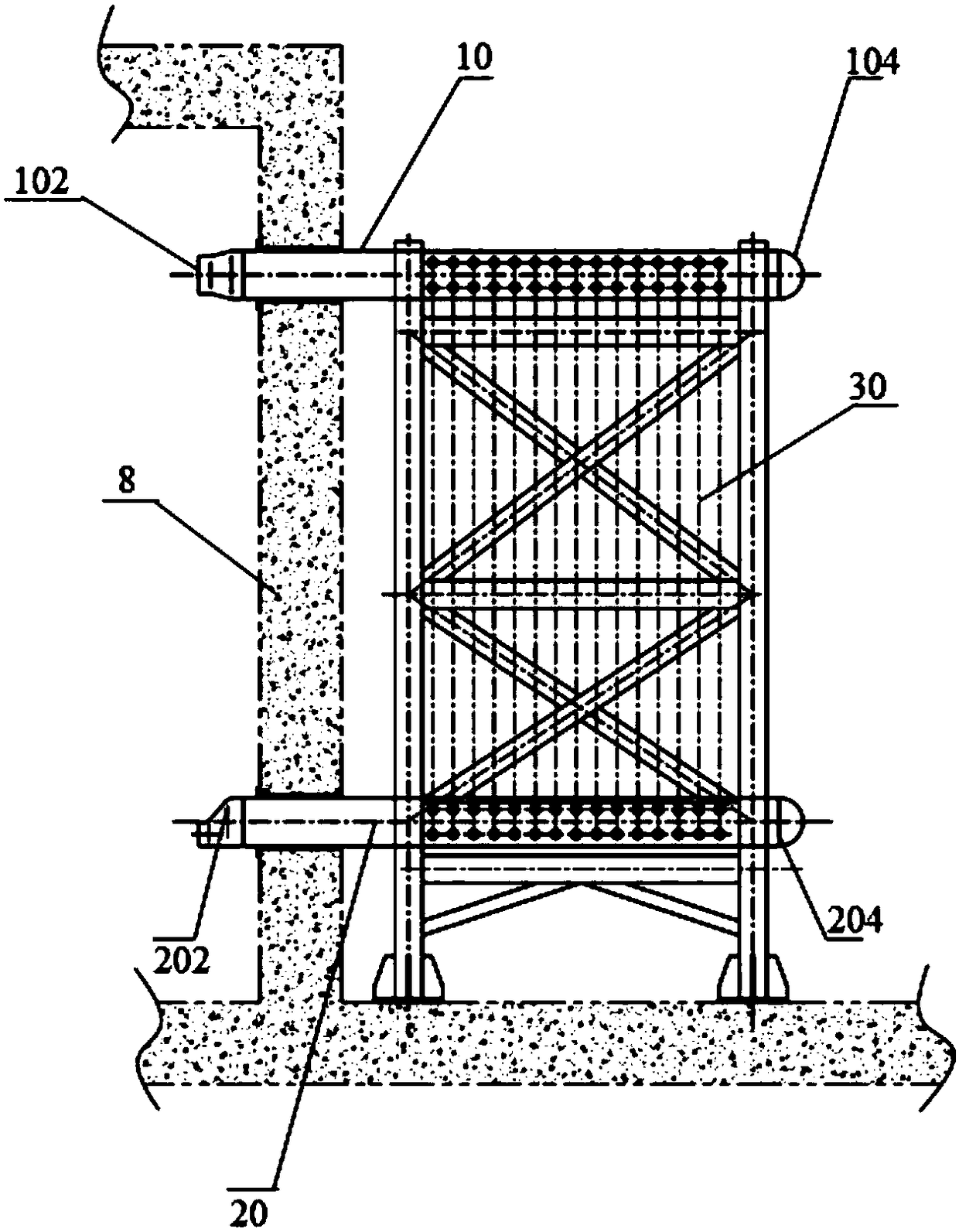

Rod-like connector, thermal-insulation wall and construction method thereof

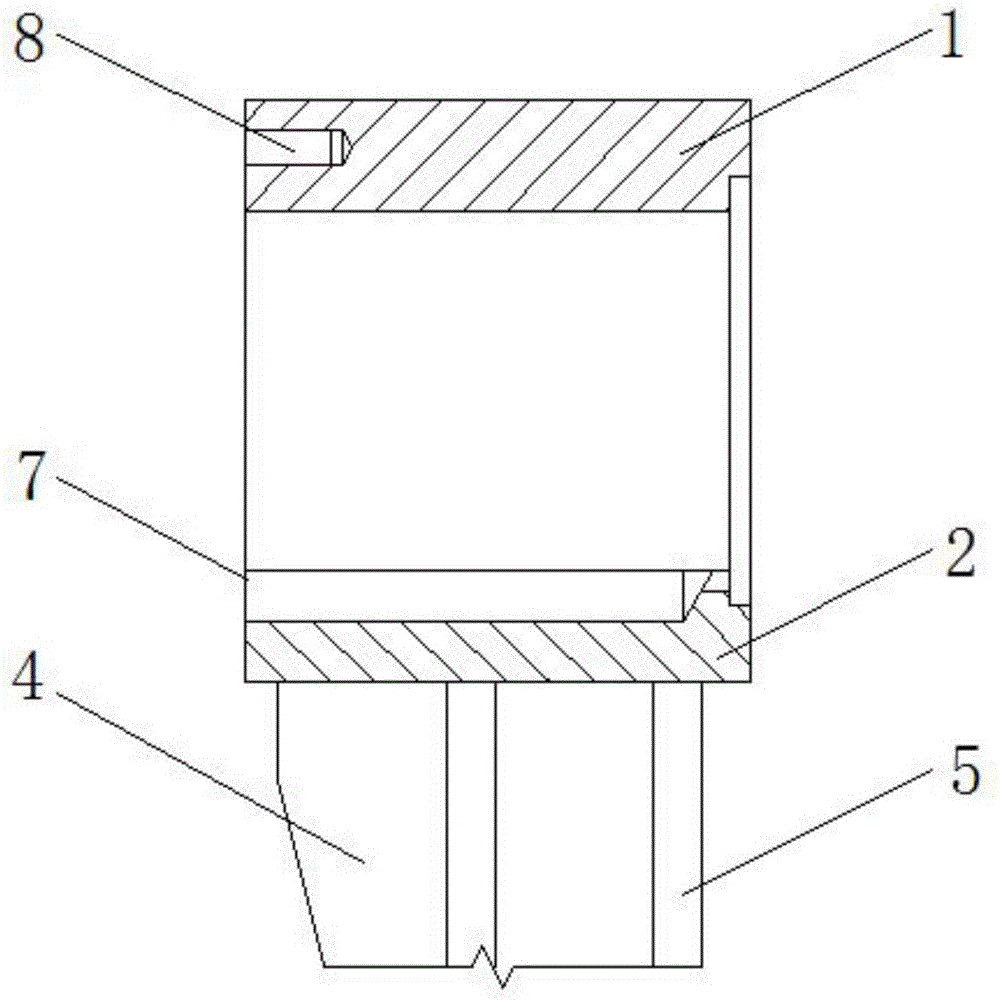

PendingCN109252592ASimple structureThe processing technology is simple and reliableHeat proofingThermal insulationEngineering

The invention relates to a rod-like connector, a thermal-insulation wall and a construction method thereof. The rod-like connector comprises a rod and a sleeve and is characterized in that the rod ismade of an FRP material; the FRP material is made by reinforcing fibers and resin; the rod comprises an upper section, a middle section and a lower section; the outer later walls of the upper sectionand the lower section of the rod are provided with notches; a sleeve sleeves the middle section of the rod; the upper end of the sleeve is provided with a horizontal sealing plate, the middle of the sealing plate is provided with a hole allowing the rod to penetrate, and the shape of the hole is adaptive to the shape of the horizontal section of the middle section; the lower end of the sleeve is provided with a sealing end socket, the middle of the sealing end socket is provided with a hole allowing the rod to penetrate, and the shape of the hole is adaptive to the shape of the horizontal section of the middle section; the outer latera wall of the rod between the sealing plate and the sealing end socket is provided a group of annular stiffening ribs along the vertical direction; the end ofthe lower section is provided with a pointed end. By the rod-like connector, the technical problems that a traditional connector in the thermal-insulation wall is complex in structure, high in processing difficulty and poor in anchoring performance are solved.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

Machining method for shower-type injector adopting thin guide pipes

The invention discloses a machining method for a shower-type injector adopting thin guide pipes. The machining method comprises the following steps: (1) machining components, specifically, machining an upper injection disc, a lower injection disc, a mouse cage and a plurality of the thin guide pipes, reserving gaps with a size of 0.03-0.8mm between upper connection holes of the thin guide pipes onthe upper injection disc and the thin guide pipes during brazing, and arranging chamfers at the lower ends of the upper connection holes of the thin guide pipes; and meanwhile, reserving gaps with asize of 0.05-0.10mm between lower connection holes of the thin guide pipes on the lower injection disc and the thin guide pipes during brazing; (2) cleaning; (3) assembling and filling brazing fillermetal; (4) brazing, specifically, carrying out vacuum heating to reach 850-900 DEG C, and carrying out heat insulation for 30-60 minutes; then heating to reach 1030-1050 DEG C in 5 minutes, and carrying out heat insulation for 10-15 minutes; and then cooling to reach 600-700 DEG C, carrying out heat insulation for 1.5-2.5 hours and then cooling to reach room temperature with the furnace; and (5) removing burrs. According to the machining method disclosed by the invention, the thin hole machining requirement is lowered, the machining requirement on a thin hole machine is low, the whole assemblyis simple to operate, the working efficiency is high, the thin guide pipes of the injector are high in consistency, and the product pass percent is high.

Owner:湖北三江航天江北机械工程有限公司

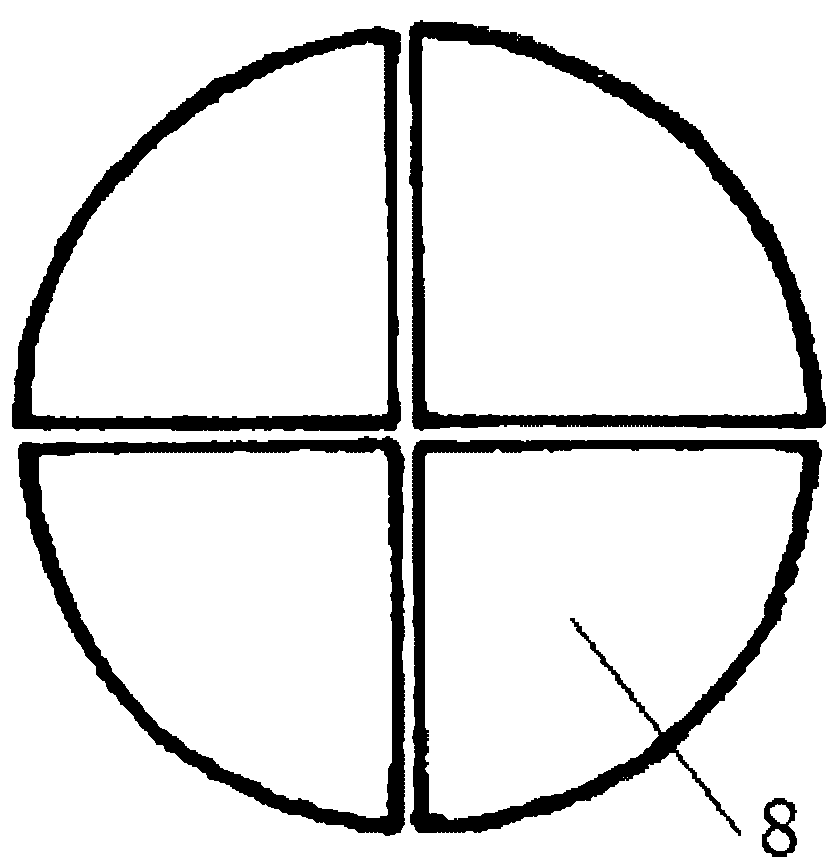

Integral combined-type heat absorber of solar thermomotor

InactiveCN102434313ASimple appearanceThe processing technology is simple and reliableHot gas positive displacement engine plantsEngineeringRadiation

The invention discloses an integral combined-type heat absorber of a solar thermomotor, wherein the heat absorber is provided with a plurality of fluid channels, fluid inlets and fluid outlets; the plurality of fluid channels are formed in a heat absorber body; the fluid inlets and the fluid outlets are formed on the surface of the heat absorber body and are respectively and correspondingly communicated with ports of two ends of each fluid channel in the heat absorber body; the fluid inlets are connected with an air cylinder through a connecting pipeline; the fluid outlets are connected with a heat regenerator through a connecting pipeline; the outer surface of the heat absorber body is a plane or a corrugated plane; the plurality of fluid channels in the heat absorber body and the heat absorber body are formed by integral casting; the heat absorber body is formed by the welding of two symmetrical plate bodies up and down; and the plurality of fluid channels are formed by the butt joint of symmetrical semi-round channel grooves on opposite surfaces of the two plate bodies which are symmetrical up and down. According to the invention, the heat absorber of the thermomotor is designed into a round integral combined-type heat absorber, or a circle is spliced by four fan-shaped objects of 90 degrees, thus solar condensation radiation heat is absorbed, the appearance is simple, the processing technology is reliable, mass production is convenient, and the cost is low.

Owner:TIANJIN GREEN ENERGY TONGHUI TECH

Transmission crank

PendingCN106640931AReliable structureReduce processing technologyCranksEccentricsMachining processInternal stress

The invention discloses a transmission crank which comprises an upper casing and a lower casing, wherein an upper ear plate and a lower ear plate are arranged on the end faces of the two horizontal sides of the upper and lower casings respectively. The transmission crank is simple and reliable in structure; the upper and lower casings are connected through bolts, so that a machining process for forging is reduced; by positioning slots, stability in connection with a fixed rod is ensured; a support structure welded by a first vertical plate, a rib plate and second vertical plates is high in stability and material-saving, the mass of the transmission crank is reduced, and meanwhile, the strength of the crank and stability during connection with a connecting rod are also ensured; by the rib plate, radial internal stress on the lower casing is effectively dispersed, and the front ends of the upper and lower casings are prevented from being cracked; by design of extending plates and notches, fit between the upper and lower casings is ensured, and meanwhile, torque on the bolts during rotation is weakened; the machining process is simple, the transmission crank can be rapidly produced in batches, and the strong-strength crank connecting rod application requirement can be met.

Owner:JIANGSU DATANG MACHINERY

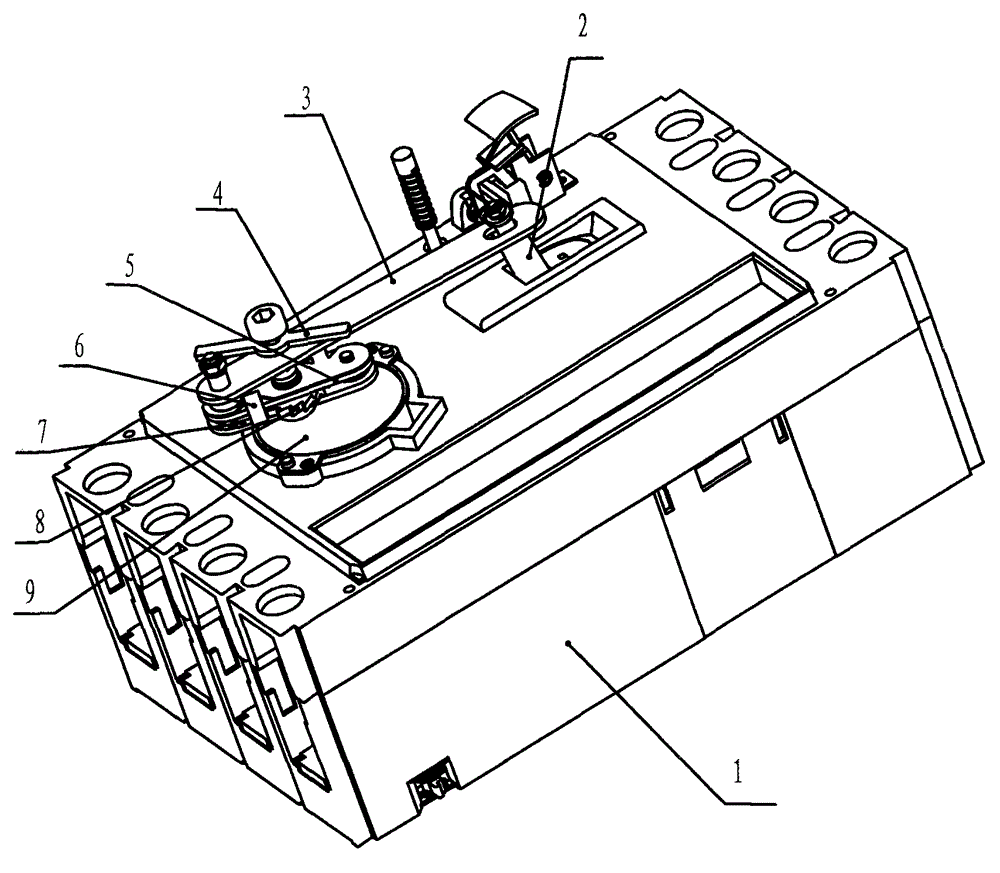

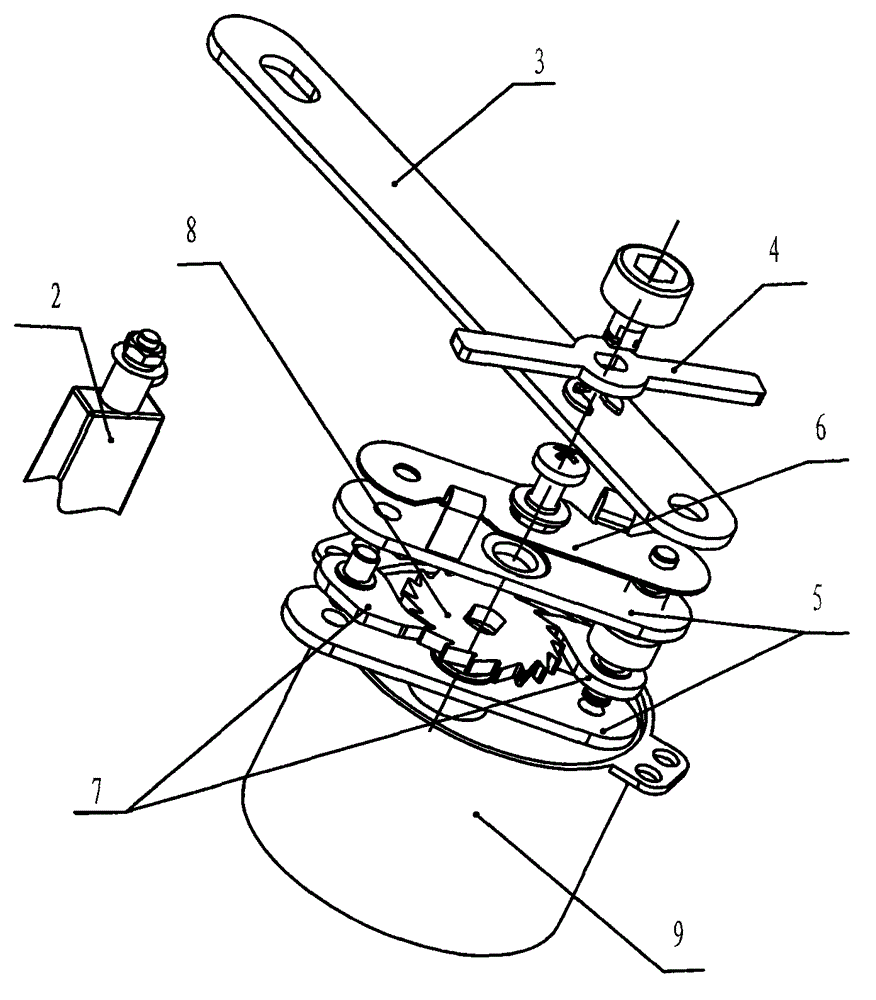

Operating mechanism of electricity leakage reclosure circuit breaker

ActiveCN103311058BAvoid damageSmooth runningProtective switch operating/release mechanismsElectricityEngineering

The invention discloses an operating mechanism of an electricity leakage reclosure circuit breaker, relating to the technical field of circuit breakers and overcoming the defects that the radial force of a motor rotating shaft of the existing electricity leakage reclosure circuit breaker is unbalanced to cause the damage of a motor. The operating mechanism comprises a handle and a motor which are arranged on a body, the handle is connected with the motor by a connecting rod, a ratchet wheel is arranged on the motor, the connecting rod is connected with a pawl through a crank, the ratchet wheel and the pawl are meshed, an elastic sheet is arranged between the connecting rod and the crank, and a manual push rod is arranged on the connecting rod; when the motor works, a multi-pawl structure can ensure the balance of radial force of the motor rotating shaft, thus avoiding the damage to the motor due to radial force generated in rotation of a crank connecting rod mechanism; when the motor is not needed to work, the ratchet wheel does not work when manual operation is adopted, the pawls and the ratchet wheel can be separated by rotating a shaft on the crank, so that the crank connecting rod mechanism can successfully run reliably towards one way.

Owner:长城电器集团浙江科技有限公司

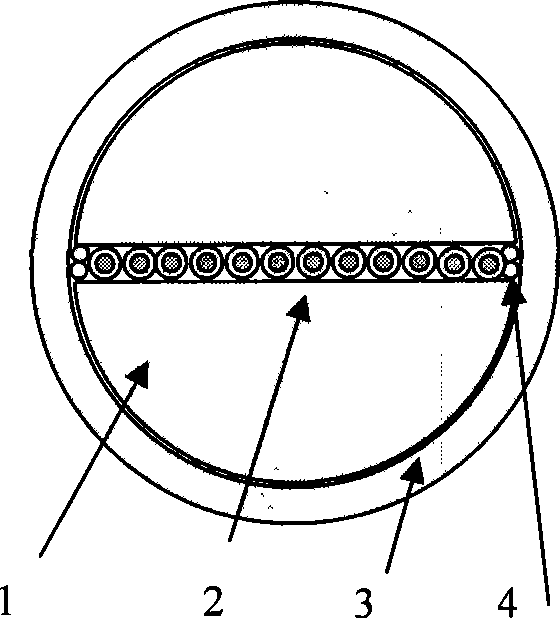

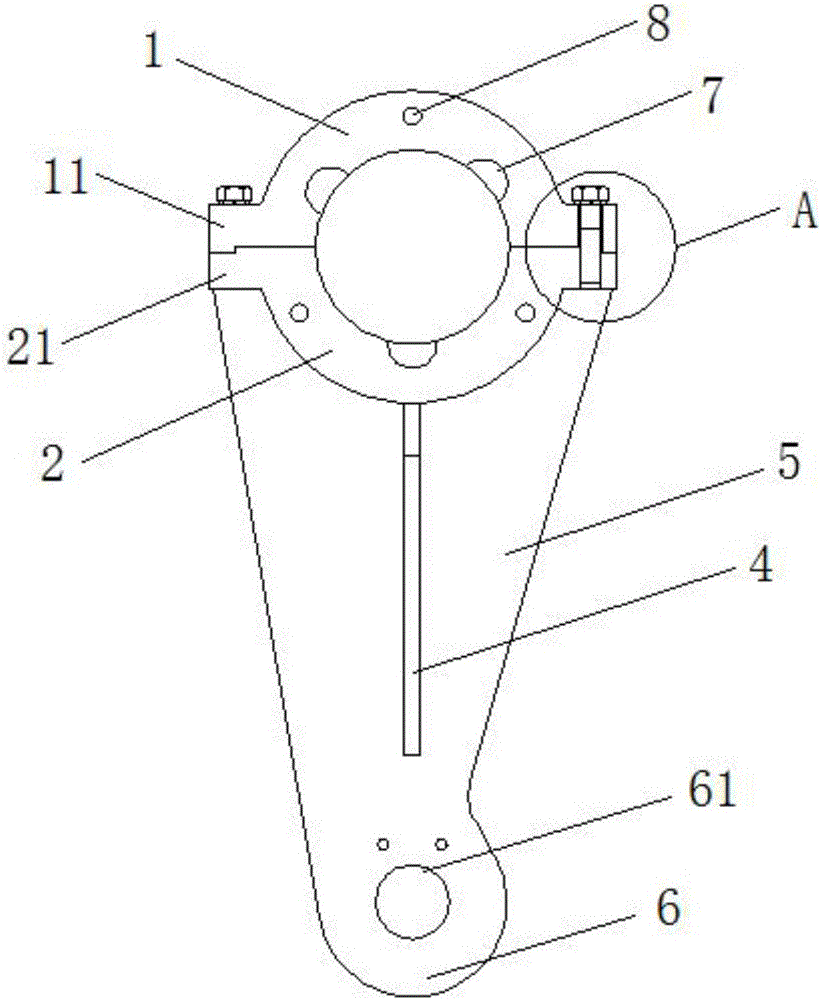

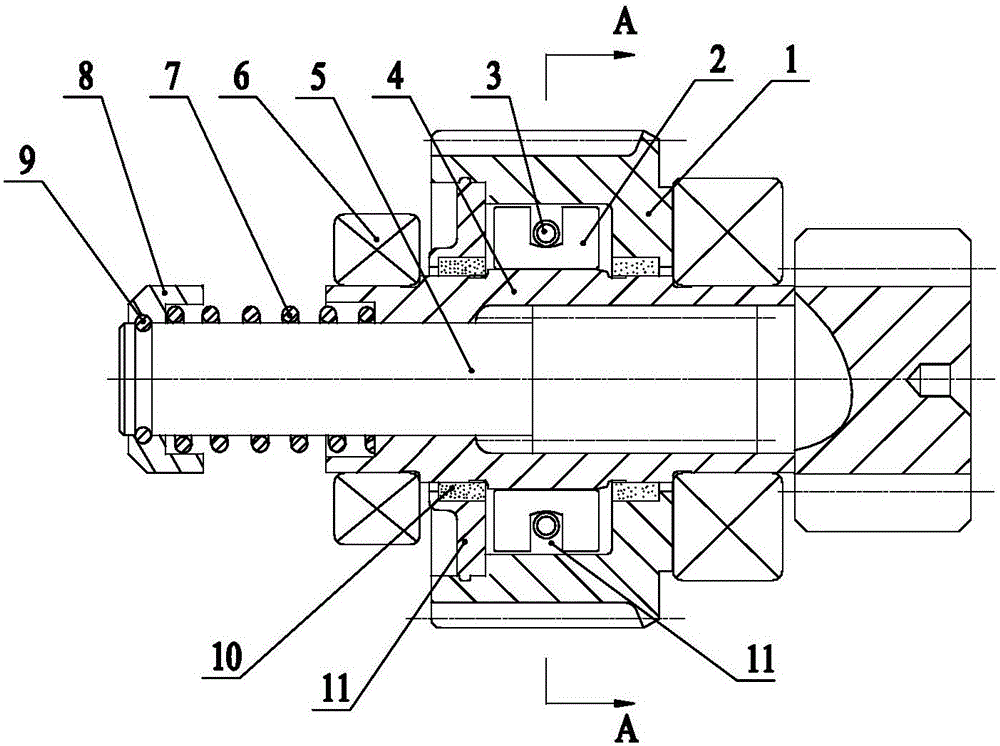

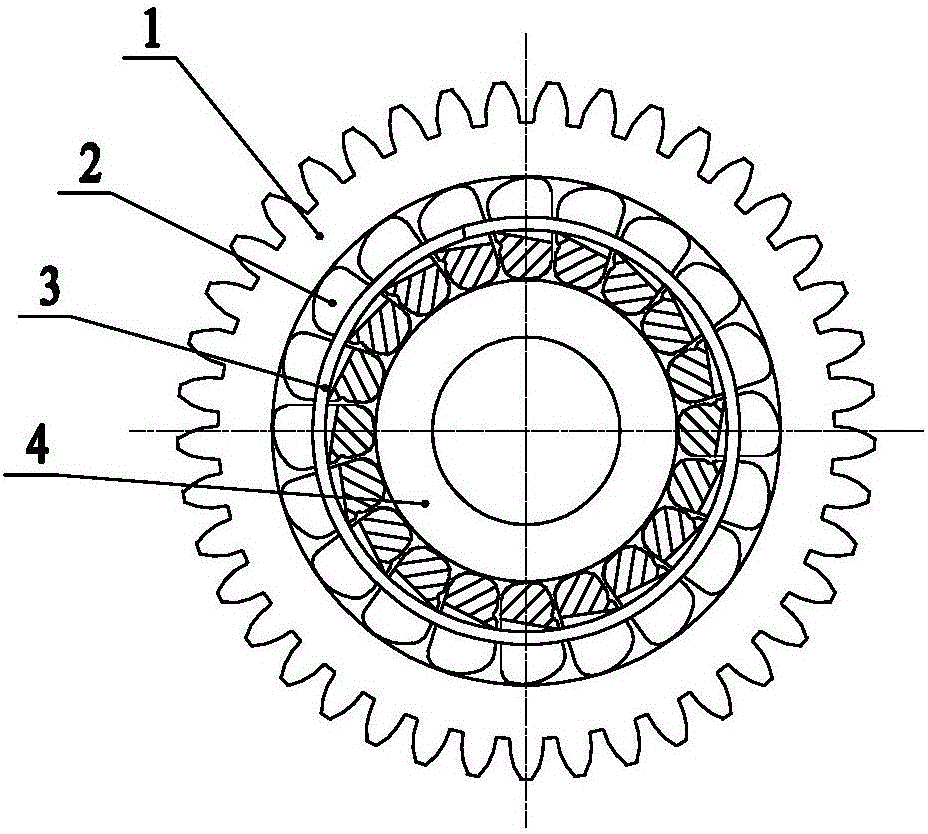

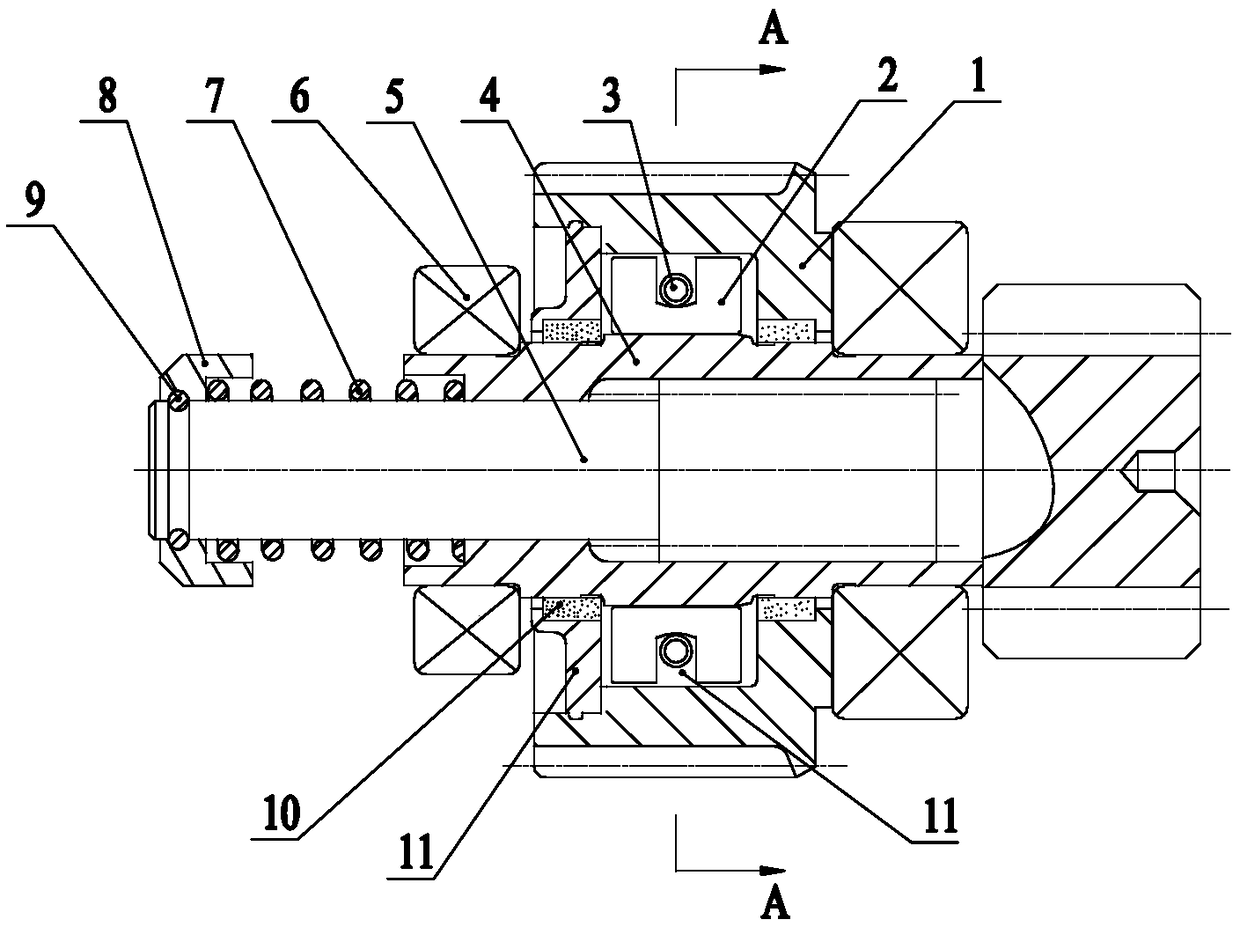

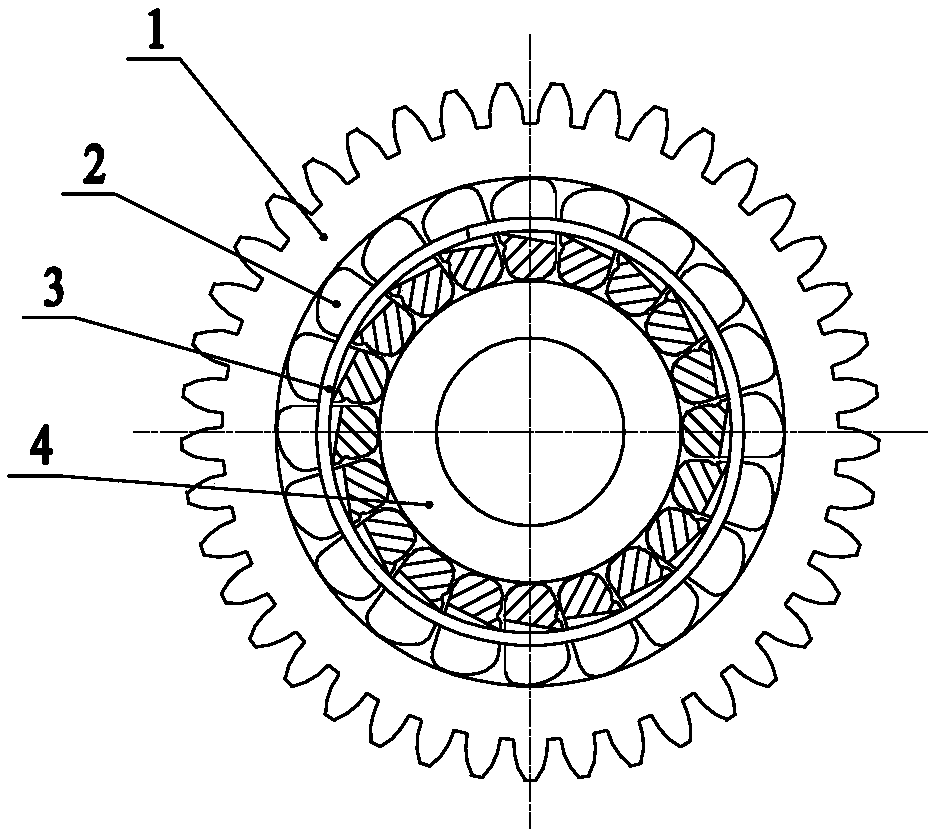

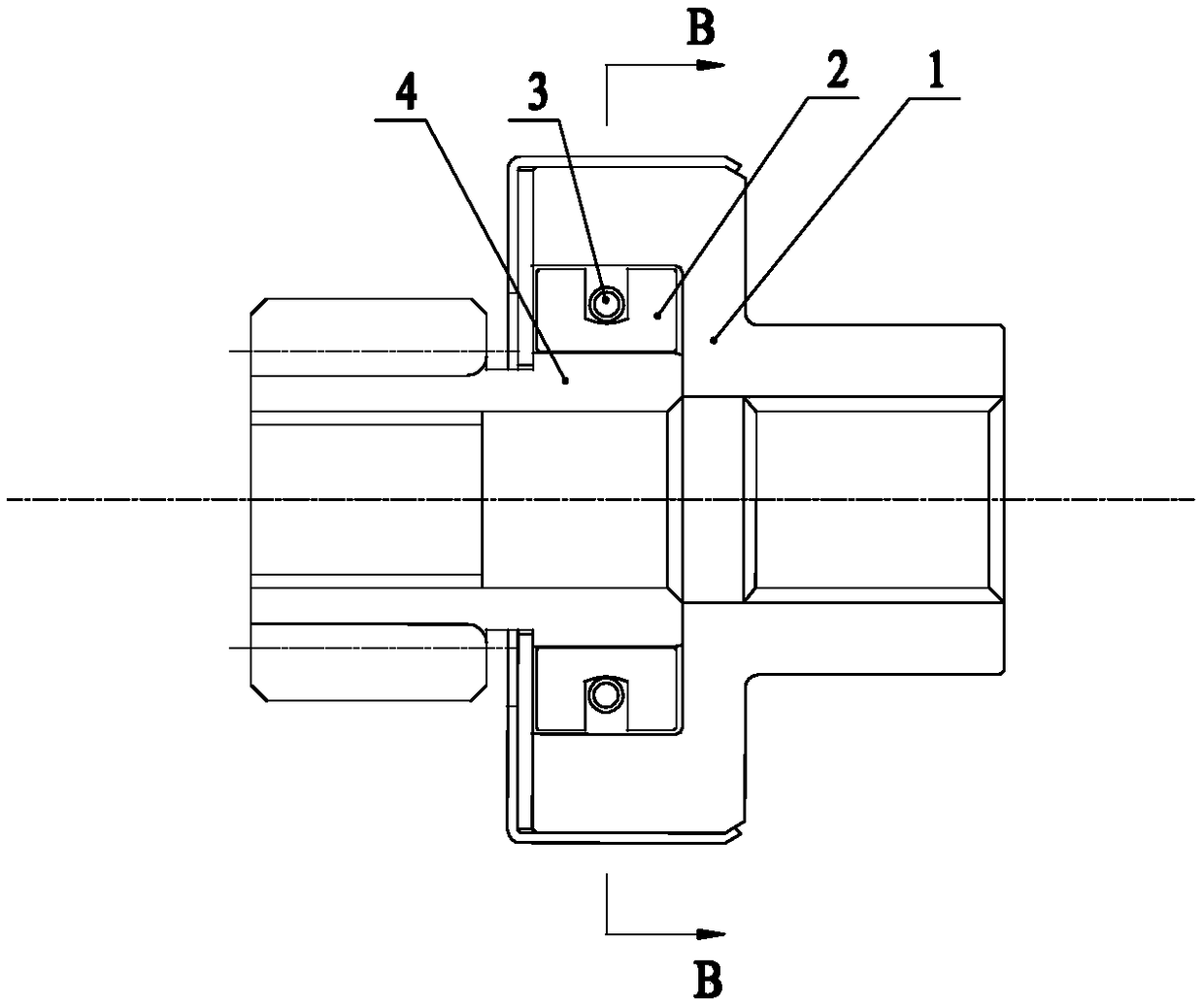

Wedge block type one-way clutch

ActiveCN106122310AImprove work performanceImprove reliabilityFreewheel clutchesWork performanceClutch

The invention relates to a wedge-block type one-way clutch. The surface of a star wheel inner hole is a smooth cylindrical face. A drive gear in a drive gear assembly is arranged in the star wheel inner hole, and the peripheral surface of the drive gear is a smooth cylindrical face. A plurality of wedge blocks are arranged between the star wheel inner hole and the periphery of the drive gear, and the multiple wedge blocks are tightly arranged to form a circle in a surrounding manner in the circumferential direction. Each wedge block is provided with a slotted groove with an opening located in the outer end of the wedge block. The bottom faces of the slotted grooves are inclining faces, and the inclining directions of the bottom faces of the slotted grooves of all the wedge blocks are the same. Elastic rings are embedded in the slotted grooves of the wedge blocks forming one circle in the surrounding manner and have inward tightening force for the wedge blocks forming one circle in the surrounding manner. Under the action of the tightening force of the elastic rings, the outer ends of the wedge blocks conduct wedge-caulking on the surface of the star wheel inner hole, and the inner ends of the wedge blocks conduct wedge-caulking on the surface of the periphery of the drive gear. The wedge-block type one-way clutch is compact in structure, ingenious in design, small in size, small in weight, large in transmission power and high in machining precision, and the one-way clutch can have more stable work performance, higher reliability and longer service life.

Owner:无锡市神力齿轮冷挤有限公司

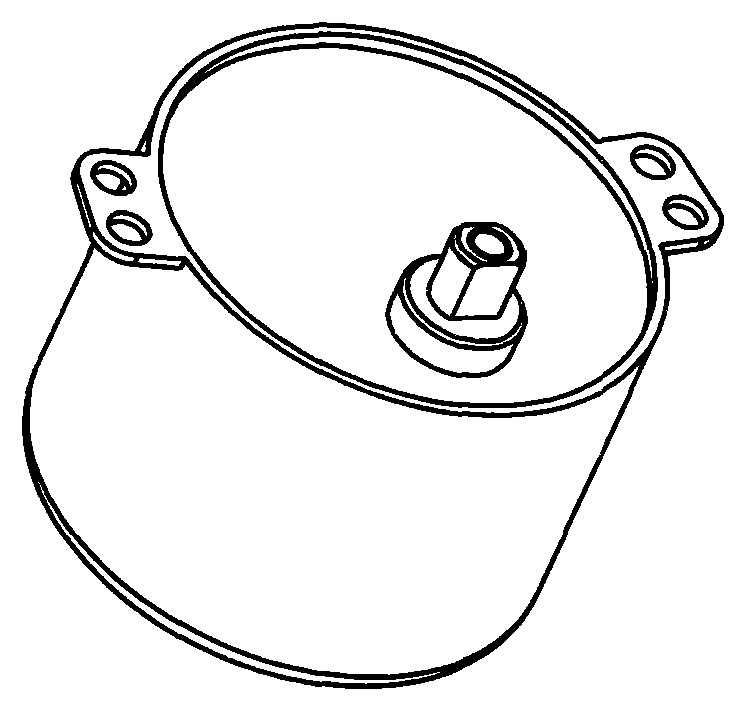

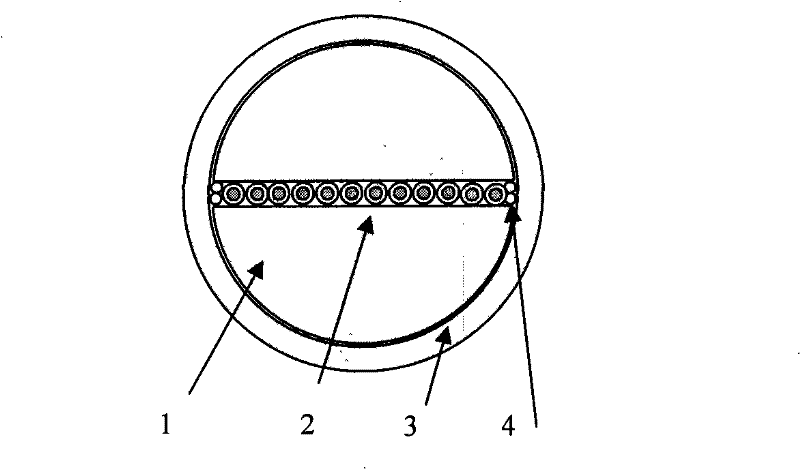

Cast aluminum alloy motor casing with built-in stainless steel spiral coiled pipe water channel

PendingCN107294256AReduce in quantityThe processing technology is simple and reliableSupports/enclosures/casingsPipe waterWater cooling

The invention discloses a cast aluminum alloy motor casing with a built-in stainless steel spiral coiled pipe water channel, which comprises a motor shell cast by aluminum alloy, and is characterized in that a stainless steel spiral coiled pipe water channel connected with a water cooling circulation system is inlaid and cast in the motor shell, and one end of the stainless steel spiral coiled pipe water channel is connected with a technological support framework. According to the invention, the operation of molding the prefabricated stainless steel spiral coiled pipe water channel in an EPS white die of the motor casing does not need to be divided into multiple times of molding, and the internal part of the stainless steel spiral coiled pipe water channel is not required to be filled with sand before casting neither, so that the production takt is greatly shortened, and the production efficiency is effectively improved. The cast aluminum alloy motor casing with the built-in stainless steel spiral coiled pipe water channel is ensured to be high in strength and stable and reliable in structure through arranging the technological support framework in the motor shell and arranging a water inlet and water outlet structure and an auxiliary structure on the stainless steel spiral coiled pipe water channel and not easy to deform or crack, thereby being capable of improving the casting precision of the motor casing, reducing casting defects of the motor casing and reducing the production cost.

Owner:福建巨能精密铸造科技有限公司

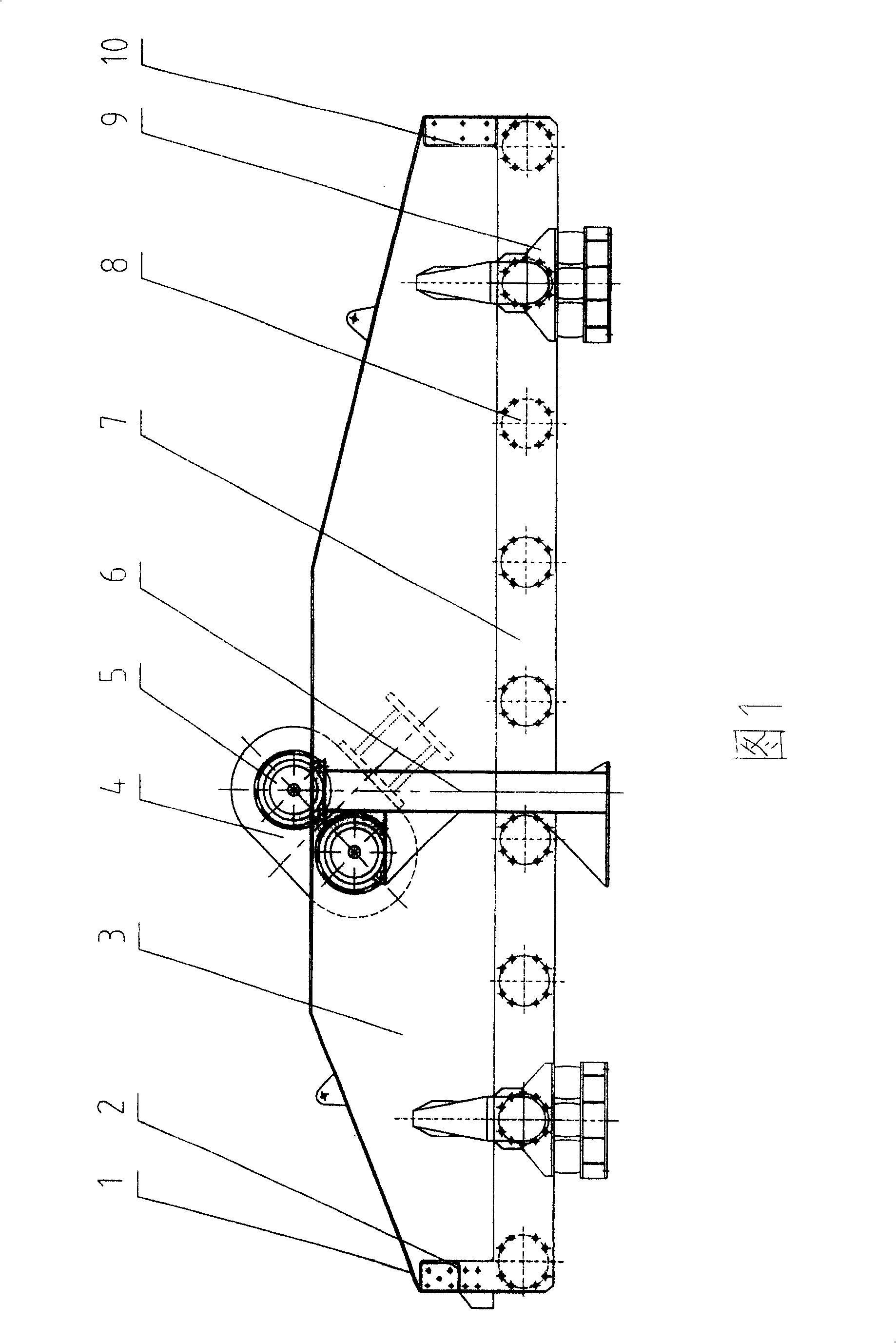

Plate type static-indeterminant combination bearing beam oversize vibration screen

InactiveCN100438993CLarge stiffness valueImprove reliabilitySievingScreeningStructural reliabilityHigh intensity

The model type super statically combined bearing beam large scale vibrating screen comprises screening plate, beam connection formed screening box, elastic support under the screening box, laser vibrator, motor and drive device on the motor base, model like super statically combined bearing beam inside the screening box, connecting with the screening box through high intensity hinging screw, output and inlet end of the screening box having rectangular closed beam connected with the combined bearing beam, and forming an enclosed big rigid container. It has increased structural rigidity, alleviated vibrating weight, improved efficiency, simplified structure, and simple processing. Due to its structural reliability, improved composite mechanical reliable life, it can meet extensive application in many industries.

Owner:CHINA UNIV OF MINING & TECH

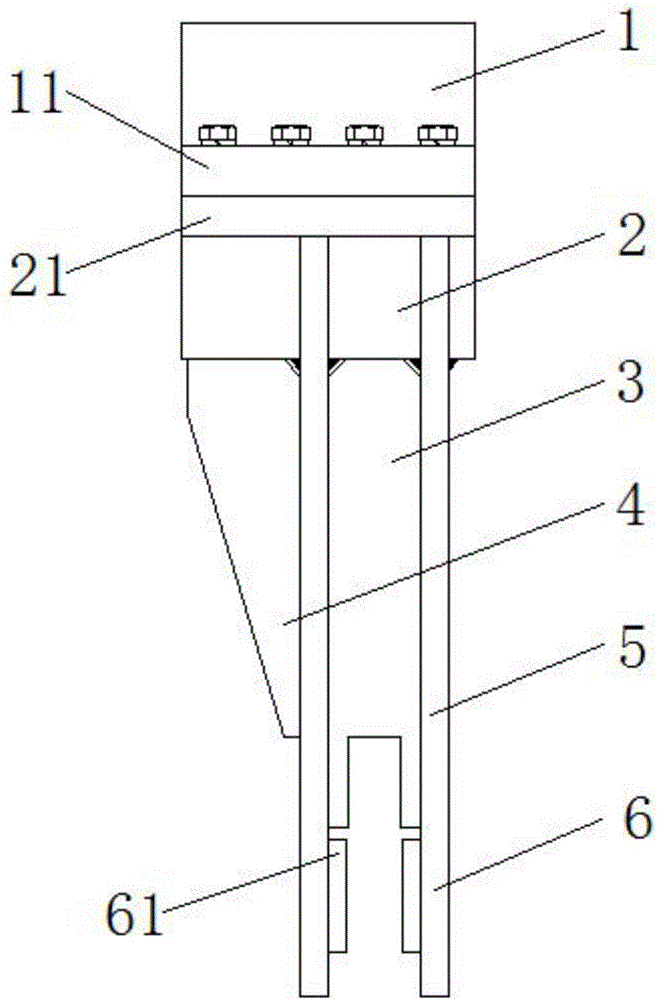

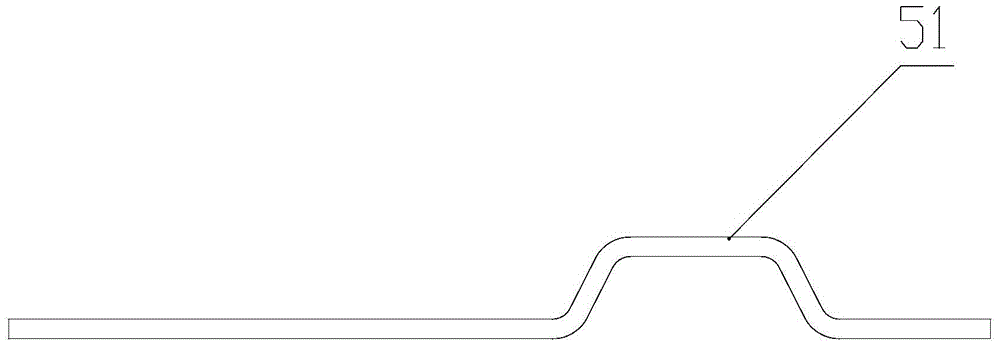

A thermal expansion valve

ActiveCN103423926BSimple processThe processing technology is simple and reliableMechanical apparatusFluid circulation arrangementEngineeringValve stem

The invention discloses a thermal expansion valve with a one-way control function, which comprises a valve body (1), a temperature-sensing component (2), and a first valve core component ( 4), the first valve core part (4) includes a valve stem (41) and a first valve core (42), and the valve body (1) is also provided with a housing part, and a cover body ( 5), the inner hole (16) of the cover body (5) communicates with the inlet channel (11) and the inner cavity (13) to form a fluid auxiliary channel. Compared with the prior art, the belt The thermal expansion valve with one-way control function simplifies the processing technology of the valve body by providing a cover body on the valve body. And in the preferred solution, the valve port and sealing position can be processed at one time by stretching, and the guiding part or restricting part is set by stamping, which makes the processing process simpler and more reliable, and is suitable for mass production.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CONTROLS CO LTD SHAOXING CITY

Nanoscale non-volatile resistive random access memory unit and preparation method thereof

ActiveCN102487123BSimple materialSimple processElectrical apparatusDigital storageHydrogenNanoscopic scale

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

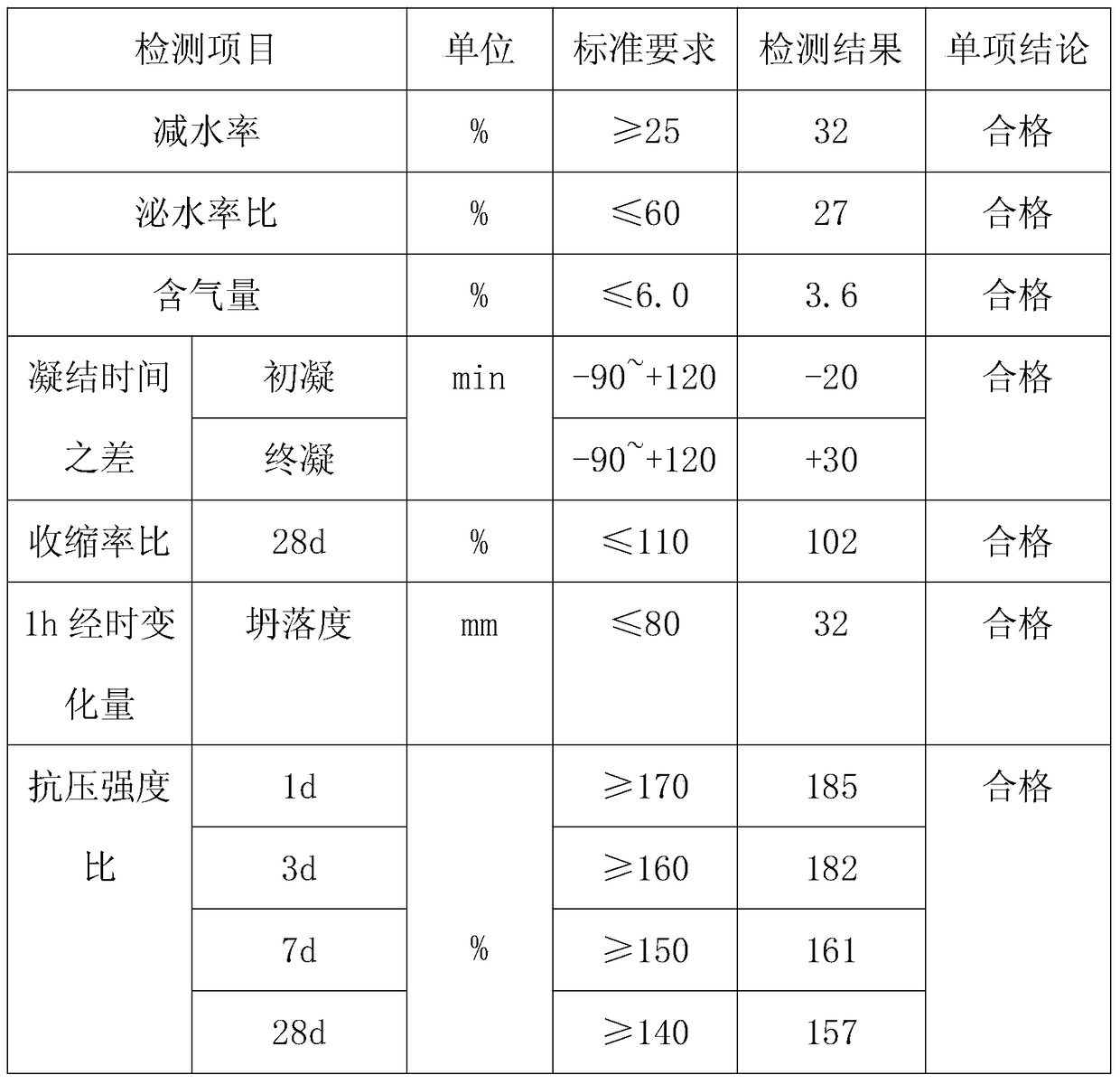

A kind of preparation method of polycarboxylate superplasticizer

Owner:HUNAN MAINHORN TECH DEV CO LTD

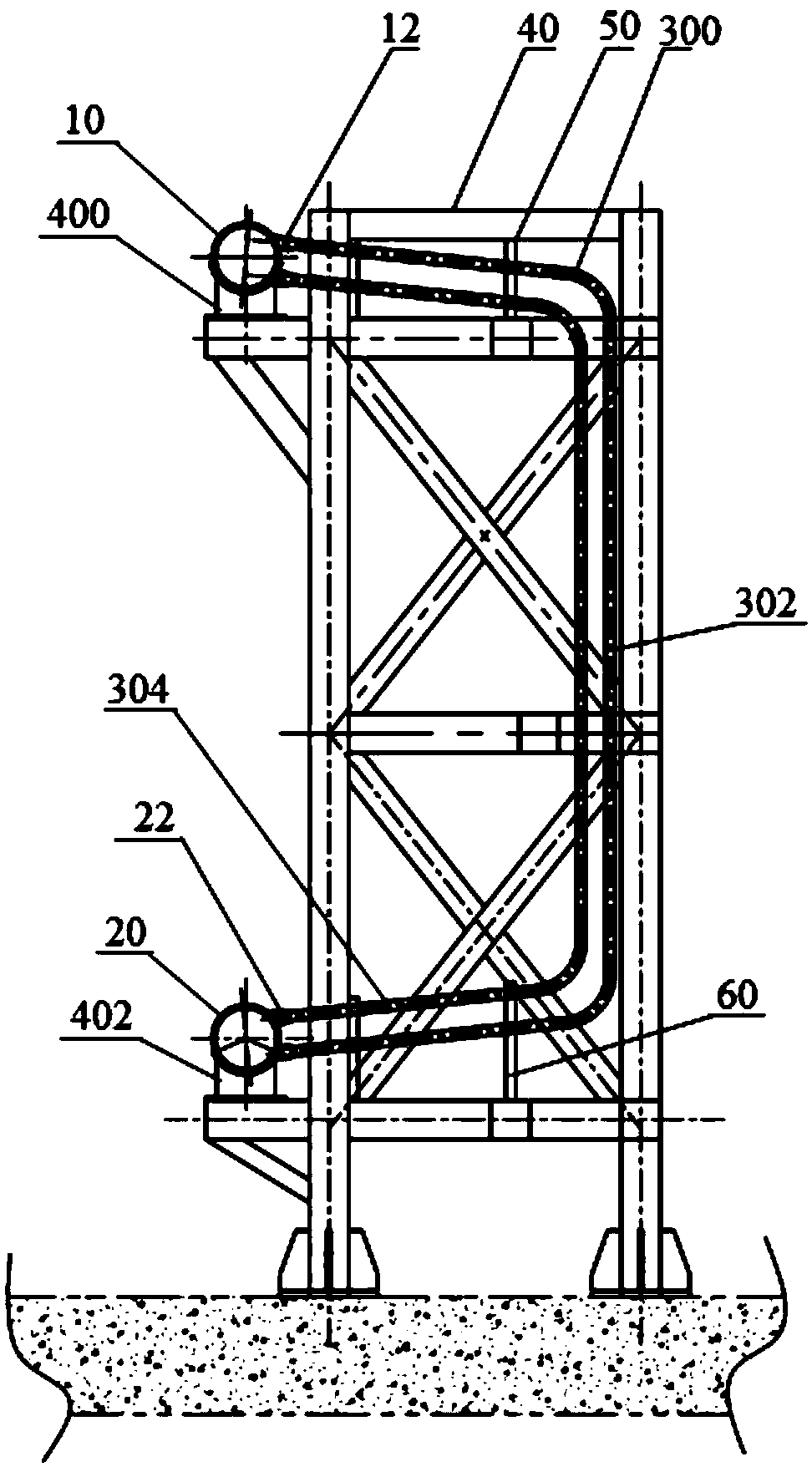

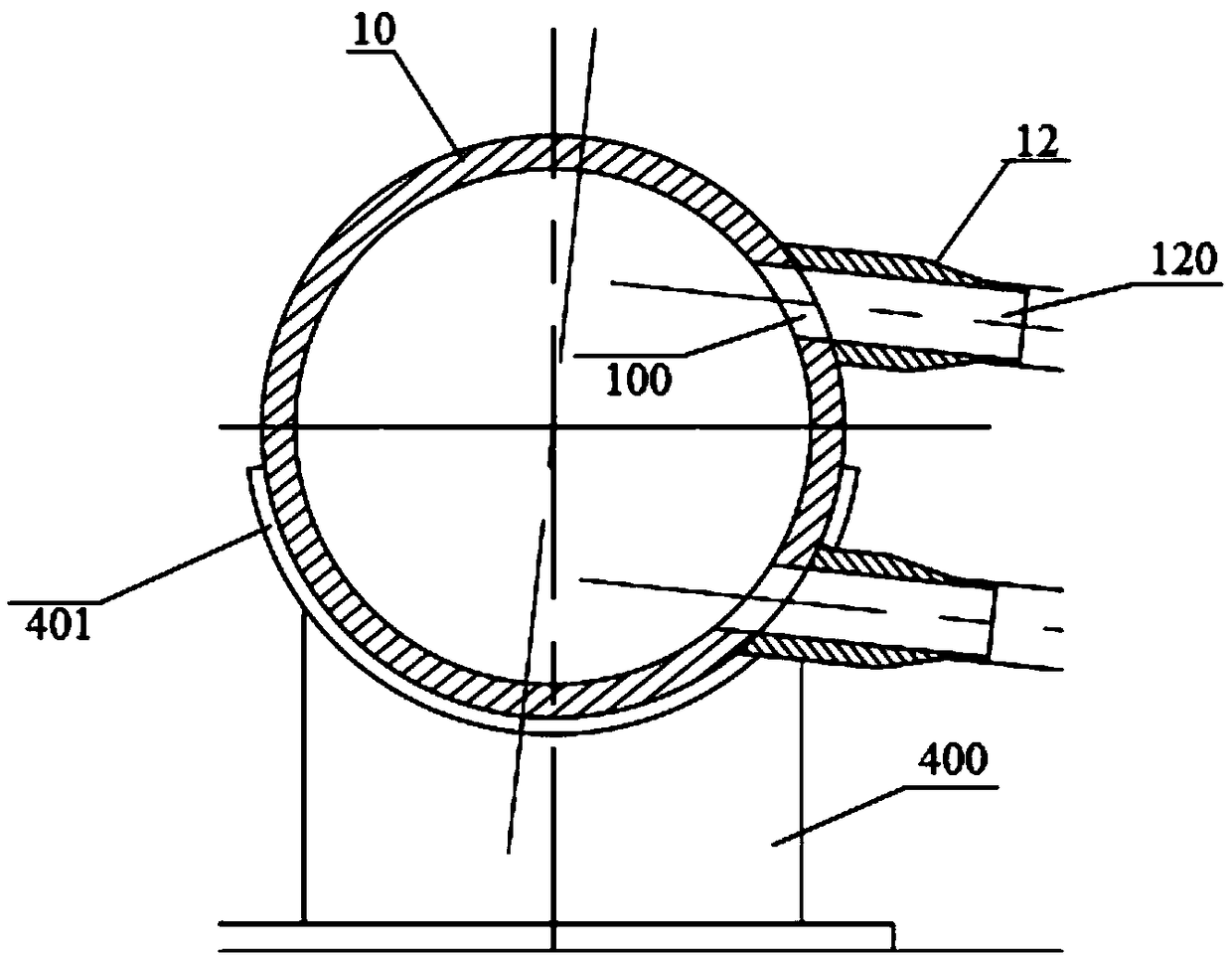

Passive condenser of nuclear power plant

ActiveCN109387089AEven by forceLess girth weldNuclear energy generationSteam/vapor condensersNuclear powerEngineering

The invention discloses a passive condenser of a nuclear power plant, which comprises an upper collecting pipe, wherein a plurality of heat exchange pipe steam inlets are arranged in the upper collecting pipe, one end of the upper collecting pipe is of an opening structure, the other end of the upper collecting pipe is of a closed structure, and one end of the opening structure is fixedly connected with a first joint; a first flange which is provided with first through holes, wherein the first through holes are arranged at the heat exchange pipe steam inlets and are fixedly connected with theupper collecting pipe, and the first through holes are communicated with the steam inlets; a lower collecting pipe, which is provided with a plurality of heat exchange pipe condensate return ports, wherein one end of the lower collecting pipe is of an opening structure, the other end of the lower collecting pipe is of a closed structure, and one end of the opening structure is fixedly connected with a second joint; a second flange which is provided with second through holes which are arranged at the heat exchange pipe condensate return ports and are fixedly connected with the lower collectingpipe, and the second through holes are communicated with the condensate return ports; a heat exchange pipe bundle which comprises a plurality of heat exchange pipes, the heat exchange pipe comprise anupper inclined section, a middle connecting section and a lower inclined section, the upper inclined section is fixedly connected with the first flange, and the lower inclined section is fixedly connected with the second flange.

Owner:中广核工程有限公司 +2

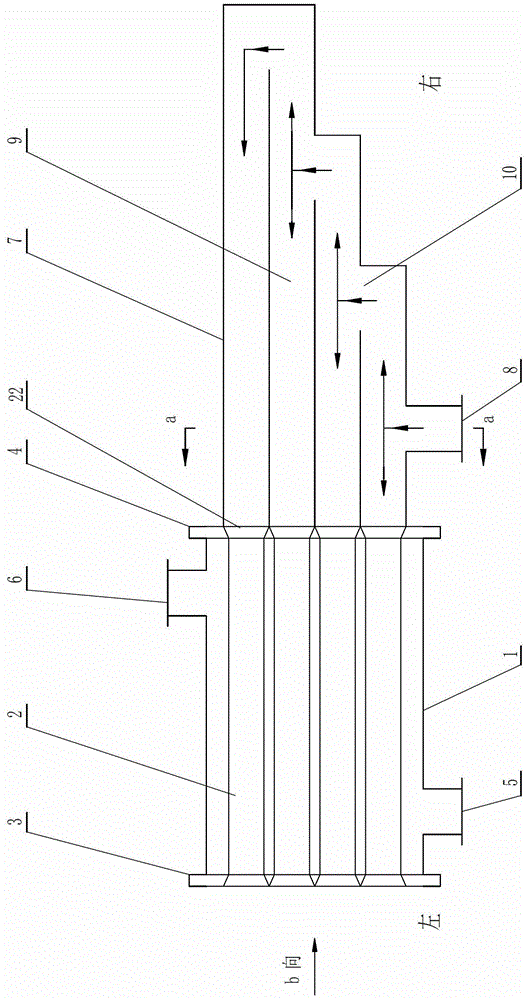

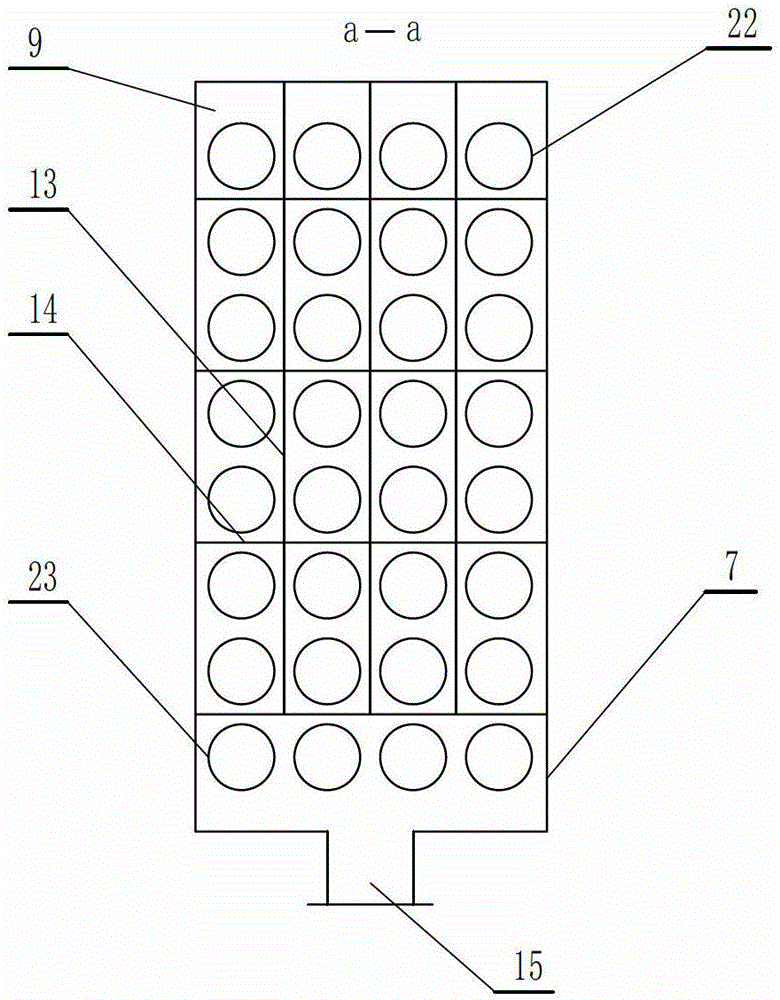

Tubular channel-type heat exchange method for sewage or surface water

ActiveCN103033073BAvoid Insufficient Pressure CapacityAvoid high steel consumptionHeat exchanger casingsStationary tubular conduit assembliesEnergy technologyWater leakage

The invention relates to a tubular channel-type heat exchange method for sewage or surface water, and belongs to the field of energy technology. The method aims at solving the problems that the heat exchange manner of an existing plate-type structure has an insufficient pressure bearing capacity, the water leakage accident is terrible, the tubular structure consumes a large amount of steel, the pipe mouth of the tubular structure is often blocked, and suspended solids and impurities retain in the channel of a plate-type broad runner structure. The method provided by the invention is that a plurality of side-by-side runners are arranged in a channel-type case; part of the sewage or surface water flows to a pipe mouth 22, and the other part of the sewage or surface flows in an opposite direction, which means that the flow directions of the two parts of sewage or surface water form an angle of 180 DEG C, so that suspended solids cannot form a blockage in an inlet; a plurality of channelizing baffle plates are arranged on tube plates at both ends of a heat exchange pipe, and the outlet of one exchange pipe only corresponds to the inlet of the next heat exchange pipe, so that the inlet of an internal heat exchange pipe cannot be blocked. When the method provided by the invention is used for extracting the heat of sewage or surface water, the sewage or surface water as well as media cannot be blocked, the heat exchange efficiency is high, and the method is simple in theory and reliable.

Owner:青岛科创蓝新能源股份有限公司

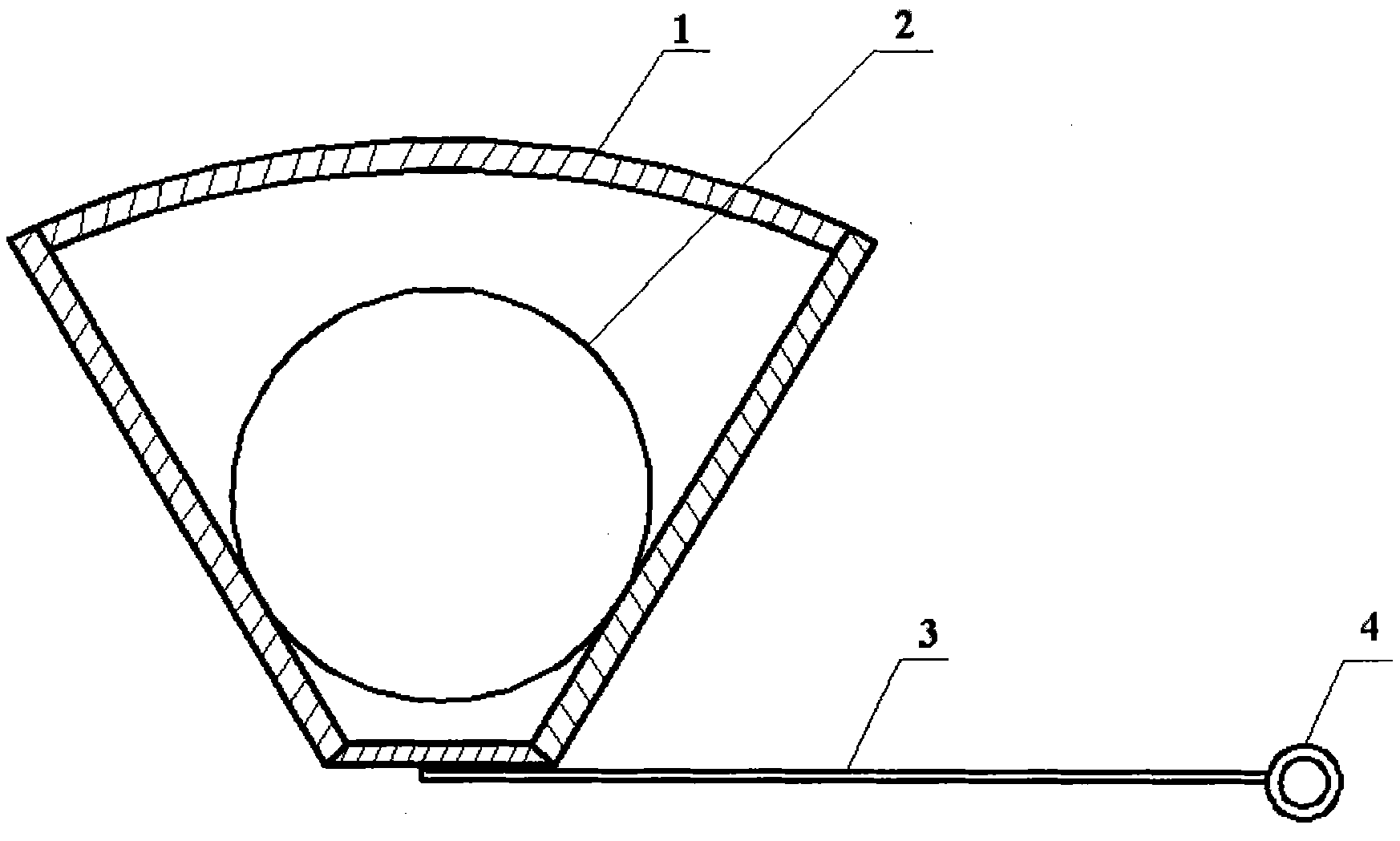

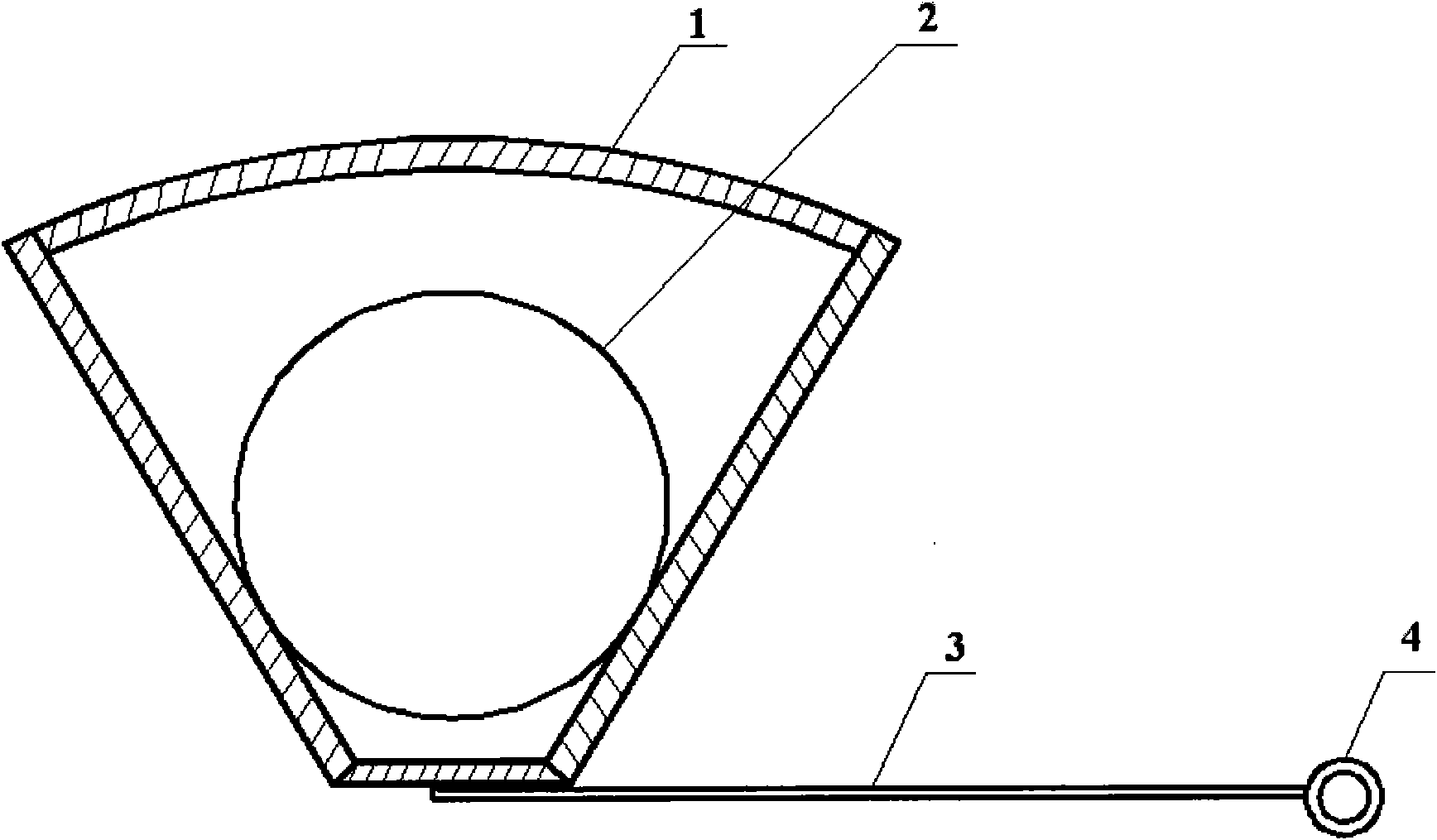

Retractable guniting wall protector and construction method thereof

InactiveCN101975071AAvoid breakingWith continuous bearing strengthUnderground chambersTunnel liningTunnel wallEngineering

The invention discloses a retractable guniting wall protector and a construction method thereof. The retractable guniting wall protector is composed of a retractable device and a connecting device, wherein the retractable device is composed of an elastic tubular fan-shaped frame and an elastic annular tube; the fan-shaped frame is composed of a cambered baffle as the top surface and planar baffles as the rest of three surfaces; the height of the fan-shaped frame is suitable for the thickness of the guniting wall; the annular tube is welded in the fan-shaped frame; and in the connecting device, one end of a connecting rod is provided with a lantern ring, and the other end of the connecting rod is connected to the bottom frame opening of the fan-shaped frame. The construction method comprises the following steps: before guniting, installing the retractable guniting wall protector in the position which easily cracks, fixing with an anchor rod through the lantern ring, and guniting to embed the retractable device in the concrete. The retractable guniting wall protector has certain continuous bearing strength and strong deformability, and can sufficiently release tunnel wall deformation, thereby preventing the tunnel wall from rupture due to failure of deformation.

Owner:SHANDONG UNIV OF SCI & TECH

sprag type one-way clutch

ActiveCN106122310BImprove work performanceImprove reliabilityFreewheel clutchesWork PerformancesClutch

The invention relates to a wedge-block type one-way clutch. The surface of a star wheel inner hole is a smooth cylindrical face. A drive gear in a drive gear assembly is arranged in the star wheel inner hole, and the peripheral surface of the drive gear is a smooth cylindrical face. A plurality of wedge blocks are arranged between the star wheel inner hole and the periphery of the drive gear, and the multiple wedge blocks are tightly arranged to form a circle in a surrounding manner in the circumferential direction. Each wedge block is provided with a slotted groove with an opening located in the outer end of the wedge block. The bottom faces of the slotted grooves are inclining faces, and the inclining directions of the bottom faces of the slotted grooves of all the wedge blocks are the same. Elastic rings are embedded in the slotted grooves of the wedge blocks forming one circle in the surrounding manner and have inward tightening force for the wedge blocks forming one circle in the surrounding manner. Under the action of the tightening force of the elastic rings, the outer ends of the wedge blocks conduct wedge-caulking on the surface of the star wheel inner hole, and the inner ends of the wedge blocks conduct wedge-caulking on the surface of the periphery of the drive gear. The wedge-block type one-way clutch is compact in structure, ingenious in design, small in size, small in weight, large in transmission power and high in machining precision, and the one-way clutch can have more stable work performance, higher reliability and longer service life.

Owner:无锡市神力齿轮冷挤有限公司

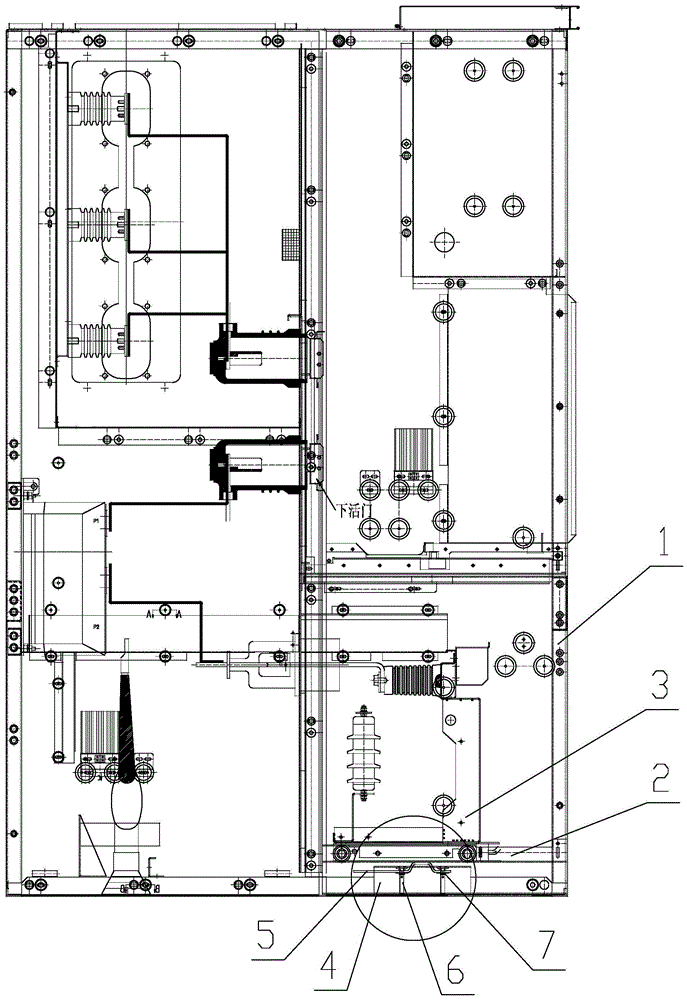

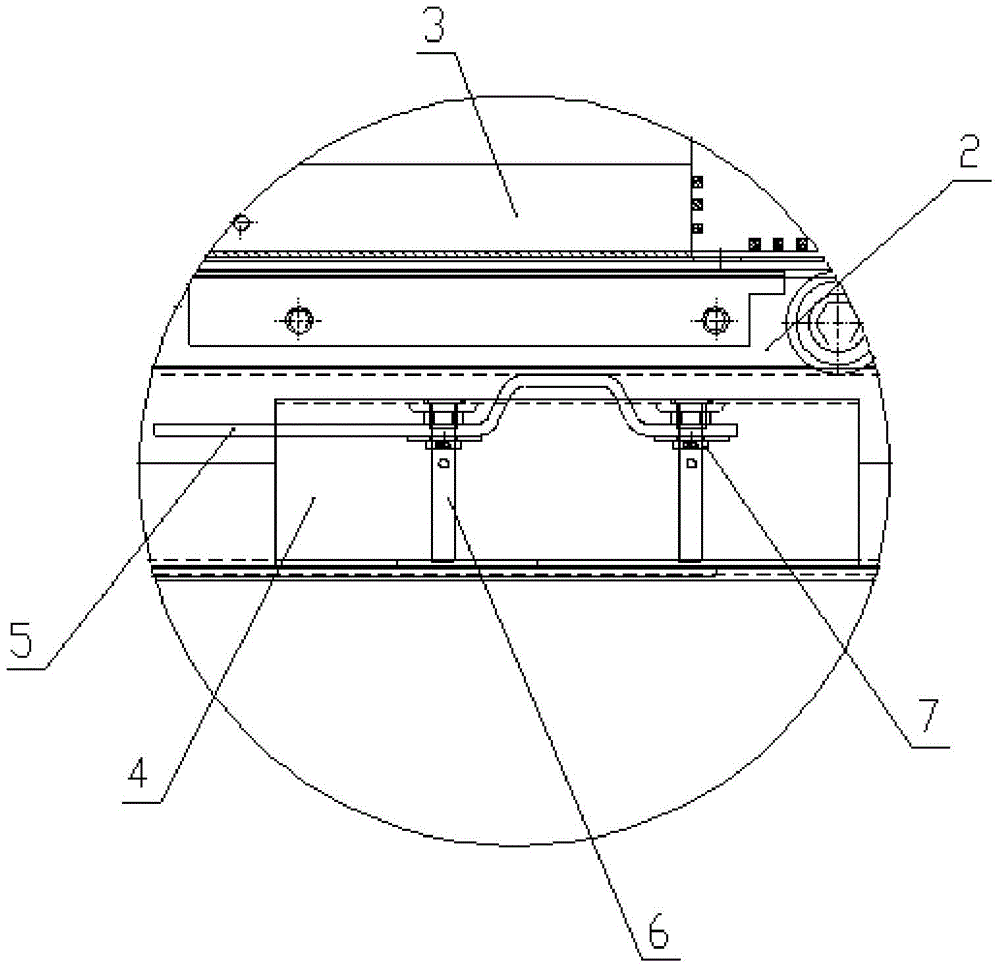

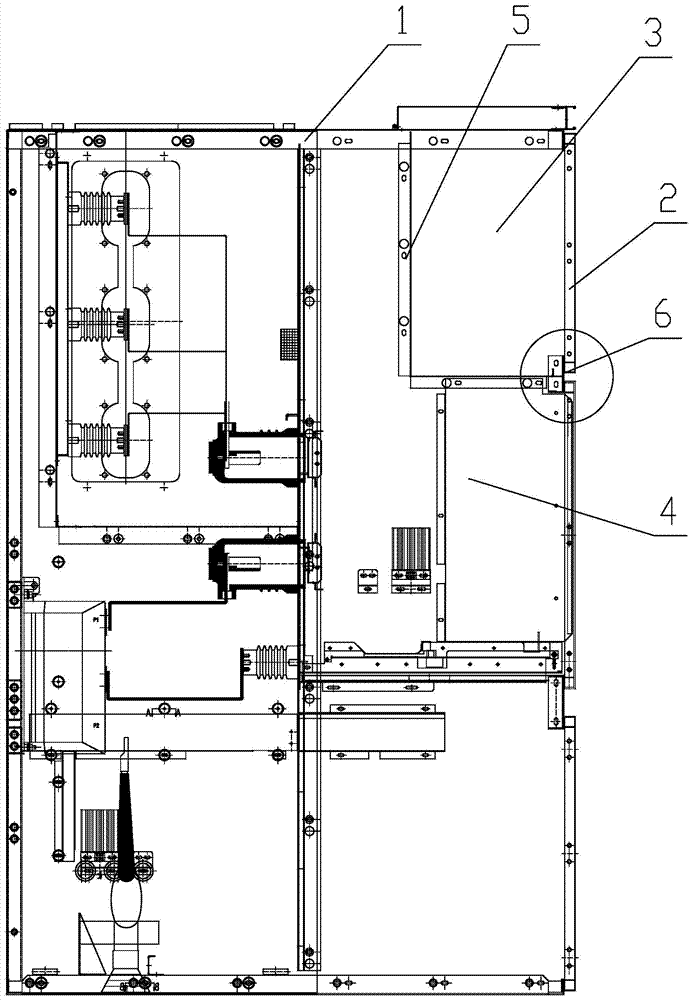

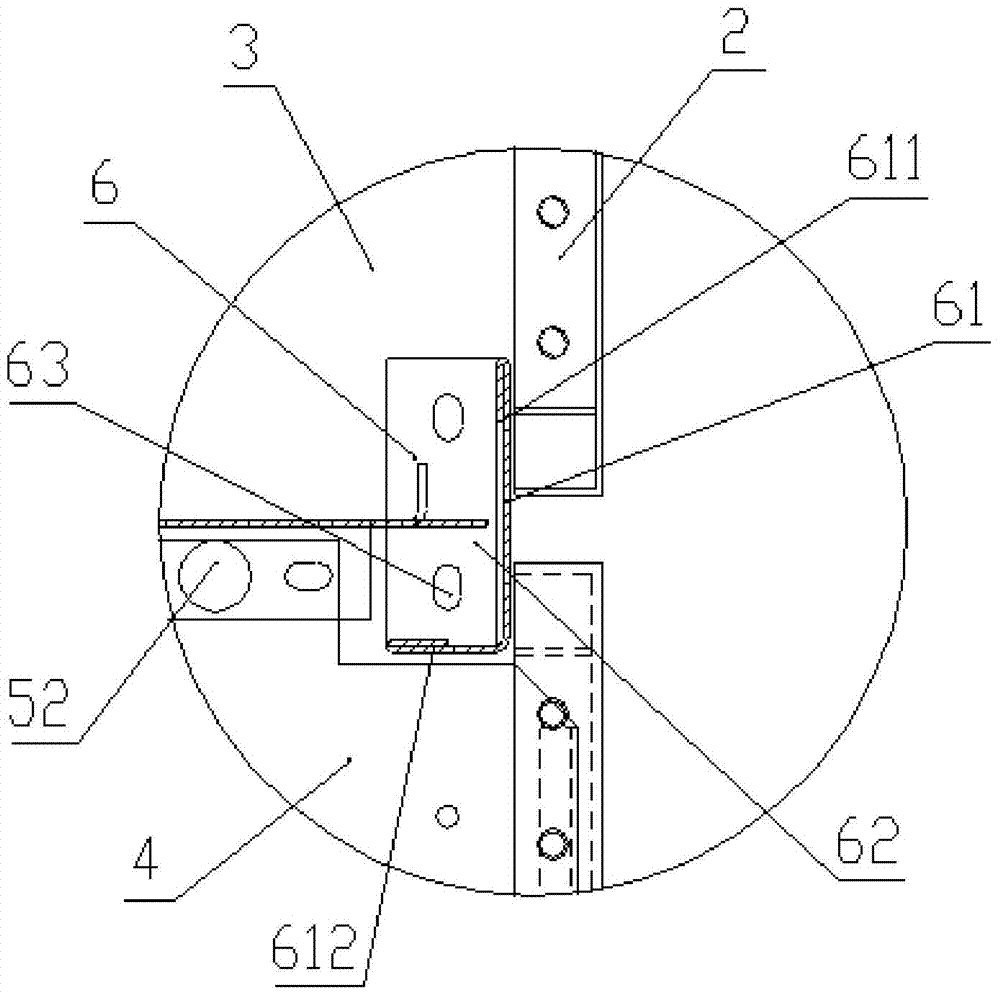

An electric control cabinet grounding installation board and an electric control cabinet

InactiveCN103490326BAchieve groundingProtection securitySwitchgear earthing arrangementsEngineeringInstrumentation

The invention discloses a grounding installation plate of an electric control cabinet and an electric control cabinet, which are designed to solve the problems of unsafe use of the existing electric control cabinet and the like. The grounding mounting plate of the electric control cabinet includes a base plate, the two side edges of the base plate are respectively bent inwards and provided with first bending edges, and the outer edges of the first bending edges are respectively bent outwards and provided with second bending edges. Bending edges; the base plate and the first bending edges on both sides enclose an accommodating space for accommodating the grounding bar and the grounding terminal; the base plate has a ground terminal installation hole; the second bending edge There are fixing holes for fixing the grounding mounting plate on the top. At the same time, an electric control cabinet with the grounding mounting plate is proposed. By setting the grounding mounting plate supporting the grounding bar, the grounding bar is in contact with the guide rail of the handcart to realize the grounding of the handcart and effectively protect the safety of operators and carrying instruments.

Owner:LIUZHOU HAIGE ELECTRICAL

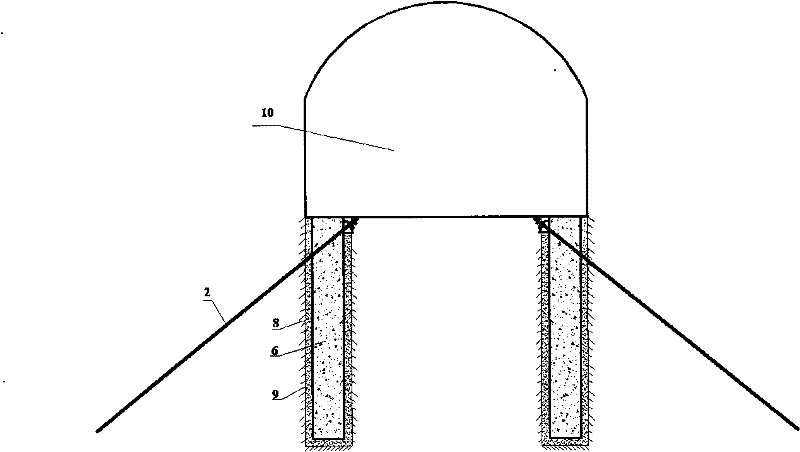

Soft rock roadway anchored concrete filled steel tube anti-floor heave device and construction method thereof

ActiveCN101975074BImprove skid resistanceImprove reinforcement effectBulkheads/pilesAnchoring boltsStress distributionCement mortar

The invention discloses a soft rock roadway anchored concrete filled steel tube anti-floor heave device and a construction method thereof. The construction method comprises the following steps: punching pile holes at the two sides of the floor of a roadway, embedding a steel tube body in the pile holes, pouring cement mortar, fixing the steel tube body in the pile holes, pouring concrete in the steel tube body to form a steel pipe pile, enabling an anchor rod or an anchor cable to penetrate the through holes of the steel tube pile and be anchored in rock formation at the two base angles of the roadway, sheathing cushion blocks, and fastening by nuts to form an anchoring structure. The invention can effectively control the roadway floor heave, improve stress distribution, and have the advantages of simple and convenient construction process, low cost, short time limit, superior cost performance, and stable physical mechanical properties.

Owner:滕州市产品质量监督检验所

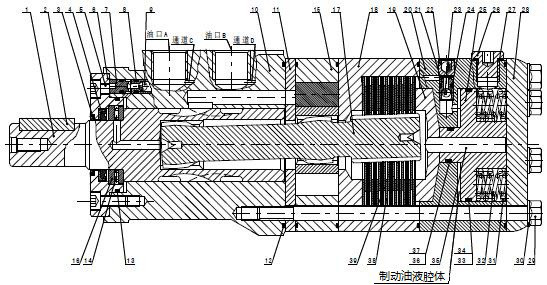

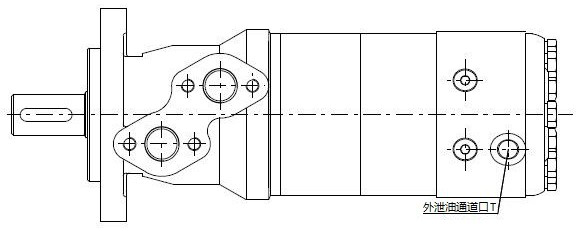

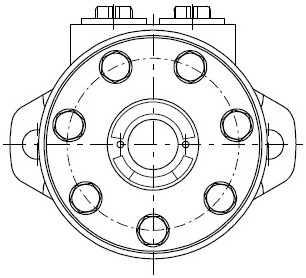

Hydraulic brake motor device

PendingCN111980913AThe processing technology is simple and reliableImprove applicabilityFluid actuated brakesBraking element arrangementsManufacturing technologyControl theory

The invention relates to a hydraulic brake motor device, and belongs to the technical field of hydraulic transmission. The hydraulic brake motor device comprises a motor positioning and mounting driving part, a motor main body meshing pair part and a motor braking device part; a motor internal integrated shuttle valve is formed by combining two independent one-way valve functional components, andis radially arranged in radial direction; the two independent one-way valve functional components communicate through a brake release oil cavity to form the shuttle valve. The hydraulic brake device is quite compact in structure, small in radial section size, simple in overall structure, good in manufacturing manufacturability and good in assembling and maintaining manufacturability.

Owner:ZHENJIANG DALI HYDRAULIC MOTOR

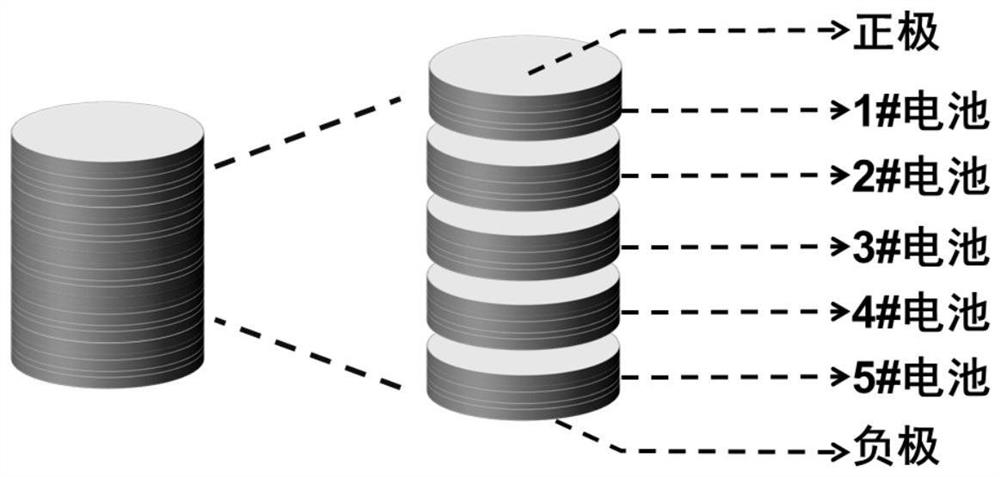

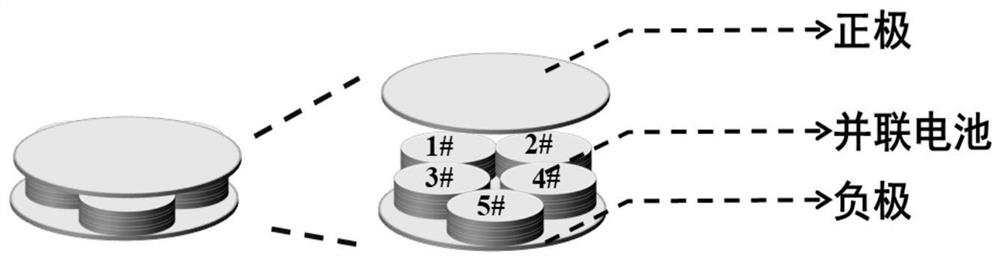

A fire-responsive temperature-controlled battery and its preparation method and application

ActiveCN112018404BPower output controlExtended service lifeDeferred-action cellsForest fire alarmsTemperature controlElectrical battery

The invention discloses a fire-responsive temperature-controlled battery, a preparation method and application thereof, and belongs to the technical field of fire monitoring. The temperature-controlled battery of the present invention includes an electrode and an electrolyte, and a phase change protection layer is arranged between the electrode and the electrolyte to isolate the contact between the electrolyte and the electrode. The temperature-controlled battery of the present invention has no electric energy output in a natural environment, but in a high-temperature environment, the phase change material changes to make the battery work and output electric energy, so that the temperature can control the power output of the battery. The temperature-controlled battery is low in cost, suitable for large-area control in a natural environment, and can effectively increase the placement density of fire monitoring nodes.

Owner:RENMIN UNIVERSITY OF CHINA

Electric control cabinet control room beam and electric control cabinet

InactiveCN103490289AAvoid harmThe overall structure is simple and reliableSubstation/switching arrangement casingsControl roomEngineering

The invention discloses an electric control cabinet control room beam and an electric control cabinet. The problem that an existing electric control cabinet is not safe in use is solved. The electric control cabinet control room beam comprises sealing partition boards with L-shaped sections. The sealing partition boards comprise the first sealing partition board and the second sealing partition board, the two sides of the first sealing partition board are respectively bent inwards so that connecting side boards can be formed; the control room beam is fixedly connected to a cabinet body of the electric control cabinet through the connecting side boards. The outer edge of the first sealing partition board and the outer edge of the second sealing partition board are double-layer pressing edges respectively. Meanwhile, the invention provides the electric control cabinet provided with the electric control cabinet control room beam. Due to the fact that the control room beam is arranged and matched with the bent boards of the control room, the control room and a breaker room are thoroughly separated, hurt to a person due to faulty operation is effectively avoided, and the control room beam is simple and reliable in structure, simple in manufacturing method and high in strength.

Owner:KUNSHAN ZHENHONG ELECTRONICS MACHINERY

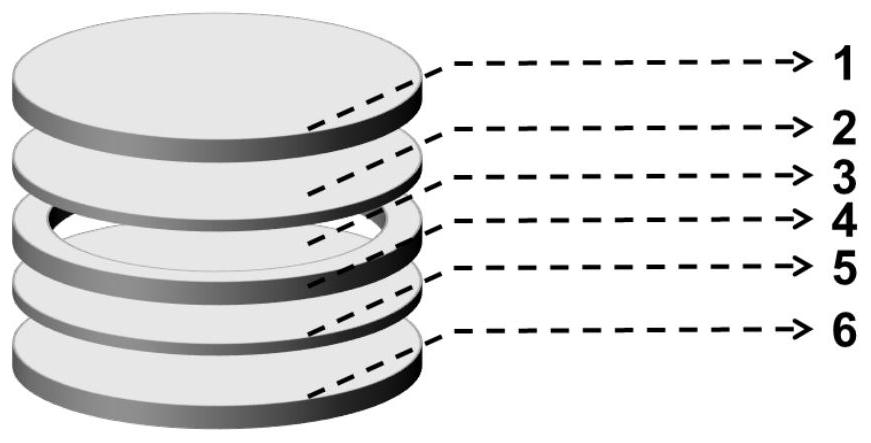

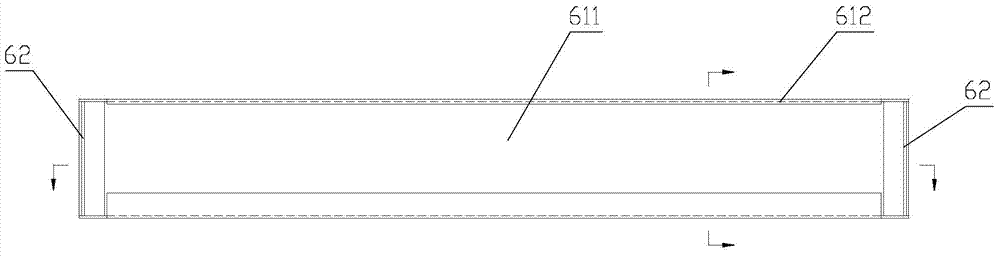

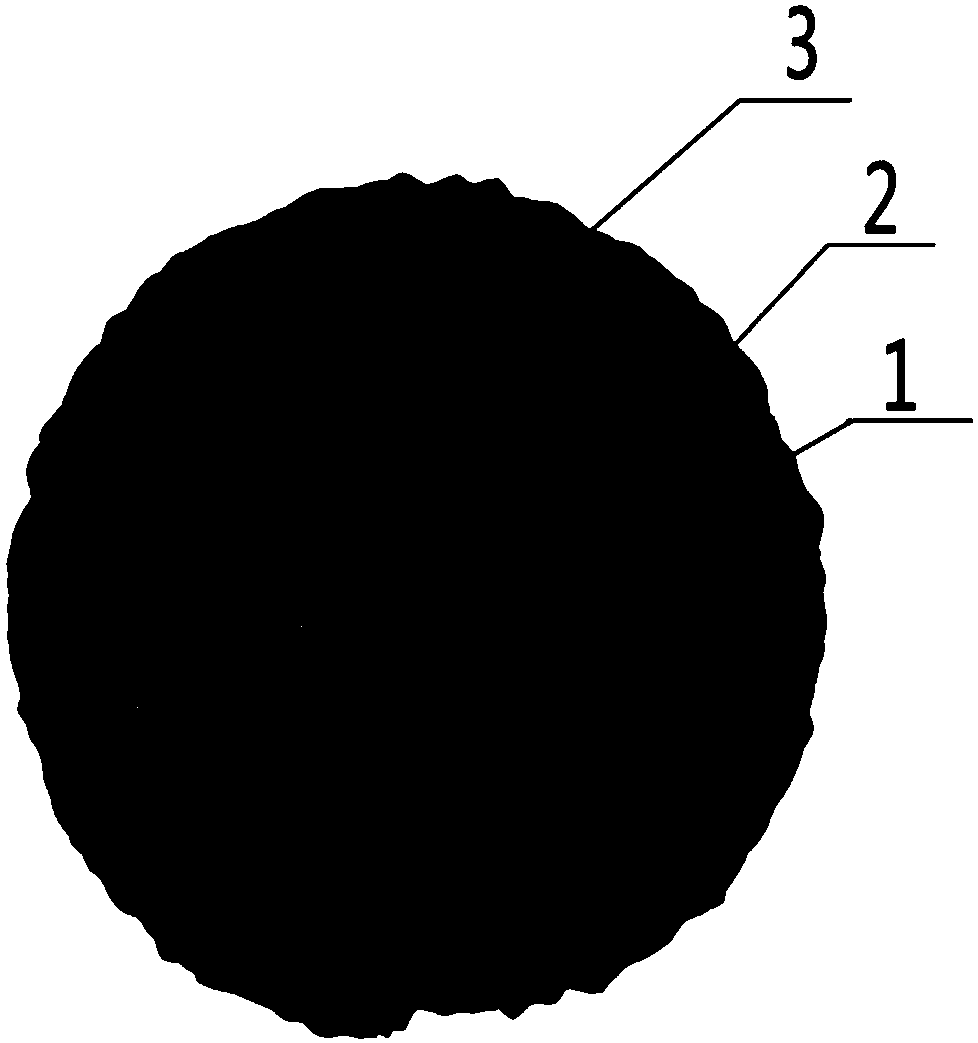

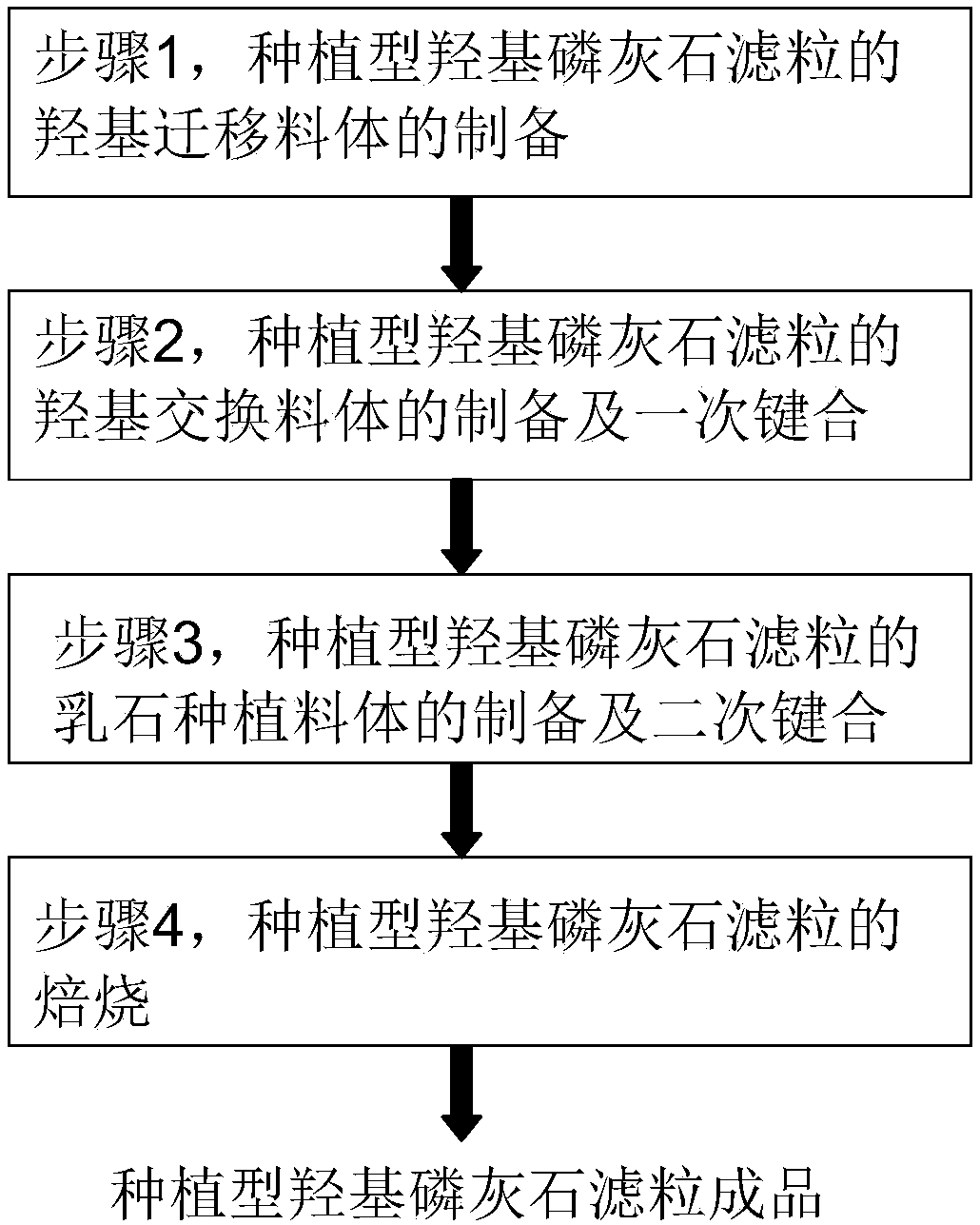

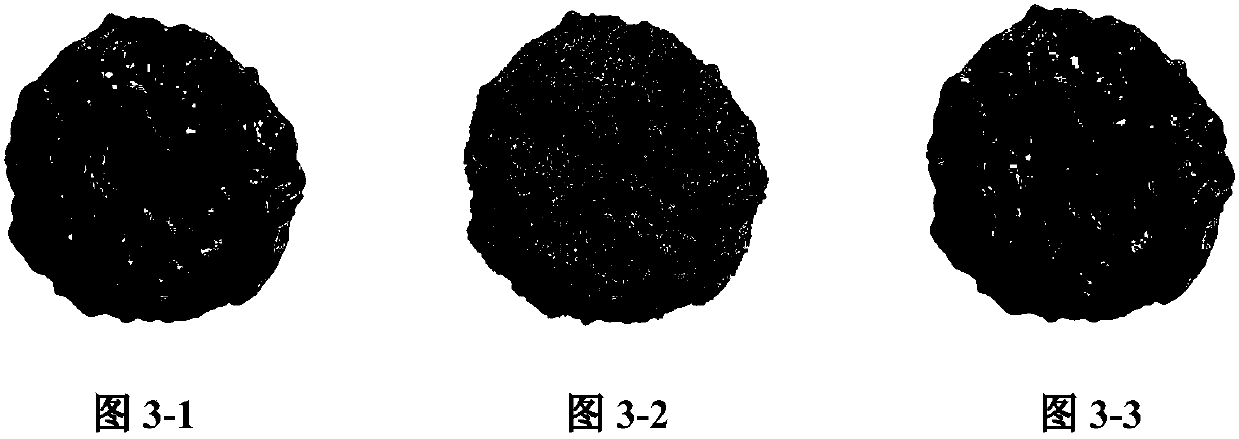

Planting-type hydroxyapatite filter particles based on planting method for defluoridation water treatment and preparation method thereof

ActiveCN106745364BMeet the needs of continuous productionImprove processing efficiencyWater contaminantsWater/sewage treatment by ion-exchangeSoil scienceFiltration

The invention relates to a planting type hydroxyapatite filter particle for defluorination water treatment based on a planting method and a preparation method of the planting type hydroxyapatite filter particle. The planting type hydroxyapatite filter particle is characterized in that the planting type hydroxyapatite filter particle structurally comprises a core planting layer 1, a transition planting layer 2 and an outer surface planting layer 3 in sequence from a core to an outer surface in a manner that the contents of hydroxyl are increased, wherein the two adjacent layers are chemically bonded; a main body of the core planting layer 1 is a hydroxyl transfer material body of the planting type hydroxyapatite filter particle; a main body of the transition planting layer 2 is a hydroxyl exchange material body of the planting type hydroxyapatite filter particle; and a main body of the outer surface planting layer 3 is a galalith planting material body of the planting type hydroxyapatite filter particle. The material body of the planting type hydroxyapatite filter particle provided by the invention is high in defluorination efficiency; and a method of a defluorination water treatment process is simple, convenient and reliable, so that the requirement of the defluorination water treatment process based on the planting method can be met.

Owner:JIANGSU YONGGUAN WATER & WASTERWATER EQUIP CO LTD

Preparation method of parallel array multi-core fiber

InactiveCN101533124BAvoid inconsistenciesAvoid deformationGlass making apparatusOptical fibre with multilayer core/claddingFiberMechanical engineering

The invention provides a method for preparing a parallel array multi-core fiber. Firstly, specially prepared fiber core filigree member is sectionally cut out according to certain length to obtain a group of fiber core filigrees with the same standard performance; the group of fiber core filigrees is tightly adjacent and is clamped between two high purity semi-column structure silica glass members, and is inserted into a high purity quartz outer sleeve after combination, so that a parallel array fiber core fiber preformed bar is formed; the group of the fiber core has the same axial direction with the quartz outer sleeve, and is positioned at the diameter position of the end face of the quartz outer sleeve; one end of the parallel array fiber core fiber preformed bar is sintered and sealed by high temperature oxyhydrogen flame, and then drawn into parallel array core fiber on a fiber wire-drawer-tower; in the process of fiber wire-drawing, a negative pressure is applied at the other end of the fiber preformed bar that is non-sintering end. The processing size is easy to control and the processing technology is simple and convenient, so the technology used for preparing the whole fiber preformed bar is simple, convenient and reliable, and has good economical efficiency.

Owner:HARBIN ENG UNIV

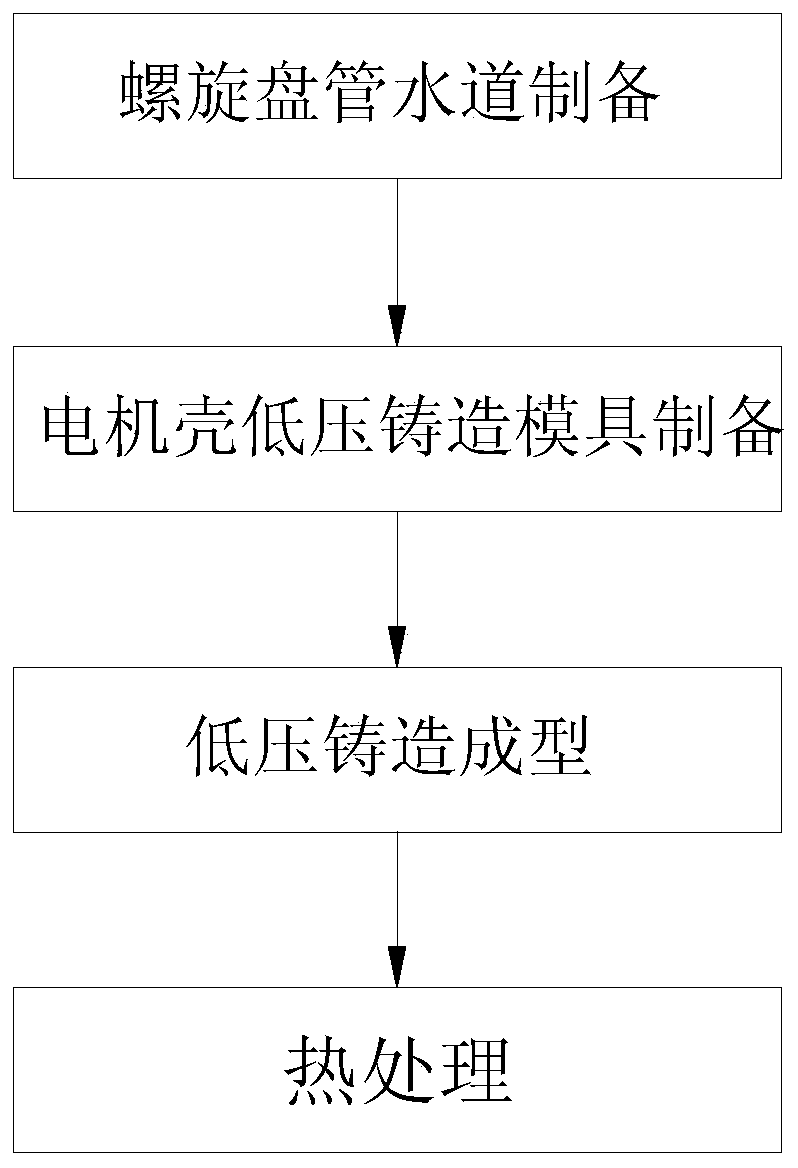

A low-pressure casting method of an aluminum alloy motor casing with a built-in spiral coil water channel

ActiveCN107498025BUniform and stable wall thicknessSmall reserved machining allowancePipe waterPressure casting

The invention discloses a low-pressure casting method of an aluminum alloy motor shell internally provided with a spiral coil pipe water way. A stainless steel or copper or aluminum spiral coil pipe water way is prefabricated, a water inlet and a water outlet are formed in the side faces of the spiral coil pipe water way, a boss for positioning is arranged on the water inlet and the water outlet, according to the structure of the spiral coil pipe water way, a motor shell low-pressure casting mold is prepared, the spiral coil pipe water way is positioned and assembled in the motor shell low-pressure casting mold, the assembled motor shell low-pressure casting mold is placed above a heat preservation furnace of a low-pressure casting machine to be subject to low-pressure casting forming, and through low-pressure casting, the prefabricated spiral coil pipe water way is casted in the aluminum alloy motor shell. The casting auxiliary process and the auxiliary time can be greatly saved, production efficiency is improved, after casting, no sand core in the motor shell needs to be cleaned, the casted aluminum alloy motor shell is few in defect, high in precision, and not prone to deformation, cracking and water leaking, the aluminum alloy motor shell is high in casting quality, and the production cost is low.

Owner:福建巨能精密铸造科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com