Pressure tank for bottom gating steel casting

A technology for pressure tanks and steel castings, which is applied in the field of pouring equipment, can solve problems such as low production efficiency, unstable process parameters, and imperfect technical solutions, and achieve product quality assurance, huge economic benefits, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

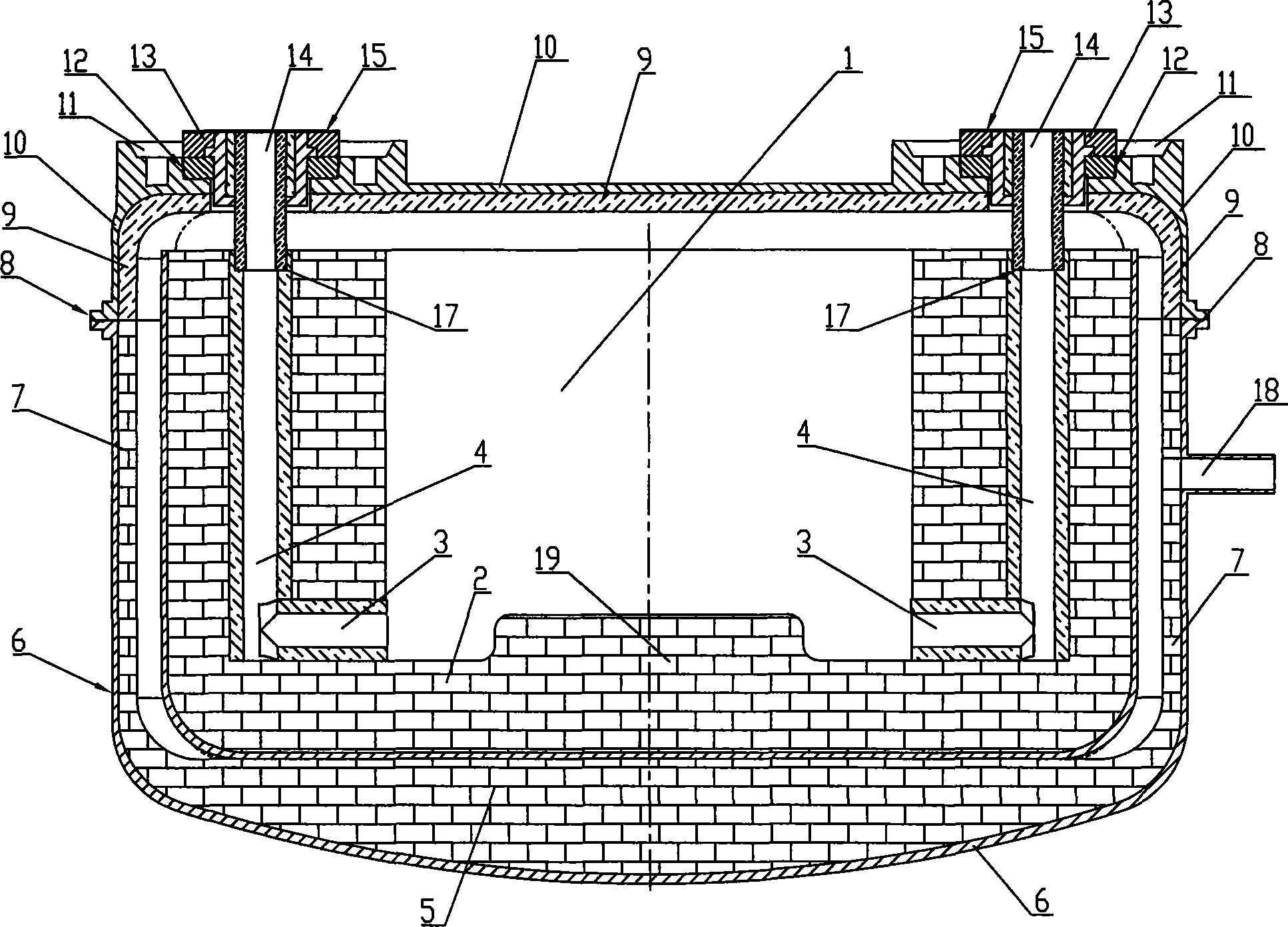

[0014] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0015] As shown in Figure 1: a pressure tank for bottom casting steel castings, the pressure tank includes a tank body 6 and a tank body upper cover 10 sealingly connected with the tank body 6, the tank body 6 and the tank body upper cover 10 There is a quick opening and closing structure 8 between them, and the two need to have good sealing performance;

[0016] The tank body 6 is provided with at least one air pressure regulating port 18 in the tank, which is used to control the gas pressure in the tank, and its opening diameter and quantity are determined according to requirements;

[0017] A ladle 1 with an open top is arranged in the tank body 6, and the volume of the ladle 1 is designed according to specific needs;

[0018] The inner wall of the ladle 1 is provided with two molten steel passages, and the molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com