Primer coating and preparation method thereof, and polyester film and preparation method thereof

A technology of polyester film and primer, which is applied in the direction of coating, primer, polyurea/polyurethane coating, etc., can solve the problem of low ink layer adhesion, and achieve continuous production, good adhesion performance, and adhesion excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of primer provided by the invention may further comprise the steps:

[0073] (1) Add the amine-functionalized acrylic copolymer and epoxy resin into a glass beaker with a certain mass of solvent according to the proportion, and stir it electrically for 1 hour to form a uniformly mixed solution;

[0074] (2) Add the olefin-acrylonitrile copolymer, polyester polyol, and polycyclic heteroatom compound to the solution obtained in step (1) according to the proportioning ratio, and dilute with a solvent to obtain a uniformly mixed solution;

[0075] (3) Add additives and catalysts into the solution obtained in step (2) according to the proportioning ratio, and configure it as a primer.

[0076] The preparation method of polyester film provided by the invention may further comprise the steps:

[0077] (1) Evenly coat the uniformly mixed primer on the surface of the PET film using a specific wire bar coater;

[0078] (2) the PET film coated with primer ...

Embodiment 1

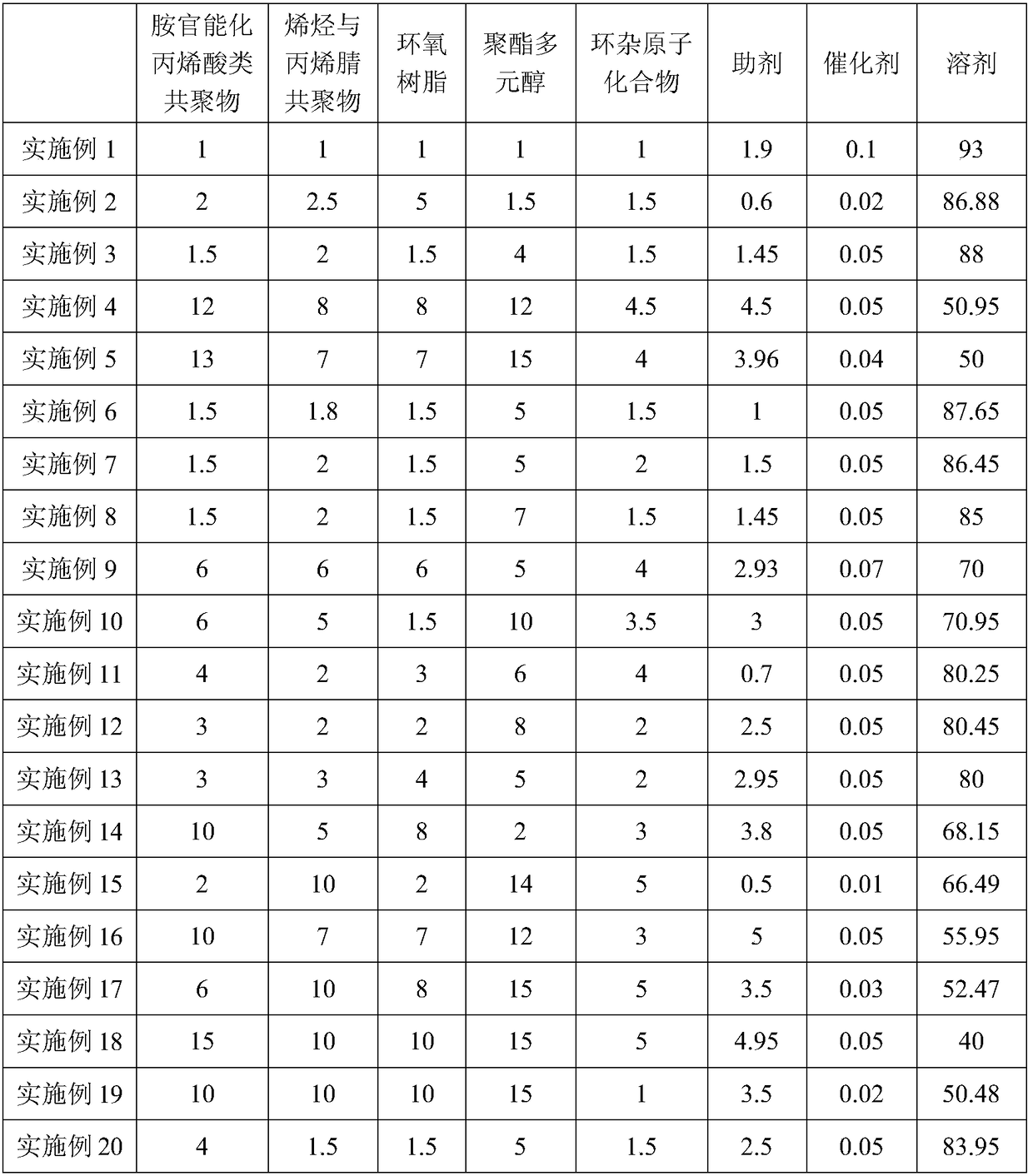

[0090] Primer formulation in embodiment 1 is as shown in table 1, wherein:

[0091] The amine-functionalized acrylic copolymer is primary amine-functionalized polyacrylic acid-methyl acrylate copolymer; the olefin-acrylonitrile copolymer is polyethylene-acrylonitrile copolymer with a number average molecular weight of 12000; the epoxy resin is bisphenol A- Epoxy polycondensate; polyester polyol is polycarbonate-1,6-hexanediol; polycyclic heteroatom compound is ethylene oxide; additive is 2-hydroxy-2-methyl-1-benzene Base-1-acetone, diphenylmethane diisocyanate, the weight ratio of the two is 0.05:99.95; the catalyst is dibutyltin dilaurate; the solvent is ethyl acetate.

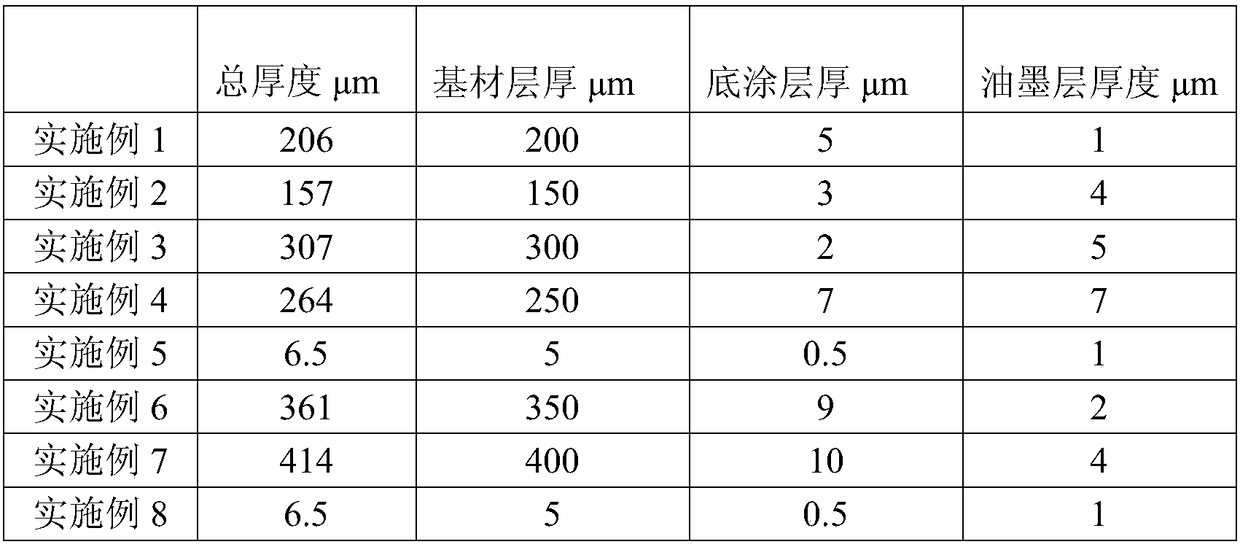

[0092] The performance test results of primer and polyester film are shown in Table 2, and the thickness of polyester film is shown in Table 3.

Embodiment 2

[0094] Primer formulation in embodiment 2 is as shown in table 1, wherein:

[0095] The amine-functionalized acrylic copolymer is a tertiary amine-functionalized polymethyl acrylate-ethyl acrylate copolymer; the olefin-acrylonitrile copolymer is a polyvinyl chloride-acrylonitrile copolymer with a number average molecular weight of 7000; the epoxy resin is a resin Cyclic epoxy resin; polyester polyol is polyε-caprolactone diol; polycyclic heteroatom compound is propylene oxide; additive is 2,4,6,-trimethylbenzoylphosphonic acid ethyl ester And diphenylmethane diisocyanate, the weight ratio of the two is 0.05:99.95; the catalyst is triethylamine; the solvent is ethyl acetate.

[0096] The performance test results of primer and polyester film are shown in Table 2, and the thickness of polyester film is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com