Patents

Literature

96results about How to "Meet the needs of continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Di-demethoxycurcumin precursor liposome and preparation method thereof

InactiveCN101569607AImprove stabilityConstant indexPowder deliveryDigestive systemCholesterolFreeze-drying

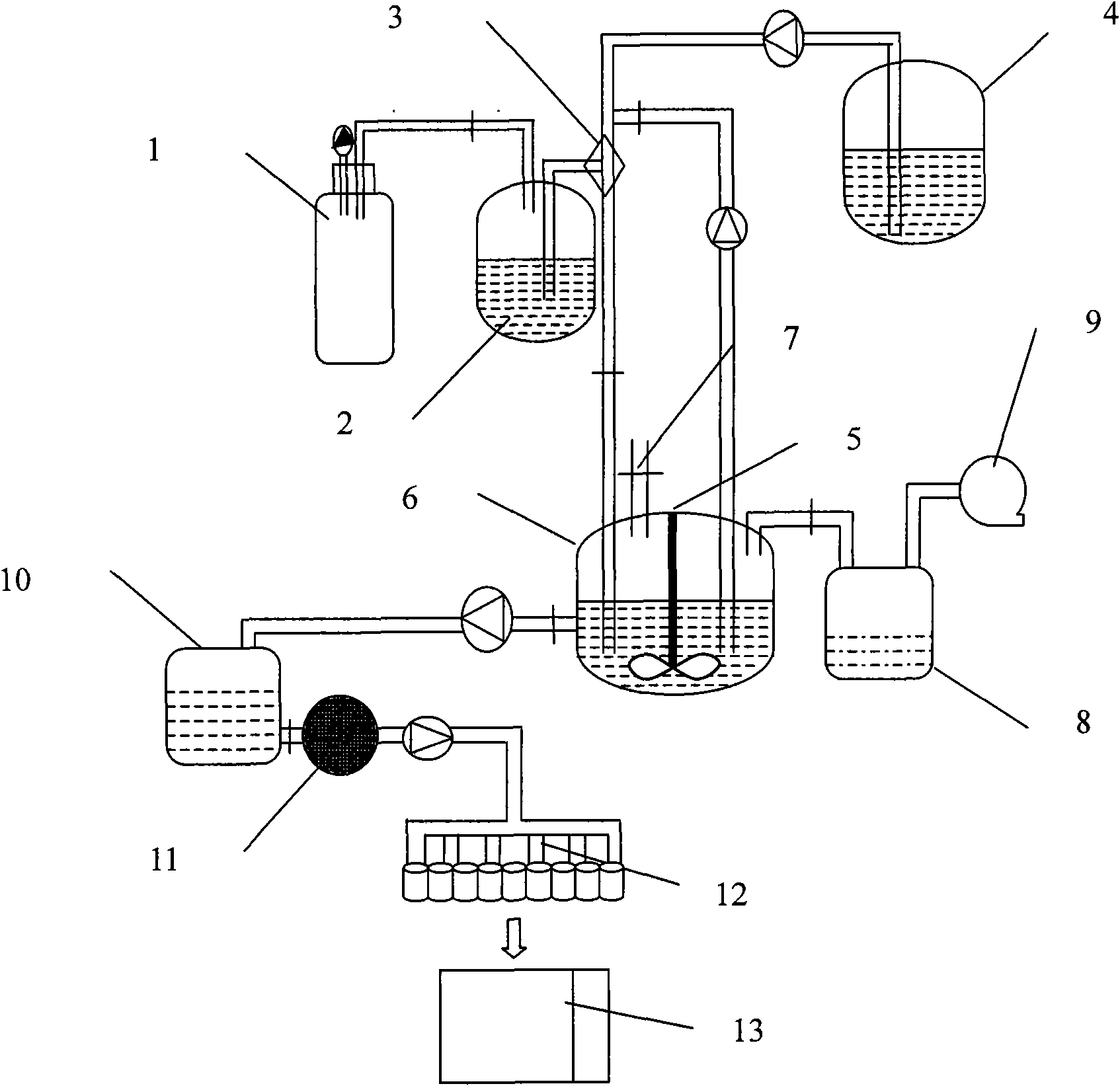

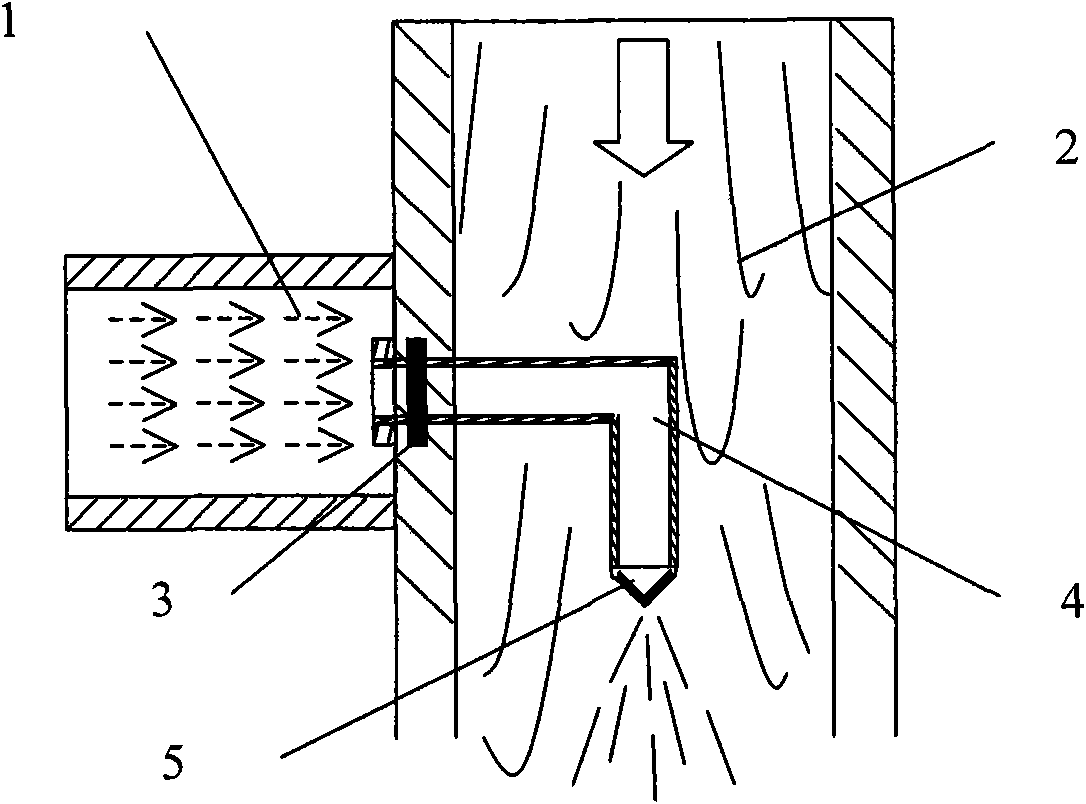

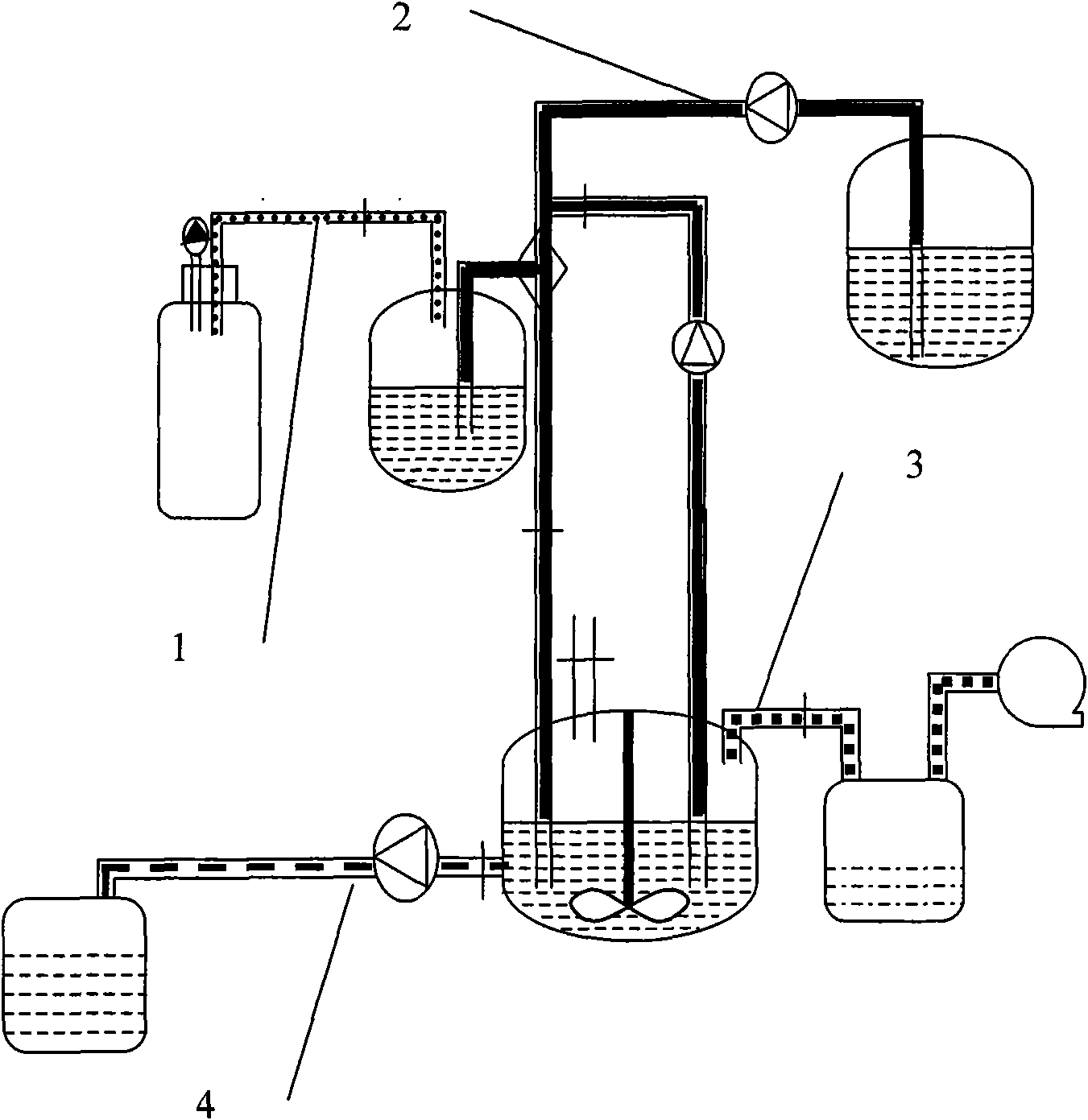

The invention provides a precursor liposome containing di-demethoxycurcumin and a preparation method capable of industrial application. The weight ratio of the di-demethoxycurcumin to phospholipids together with phospholipid derivatives is 1:5-65, 3 to 20 portions of cholesterol together with derivatives thereof and 0.5 to 5 portions of surfactant are prepared into a freeze-dried powder injection according to the portion ratio of the phospholipids to freeze-drying protective agents being 1:0.25-4. The invention relates to a novel technique and a device for preparing a precursor liposome by an efficient jetting-mixing method, has the advantages of good process reproducibility, controllable technical parameters and the like, and can provide a unilocular liposome with fat-soluble medicaments which are stably wrapped in a phospholipid bilayer. The liposome has the average particle size of between 80 and 300 nm, is narrow in the distribution range of particle size, has entrapment rate of more than 85 percent, is low in leakage rate, and is significantly improved in the stability of preparation storage process. The in vivo circulation time of the novel preparation is obviously prolonged during intravenous injection administration, and the AUC of the novel preparation is 2.67 times that of the common injection.

Owner:CHINA PHARM UNIV

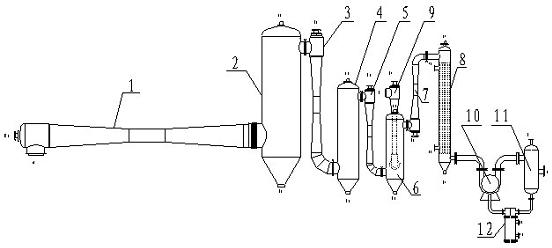

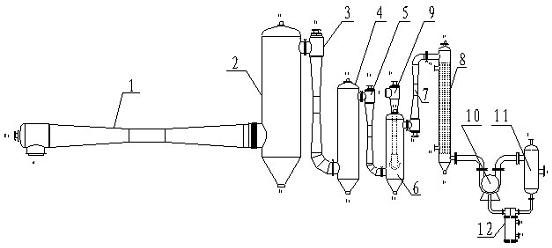

Coke oven gas hydrogen production technology

InactiveCN107512702AReduce pollutionSatisfy recyclingGas treatmentFatty/oily/floating substances removal devicesChemistryHydrogen production

The invention belongs to the technical field of coke oven gas hydrogen production. Aiming at solving the technical problems of existing coke oven gas hydrogen production that the pollution is serious and the hydrogen production quality is relatively poor, the invention provides a coke oven gas hydrogen production technology. The coke oven gas hydrogen production technology comprises the following steps: A, after carrying out first-grade pressurization on coke oven gas through a gas compressor, carrying out a pre-treatment procedure on the coke oven gas after the coke oven gas passes through an oil remover, obtaining oil-removed and purified coke oven gas; returning the oil-removed and purified coke oven gas back to the gas compressor, carrying out second-grade and third-grade pressurization and then conveying the coke oven gas out of a compression procedure to obtain compressed coke oven gas; B, enabling the compressed coke oven gas to enter from the bottom of a first oil removing tower and then enabling the compressed coke oven gas to directly enter an adsorption tower of a PSA (Pressure Swing Adsorption) hydrogen purification procedure; treating the compressed coke oven gas treated by the adsorption tower to obtain pressure swing adsorption crude hydrogen; C, introducing the pressure swing adsorption crude hydrogen into an oxygen removing tower; then cooling through a cooler to room temperature, so as to obtain oxygen removed hydrogen; conveying the oxygen removed hydrogen into an isobaric regenerated TSA (Temperature Swing Adsorption) drying procedure to obtain dry hydrogen. The coke oven gas hydrogen production technology has the characteristics of small pollution and good hydrogen production quality.

Owner:CHENGDU JUTAO OIL ENG CO LTD

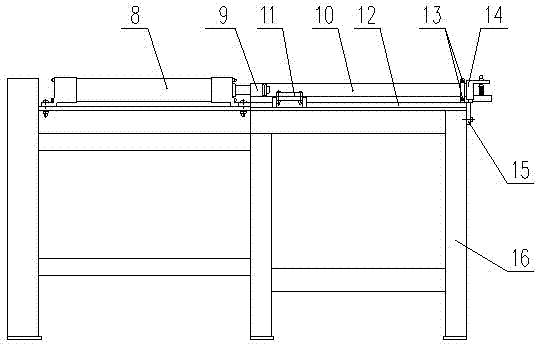

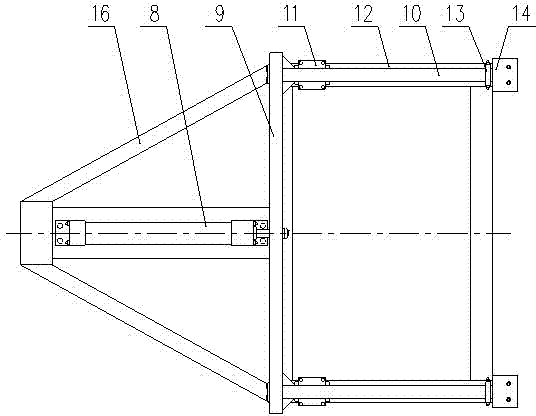

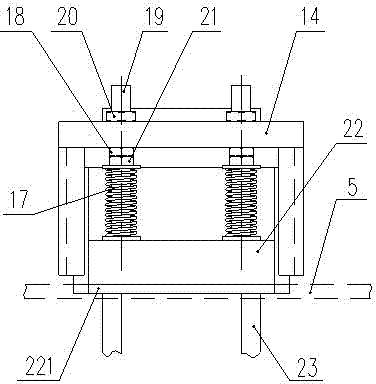

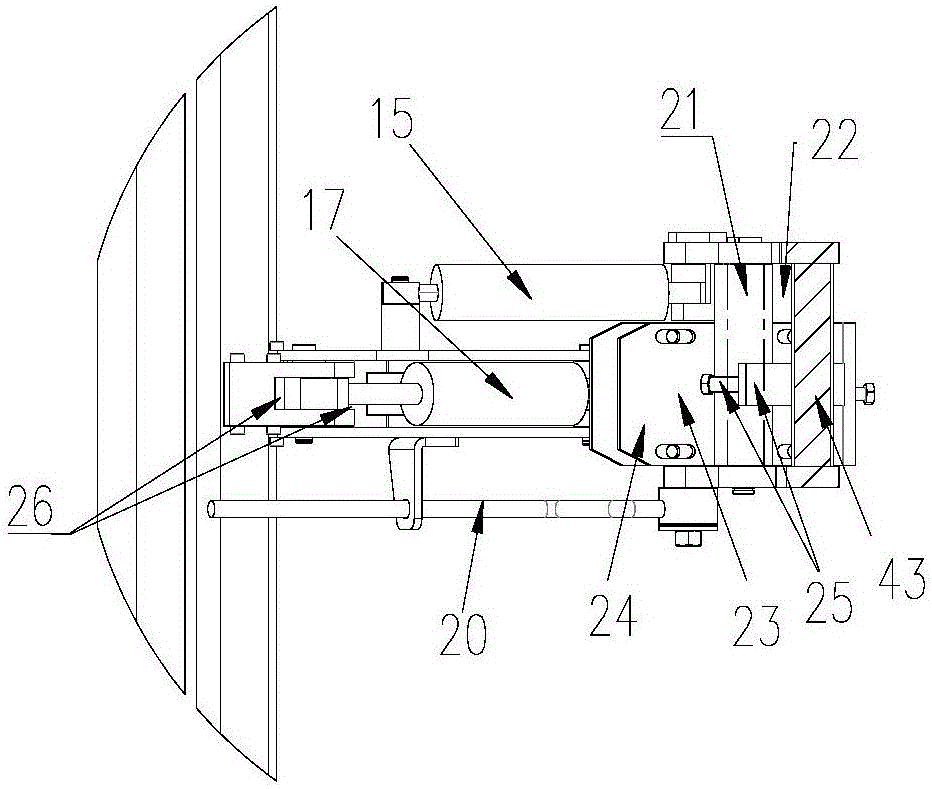

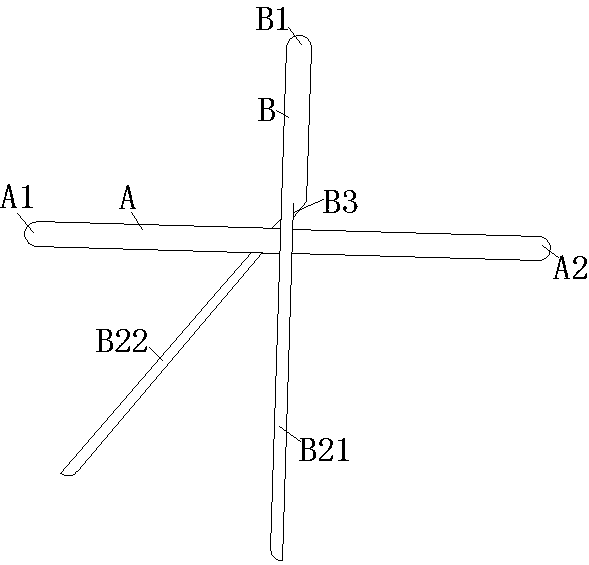

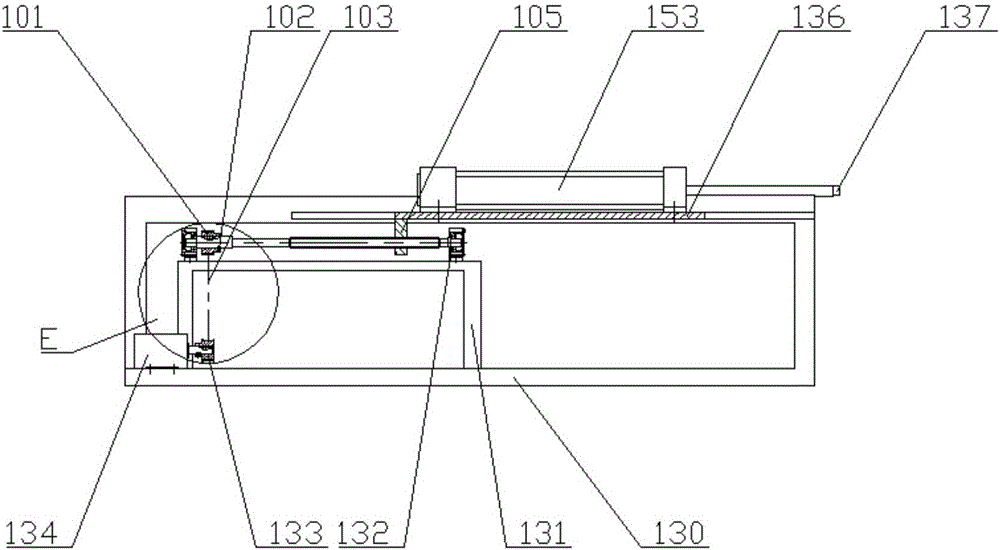

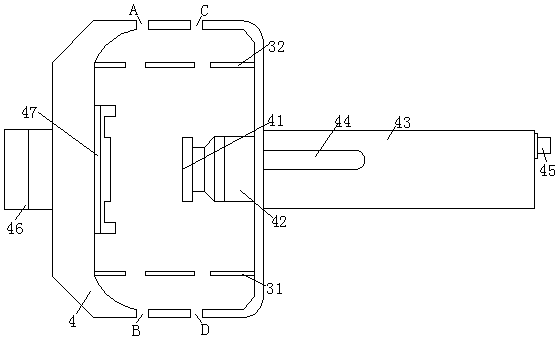

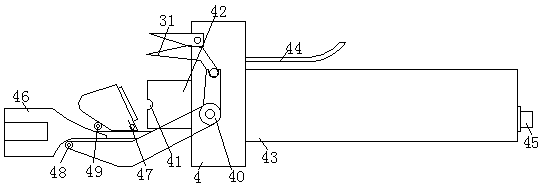

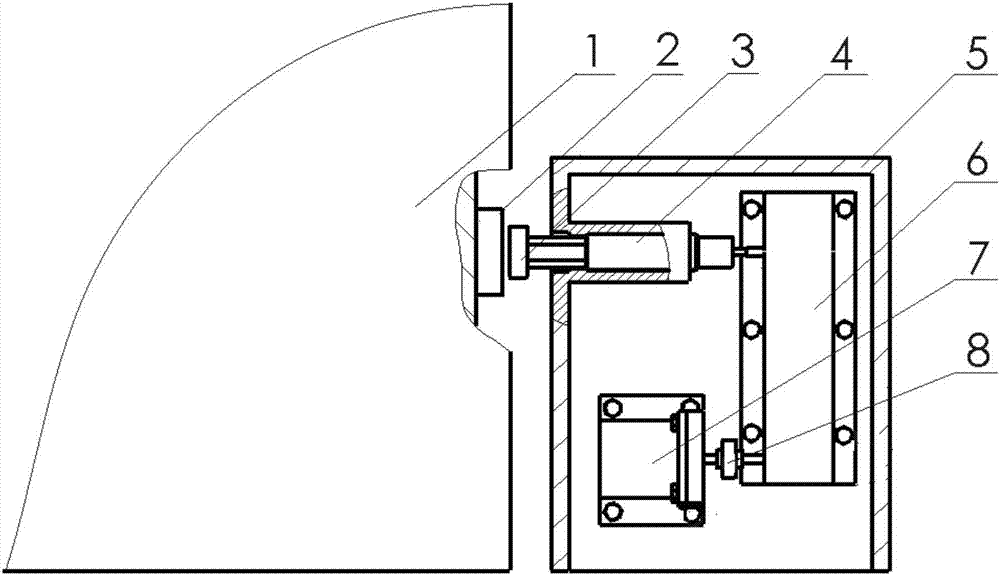

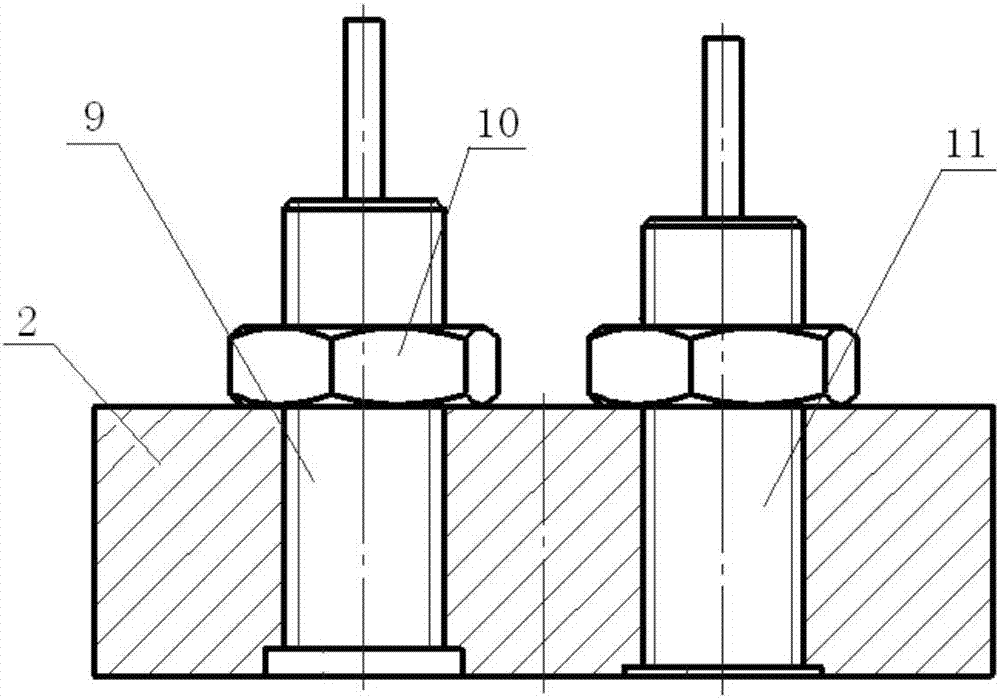

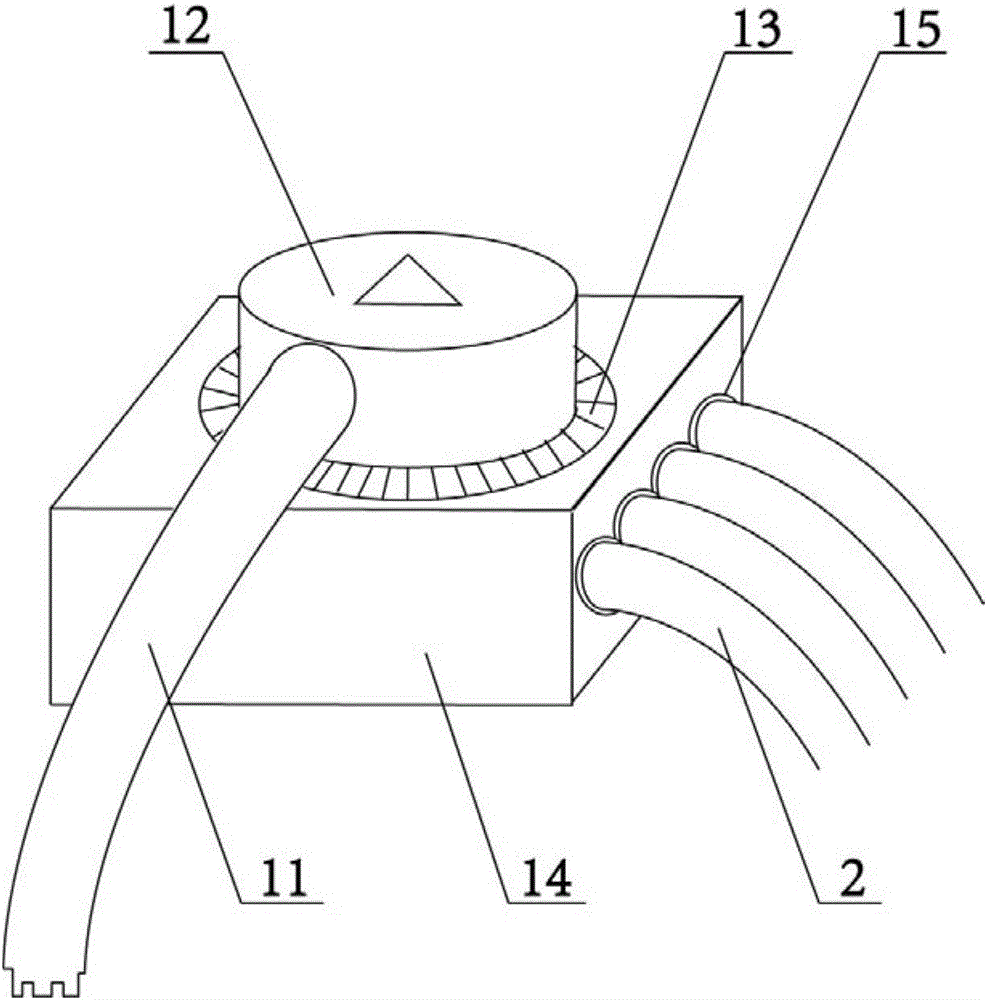

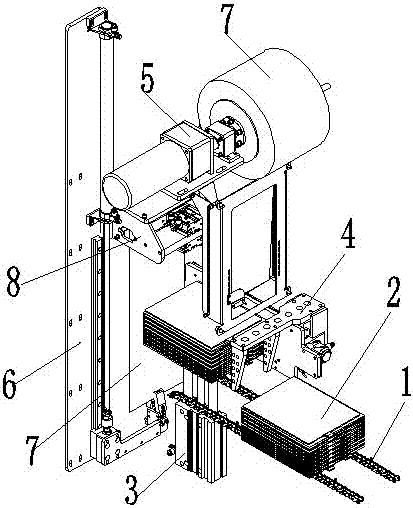

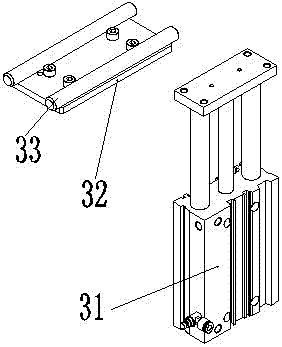

Template pushing device for conveying template

InactiveCN102344034AEasy to pushMeet the needs of continuous productionConveyorsEngineeringMechanical engineering

The invention discloses a template pushing device for conveying a template. The device comprises a push plate bracket, wherein a push plate cylinder is fixedly arranged on the push plate bracket; the device is characterized in that: a piston rod of the push plate cylinder is connected with a push rod; the push rod is fixedly connected with a linear guide rail slide block; the linear guide rail slide block is arranged on a linear guide rail and can slide back and forth on the linear guide rail; the linear guide rail is fixed on the push plate bracket; the push plate bracket is also provided with a limiting device which can limit travel of the push plate cylinder; and the front end of the push rod is provided with a pusher device for pushing the template. The device has the advantages of meeting requirements of continuous production, facilitating continuous pushing of the template into a specified position, saving labor in operation, saving production time and increasing working efficiency. The device can be applied to producing a glass magnesium board in building decoration material industry.

Owner:张家港市玉龙科技板材有限公司

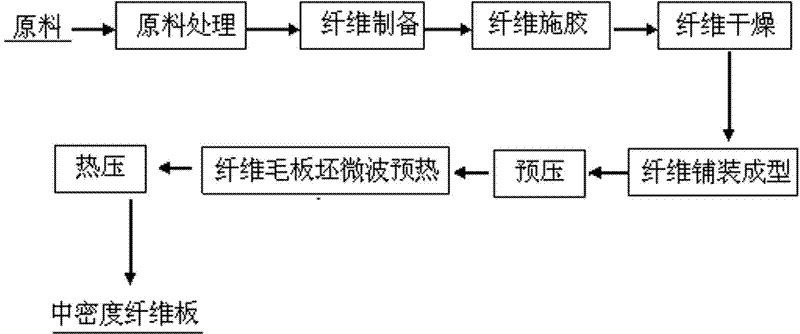

Method for preparing medium density fiberboard by using microwave to pre-heat

InactiveCN102335947AReduce heating time of heat pressShort manufacturing timeWood working apparatusDomestic articlesFiberTemperature control

The invention discloses a method for preparing a medium density fiberboard by using microwave to pre-heat. The method comprises the procedures of treating raw materials, preparing fibers, gluing the fibers, drying the fibers, paving and molding the fibers, pre-pressing and hotly pressing. The method also comprises a procedure for pre-heating a fiber plate blank by using the microwave between the procedure for pre-pressing and the procedure for hotly pressing. The procedure for pre-heating the fiber plate blank by using the microwave to pre-heat is used for rapidly pre-heating the pre-pressed fiber plate blank by using the microwave through arranging a continuous tunnel type microwave heating device and the temperature of the fiber plate blank which is pre-heated by the microwave is controlled in a range of 50-60 DEG C. With the adoption of the method provided by the invention, the time for hotly pressing and raising the temperature of the fiber plate blank can be reduced so that the whole preparation time of the medium density fiberboard is shortened, the production efficiency of the medium density fiberboard is improved and the energy is saved, and the quality of the medium density fiberboard product also can be improved and enhanced.

Owner:FUJIAN YONGAN FORESTRY GRP CO LTD

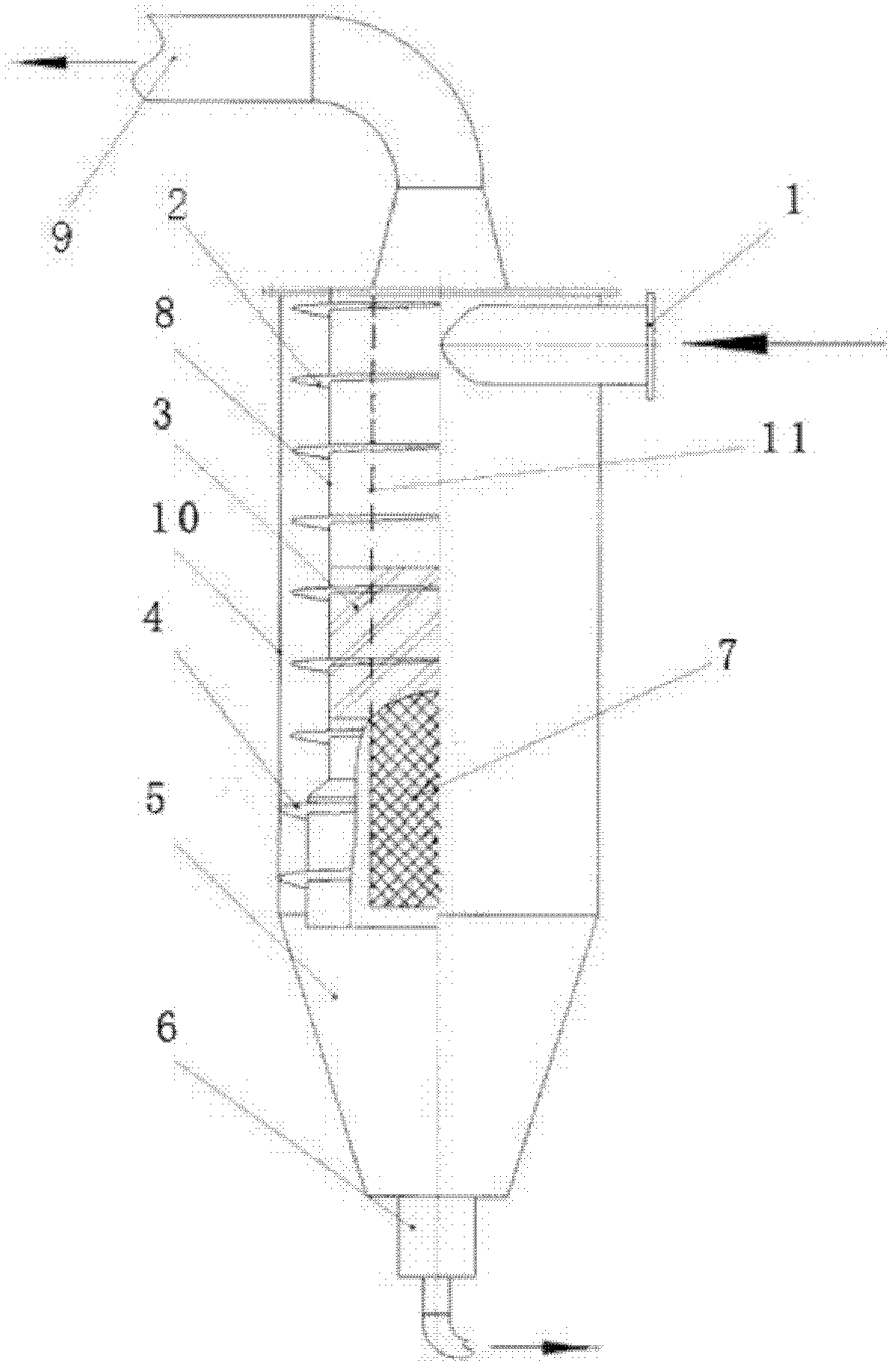

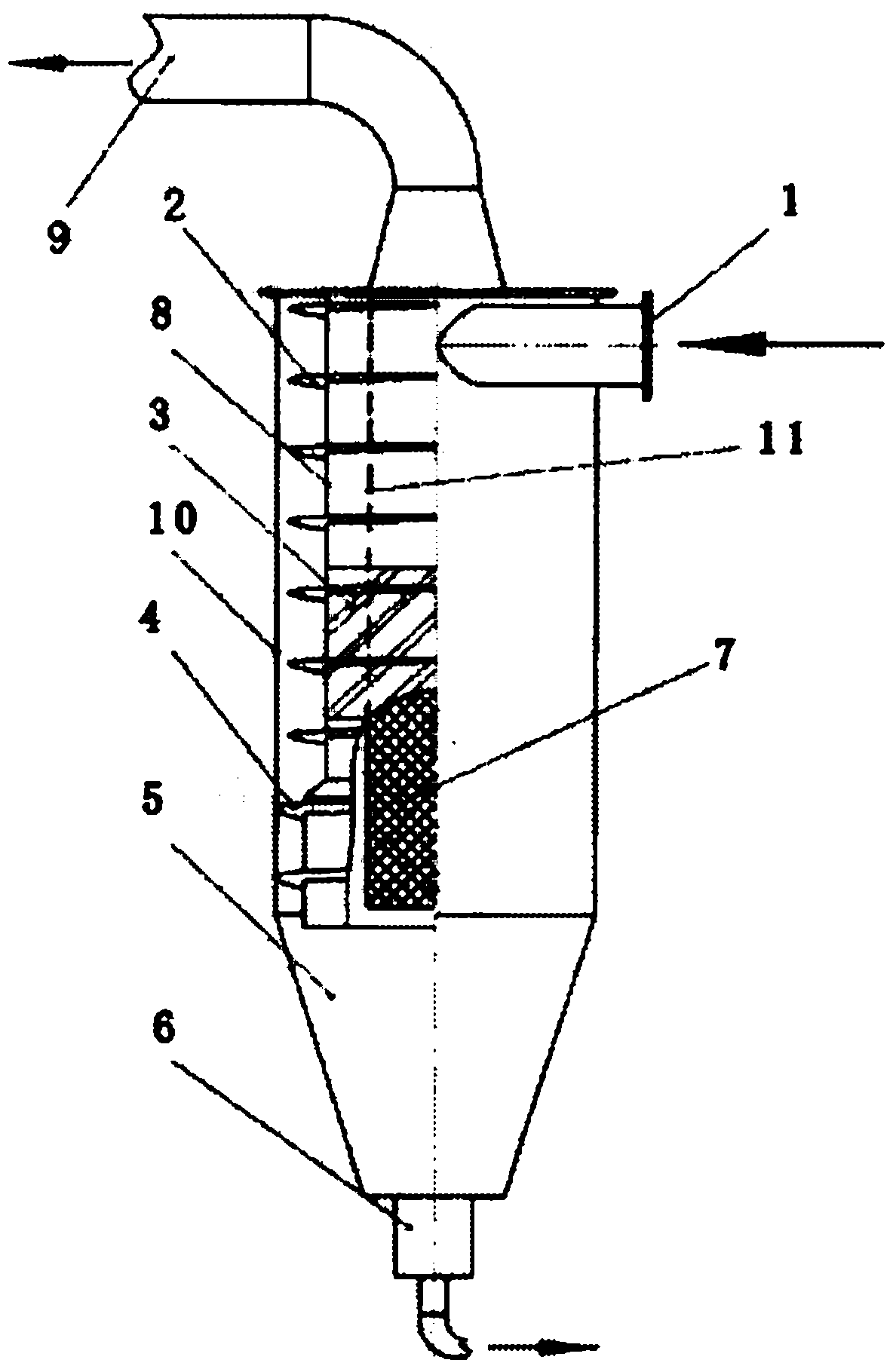

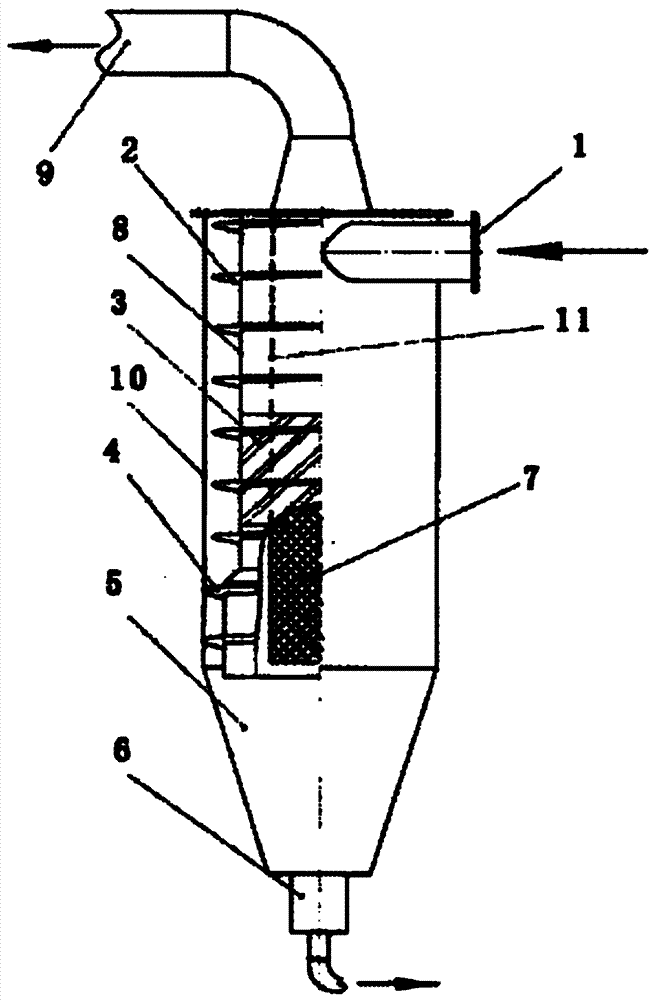

Dual-swirl water purifier

InactiveCN102614711AReach the standard of recyclingRealize the function of filtration and purificationFiltration circuitsWater resourcesOblique cutting

The invention belongs to the field of water treatment equipment and discloses a dual-swirl water purifier, which can perform tertiary sewage treatment without extra power. The dual-swirl water purifier is formed by sleeving three layers of pipe sleeves with different diameters, wherein the upper part of an outer sleeve is provided with a water inlet which is communicated with a primary swirl cavity; a sewage collecting and settling area and a sewage outlet are formed on the lower part in the outer sleeve; a water inlet oblique cut is formed on the surface of a middle section of a middle sleeve along the tangential direction; the outer surface is wound with spiral swirl vanes and spiral swirl lower vanes; gaps are reserved between the vanes and the outer sleeve; a gap is not reserved between the lower vanes and the outer sleeve; and a filtering net is arranged on an outer surface of an inner meshed pipe framework and is communicated with a purified water outlet. Three filtering and purifying functions, namely primary filtering, middle precision filtering and final filtering are realized, and the invention has the characteristics that the water purifier is small in size, compact in structure and high in sewage treatment amount, a recycling ratio of water is improved, and the water resources are saved.

Owner:北京五一环保科技股份有限公司

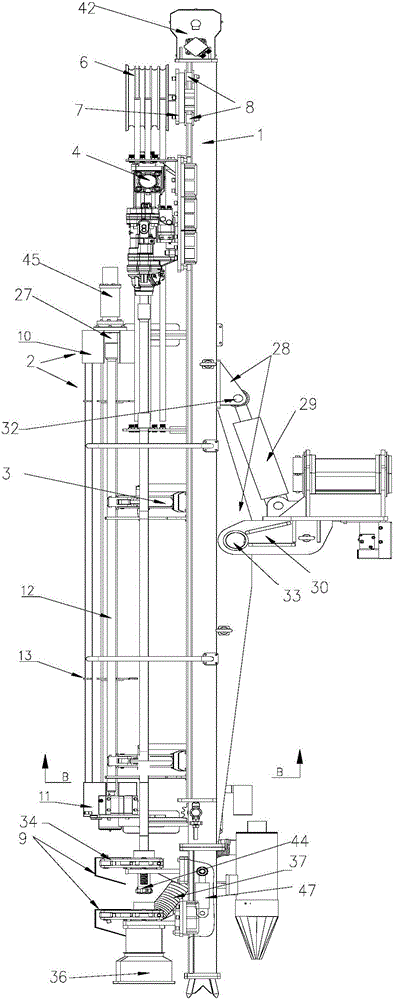

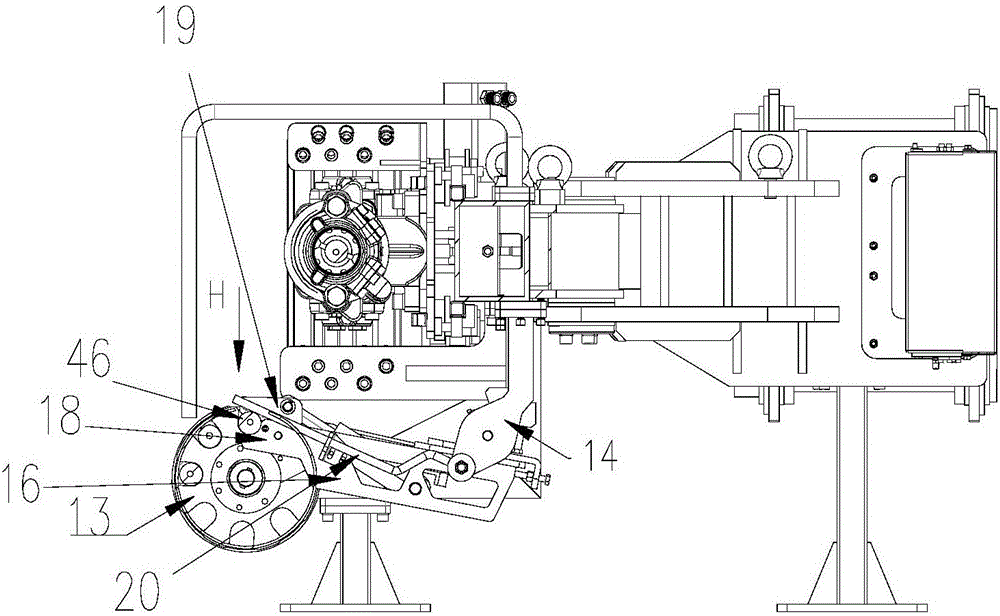

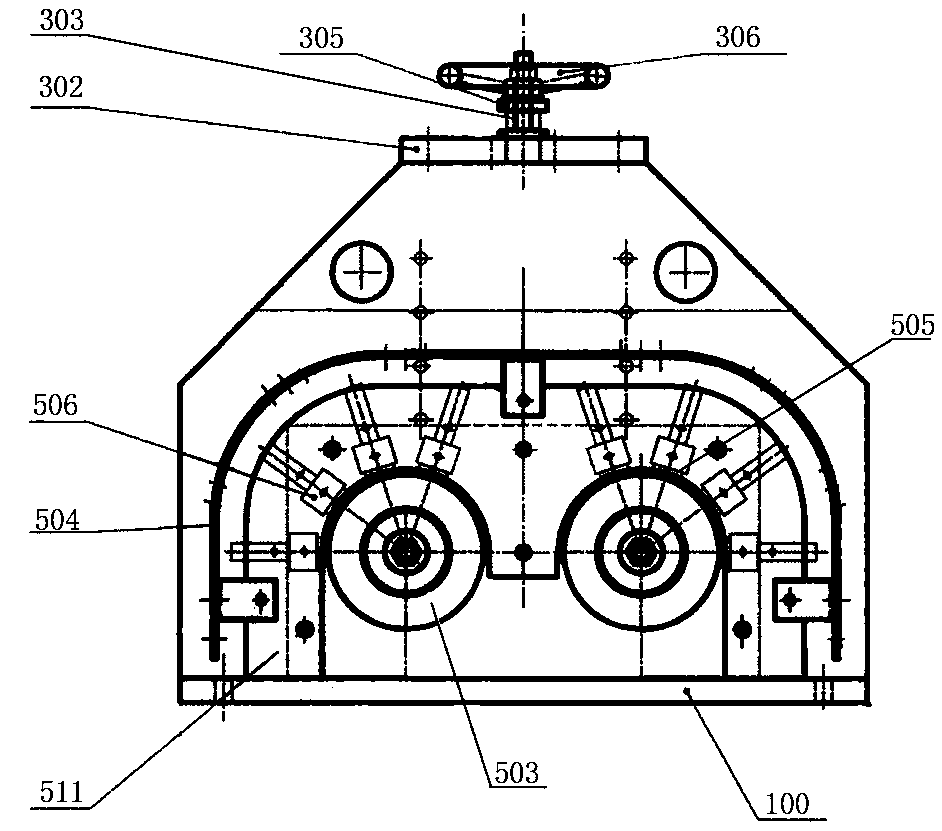

Outer-hanging type automatic rod replacing drilling machine

ActiveCN106194072AAchieve clampingAchieve releaseDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention discloses an outer-hanging type automatic rod replacing drilling machine and belongs to the field of rock drilling machines. The outer-hanging type automatic rod replacing drilling machine comprises a guide rail, a transmission mechanism, a clamping device, a rod storage device, a mechanical arm and a rock drilling device. The guide rail is a vertical plate provided with a guiding groove or a guiding rod. The transmission mechanism comprises a power source and a lifting device. The clamping device comprises a plurality of clamping units installed on the guide rail. The rod storage device comprises a rotary shaft and a clamping piece. The mechanical arm comprises a machine frame plate, a side-sway component and a clamping component. The side-sway component is hinged to the machine frame plate. The clamping component is hinged to the side-sway component. The rock drilling device is installed on the guide rail through a guide rail support and driven by the lifting device to slide up and down. According to the outer-hanging type automatic rod replacing drilling machine, two hydraulic oil cylinders control a swing arm plate to swing around a hinging point and a movable chuck to rotate around the hinging point correspondingly, accurate automatic rod clamping, rod fetching and rod placing are achieved, the labor intensity is relieved, the rod replacing efficiency is improved, and potential safety hazards are reduced.

Owner:湖南烈岩科技有限公司

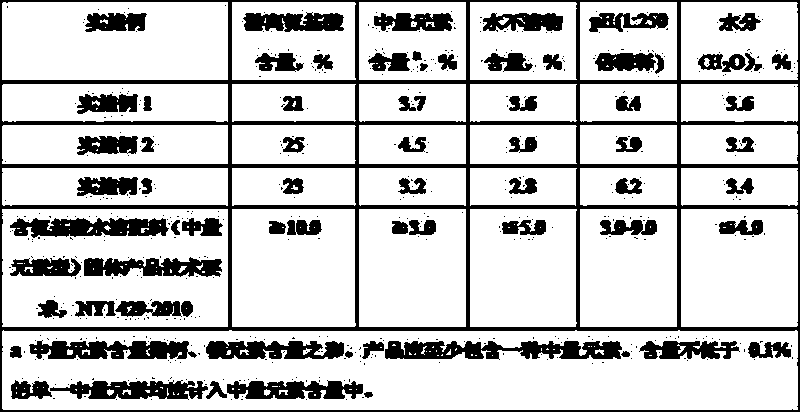

Method for producing natural amino acid water-soluble fertilizer by utilizing tobacco liquid waste regenerated by paper-making process

ActiveCN103708898AWide variety of sourcesIncrease productionFertiliser formsFertilizer mixturesLiquid wasteGranularity

The invention discloses a method for producing natural amino acid water-soluble fertilizer by utilizing tobacco liquid waste regenerated by a paper-making process. The method comprises the following steps: filtering and separating the tobacco liquid waste regenerated by the paper-making process, wherein the granularity of a filtering net is 40-60 meshes; adding 0.3-0.6 percent of protease and 10-20 percent of feed grade protein powder into the liquid waste at a mass ratio, feeding the mixture into a constant temperature reactor, and performing fermentation reaction at a temperature of 33-38 DEG C for 5-20 days, thereby obtaining a fermented product, and the like. The method is simple and low in production cost, the obtained product is the natural amino acid fertilizer, and after the fertilizer is applied, the crop growth can be promoted, and the soil structure is improved. The problems that the wastewater treatment cost is high, the discharge amount is large and environmental pollution is caused in the process of producing the regenerated tobaccos by the paper-making process are solved.

Owner:YUNNAN FUFA BIOTECH CO LTD

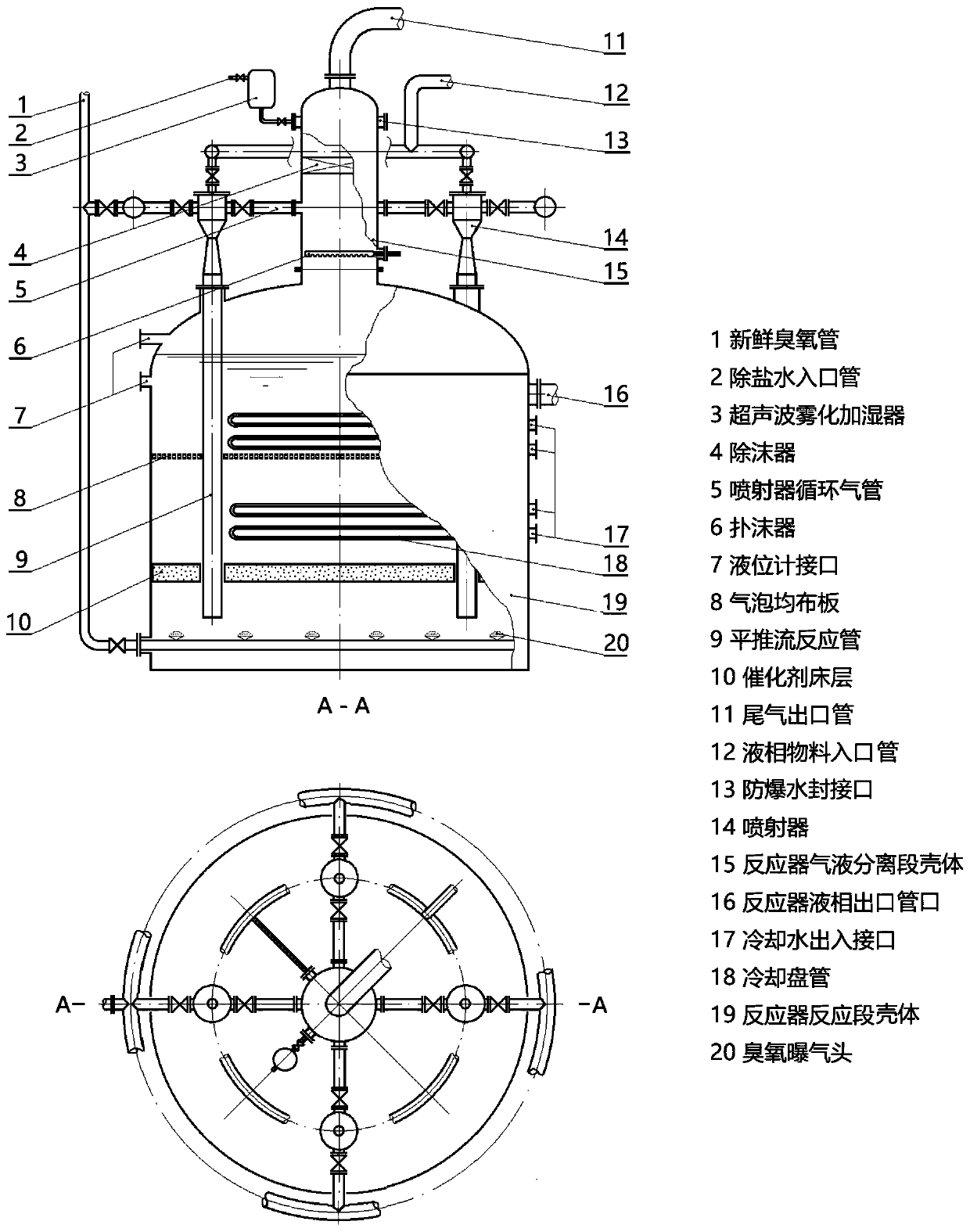

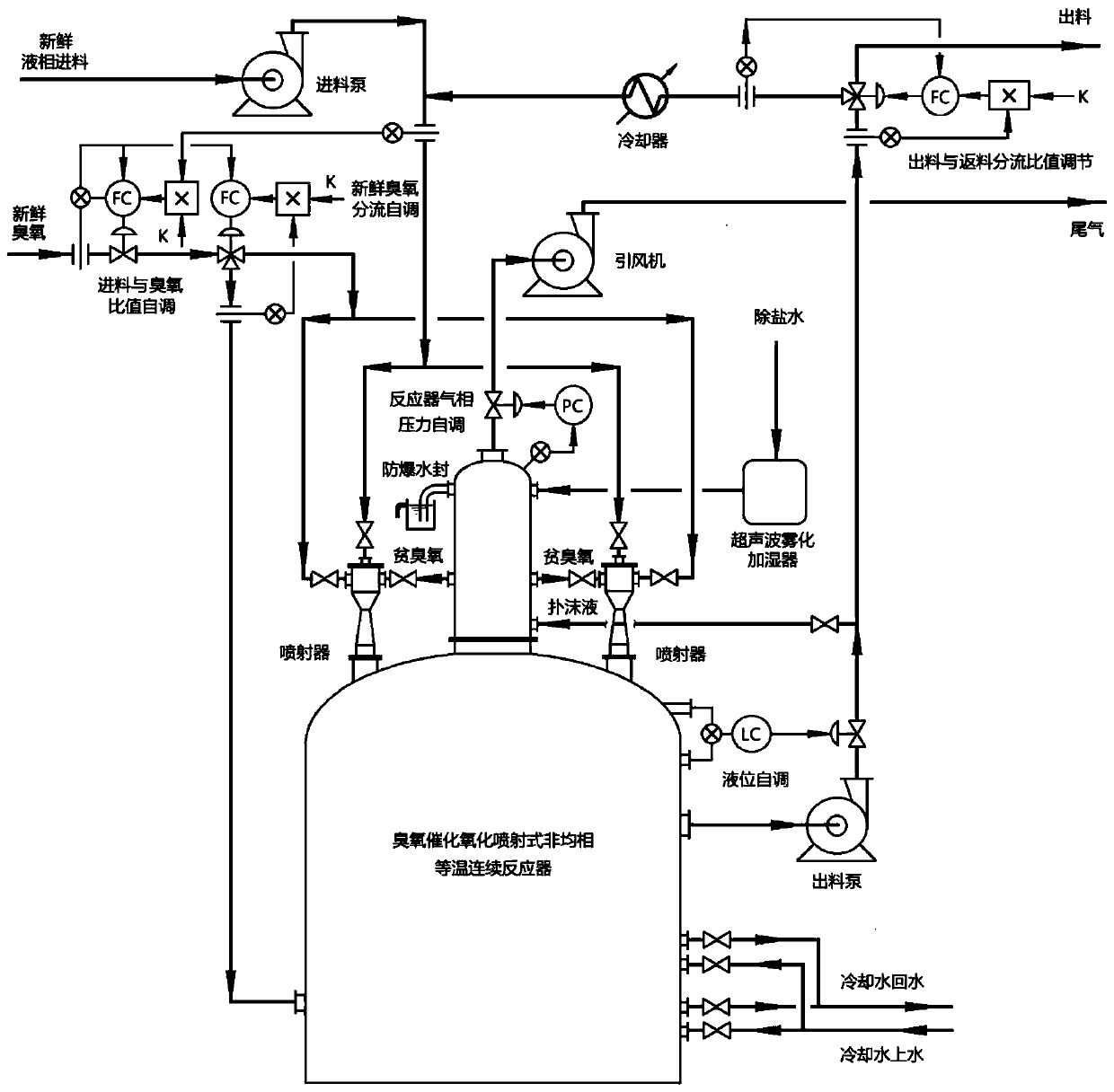

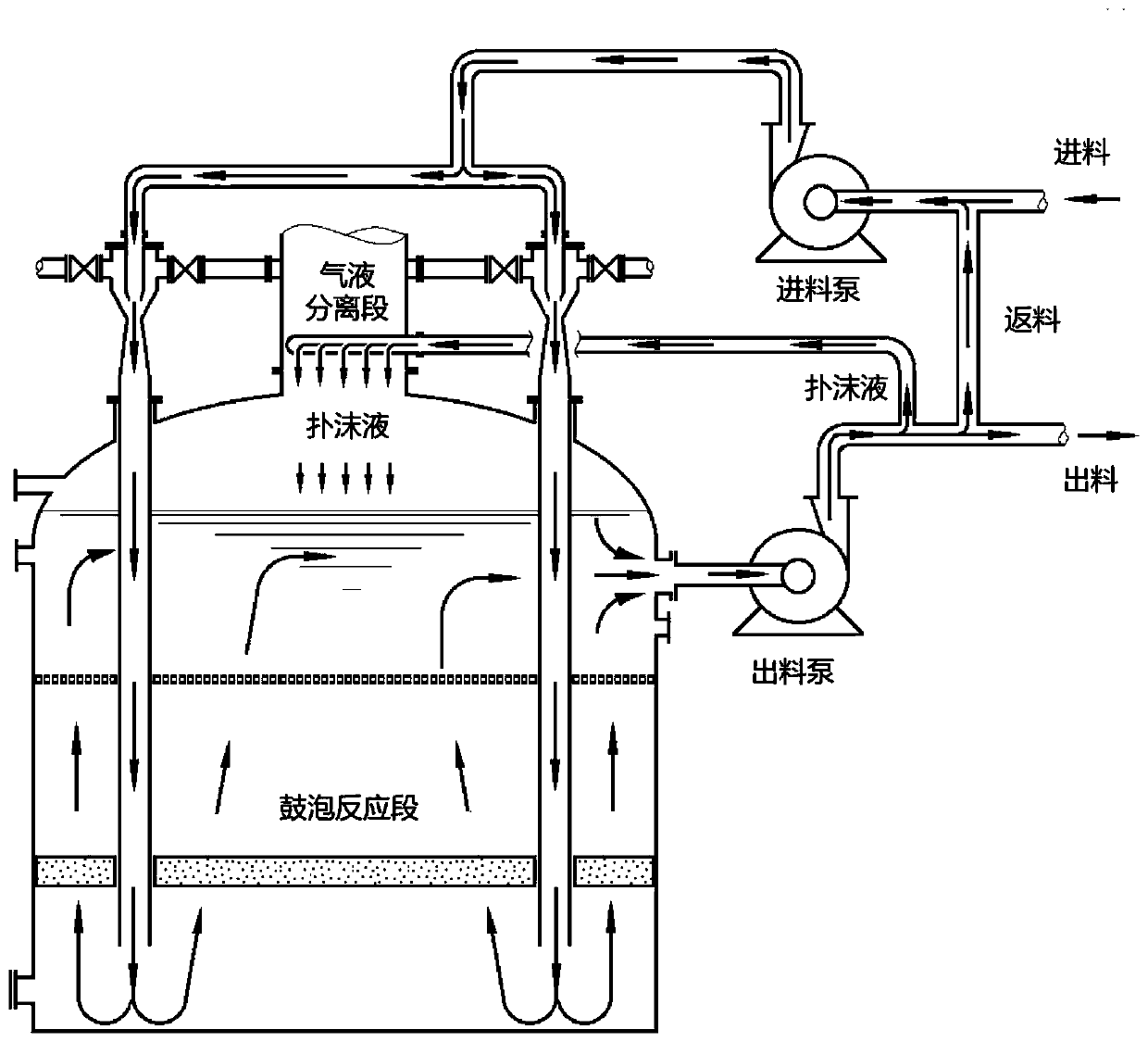

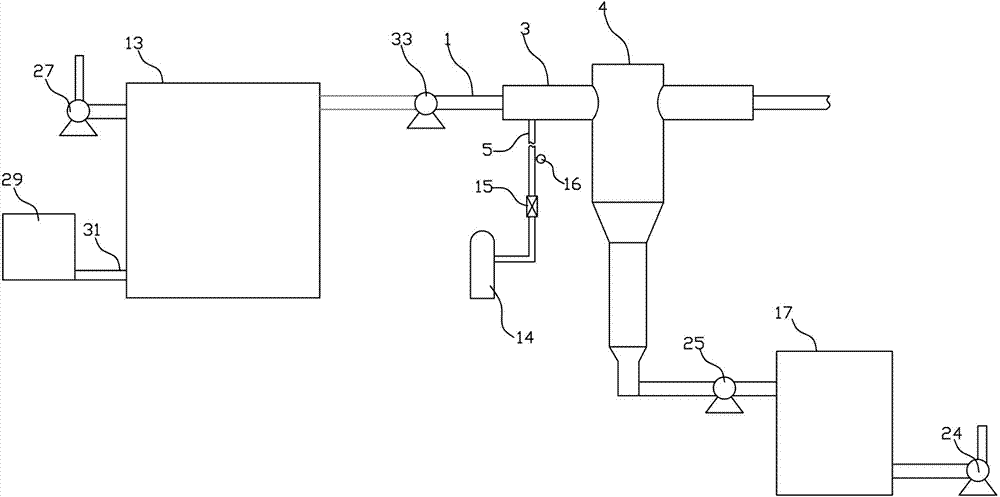

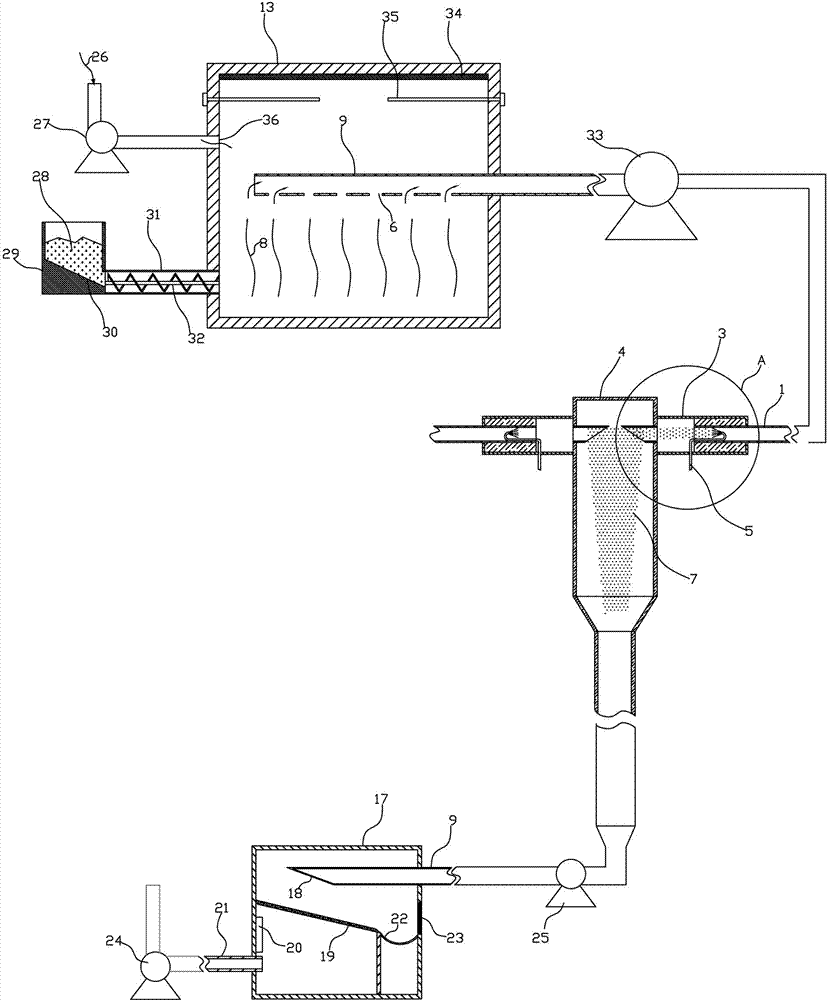

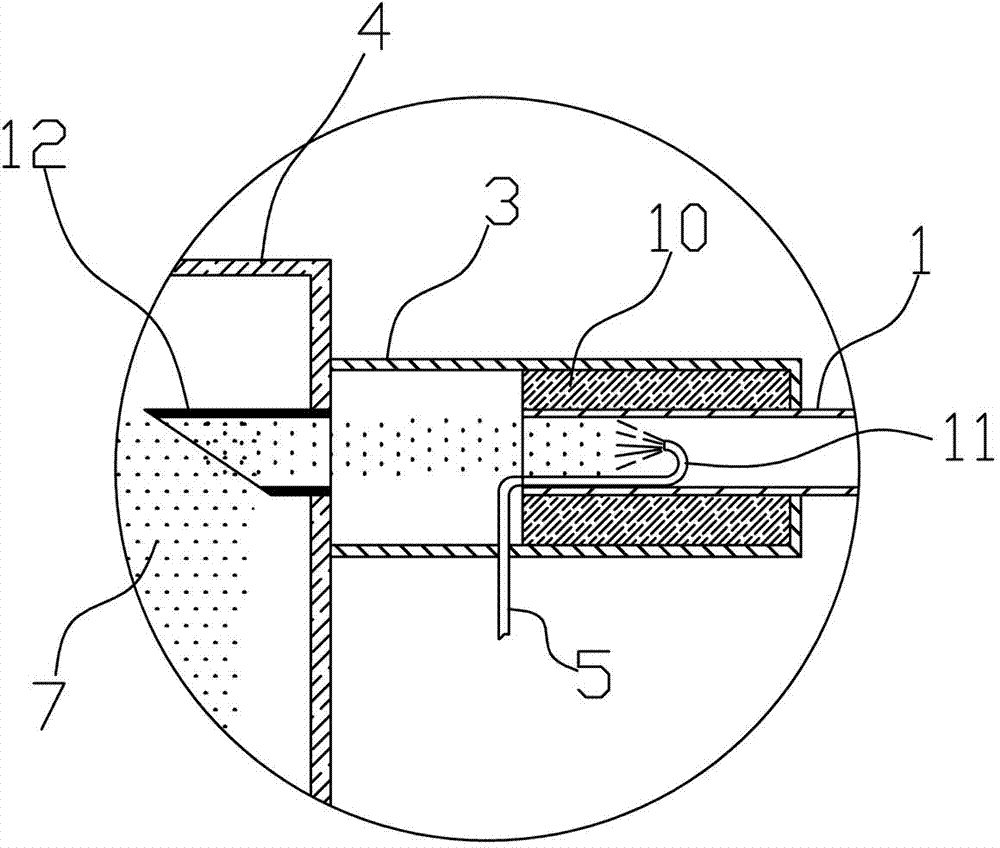

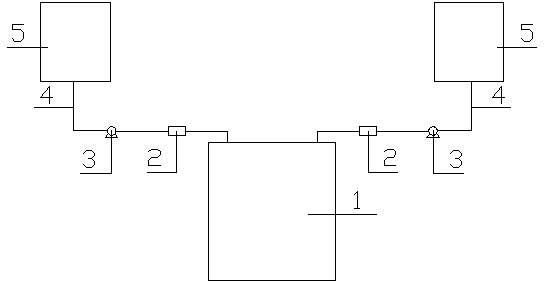

Continuous technological method for multi-stage circular reaction of catalytic ozonation

InactiveCN110002575AIncrease profitReduce consumptionWater/sewage treatment by oxidationContinuous reactorControl system

A continuous technological method for a multi-stage circular reaction of catalytic ozonation is applicable to the field of chemical oxidation using ozone as an oxidant and water treatment. The continuous technological method has the functions of multi-stage utilization through circular ozone contact and an enhanced technological reaction, overcomes the shortcomings of low efficiency, large equipment size, unsuitability for large-scale automatic production and the like of a bubbling reactor in the current ozone technology, and can achieve the effects of lowering the ozone consumption and savingthe equipment investment while continuous automatic production is met. In the continuous technological method, catalytic ozonation jet-type heterogeneous isothermal continuous reactor is used as coreequipment which is jointed with a feed pump, a discharge pump, an induced draft fan and a plurality of instrument self-adjusting control systems. According to different technological process requirements, single or multiple reactors are set. Circulation of ozone is achieved through a venturi jet in the reactor, and the multi-stage reaction is achieved through serial operation of the multiple reactors.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

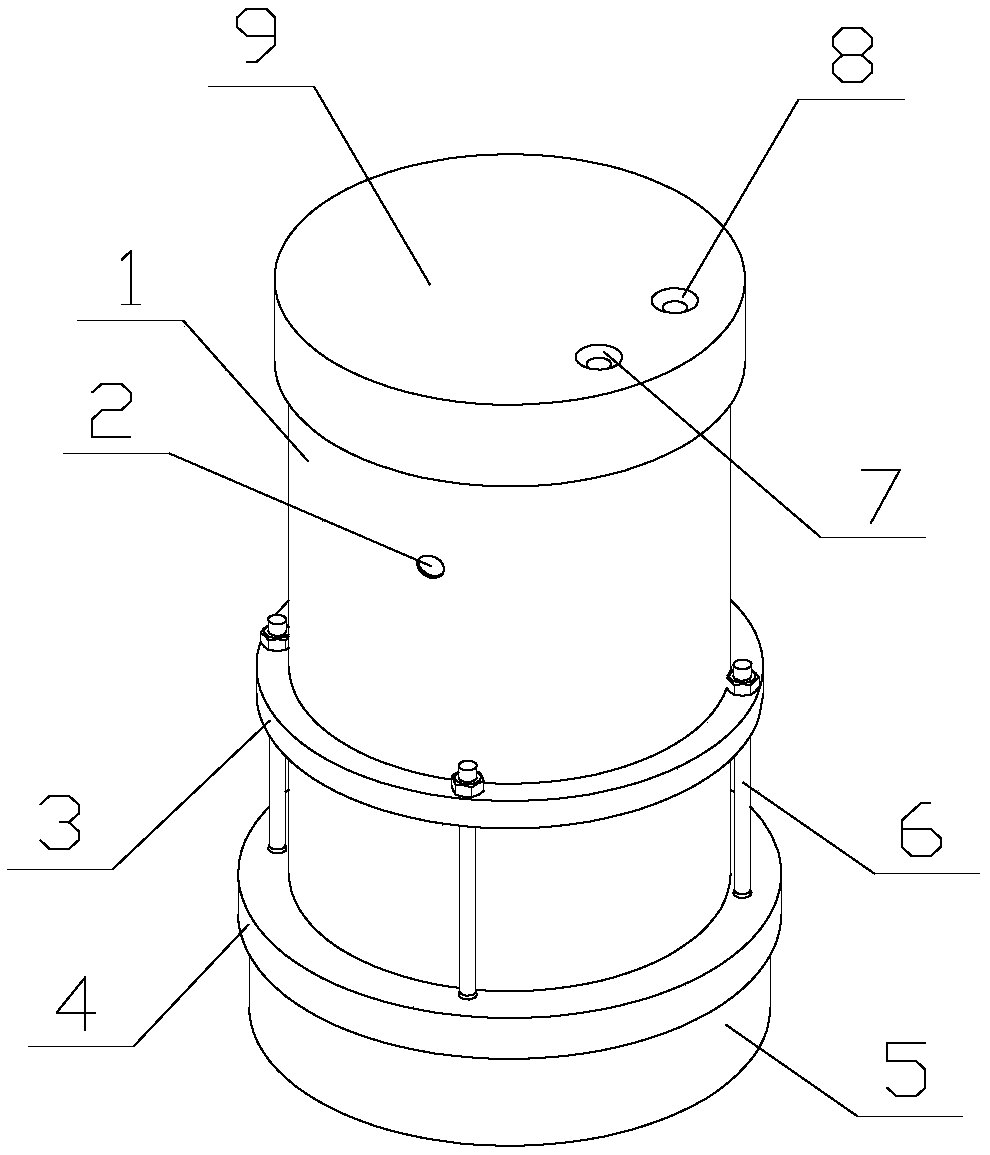

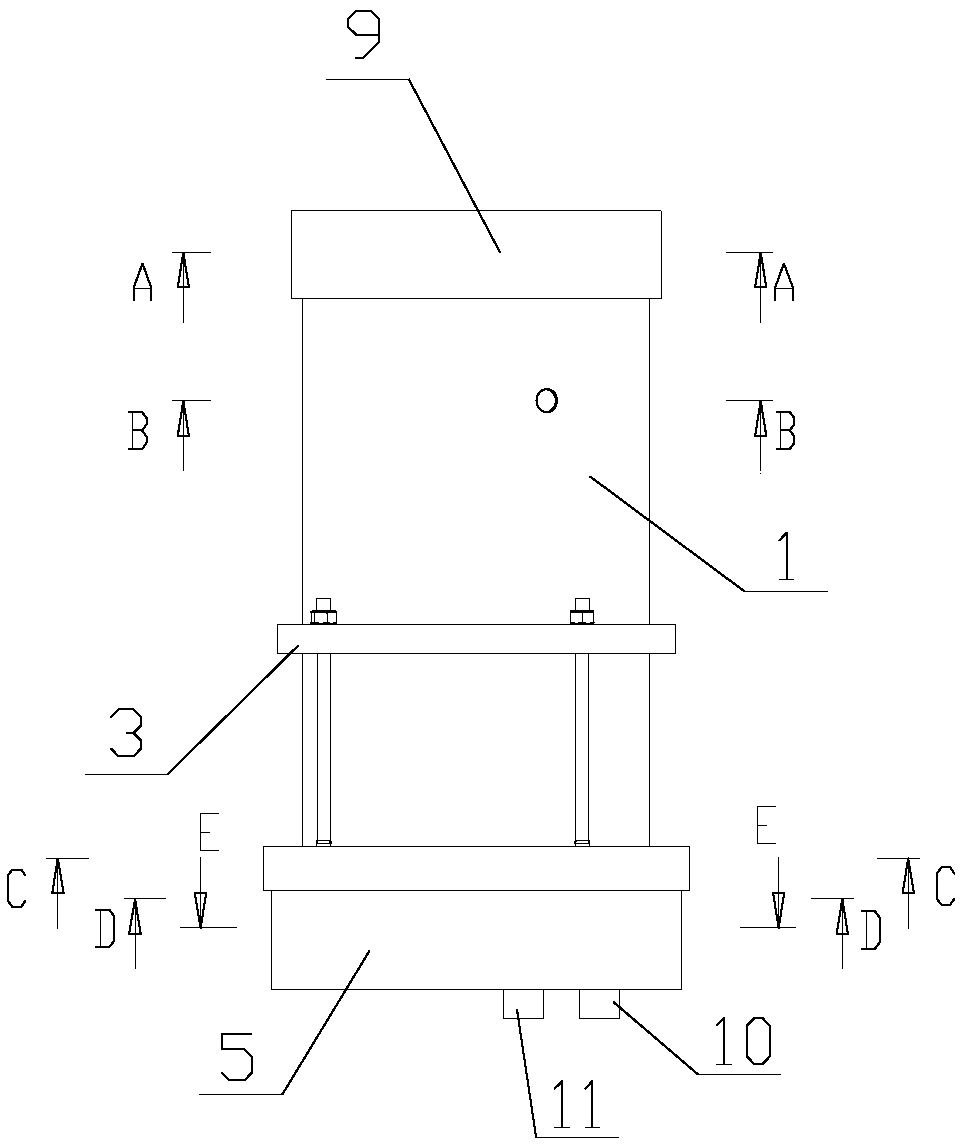

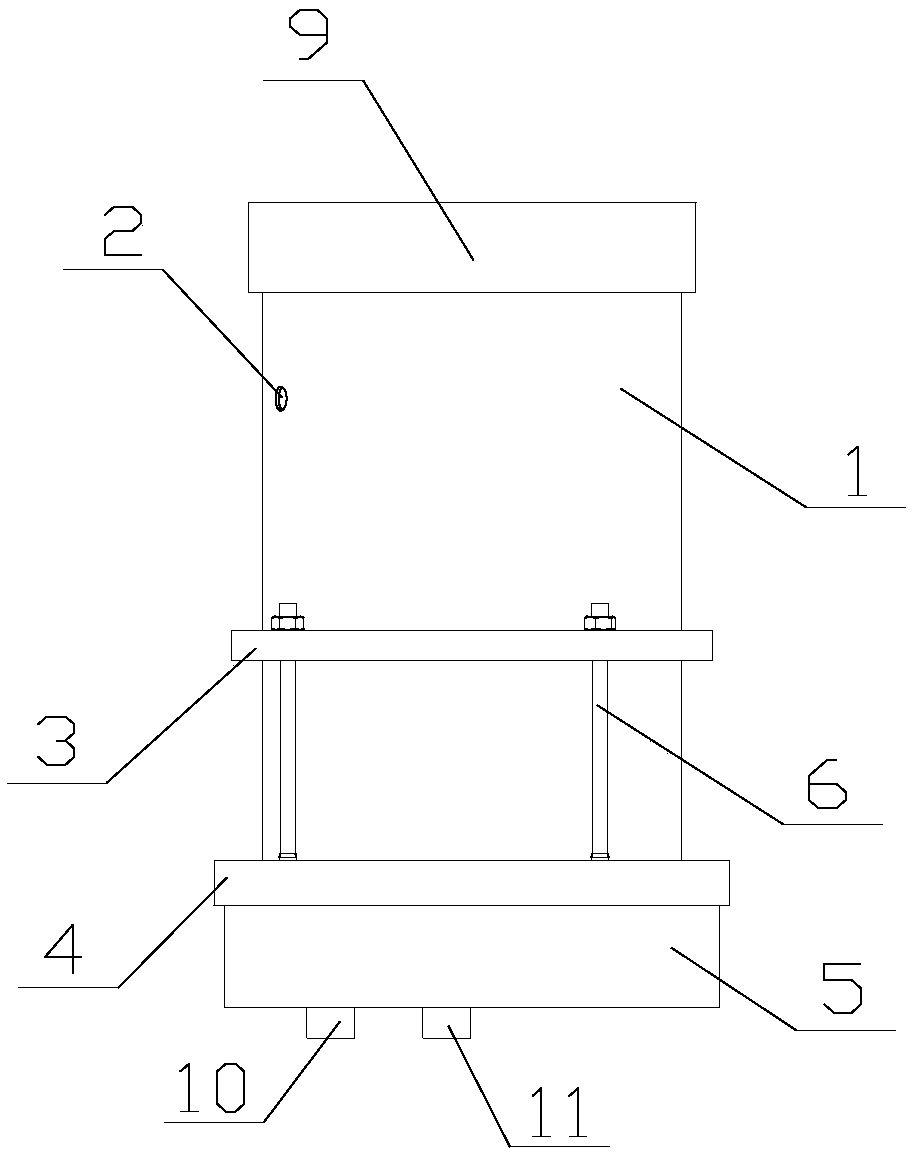

Continuous oil slurry static separation device, system and method

ActiveCN109517621AImprove separation efficiencyMeet the needs of continuous productionTreatment with plural serial refining stagesRefining by electric/magnetic meansAutomatic controlSlurry

The invention provides a continuous oil slurry static separation device, system and method. The separation device comprises an outer tube, wherein an inner tube is in concentric arrangement in the outer tube; a plurality of separation plates in vertical arrangement are arranged between the inner tube and the outer tube; a top cover rotationally connected with the outer tube is arranged on the topof the outer tube; an oil slurry inlet and a flushing liquid inlet are formed in the top cover; a sieve plate is arranged at the bottom of the outer tube; a bottom cover rotationally connected with the sieve plate is arranged at the bottom of the sieve plate; an oil slurry outlet and a flushing liquid outlet are formed in the bottom cover. The flushing liquid is injected from the flushing liquid inlet and is discharged from the flushing liquid outlet; then, the top cover is rotated, the oil slurry is injected into the treatment region from the oil slurry inlet for purification treatment; next,the bottom cover is rotated, the treated oil slurry is discharged from the oil slurry outlet; the steps are performed repeatedly in order. The continuous production is realized; the flushing processand the purification process are not mutually interfered; the flushing is convenient; the separation efficiency is high; the regulation can be performed according to different work conditions; the application range is wide; the automatic control can be easily realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

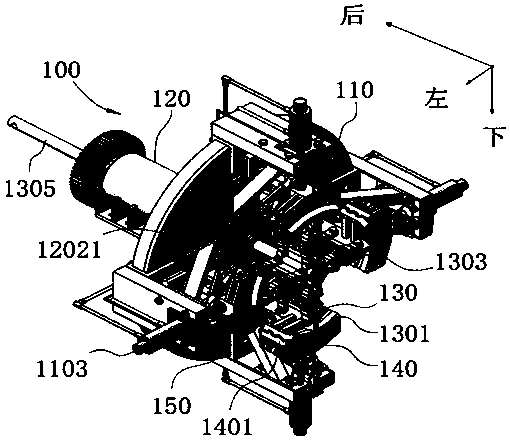

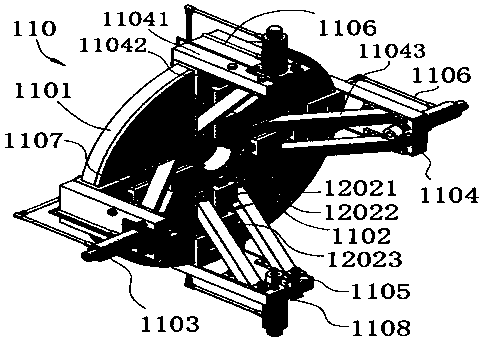

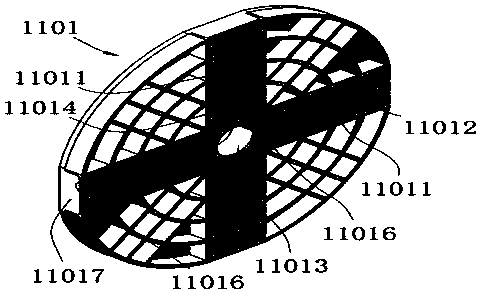

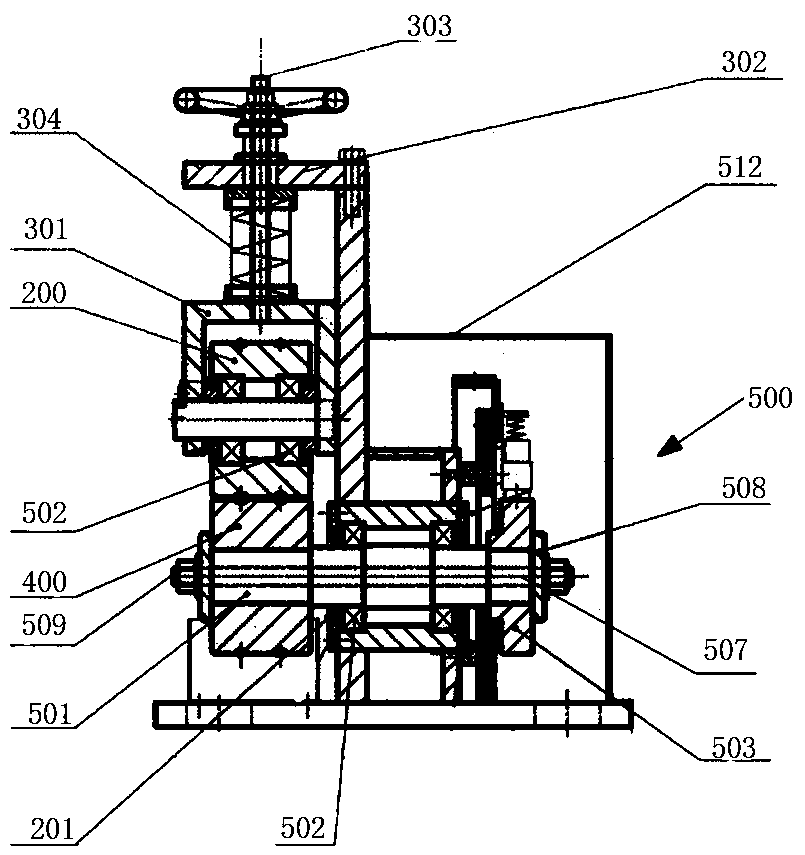

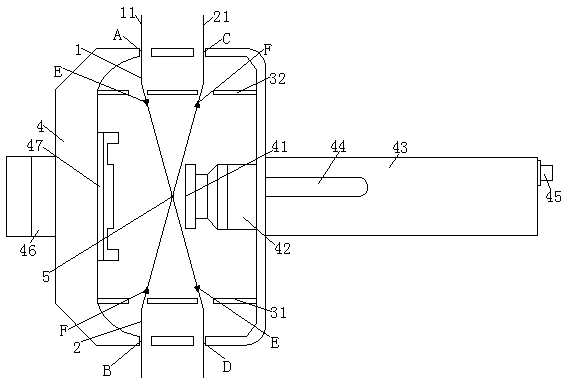

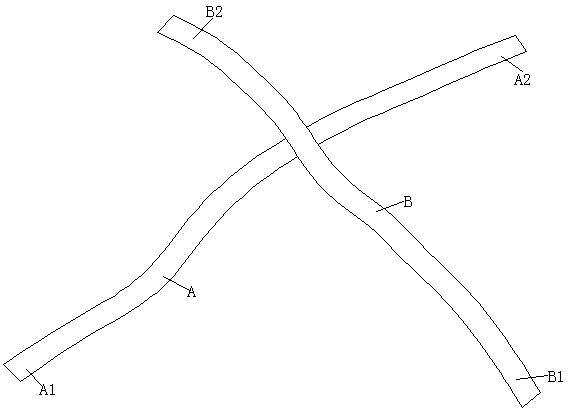

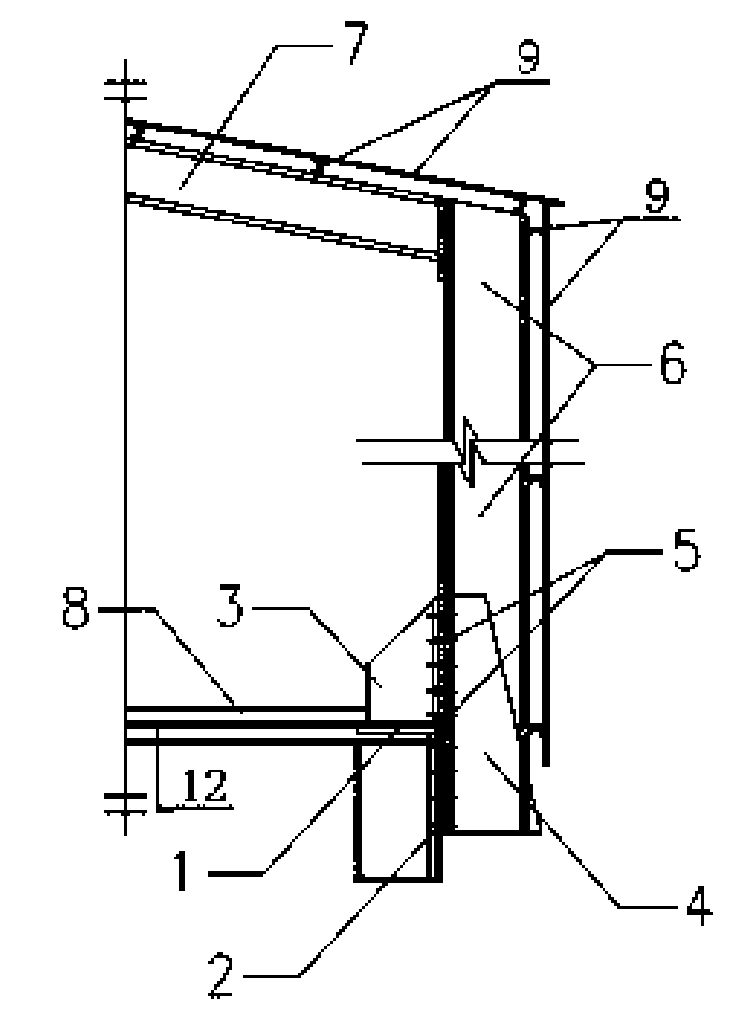

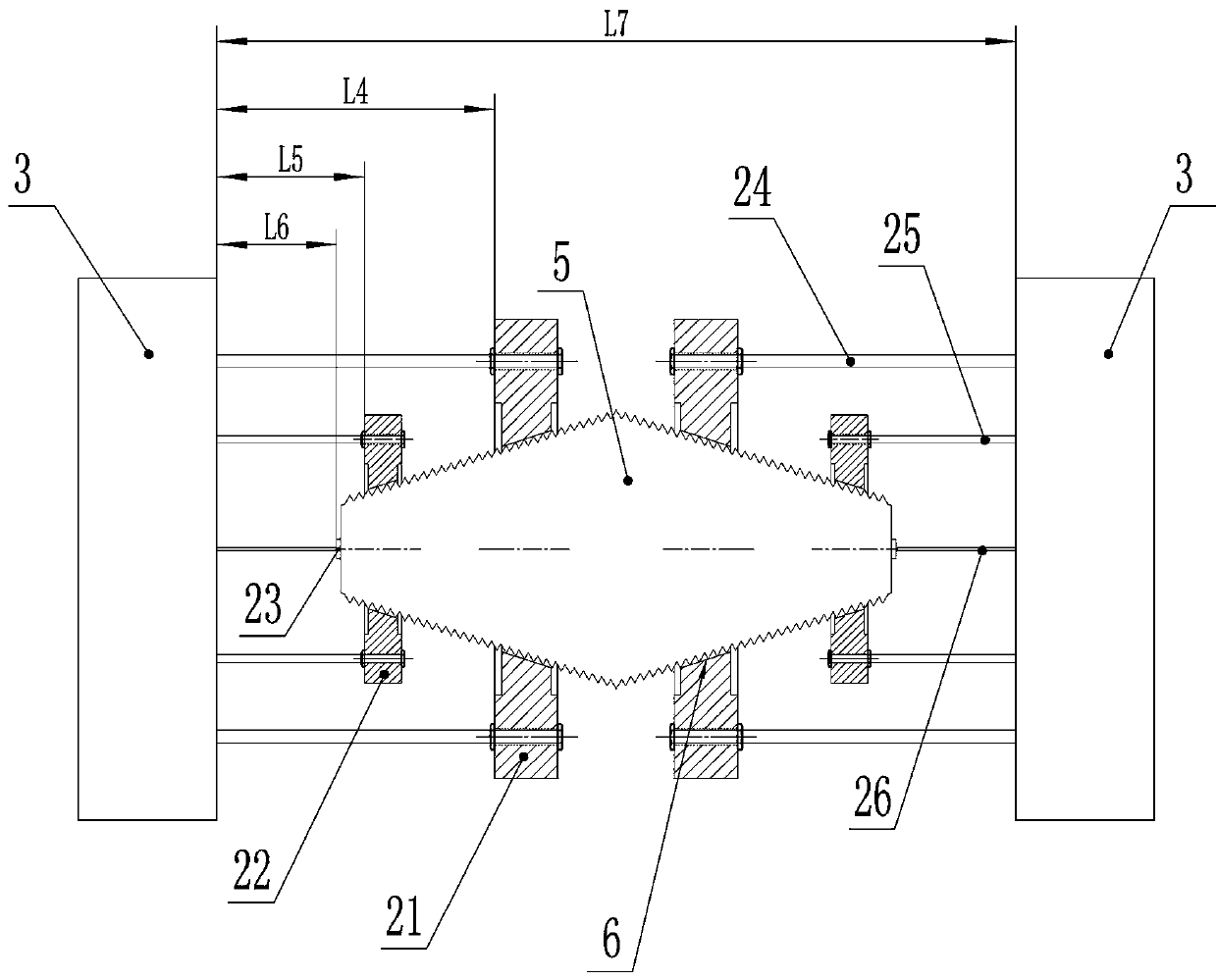

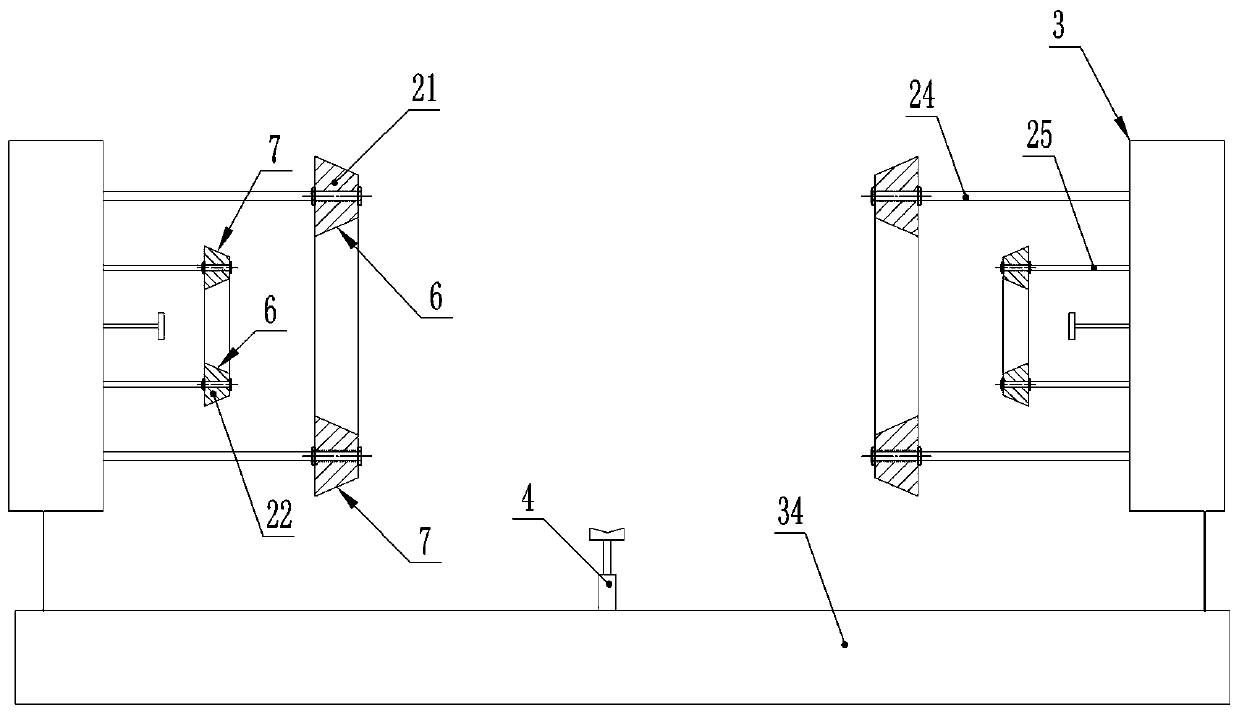

Inner and outer arc-shaped template linkage mechanism and equipment for steel tube bearing and flaring mouths

PendingCN111283099AMeet the needs of continuous productionSmall sizeShaping toolsDigital controlMechanical engineering

The invention discloses steel tube bearing and flaring mouths manufacturing equipment which operates through digital control. A production process is optimized and digital control operation reliability is improved for different specification dimensions and different material requirements of steel tube bearing and flaring mouths according to different mechanism structural features and processes, sothat the sizing dimensions of the steel tube bearing and flaring mouth are more precise. The inner and outer arc-shaped template linkage mechanism can realize manufacturing of steel tube bearing andflaring mouths of different pressure grades, can realize automatic operation under digital control, is high in efficiency, is high in production speed, and can meet continuous manufacturing and producing needs of the steel tube bearing and flaring mouths with diameters of 300-4000 millimeters within a pressure grade range of 2.0 MPa.

Owner:济南寻龙机械科技有限公司

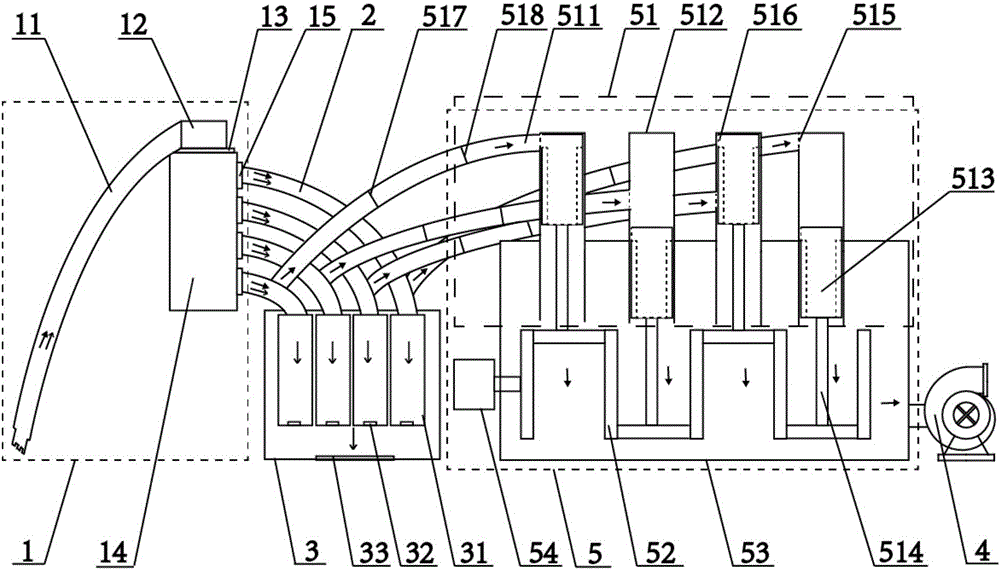

Continuous production system and method for purple perilla paste

PendingCN110140937AMeet the needs of continuous productionSimplify production stepsFood dryingFood treatmentDrive motorEngineering

The invention discloses a continuous production system for purple perilla paste. The continuous production system comprises a base, a top plate and a sliding plate, wherein the sliding plate slides atthe lower end of the top plate; a speed reducing motor and a driving motor are arranged in the base in the moving direction of the sliding plate from front to rear in an arraying manner; the speed reducing motor is used for driving a cleaning bucket to rotate; the driving motor is used for driving a dehydration bucket to rotate; water outlet pipes are respectively arranged at the lower part of the dehydration bucket and the lower part of the cleaning bucket; a lifting oil cylinder is vertically arranged at the lower end of the sliding plate; a piston rod of the lifting oil cylinder is connected with a mounting seat through a bearing; material lifting rods are oppositely arranged at the lower end of the mounting seat; the lower ends of the material lifting rods are movably connected with the side wall of a processing bucket; and the processing bucket can rotate along with the cleaning bucket or the dehydration bucket. The invention also provides a continuous production method for purple perilla paste. The method comprises the following steps of performing cleaning, performing dehydration, performing discharging, performing raw material preparation, performing stir-frying, performing packaging and the like. The continuous production system disclosed by the invention aims to quickly clean purple perilla, and the production efficiency is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

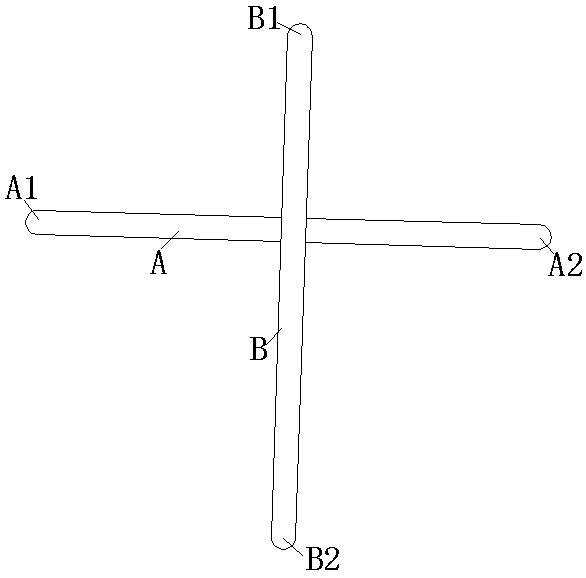

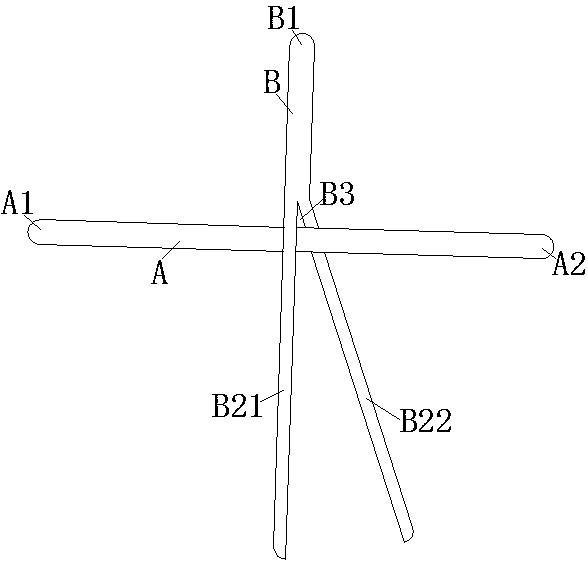

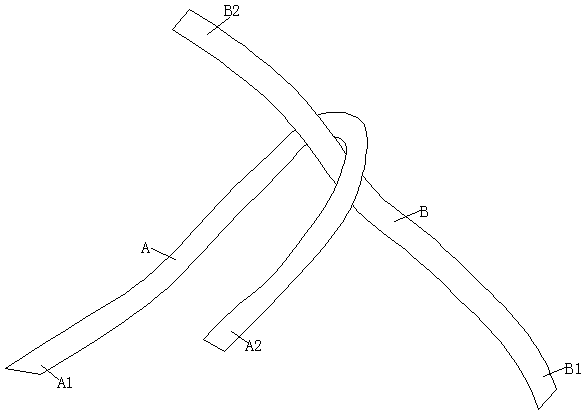

Yarn knotting method

InactiveCN108357984AQuality is not affectedMeet the needs of continuous productionFilament handlingYarnEngineering

The invention relates to a yarn knotting method. The yarn knotting method comprises the steps that second yarn is erected on the upper side of first yarn; cutting is conducted in the length directionof the second yarn; the first yarn is arranged between an upper cutting part and a lower cutting part of the second yarn; the lower cutting part of the second yarn is erected on the upper side of theupper cutting part of the second yarn; the first yarn is erected on the upper side of the lower cutting part of the second yarn; the lower cutting part of the second yarn penetrates through a ring hole; the lower cutting part of the second yarn is wound around the second yarn; the lower cutting part of the second yarn is pulled; the upper cutting part of the second yarn, the lower cutting part ofthe second yarn and the tail end of the first yarn are combined into a strand of combined yarn; the first yarn is divided in half; one end of the combined yarn penetrates through an opening; one end of the combined yarn penetrates through an inner ring; and one end of the combined yarn is pulled tightly. According to the yarn knotting method, yarn clews are connected in an end-to-end mode, the continuous production need is met, connected knots can be automatically dispersed, and the use performance of a product and the finished product quality are not affected.

Owner:JUSHI GRP CO

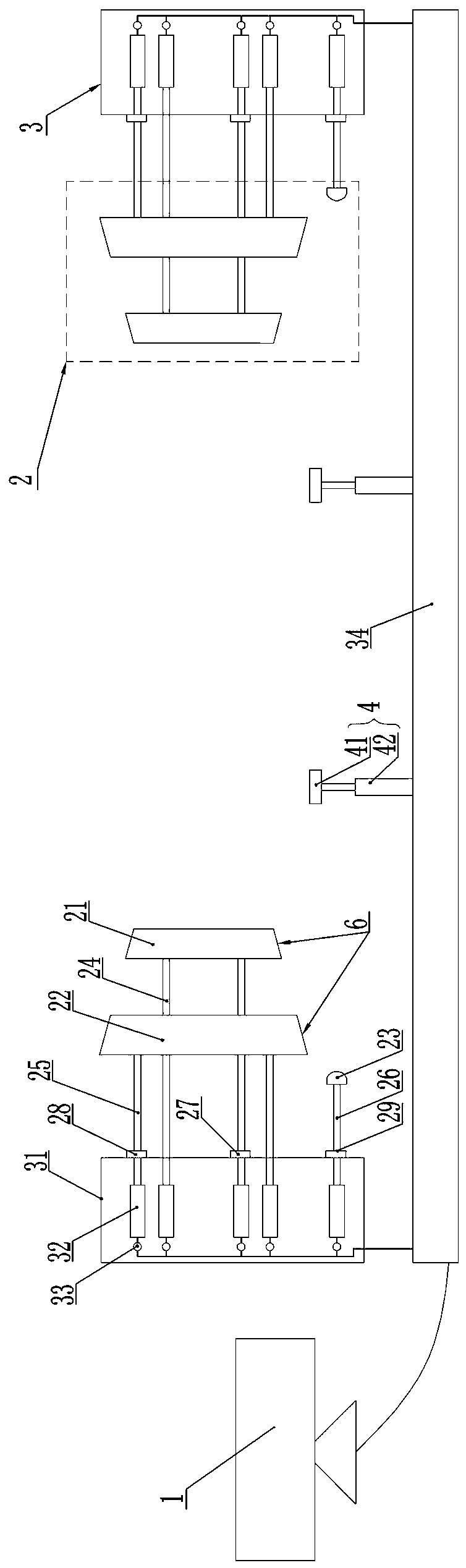

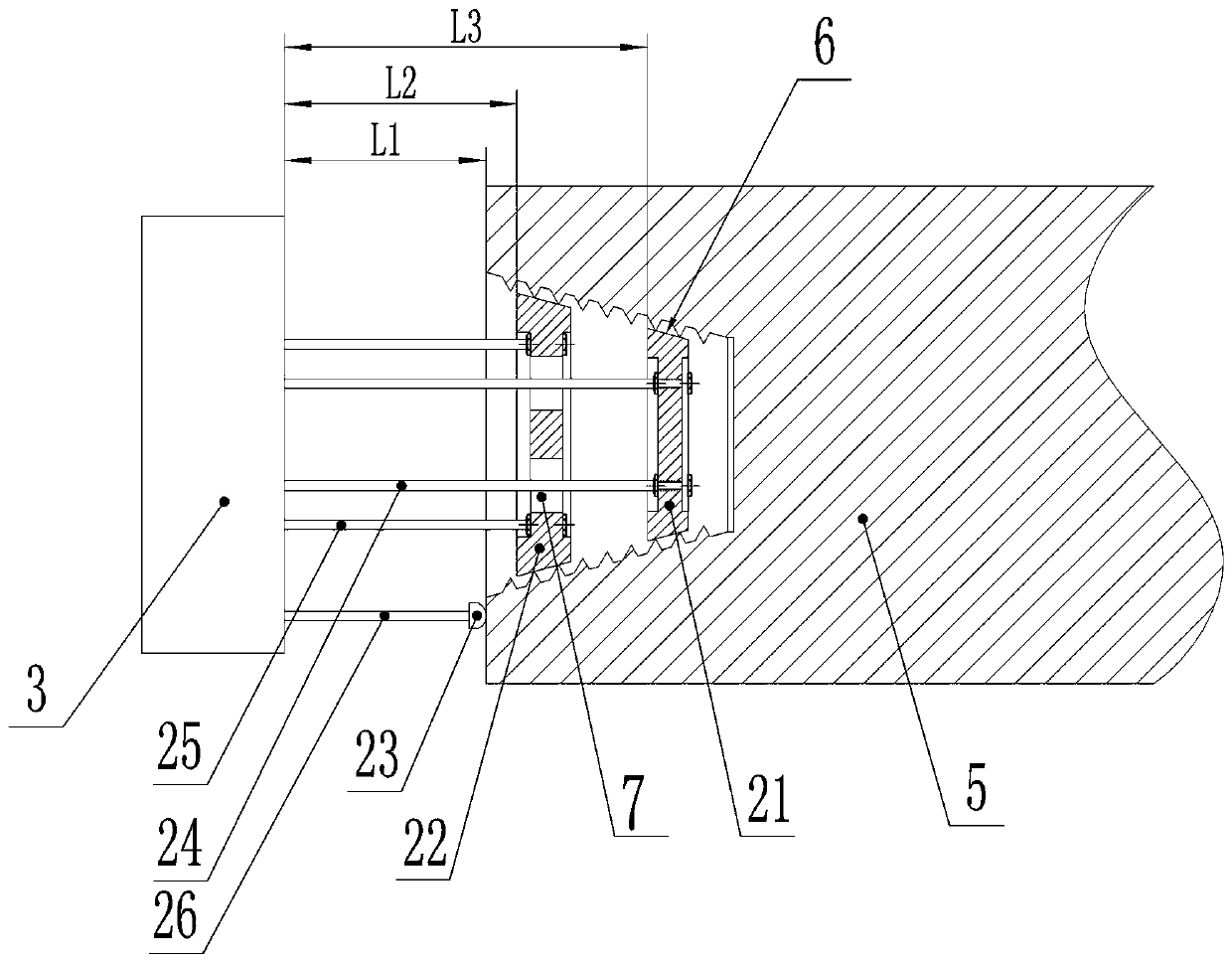

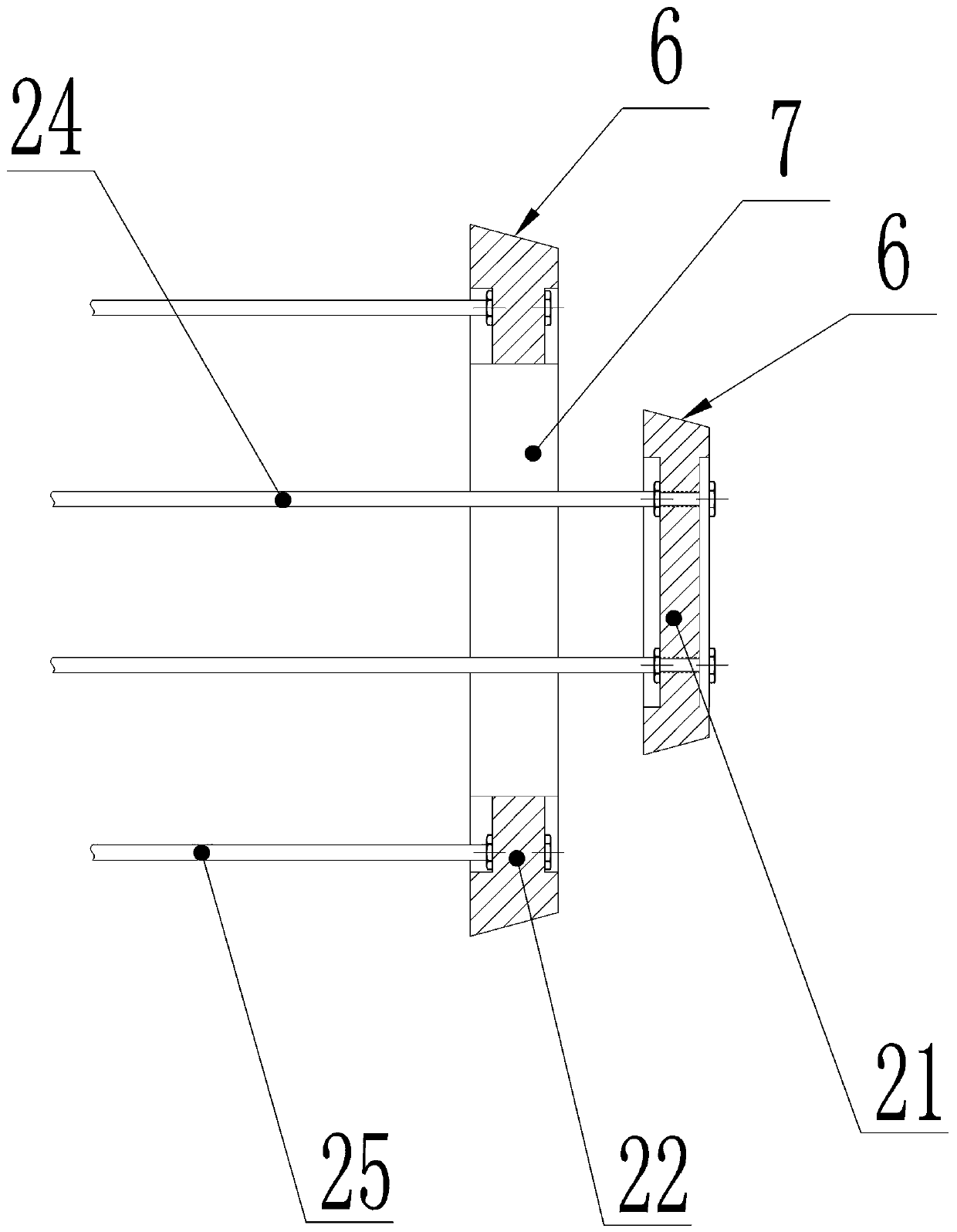

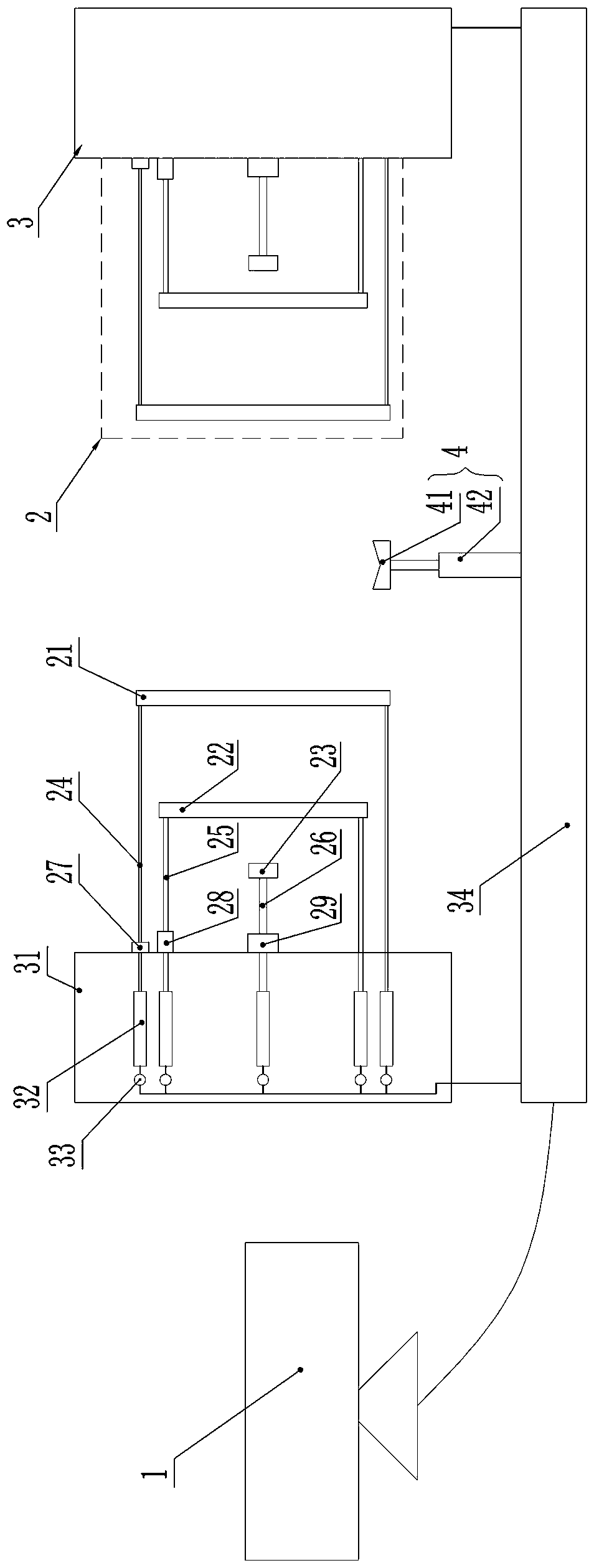

Automatic measurement device, system and method for taper thread of graphite electrode body or joint

InactiveCN108253910AAutomate your measurementsEasy to useMeasurement devicesObservational errorMeasurement device

The invention discloses an automatic measurement device, a system and a method for the taper thread of a graphite electrode body or a joint and belongs to the technical field of automatic measurement.The technical problem in the prior art that the existing manual measurement is large in error and low in precision can be solved. The device comprises symmetrically arranged driving assemblies and measurement tool assemblies, wherein each measurement tool assembly is provided with a standard-taper type smooth conical surface. The measurement tool assemblies are arranged between the two driving assemblies and are correspondingly connected with the driving assemblies through connecting assemblies. A distance measurement unit is further arranged between the driving assemblies and the measurementtool assemblies. A lifting unit used for driving the graphite electrode body or the joint to go up and down is arranged between the two measurement tool assemblies. According to the invention, the taper thread parameters of the graphite electrode body and the joint can be automatically measured and displayed, so that the usability is good. Meanwhile, the occurrence of manual operation errors andreading errors can be completely avoided through the automatic measurement. The precision is high, and the benefit of a manufacturer is greatly improved.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

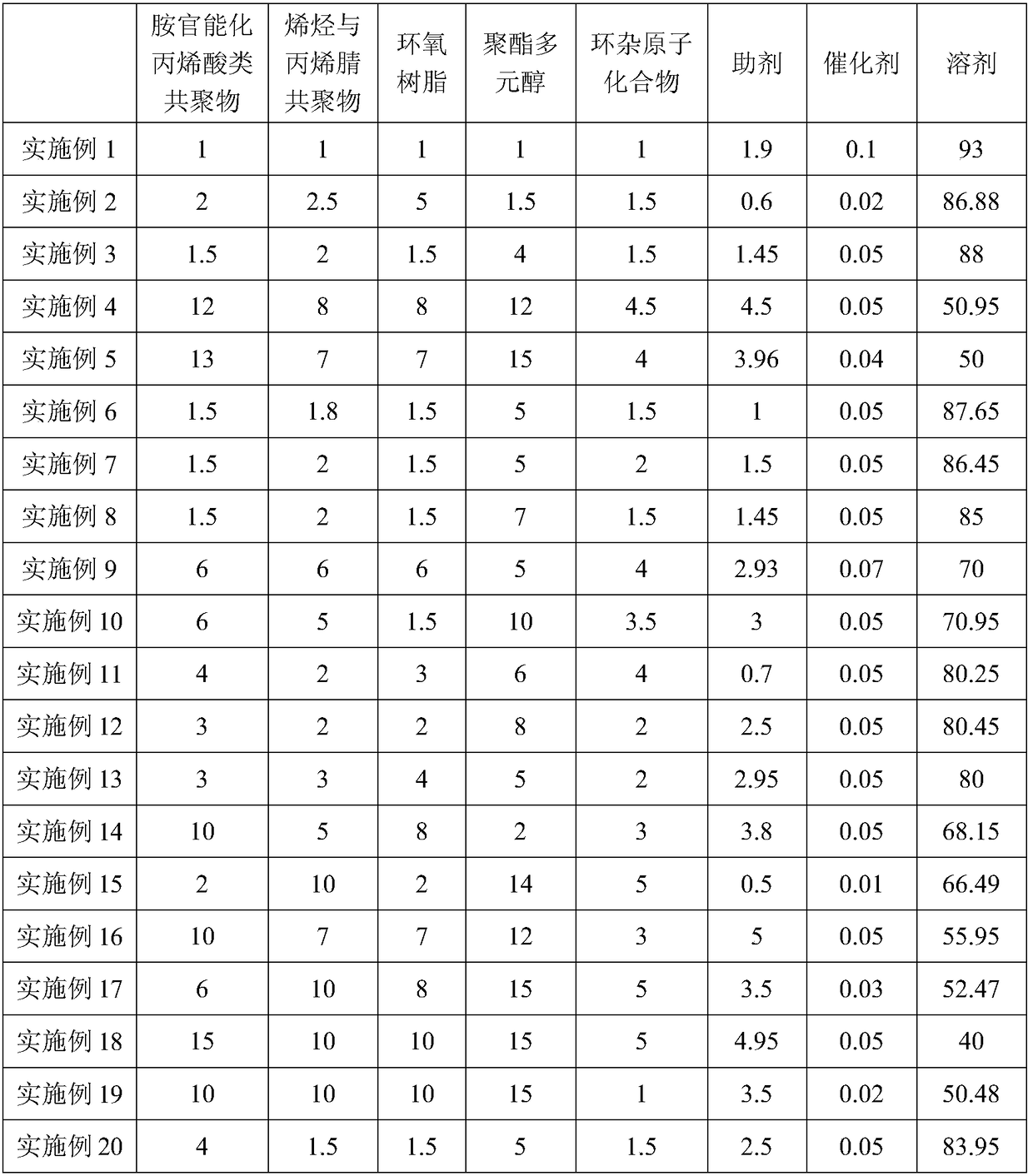

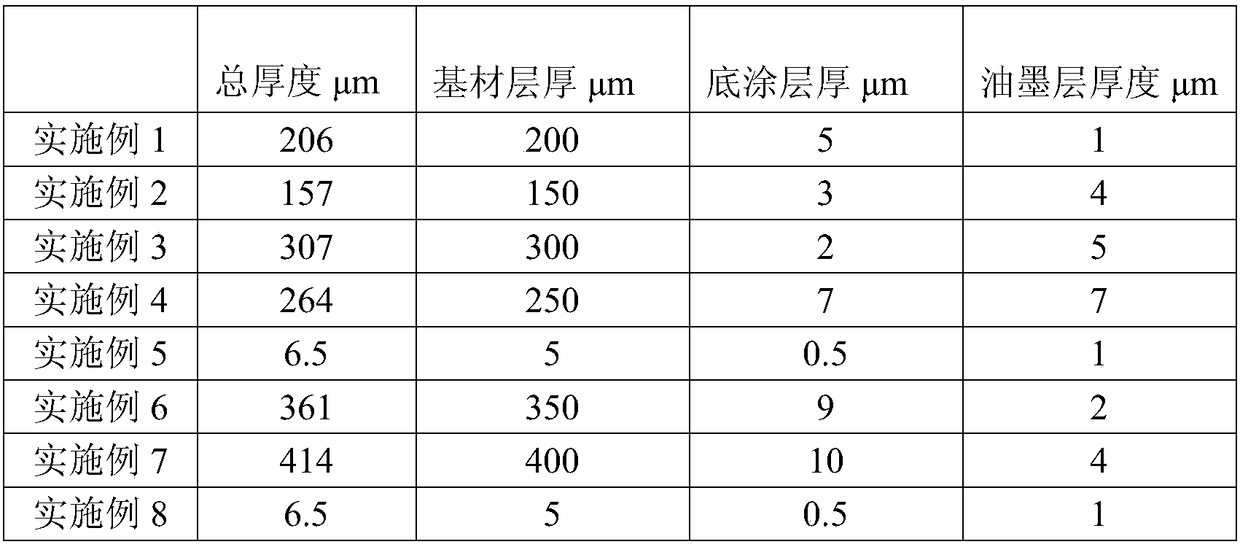

Primer coating and preparation method thereof, and polyester film and preparation method thereof

ActiveCN108250925AGood adhesionLower glass transition temperaturePolyurea/polyurethane coatingsPriming paintsPolyesterAcrylonitrile

The invention relates to primer coatings, specifically to a primer coating and a preparation method thereof, and a polyester film and a preparation method thereof. In order to solve the problem of lowadhesion force between a polyester film coated with a primer coating layer and a post-coated ink layer after placement at normal temperature and normal humidity, the invention provides the primer coating and the preparation method thereof, and the polyester film and the preparation method thereof. The primer coating comprises an amine functionalized acrylic copolymer, an olefin-acrylonitrile copolymer, epoxy resin, polyester polyol, a polycyclic heteroatomic compound, an auxiliary agent, a catalyst and a solvent. The primer coating provided by the invention forms a primer coating layer aftercoating with the polyester film, and the adhesion force between the primer coating layer and a polyester film layer can reach 0 grade without the need of standing and curing, so subsequent continuousproduction is realized; meanwhile, the polyester film coated with the primer coating layer can be stored and placed at normal temperature and normal humidity, and when UV ink is coated again, good adhesion performance between an ink layer and the primer coating layer can be still maintained.

Owner:NINGBO EXCITON TECH

Butanediol spraying vacuum pump and working method thereof

ActiveCN102536919AReduce energy consumptionReduce maintenanceJet pumpsMachines/enginesContinuous operationMoving parts

The invention relates to a butanediol spraying vacuum pump. The pump of the invention is characterized in that a primary butanediol sprayer is connected with a lower portion of a primary condenser, an upper portion of the primary condenser is connected with an upper portion of a secondary butanediol sprayer, a lower portion of the secondary butanediol sprayer is connected with a lower portion of a secondary condenser, an upper portion of the secondary condenser is connected with an upper portion of a third butanediol sprayer, a lower portion of the third butanediol sprayer is connected with a lower portion of a third condenser, an upper portion of the third condenser is connected with a lower portion of a fourth butanediol sprayer, a third auxiliary steam sprayer is communicated with an upper end of the third condenser, an upper portion of the fourth butanediol sprayer is communicated with an upper portion of a fourth condenser, a lower portion of the fourth condenser is connected with a vapor-liquid separator by a liquid-ring vacuum pump, one end of a heat exchanger is communicated with the liquid-ring vacuum pump and the other end of the heat exchanger is communicated with the vapor-liquid separator. The butanediol spraying vacuum pump has the advantages that: no waste liquid is discharged; the energy consumption is reduced; the steam spray vacuum pump in the invention has no moving part during runtime, the butanediol spraying vacuum pump is suitable for long-term and continuous operation, and the maintenance period is prolonged.

Owner:杭州华达喷射真空设备有限公司

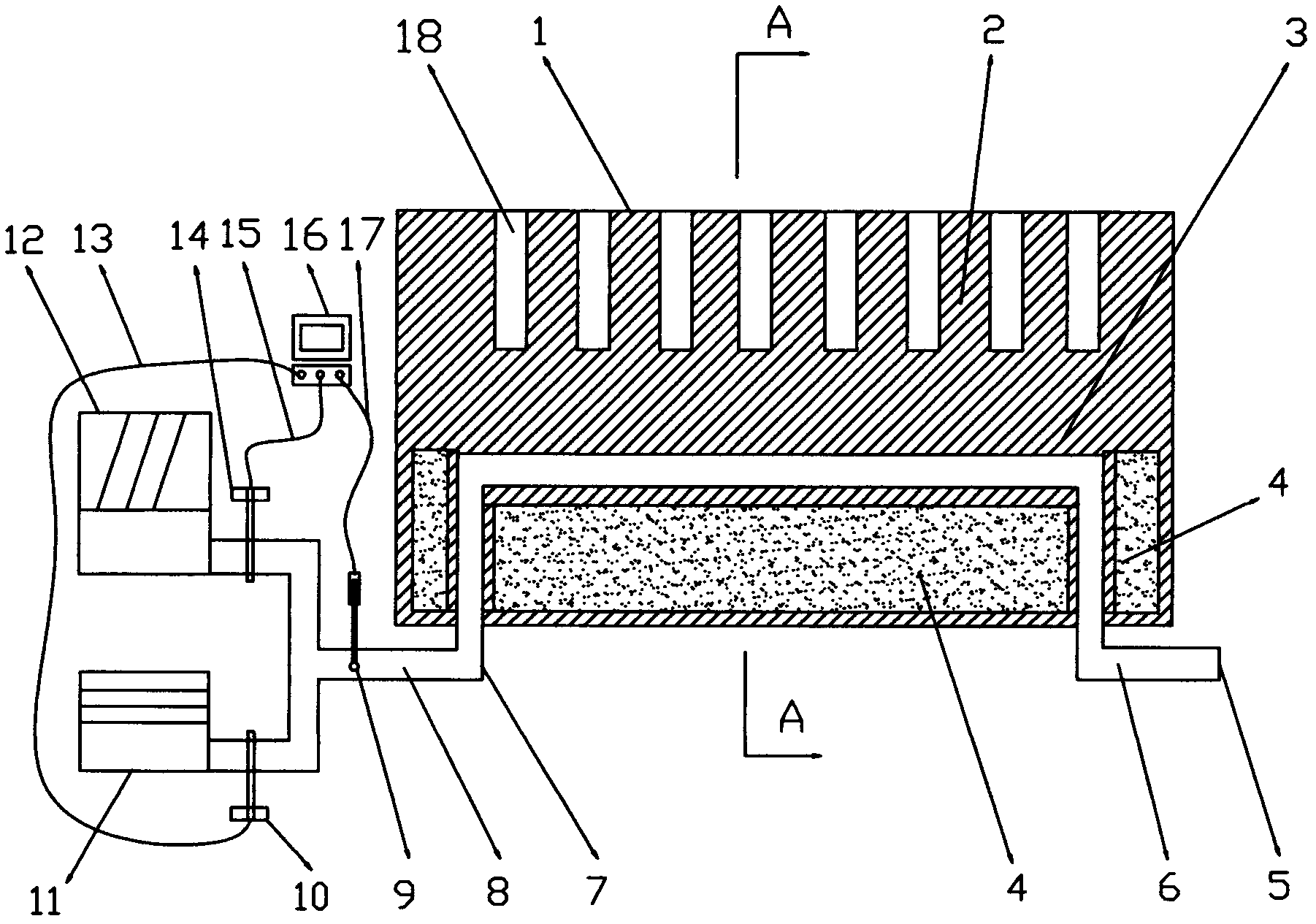

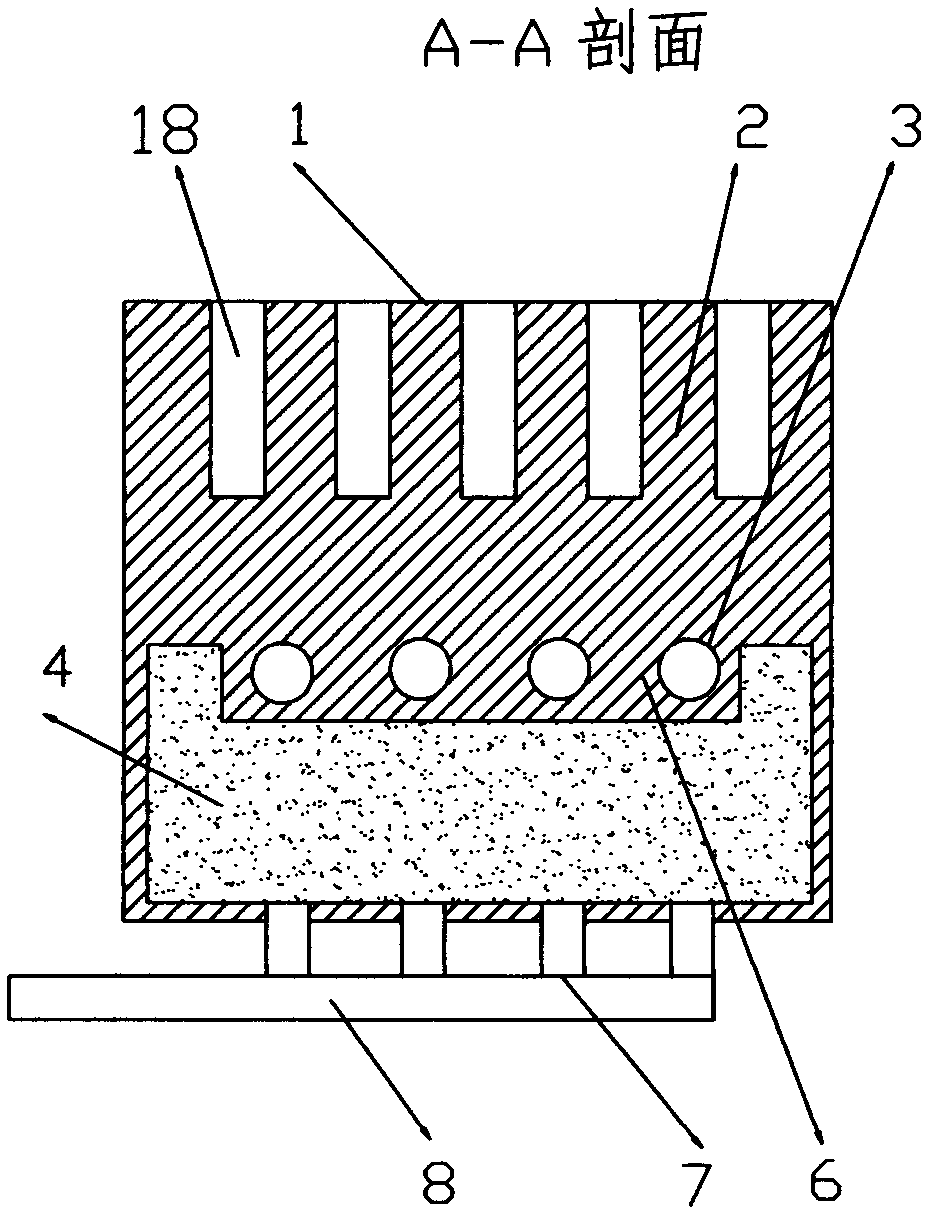

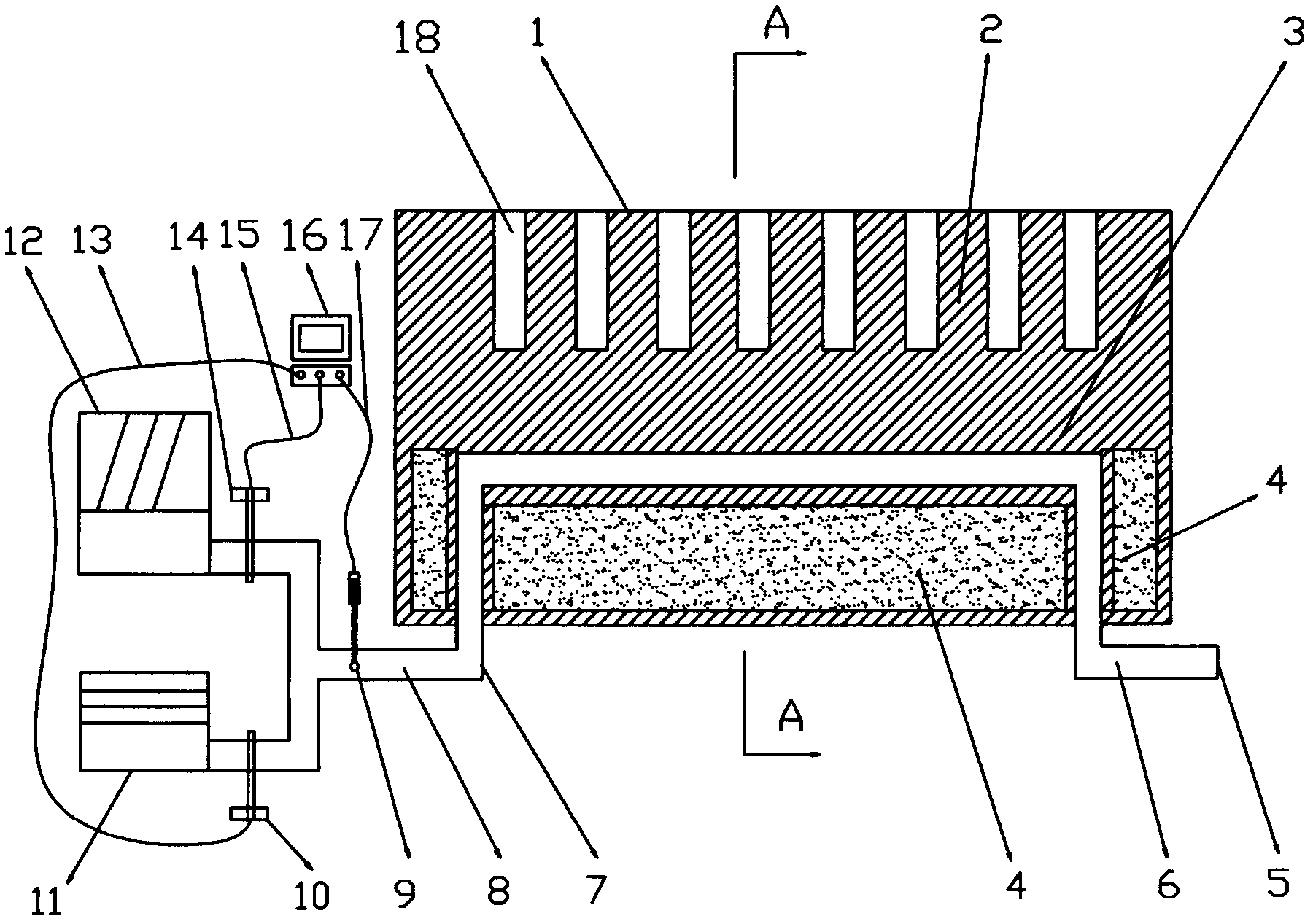

Molding mold for glass fiber reinforced plastic grate

The invention provides a molding mold for a glass fiber reinforced plastic grate, which comprises a molding template, a temperature control chamber, a warming pipeline, a heat preservation layer and other parts, wherein the temperature control chamber is arranged below or on the lower portion of the molding template, the warming pipeline and the heat preservation layer are arranged in the temperature control chamber, the heat preservation layer is wrapped on the left side, the right side and the lower side of the warming pipeline, and the heat preservation layer is made of inflaming retarding plastics or noncombustible mineral wool. Outlets and inlets of the warming pipeline are arranged below the temperature control chamber, and all the inlets are connected with the same bus pipe which is connected with a temperature measurement instrument. A heat source device is a solar energy device and a conventional coal furnace or oil furnace device which are connected in parallel and respectively connected with a valve A and a valve B. The temperature measurement instrument is connected with a control system through a signal line, and the control system is respectively connected with the two valves and controls opening and closing of the two valves through a control line. The molding mold for the glass fiber reinforced plastic grate adopts a pipeline, heat preservation layer and template integrated design and is compact in structure, good in heat preservation effect and small in energy consumption. In addition, the molding mold can adopt a self-control system and is high in automation degree and production efficiency and low in labor intensity.

Owner:于忠志

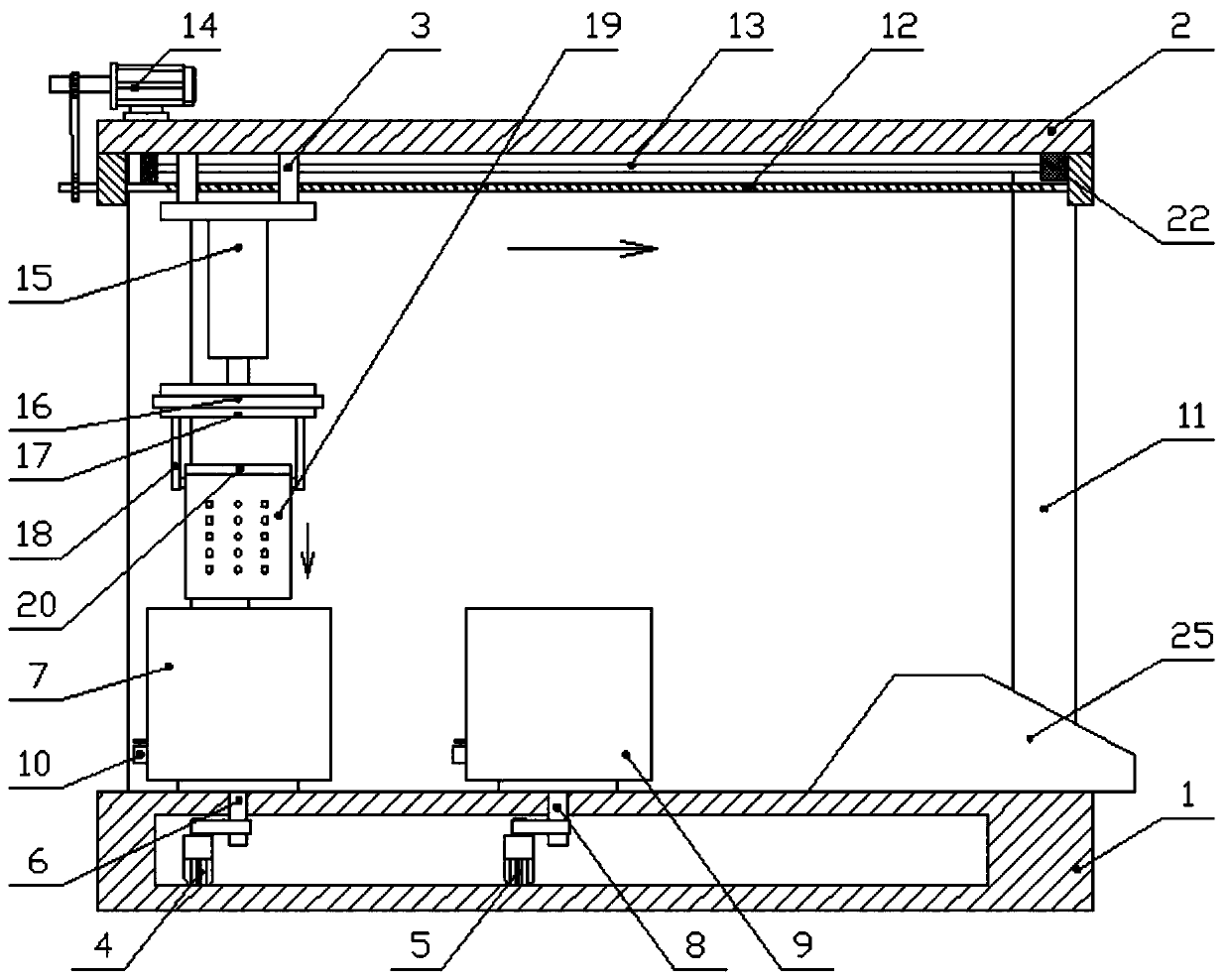

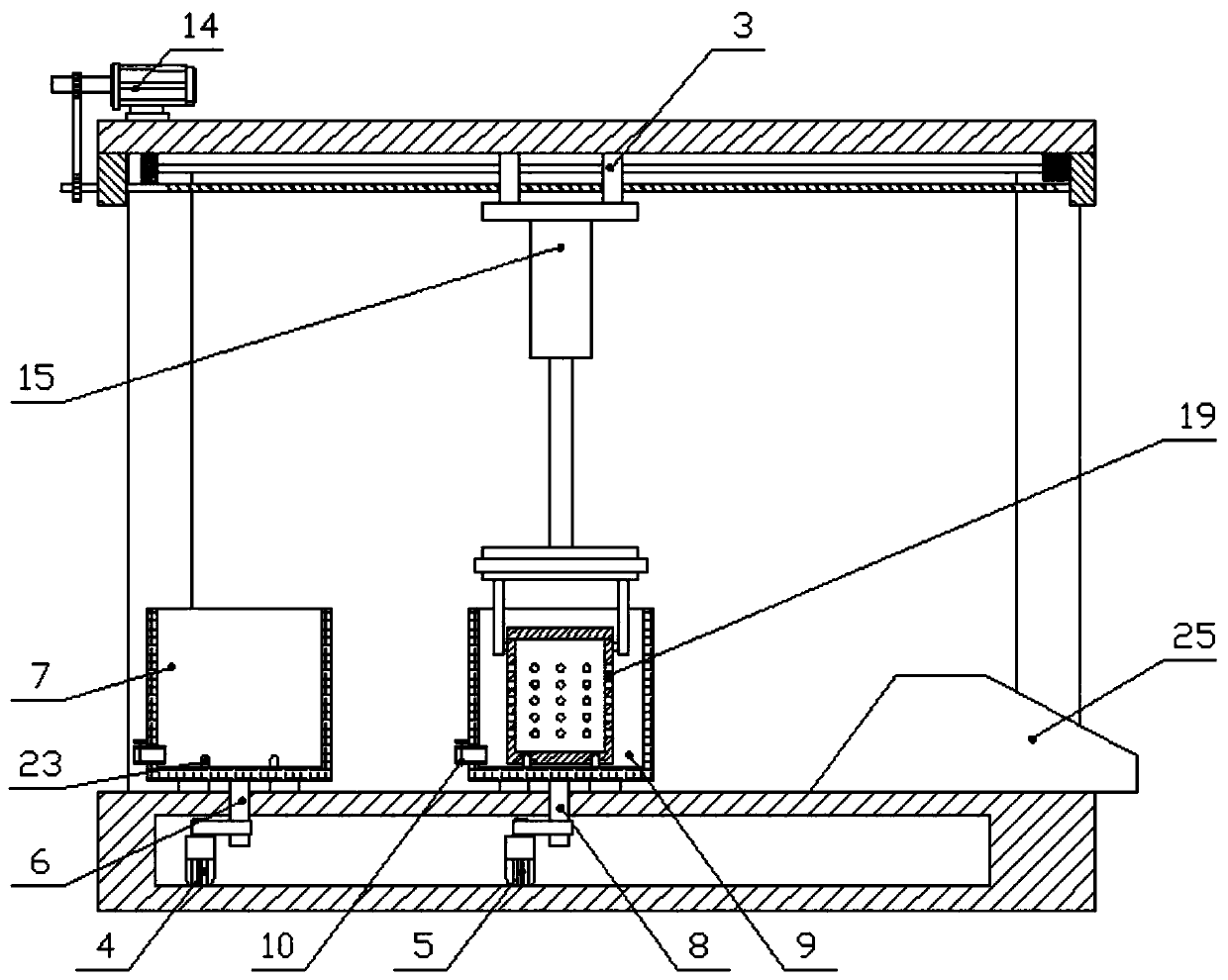

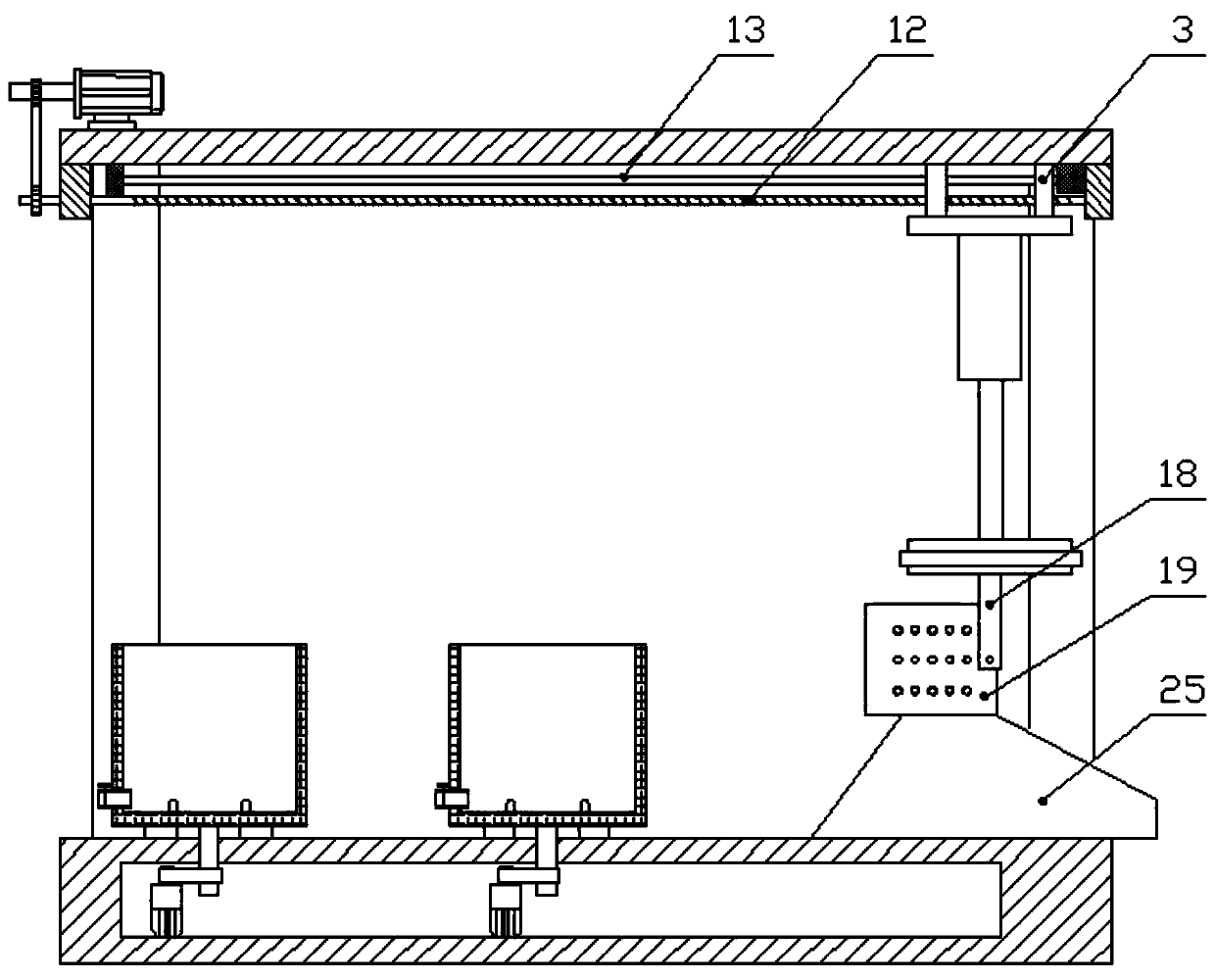

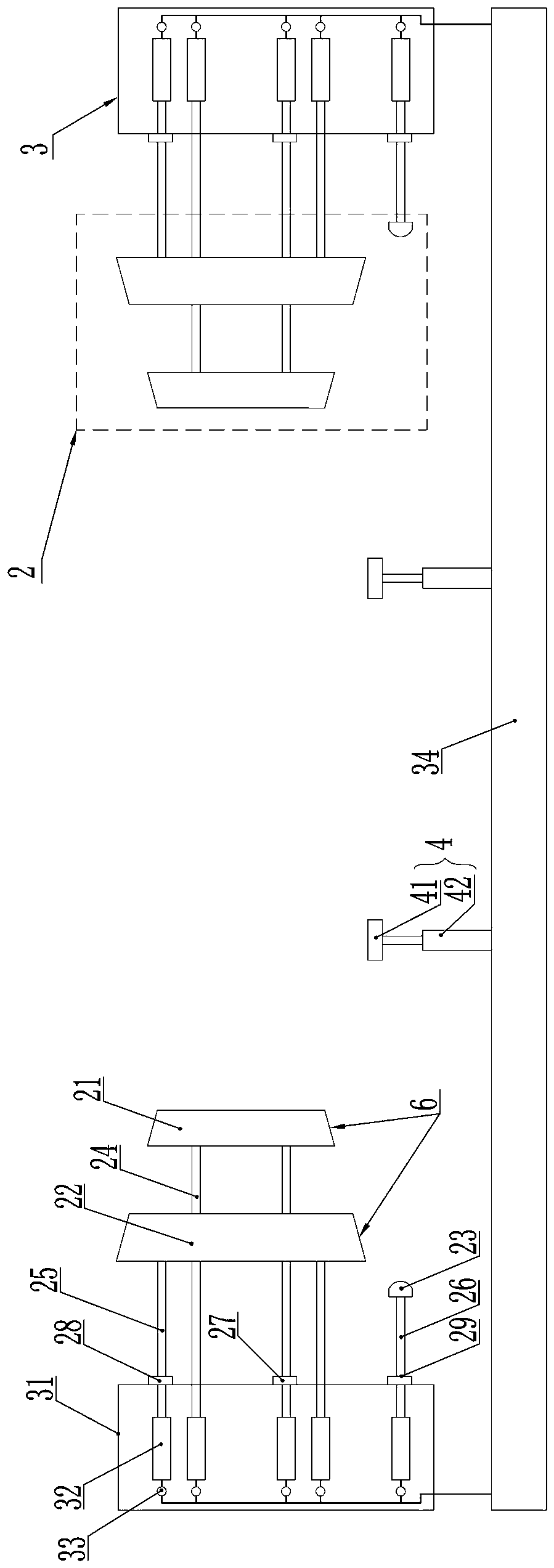

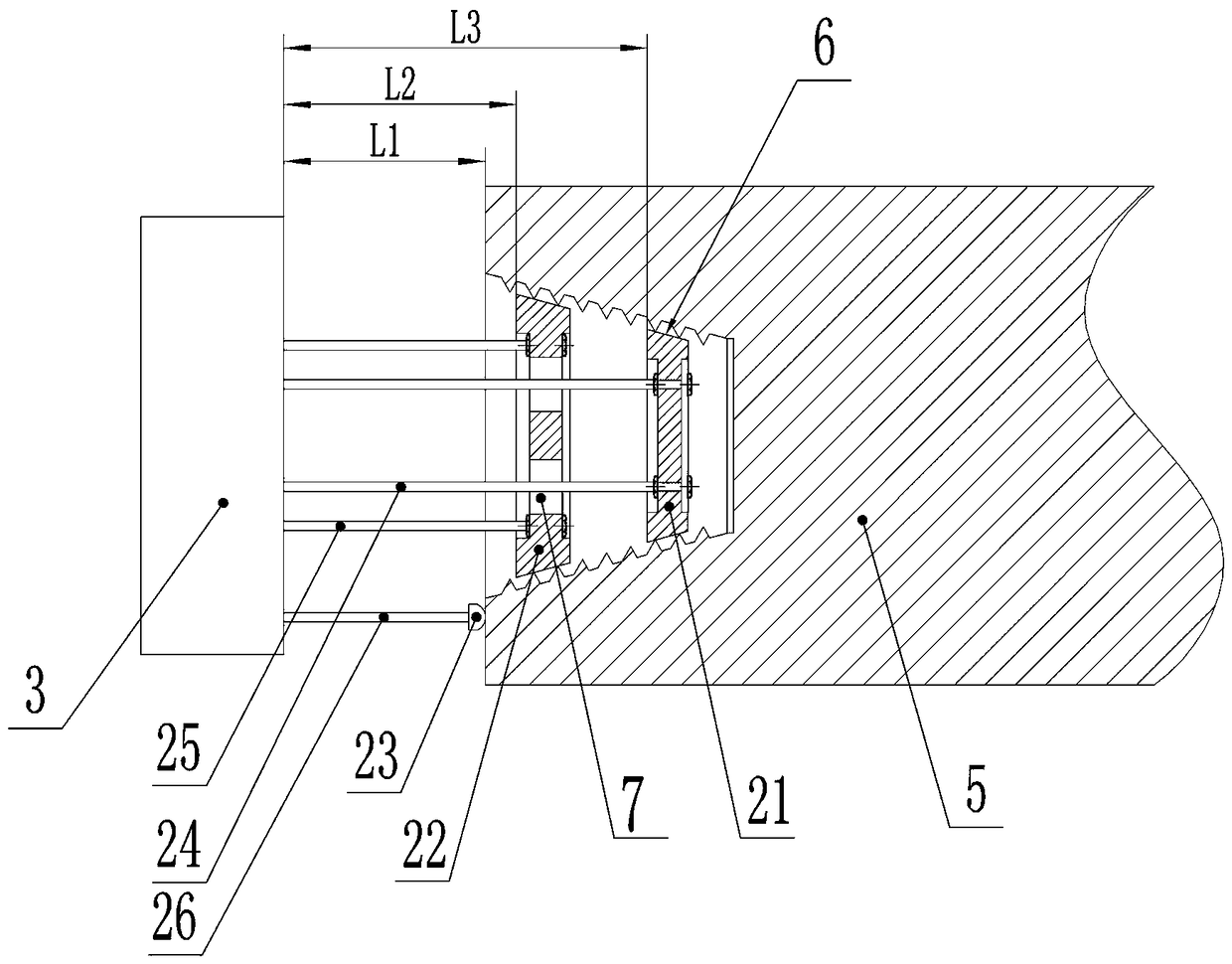

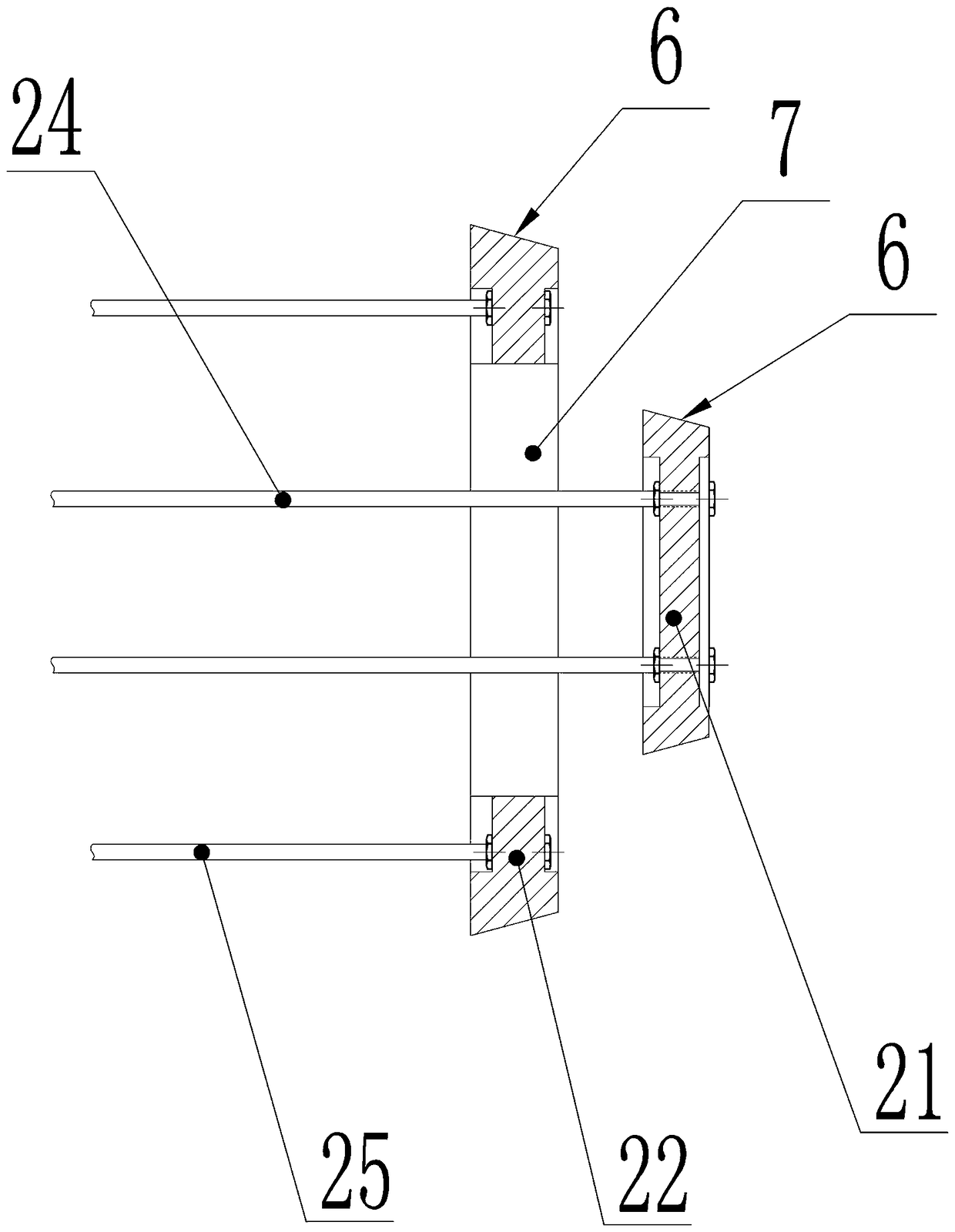

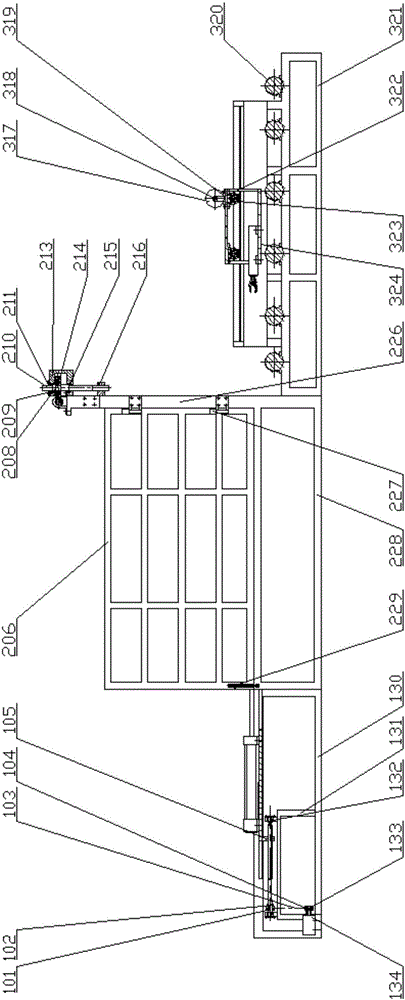

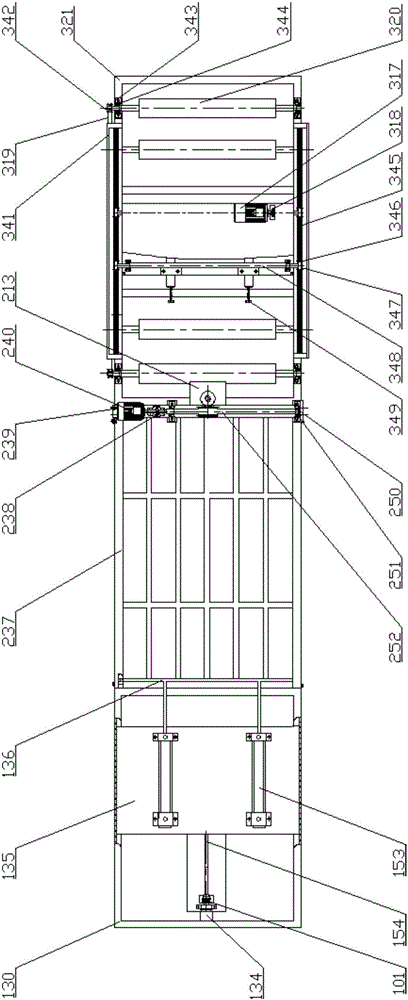

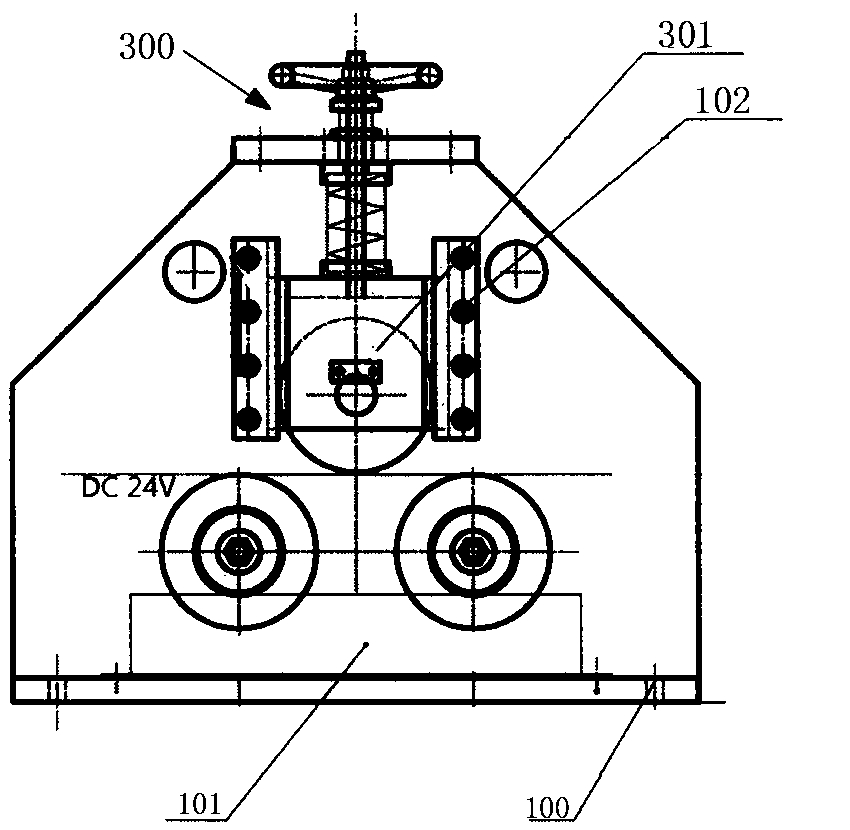

Magnesium oxide board template feeding device and magnesium oxide board loading method

ActiveCN106629084ALabor-saving operationShorten production timeConveyorsDe-stacking articlesEngineeringManufacturing line

The invention provides a magnesium oxide board template feeding device and a magnesium oxide board loading method. The device comprises a template pushing module, a template storage module and a template pulling module. Magnesium oxide board templates are stacked on the template storage module in order. The magnesium oxide board template which is stacked on the bottommost layer of the template storage module in order is pushed forwards by a certain distance through the template pushing module. The template pulling module pulls out the template which is pushed out by the template pushing module from the template storage module and places the template on a magnesium oxide board production line. According to the magnesium oxide board template feeding device, the mode that the templates are pushed and then pulled is adopted, the device is suitable for the magnesium oxide board templates of various length specifications and various thickness specifications, the magnesium oxide board templates can be continuously sent to the working positions on the production line accurately and effectively, the effect that one magnesium oxide board template is sent out each time can be guaranteed, labor is saved during operation, the production time is shortened, the working efficiency is improved, and the requirements of continuous production are met.

Owner:JIANGSU UNIV OF SCI & TECH

Cathode roller machine

PendingCN109518256AReasonable structural designImprove stabilityPhosphatisationElectrodesCopperCathode

The invention belongs to the technical field of steel wire production. A cathode roller machine comprises a machine head base; an upper roller is arranged on the machine head base, and an adjusting assembly is arranged between the upper roller and the machine head base, and drives the upper roller to act; two lower rollers are arranged on the machine head base, and the two lower rollers and the upper roller are triangularly arranged; carbon brush assemblies and the lower rollers are correspondingly arranged; each carbon brush assembly comprises a lower roller shaft; the middle portions of thelower roller shafts are arranged on the machine head base through bearings, and each lower roller is fixedly arranged at one end of the corresponding lower roller shaft; conductive sliding rings are fixedly arranged at the other ends of the lower roller shafts; and conductive copper bars are arranged on the machine head base in a supporting manner. The cathode roller machine is reasonable in structural design, stability is greatly improved, the heating amount can be effectively lowered, and the problems that the using performance of the bearings is lowered and the service life is shortened under the conductive situation can also be solved.

Owner:河南恒星钢缆股份有限公司

Device and method for automatically measuring parameters of taper thread of graphite electrode body

InactiveCN108088405AAutomate your measurementsEasy to useMeasurement devicesEngineeringElectrical and Electronics engineering

The invention discloses a device and method for automatically measuring parameters of a taper thread of a graphite electrode body in the field of automatic measuring equipment, and aims to solve the technical problems of large manual measurement error and low precision. The device includes symmetrically arranged drive assemblies and plug gauge assemblies having a smooth outer conical surface of astandard taper. The plug gauge assemblies are disposed between the two drive assemblies and are connected correspondingly to the drive assemblies by connection assemblies. Distance measurement units are also arranged between the drive assemblies and the plug gauge assemblies. A lifting unit for lifting and lowering a graphite electrode body is arranged between the two plug gauge assemblies. According to the invention, the measurement and display of the parameters of the taper thread of the graphite electrode body can be automatically realized, the usability is good, and the automatic measurement can completely avoid the artificial operation error, the reading error and is high in precision.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

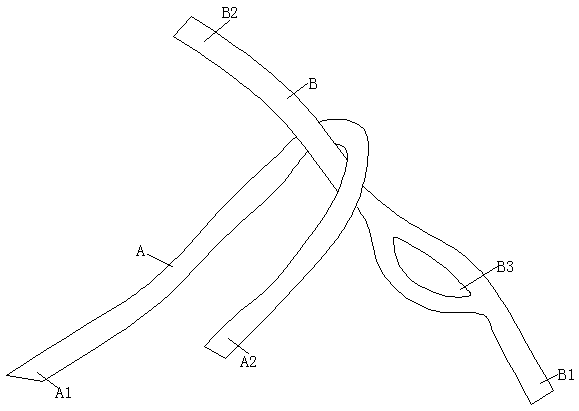

Air knot type yarn knotting method

InactiveCN108341083AMeet the needs of continuous productionDoes not affect permeabilityBundling machine detailsYarnEngineering

The invention relates to an air knot type yarn knotting method for knotting a first yarn and a second yarn. The air knot type yarn knotting method comprises the following steps: one section of the first yarn is measured from the head end of the first yarn, and one section of the second yarn is measured from the tail end of the second yarn; an air blowing knotting machine is selected according to densities of the first yarn and the second yarn, and the air pressure of the air blowing knotting machine is adjusted; the first yarn penetrates through a first clamping port and a fourth clamping portin sequence, and the second yarn penetrates through the second clamping port and a third clamping port in sequence; or the first yarn penetrates through the second clamping port and the third clamping port in sequence, and the second yarn penetrates through the first clamping port and the fourth clamping port in sequence; the first yarn and the second yarn are knotted through the air blowing knotting machine after intersection; and the knotted section of the second yarn and the knotted section of the first yarn are blown to the knotting side through an air blowing outlet to form knotted yarns. The knotting method can be applied to enable the yarns to smoothly penetrate through yarn guide holes, and facilitates industrial application.

Owner:JUSHI GRP CO

Yarn knotting method

InactiveCN108357983AQuality is not affectedMeet the needs of continuous productionFilament handlingYarnEngineering

The invention relates to a yarn knotting method. The yarn knotting method is applicable to yarn connection, and comprises the following steps: a length of No.1 yarn is measured starting from the tailend of the No.1 yarn; the No.1 yarn is erected on the upper side of No.2 yarn; a first knot position is set on the No.1 yarn; the head end of the No.2 yarn is rotated around the No.1 yarn as the central axis; the head end of the No.1 yarn is allowed to penetrate through an opening; the head end of the No.1 yarn is allowed to be in flush with that of the No.2 yarn, and a first knot is determined atthe moment; the tail end of the No.2 yarn is positioned on the lower side of the No.2 yarn, and a pull ring is formed through rotation; the combined tail ends of the No.1 yarn and the No.2 yarn are allowed to upward penetrate through the lower side of the pull ring and then are tensioned, and a second knot is determined at the moment; and the first knot and the second knot are placed in an innerring of the tail end of the No.2 yarn. By adoption of the yarn knotting method provided by the invention, the head-to-tail connection between yarn coils can be achieved, thereby meeting the continuousproduction demand; and furthermore, the connected knots can be automatically untied, thereby avoiding the influence on the product usability and the finished product quality.

Owner:JUSHI GRP CO

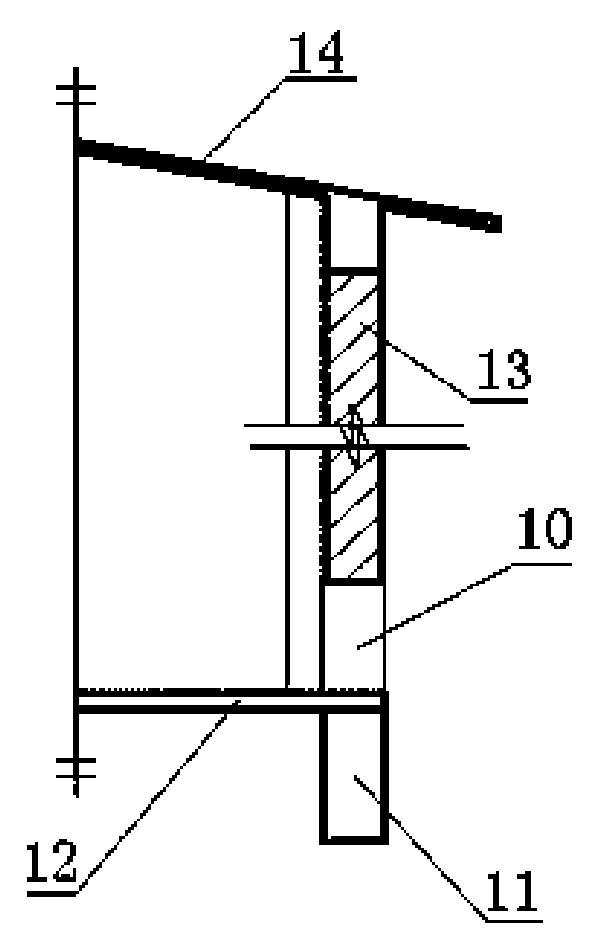

Improving method of belt porch

InactiveCN101550768AMeet the needs of continuous productionMeet the requirements of increased throughputBuilding repairsIndustrial buildingsSteel platesSheet steel

The invention provides an improving method of belt porch, comprising the following steps: firstly, a steel plate (1) and a steel plate(2) are connected on the original floor and the lateral surface of a prestressed concrete girder, then, a steel bracket (3) is connected with the steel plate (1), and a steel boot foot (4) is connected with the steel plate (2) and the steel bracket (3); a steel column (6) is firstly connected with a steel girder (7) on the field and then installed above the original belt porch; the steel column (6) is connected with the bottom edge of the steel boot foot (4), and finally, a surface layer (8) is made on the original belt porch; and the other face is symmetrical therewith, and then the middle parts of two surfaces of the steel girder (7) are welded. The invention successfully solves the improving method of widening the original belt porch under the condition of not stopping the production process, thus causing the improved belt porch to meet the requirements of conveying capacity increase and continuous production of a factory.

Owner:GUIYANG AL-MG DESIGN & RES INST

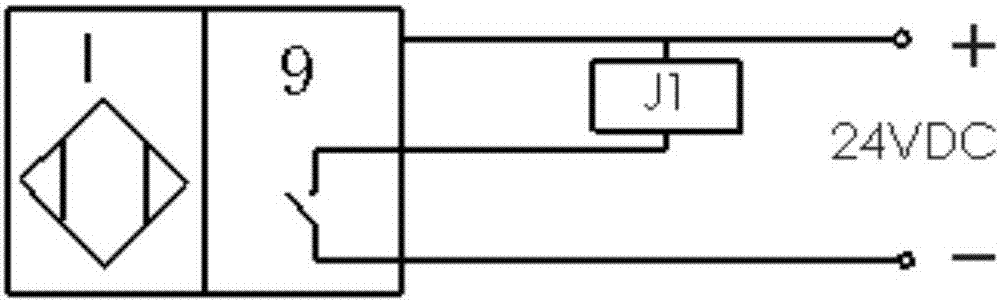

Truck scale limit automatic adjustment device and method

ActiveCN107290037ALow failure rateTroubleshoot frequent changesWeighing auxillary devicesCircular discFailure rate

A truck scale limit automatic adjustment device and a method are provided. The device includes a limit collision block, a limit screw, a box body, a reducer, a servo motor, a catcher, proximity switches, and relays. A normally open proximity switch and a normally closed proximity switch respectively connected with the relays J1 and J2 are installed on the two sides of the limit collision block. The limit screw is provided with a disk at the front end, and the rear end is connected with the square shaft of the reducer through a square groove. The reducer is connected with the servo motor through the catcher. The servo motor is connected with the relays J1 and J2. The size of the limit gap is measured using the two proximity switches installed on a scale. The coils of the relays are powered on or off under control through on-off of the two proximity switches. The closing and opening of the contacts of the two relays is controlled to make the servo motor rotate forwardly or reversely. The servo motor drives the limit screw to move back and forth through the reducer. Thus, the limit gap is adjusted. A truck scale limit device can be adjusted quickly and automatically. The adjustment time for spot inspection is reduced. The adjustment precision is improved. The failure rate of truck scales is reduced.

Owner:ANGANG STEEL CO LTD

Multifunctional object suction machine

The invention relates to the field of mechanical conveying equipment, in particular to a multifunctional object suction machine. The multifunctional object suction machine comprises an object suction unit, dispersion pipelines, a storage box, a pressure conduction unit and a draught fan. The object suction unit is connected with the storage box through the dispersion pipelines. Air way pipelines are arranged on the pressure conduction unit and connected with the dispersion pipelines. The pressure conduction unit is connected with the draught fan and comprises communicating devices, a cam shaft, a pressure conduction bin and a motor. Each communicating device comprises the corresponding air way pipeline, an air cylinder, a piston and a piston rod. According to the multifunctional object suction machine, by the adoption of the communicating devices capable of alternately communicating with the pressure conduction bin, the dispersion pipelines and storage bins corresponding to the dispersion pipelines, under the condition that the draught fan of the object suction machine is not turned off, continuous suck-in and take-out of materials are achieved; and compared with a traditional conveying device, the requirement for continuous production can be met, production efficiency can be improved, meanwhile, the loss generated when the draught fan is turned on and turned off frequently can be reduced, energy is saved, and transportation cost is lowered

Owner:刘跃

Production device and method of molybdenum oxide nanoparticles

InactiveCN104495933ALow production costSimple and fast operationMaterial nanotechnologyMolybdenum oxides/hydroxidesNanoparticleQuenching

The invention relates to a production device and method of molybdenum oxide nanoparticles, aiming to solve the technical problems of unstable product quality, complex production procedures and low production efficiency in the production of molybdenum oxide nanoparticles in the prior art. The production device comprises a gasifying unit, a quenching unit and a collecting unit, wherein the gasifying unit is used for gasifying the precursor material of molybdenum oxide nanoparticles, the quenching unit is used for quenching the gasified molybdenum oxide nanoparticles, and the collecting unit is used for collecting the finished molybdenum oxide nanoparticles. The production device and method have the advantages of high production efficiency and stable product quality.

Owner:江西省鼎力金属有限公司

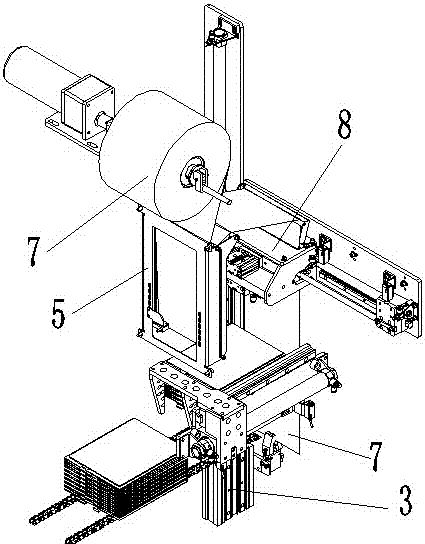

A battery pole group coating machine

ActiveCN104835986BSimple structureGuaranteed uptimeFinal product manufactureLead-acid accumulators constructionEngineeringChain link

The invention discloses a battery pole group coating machine, which comprises a chain, a pole group, a lifting mechanism, a pushing mechanism, a film feeding mechanism, a film pulling mechanism, a film, and a film cutting mechanism. There is a push mechanism, the film feeding mechanism is set above the end of the chain and the lifting mechanism, the film pulling mechanism is set behind the chain and the lifting mechanism, the film is set on the film feeding mechanism, and the film cutting mechanism is set on one side of the pulling mechanism ;The film pulling mechanism pulls the film of the film feeding mechanism into place and fixes the length, the film cutting mechanism cuts off the film, the chain conveys the pole group to the lifting mechanism, the lifting mechanism lifts the pole group, and the pushing mechanism lifts the pole group together with the film Push forward to the battery case or electrode group box or fixture, realize automatic electrode group coating and enter the battery case, electrode group box, and fixture at the same time, meet the needs of continuous automatic production, optimize the production process, and ensure the quality of the electrode group , the machine is reliable in operation, the coating effect is good, and the manufacturing cost is low.

Owner:ZHUZHOU YINGDING AUTOMATION EQUIP TECH

Novel raw material addition apparatus

ActiveCN103522559AFluctuation in specific gravityMeet the needs of continuous productionOptical articlesContinuous/uninterruptedBiochemical engineering

A novel raw material addition device provided by the invention includes a processing tank and a feeding device. The feeding device comprises a material storage chamber and an infusion tube. on end of the infusion tube is connected to the raw material storage chamber; the middle is provided with a regulator; and the other end is connected to the processing tank. For material transfer which can be achieved by gravity potential energy, a pump can be omitted. For difficulty in putting the raw material storage chamber in high position, a pump can be added to help material transfer. For different material consumption of each component in the production process, a plurality of feeding devices can be arranged. The invention has the following beneficial effects: the novel material addition device provided by the invention can be used in continuous production; slow feeding is regulated by the regulator, so that concentration, proportion and temperature of the raw liquid in the processing groove do no fluctuate severely, thereby ensuring the stability of production. The invention also fully takes into account of volatile and largely-consumed components in the raw liquid, and the additional feeding devices are connected to ensure the stability of production.

Owner:江苏格林视通光学有限公司

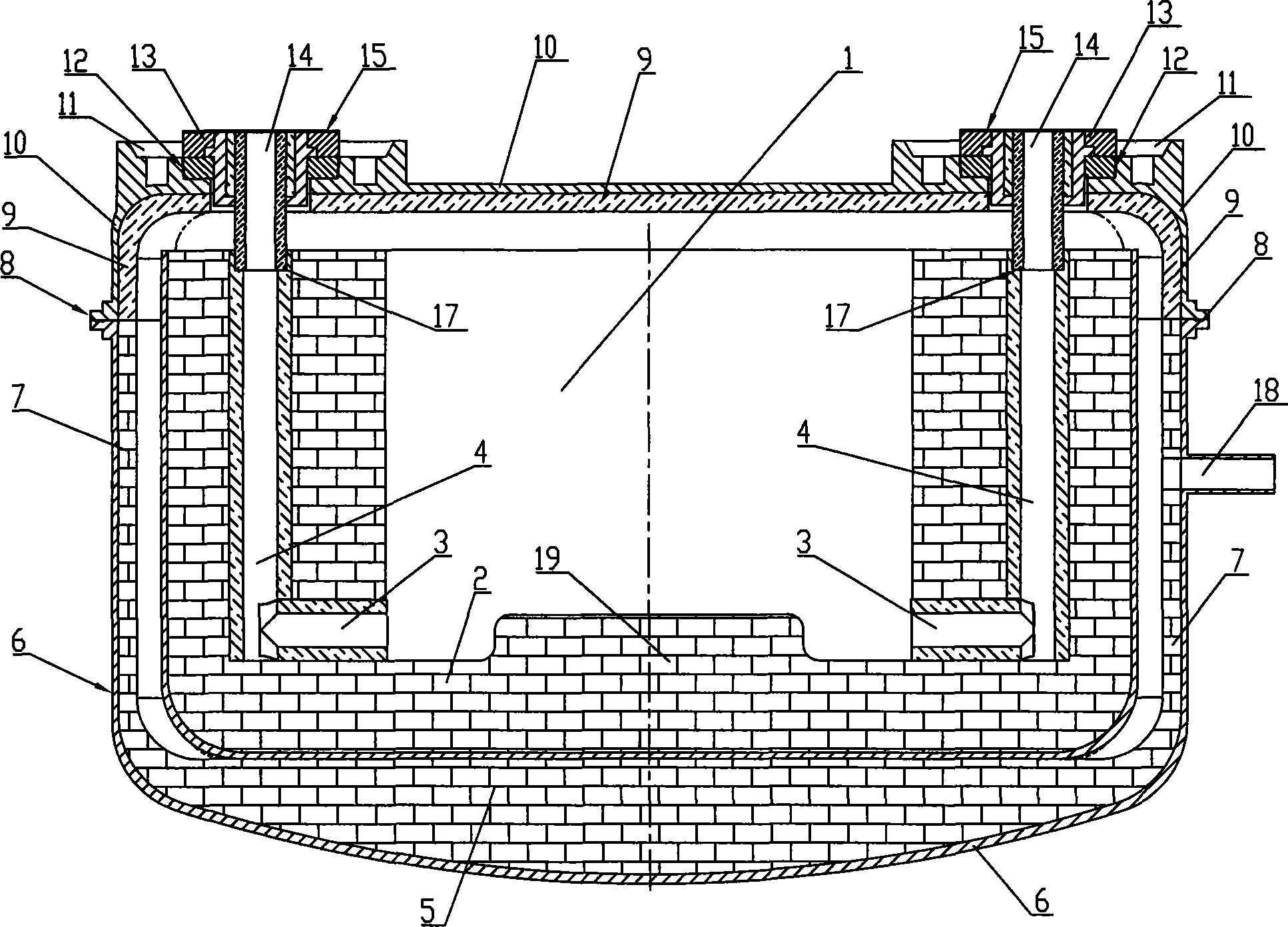

Pressure tank for bottom gating steel casting

InactiveCN101244456AStable temperatureLiquid level stabilityMolten metal supplying equipmentsMetallurgyBottom gate

The invention provides a pressure tank for bottom-pouring cast steel, which comprises a tank body and a tank top cover connected sealingly with the tank body, the tank body is provided with at least a gas pressure adjusting opening, a molten steel ladle with opening at top part is arranged in the tank body, two molten steel channels are arranged on inner wall of the molten steel ladle, the opening at lower end of the molten steel channel is arranged at bottom part inside the molten steel ladle, the opening at upper end of the molten steel channel is arranged at top part of the molten steel ladle, the opening at upper end of the molten steel channel is connected sealingly with a molten steel in-out interface, the upper part of the molten steel in-out interface is penetrated through the tank top cover, the stability of molten steel temperature and the stability of each process parameter in the pressure tank ensure product quality, moreover the liquid level of the molten steel in the pressure tank is stable so as to be easy for control when pouring, the design of the pressure tank meets the need of continuous production, so that production efficiency is improved greatly and economic efficiency is large.

Owner:天瑞集团铸造有限公司

Automatic measuring device and method for taper thread parameters of graphite electrode nipple

ActiveCN108225143AEasy to useAvoid human errorAngles/taper measurementsApertured gaugesObservational errorMeasurement device

The invention discloses an automatic measuring device and method for taper thread parameters of a graphite electrode nipple, belongs to the field of automatic measurement equipment, and aims at solving the technical problems of large error and low accuracy in existing manual measurement. The device comprises symmetric driving assemblies, and a ring gauge assembly which is provided with a standardtaper and a smooth inner tapered surface, wherein the ring gauge assembly is arranged between the two driving assemblies and is correspondingly connected to the driving assemblies through connecting assemblies; a ranging unit is further arranged between each driving assembly and the ring gauge assembly; a lifting unit for lifting the graphite electrode nipple is arranged between the two ring gaugeassemblies. With the adoption of the device and the method, taper thread parameters of the graphite electrode nipple can be measured and displayed automatically, so that the usability is high; and moreover, the measurement is automatically carried out, so that a manual operation error and a read number error can be completely avoided; and the accuracy is high.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

Dual-swirl water purifier

InactiveCN102614711BReach the standard of recyclingRealize the function of filtration and purificationFiltration circuitsWater resourcesSewage

The invention belongs to the field of water treatment equipment and discloses a dual-swirl water purifier, which can perform tertiary sewage treatment without extra power. The dual-swirl water purifier is formed by sleeving three layers of pipe sleeves with different diameters, wherein the upper part of an outer sleeve is provided with a water inlet which is communicated with a primary swirl cavity; a sewage collecting and settling area and a sewage outlet are formed on the lower part in the outer sleeve; a water inlet oblique cut is formed on the surface of a middle section of a middle sleeve along the tangential direction; the outer surface is wound with spiral swirl vanes and spiral swirl lower vanes; gaps are reserved between the vanes and the outer sleeve; a gap is not reserved between the lower vanes and the outer sleeve; and a filtering net is arranged on an outer surface of an inner meshed pipe framework and is communicated with a purified water outlet. Three filtering and purifying functions, namely primary filtering, middle precision filtering and final filtering are realized, and the invention has the characteristics that the water purifier is small in size, compact in structure and high in sewage treatment amount, a recycling ratio of water is improved, and the water resources are saved.

Owner:北京五一环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com