Dual-swirl water purifier

A technology of flow water purifier and swirl chamber, applied in the field of double swirl water purifier, can solve problems such as complex structure, achieve the effect of small volume, realize regular replacement, and promote zero discharge of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

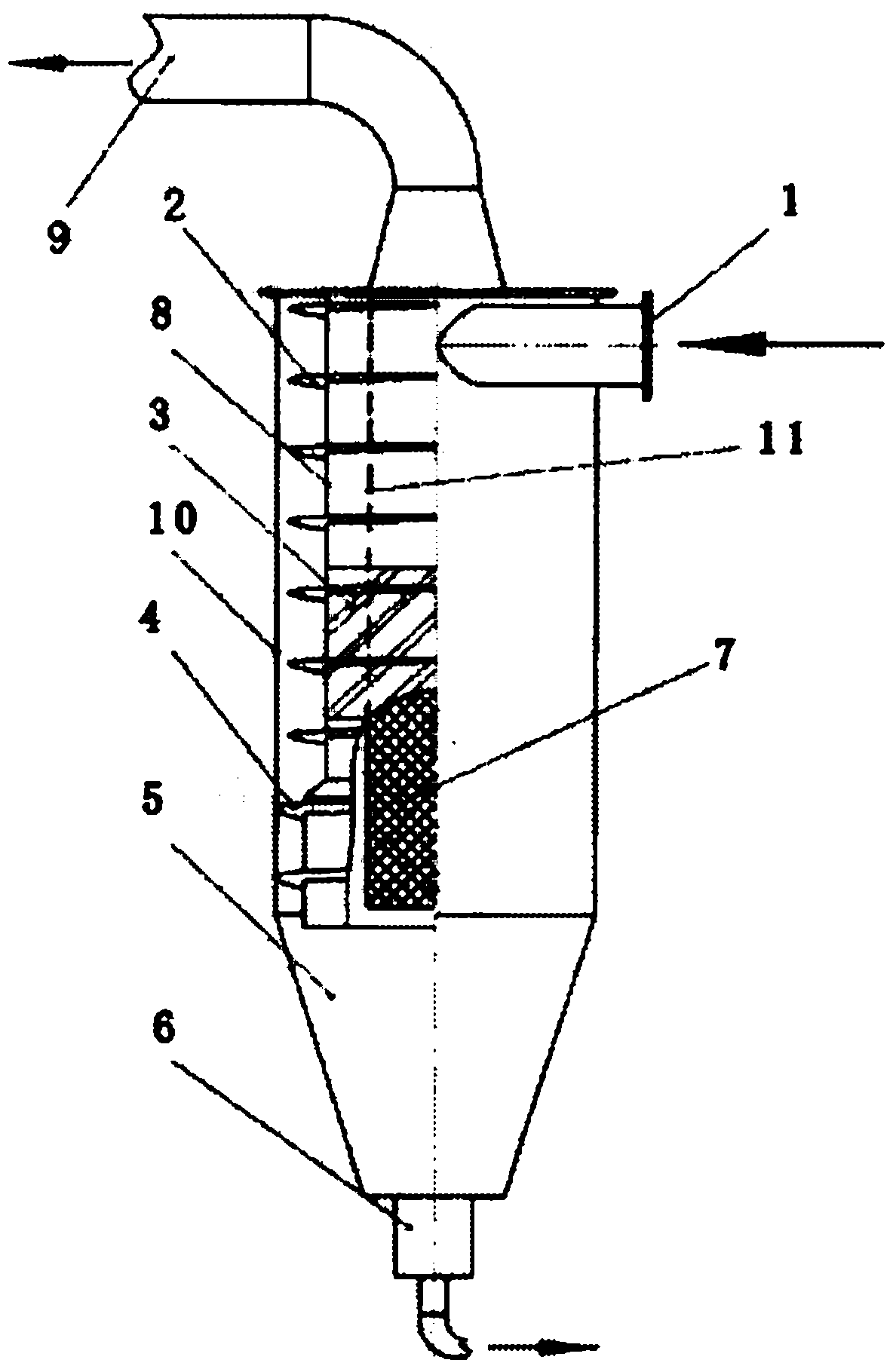

[0012] Referring to the accompanying drawings, the double-swirl water purifier is composed of three layers of pipes with different diameters, in which the cavity formed by the outer sleeve 10 and the middle sleeve 8 is a first-stage swirl cavity, and the inner network pipe 11 and The middle casing 8 forms a secondary swirl cavity, and the upper ends of the primary swirl cavity and the secondary swirl cavity are closed. The upper part of the outer casing 10 is provided with a water inlet 1 leading to the primary cyclone cavity, and the lower part of the outer casing 10 is provided with a dirt collection and settlement area 5 and a sewage outlet 6; the surface of the middle section of the middle casing 8 is along the tangential direction There is a water inlet oblique cut 3, and the outer surface is wound with the spiral swirl blade 2 and the spiral swirl lower blade 4. There is a gap between the swirl blade 2 and the outer casing 10, and the swirl lower blade 4 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com