Air knot type yarn knotting method

A yarn and air technology, which is applied in the field of air knot yarn knotting, can solve problems such as too large knots and too hard knots, and achieve the effect of meeting the needs of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

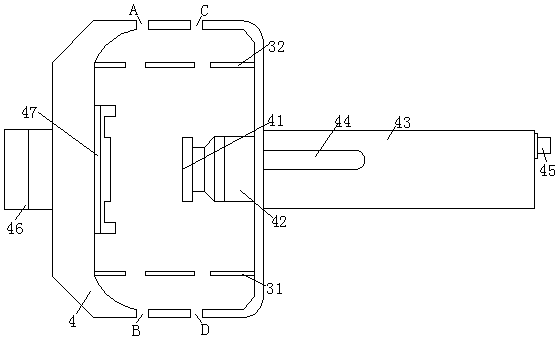

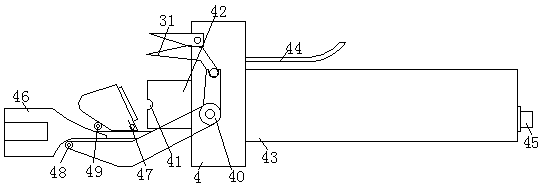

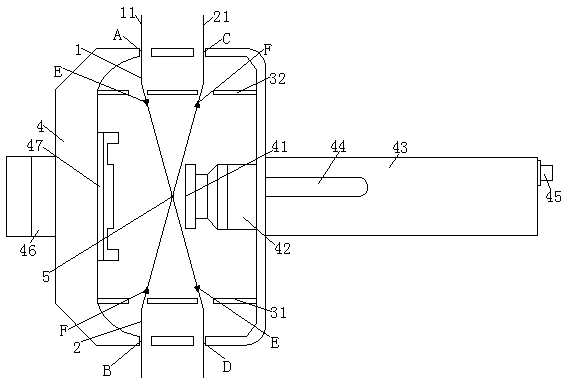

[0030] The air-knotted yarn knotting method in the present embodiment is used for knotting and connecting No. 1 yarn 1 and No. 2 yarn 2. One end of No. 1 yarn 1 is No. 1 yarn head end 11, and One end of No. yarn 2 is No. 2 yarn tail end 21, and No. 1 cutting blade 31 and No. 2 cutting blade are installed in the blowing knotter 4 for knotting No. 1 yarn 1 and No. 2 yarn 2 32. The air blowing knotter 4 is provided with a No. 1 bayonet A, a No. 2 bayonet B, a No. 3 bayonet C, and a No. 4 bayonet D. The air blowing knotter 4 includes a propulsion device 46, an air blowing device cover door 47, No. 1 propulsion pulley 48, No. 2 propulsion pulley 49 and driving force arm 40; Air blowing knotter 4 comprises propulsion device 46, air blowing device cover door 47, No. 1 propulsion pulley 48, No. 2 propulsion pulley 49 and push The force arm 40 is the same as the prior art, and the blowing device 42 is installed in the blowing knotter 4, and the blowing device 42 is positioned at the mi...

Embodiment 2

[0041] The air-knotted yarn knotting method in the present embodiment is used for knotting and connecting No. 1 yarn 1 and No. 2 yarn 2. One end of No. 1 yarn 1 is No. 1 yarn head end 11, and One end of No. yarn 2 is No. 2 yarn tail end 21, and No. 1 cutting blade 31 and No. 2 cutting blade are installed in the blowing knotter 4 for knotting No. 1 yarn 1 and No. 2 yarn 2 32. The air blowing knotter 4 is provided with a No. 1 bayonet A, a No. 2 bayonet B, a No. 3 bayonet C, and a No. 4 bayonet D. The air blowing knotter 4 includes a propulsion device 46, an air blowing device cover door 47, No. 1 propulsion pulley 48, No. 2 propulsion pulley 49 and driving force arm 40; Air blowing knotter 4 comprises propulsion device 46, air blowing device cover door 47, No. 1 propulsion pulley 48, No. 2 propulsion pulley 49 and push The force arm 40 is the same as the prior art, and the blowing device 42 is installed in the blowing knotter 4, and the blowing device 42 is positioned at the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com