Patents

Literature

131results about How to "High recycling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

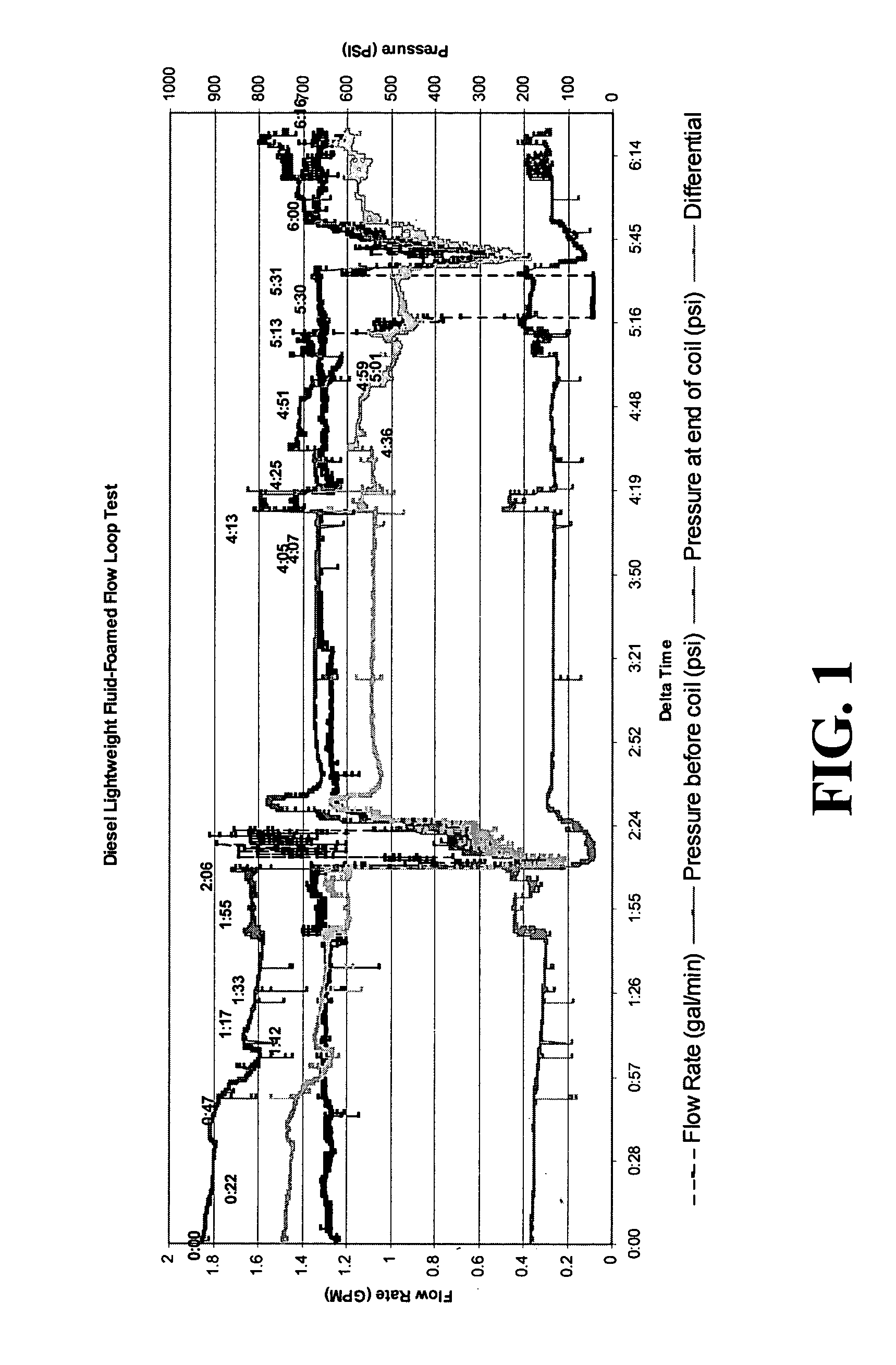

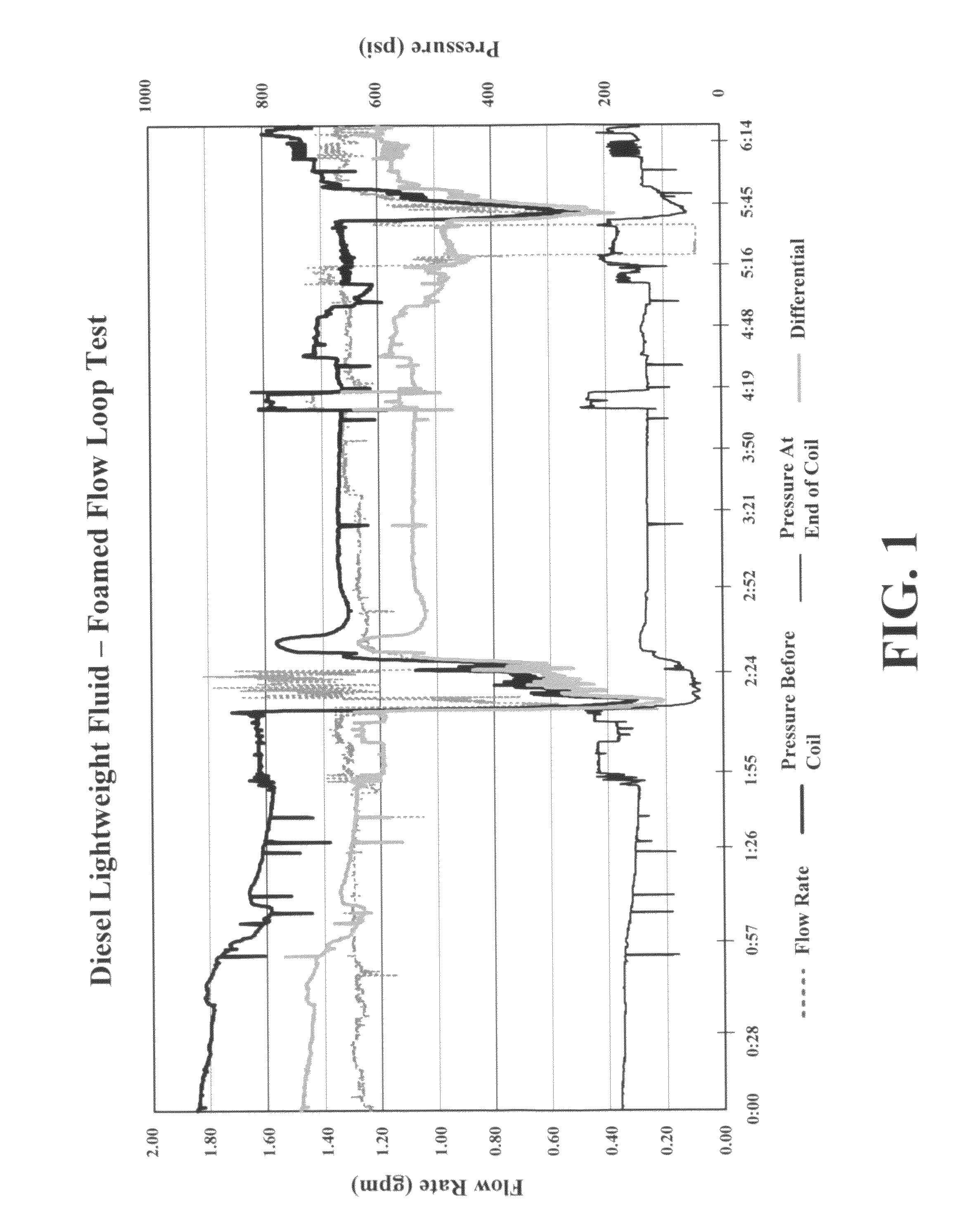

Method for foaming a hydrocarbon drilling fluid and for producing light weight hydrocarbon fluids

InactiveUS20070129257A1StableLighten in weightFluid removalMixingEnvironmental geologyDrilling fluid

A hydrocarbon drilling fluid system is disclosed including a hydrocarbon fluid and a foaming composition, where the foaming composition includes a polymer, a gelling agent and its cross-linking agent, an optional foaming agent, or mixtures or combinations thereof. Uses of this drilling fluid system in a variety of downhole application are also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

Method for foaming a hydrocarbon drilling fluid and for producing light weight hydrocarbon fluids

InactiveUS7767628B2Good removal effectLightens the fluid column weightMixingFlushingFoaming agentPolymer

Owner:WEATHERFORD TECH HLDG LLC

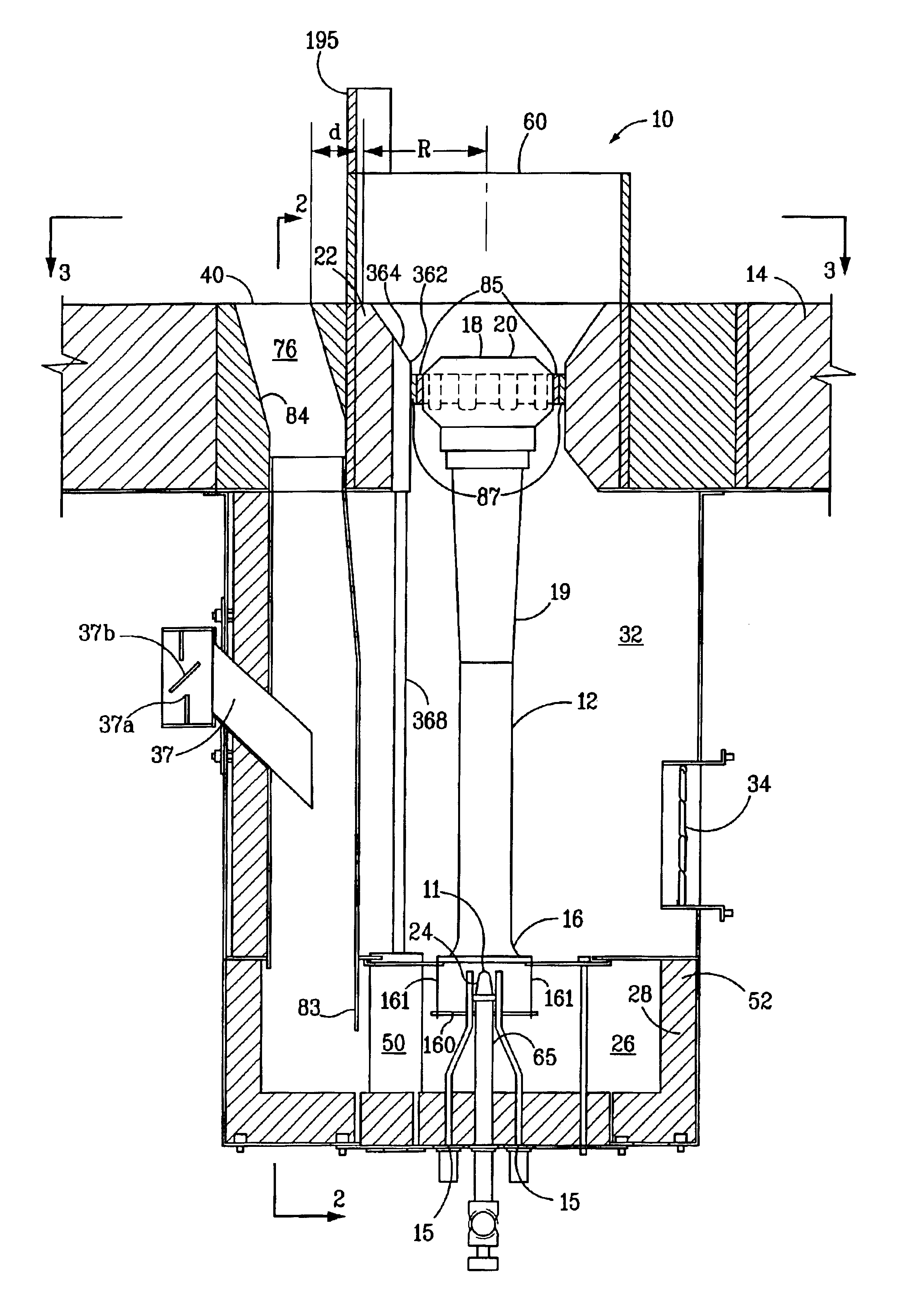

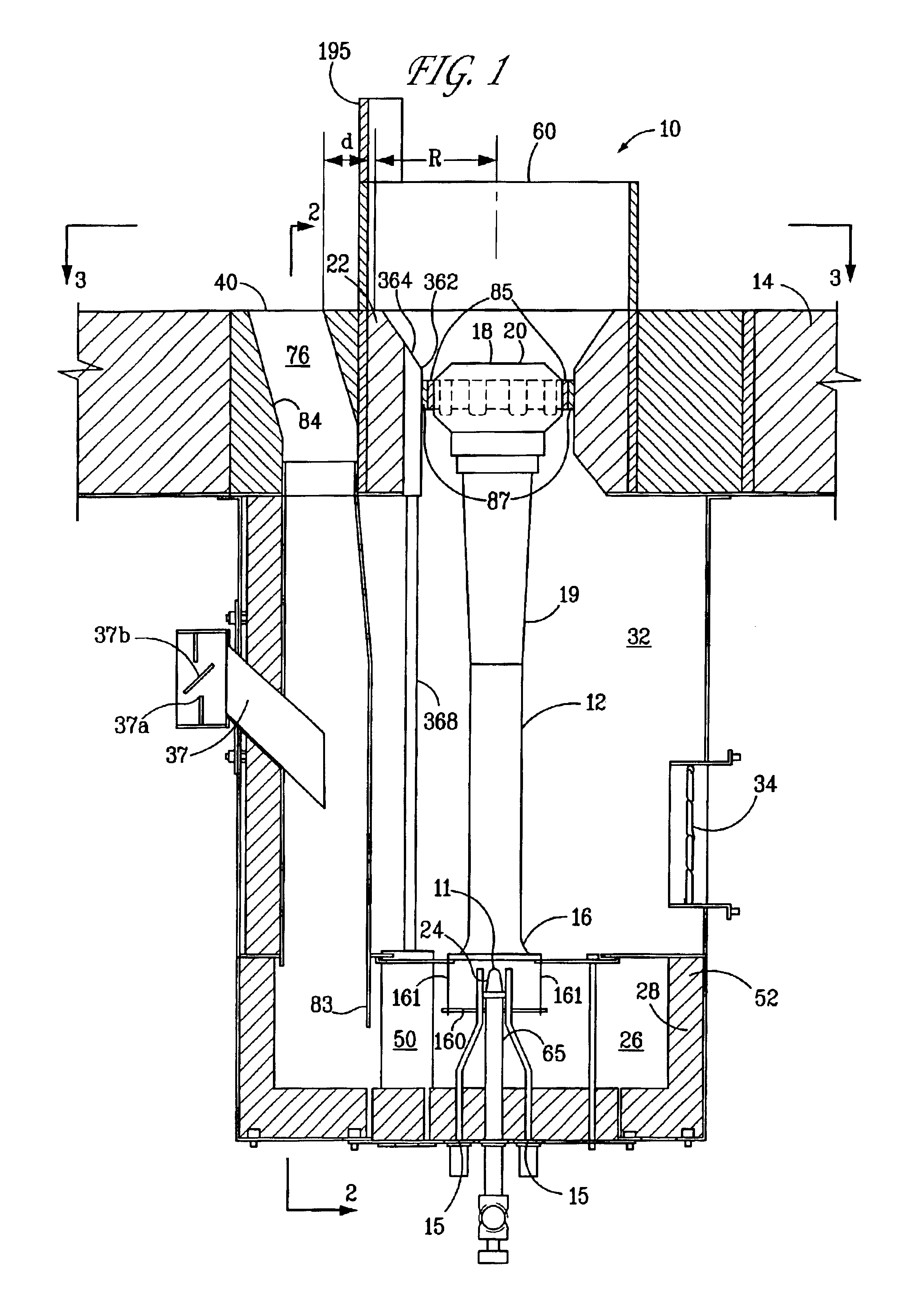

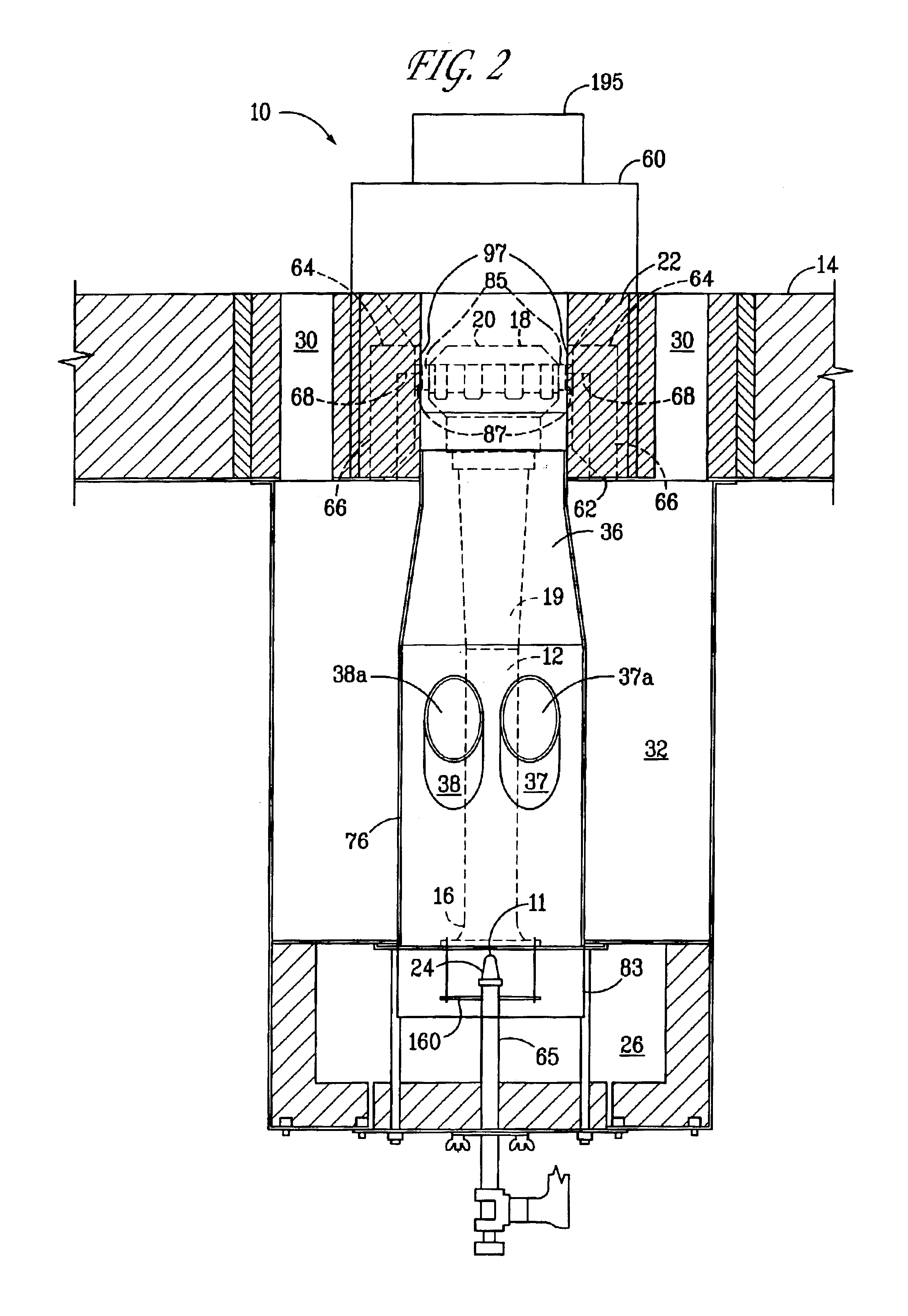

Burner with low NOx emissions

InactiveUS6877980B2Reduce the production of nitrogen oxidesDecrease in burner stabilityDomestic stoves or rangesBurner ignition devicsEngineeringCombustor

A burner for use in furnaces such as in steam cracking. The burner includes a primary air chamber; a burner tube having an upstream end, a downstream end and a venturi intermediate said upstream and downstream ends, said venturi including a throat portion having substantially constant internal cross-sectional dimensions such that the ratio of the length to maximum internal cross-sectional dimension of said throat portion is at least 3; a burner tip mounted on the downstream end of said burner tube adjacent a first opening in the furnace, so that combustion of the fuel takes place downstream of said burner tip; and a fuel orifice located adjacent the upstream end of said burner tube, for introducing fuel into said burner tube.

Owner:EXXONMOBIL CHEM PAT INC

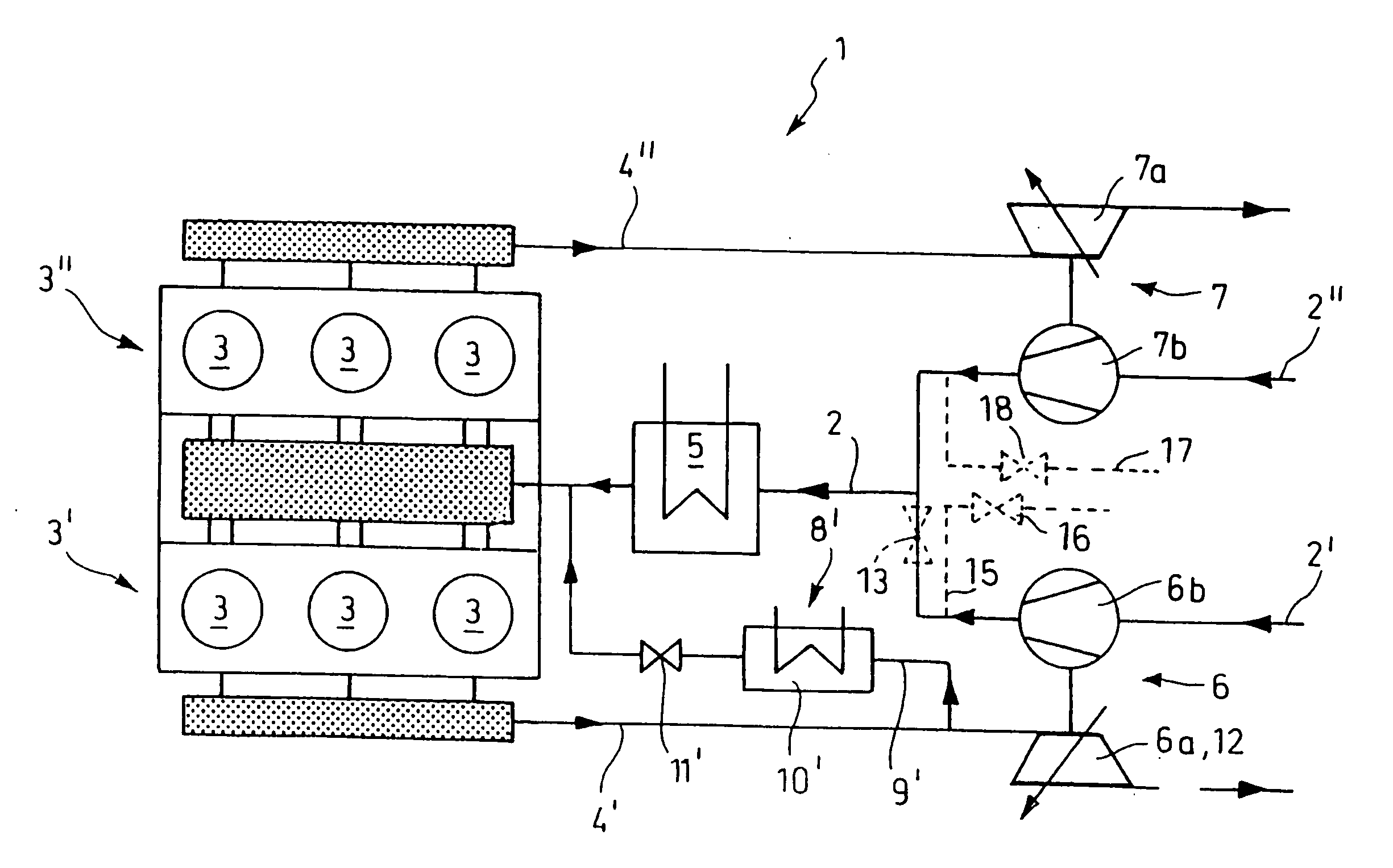

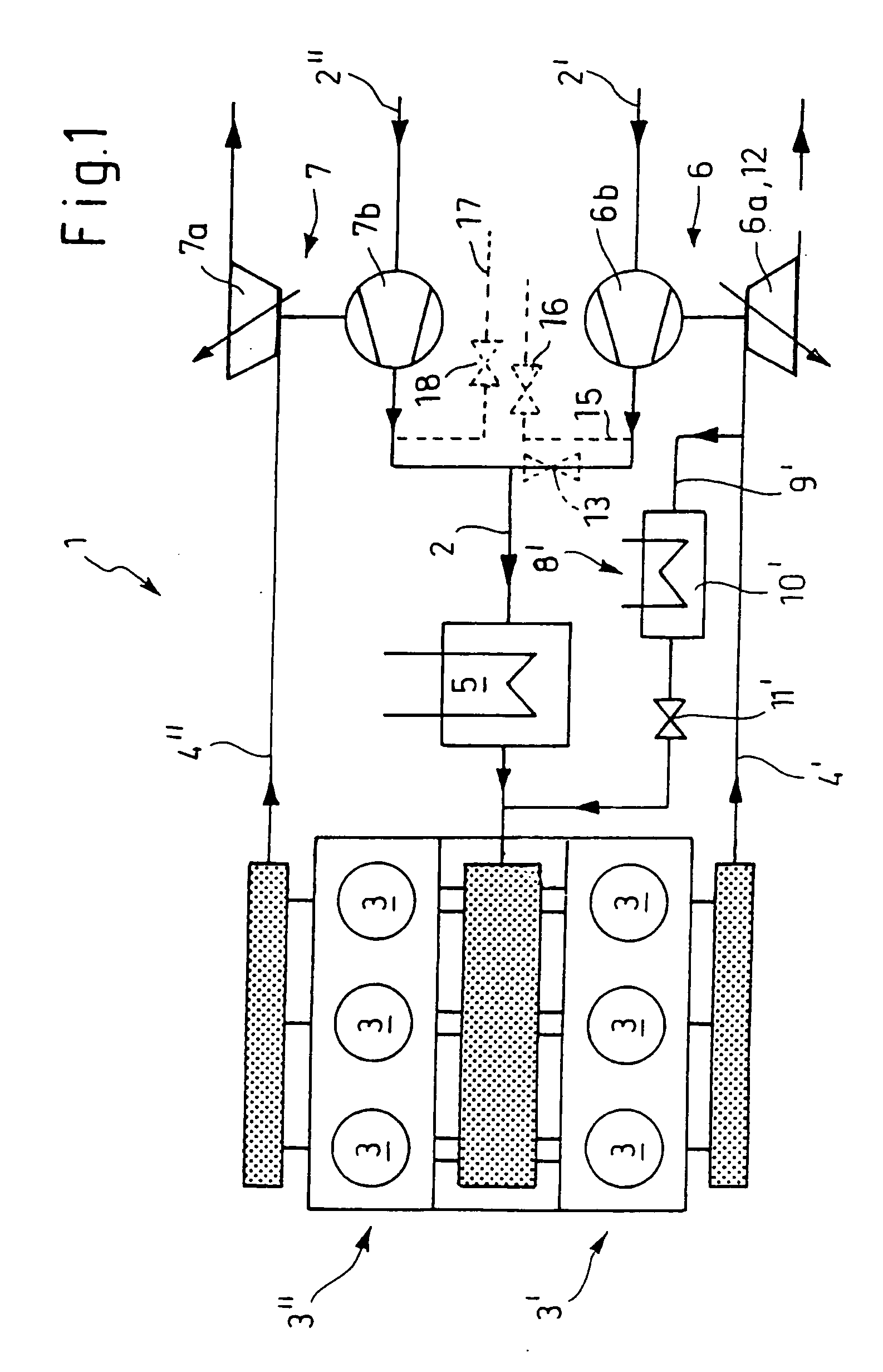

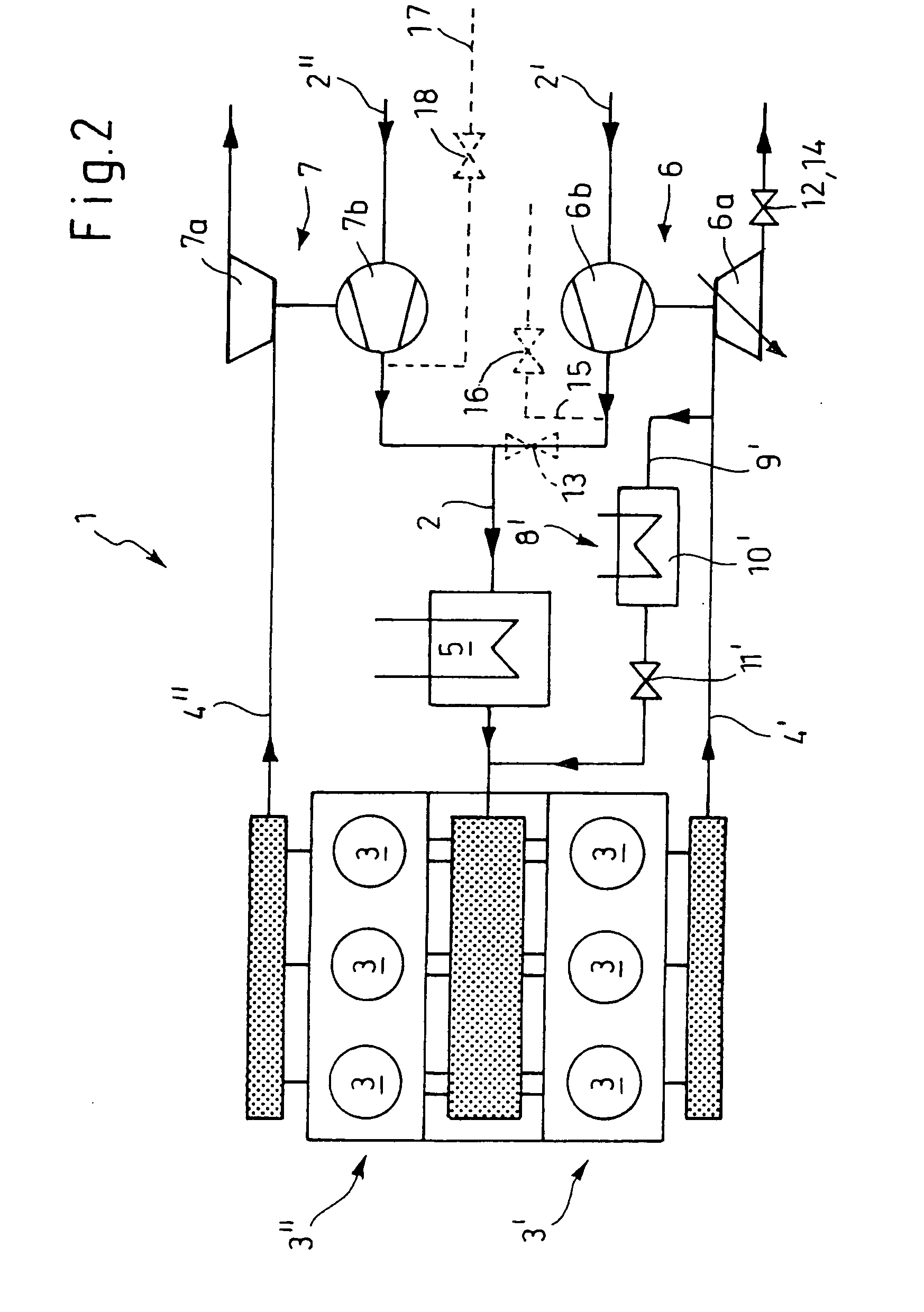

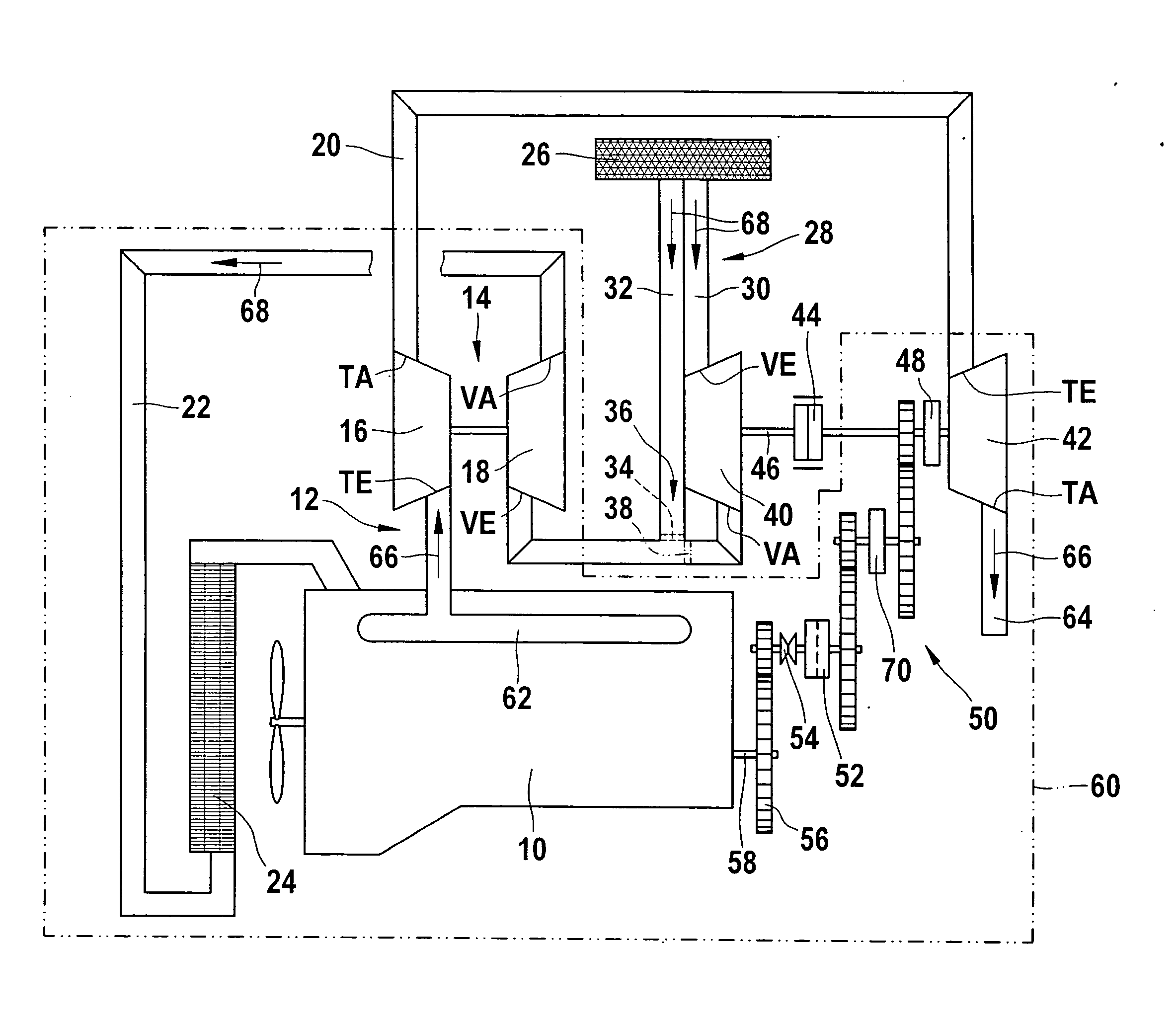

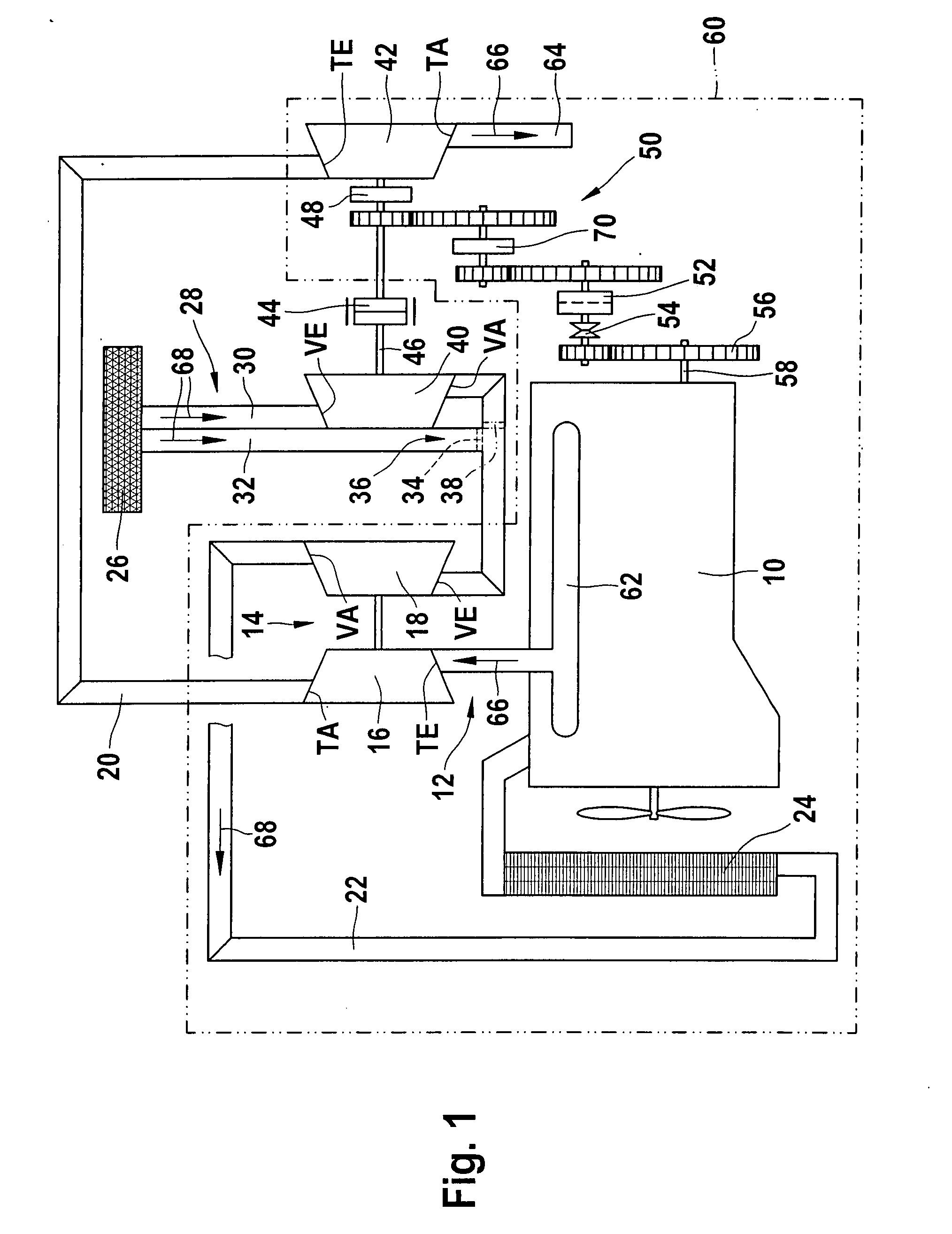

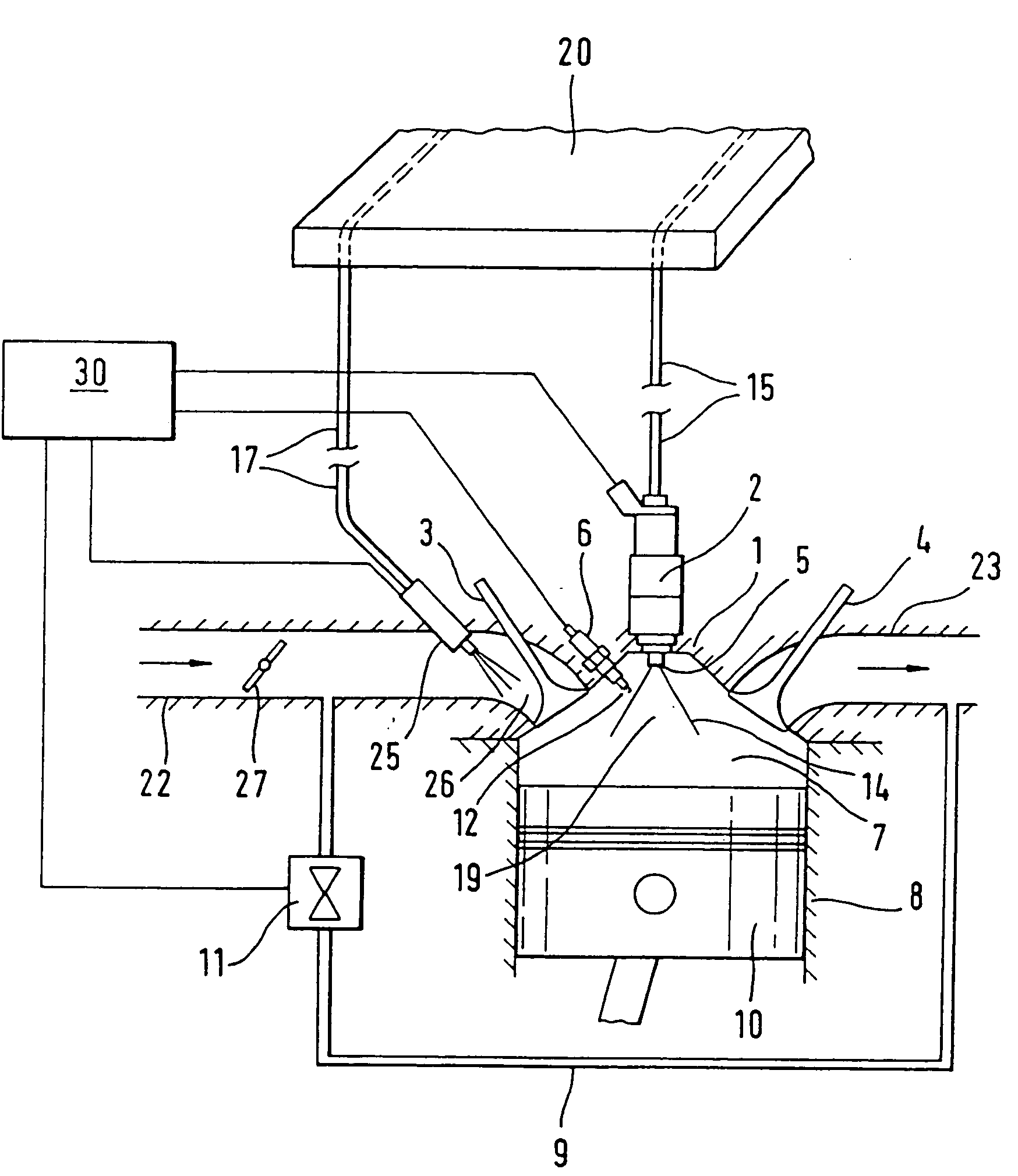

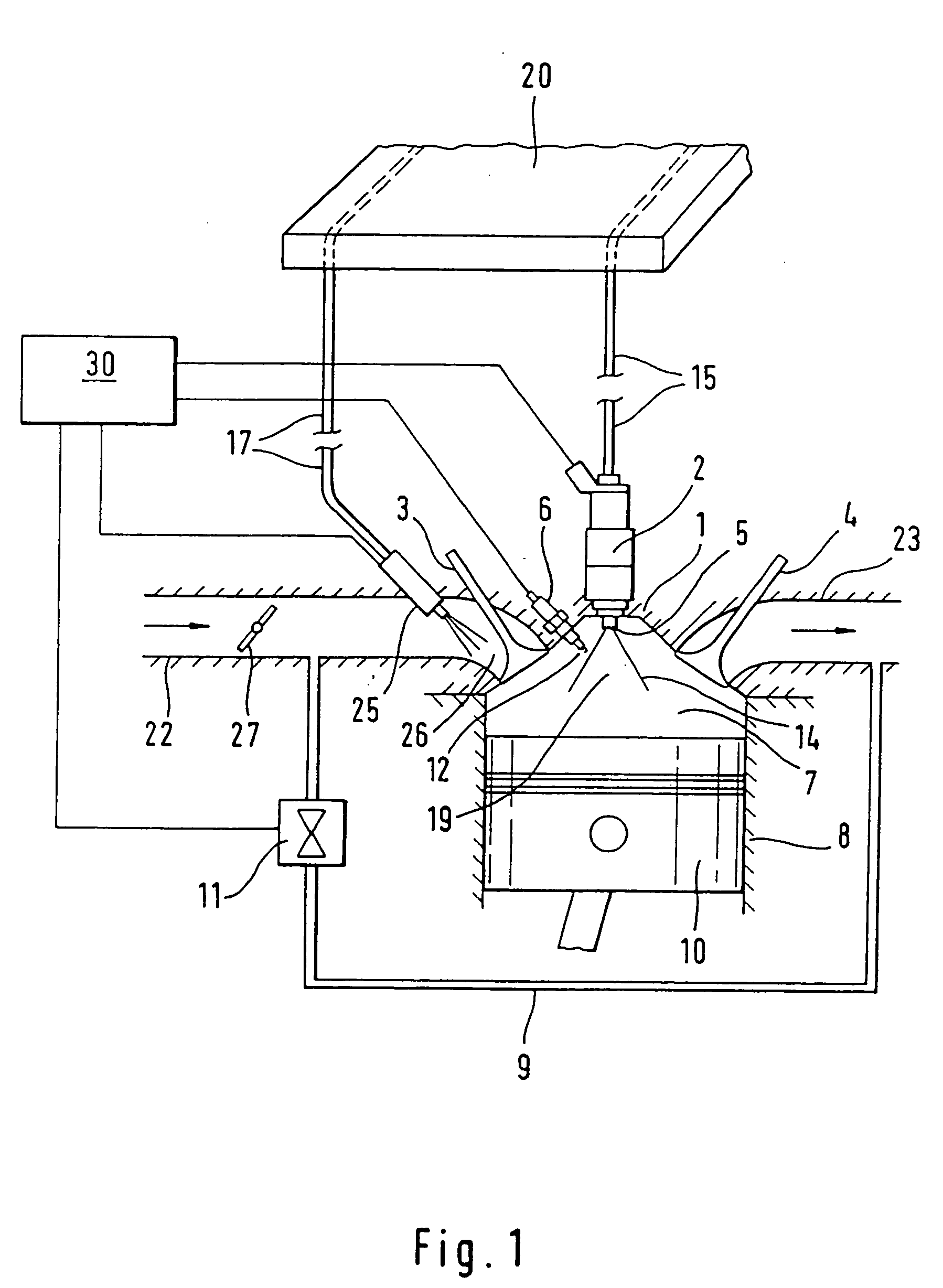

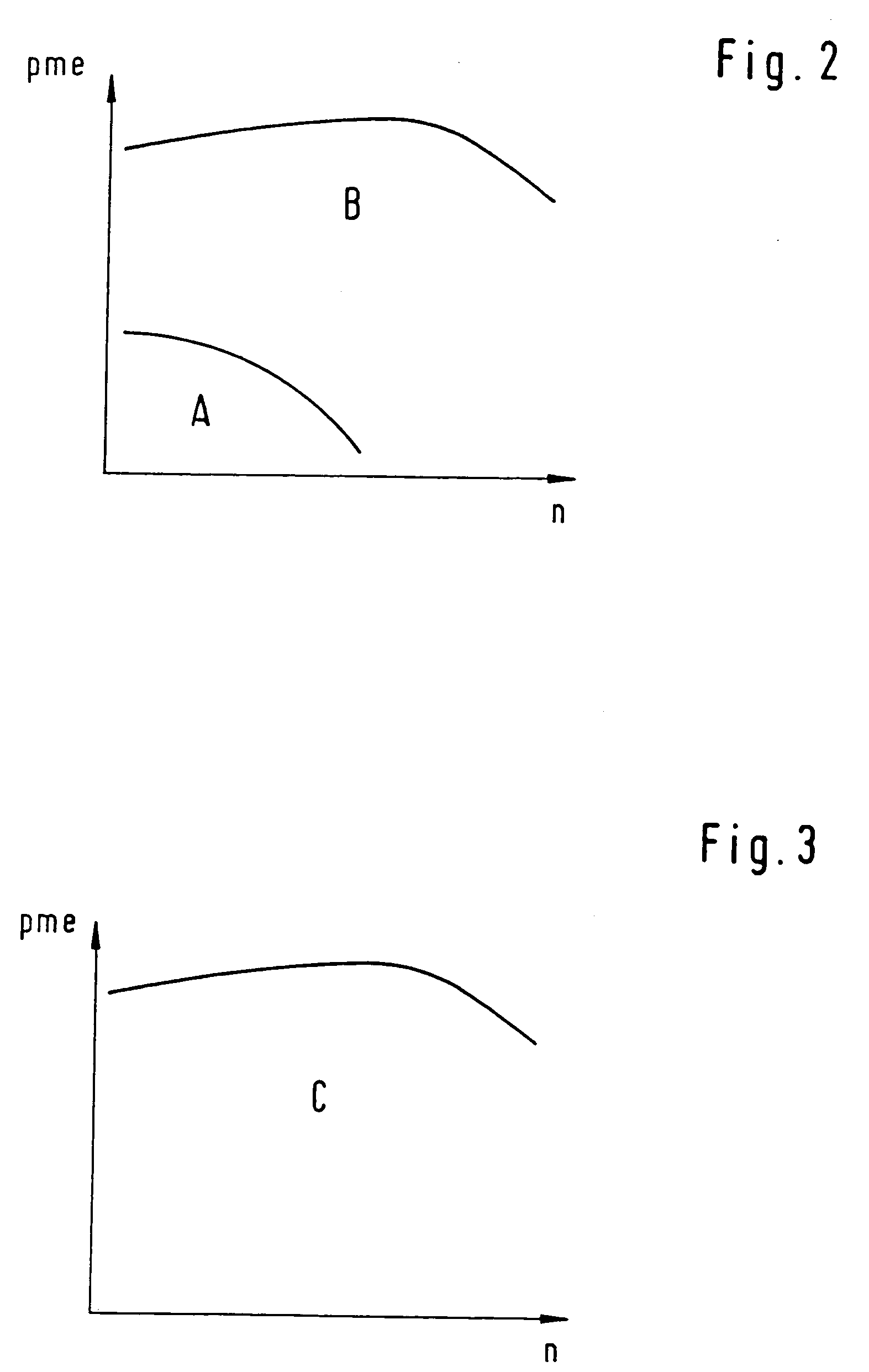

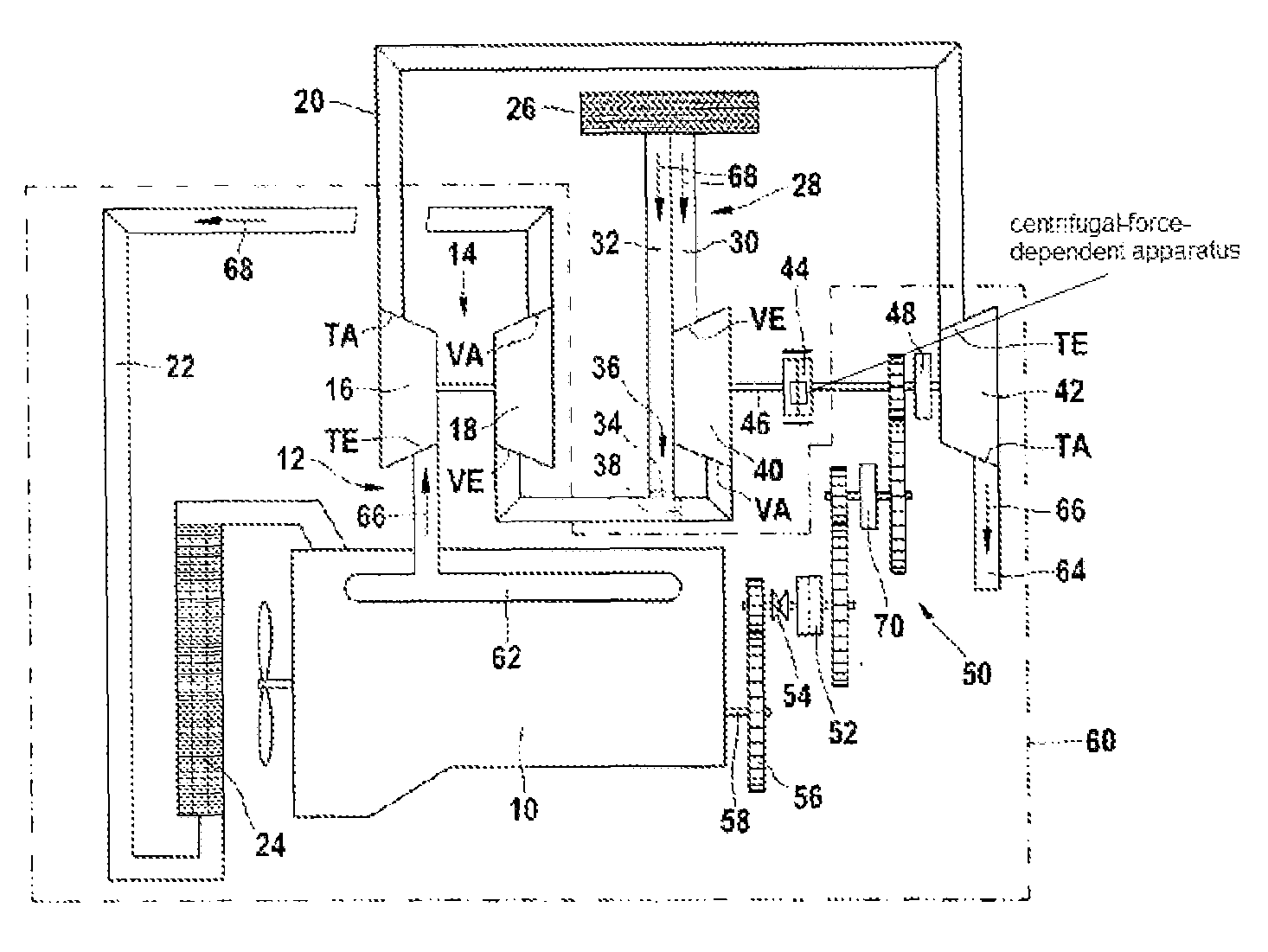

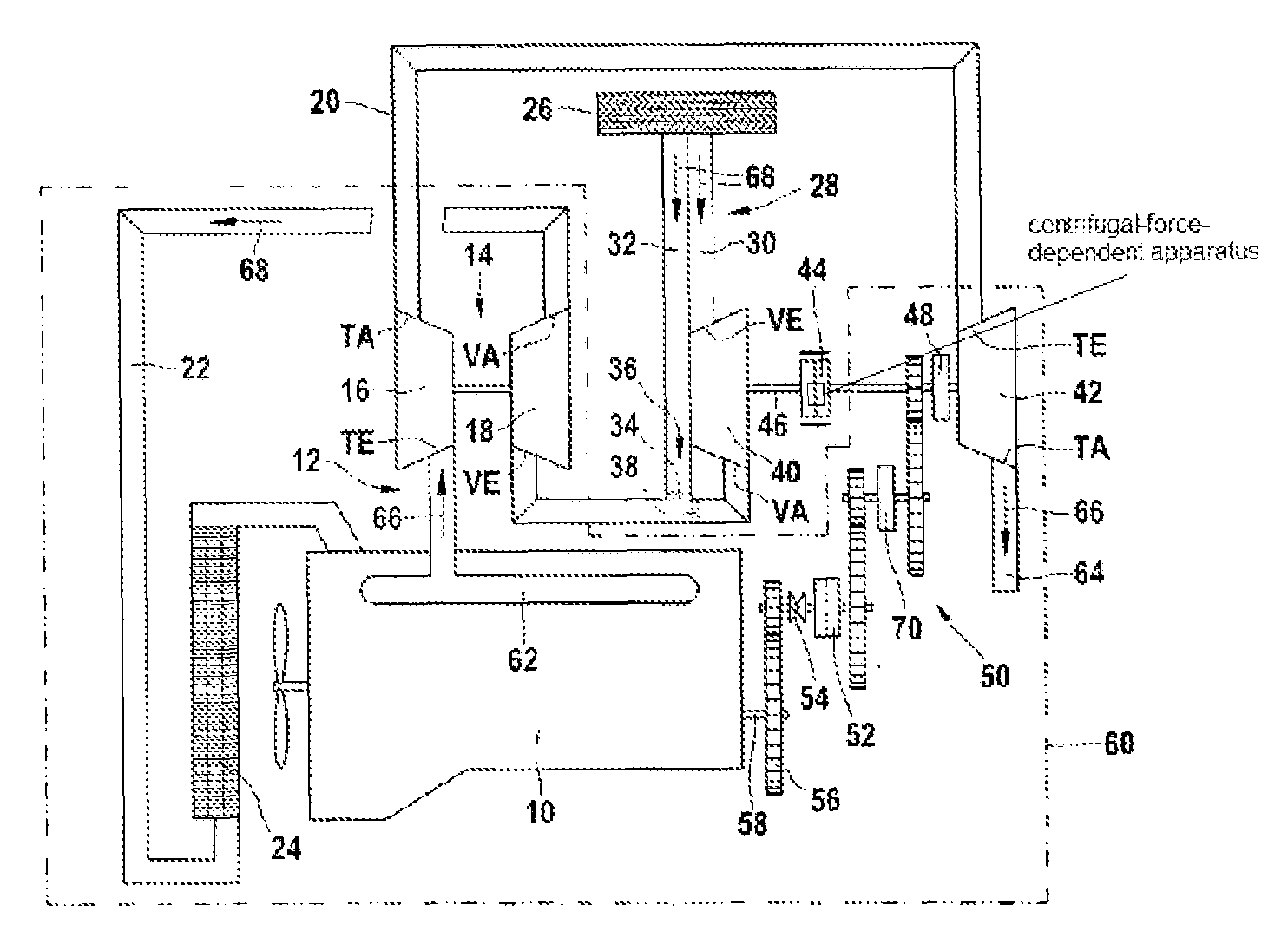

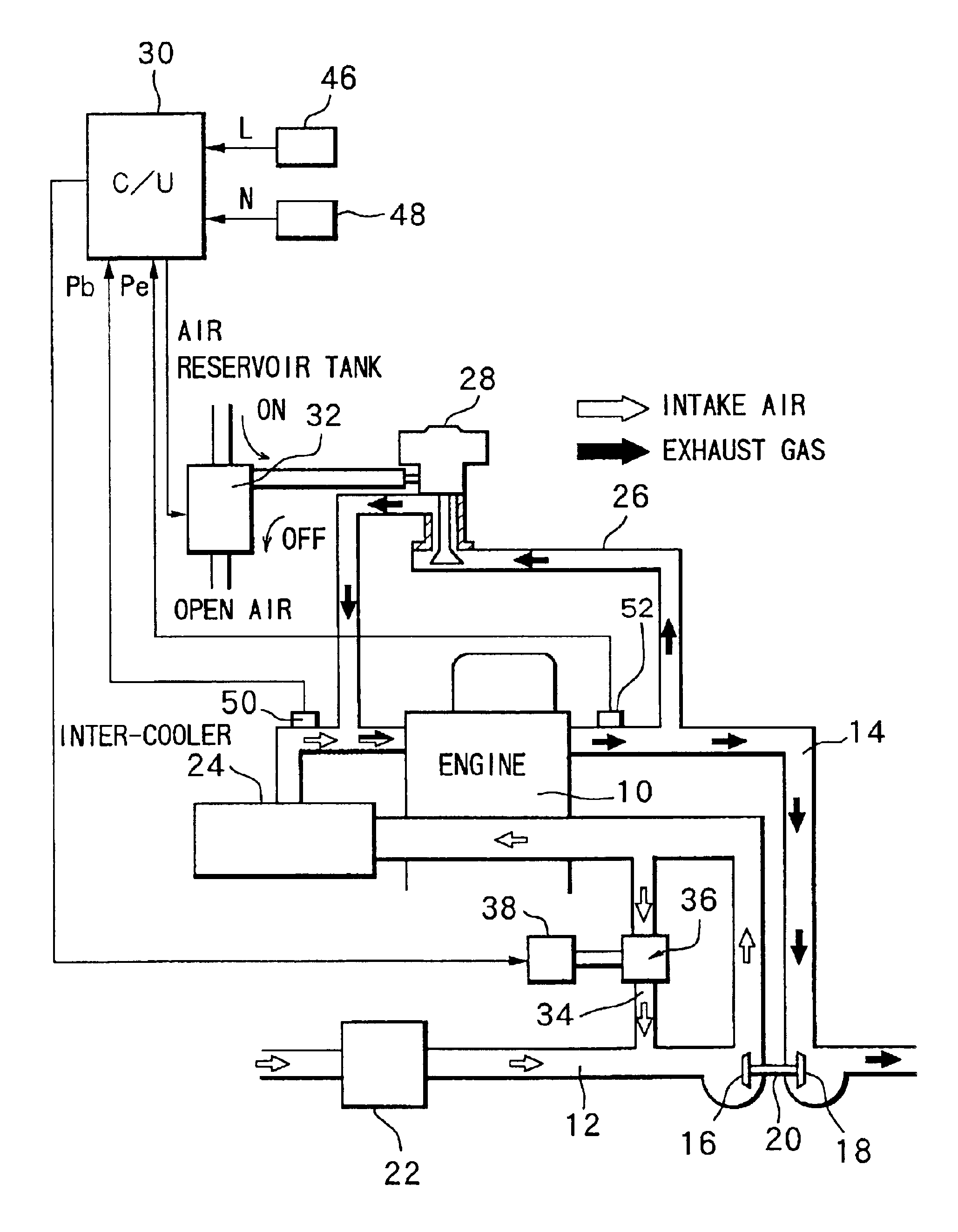

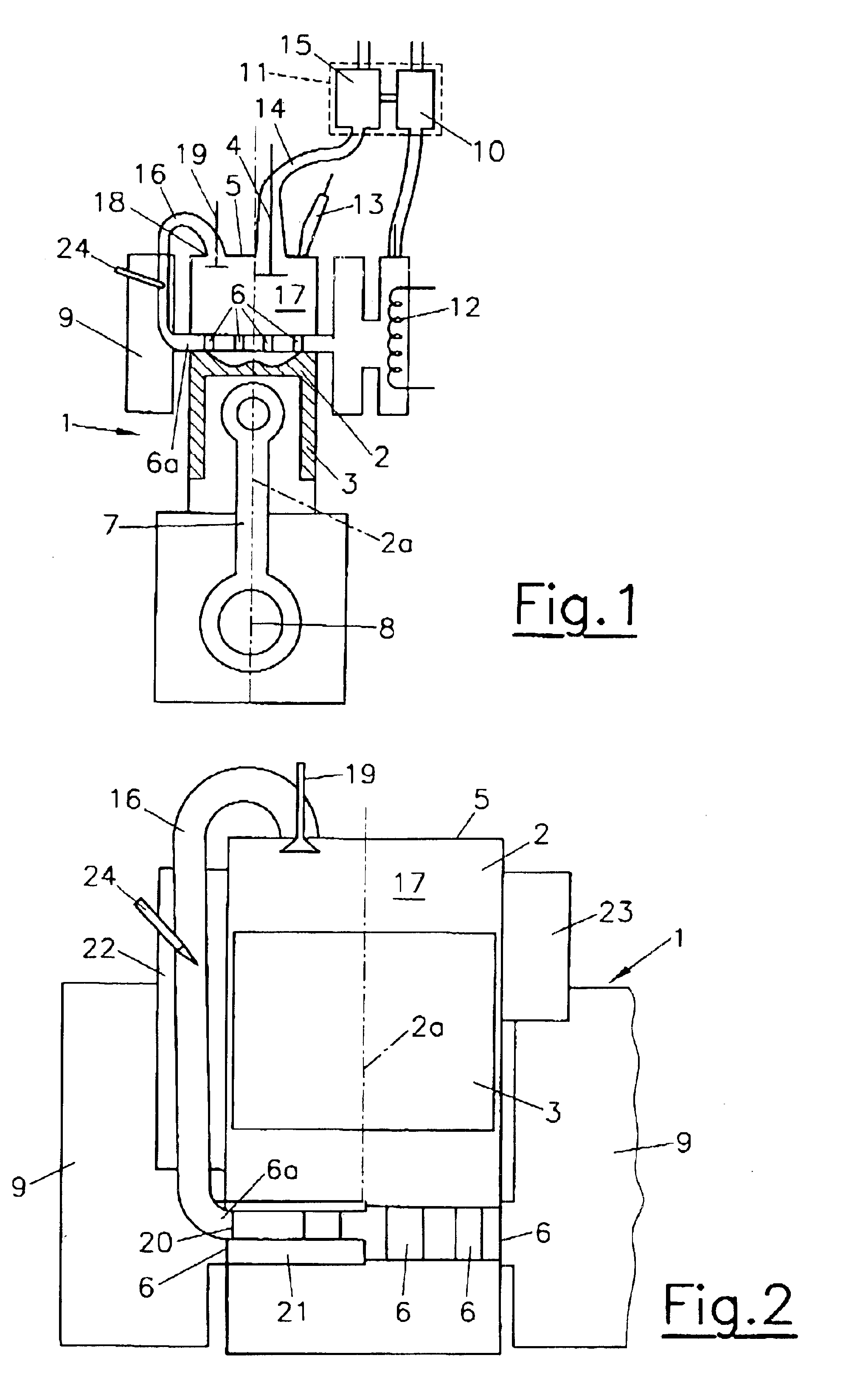

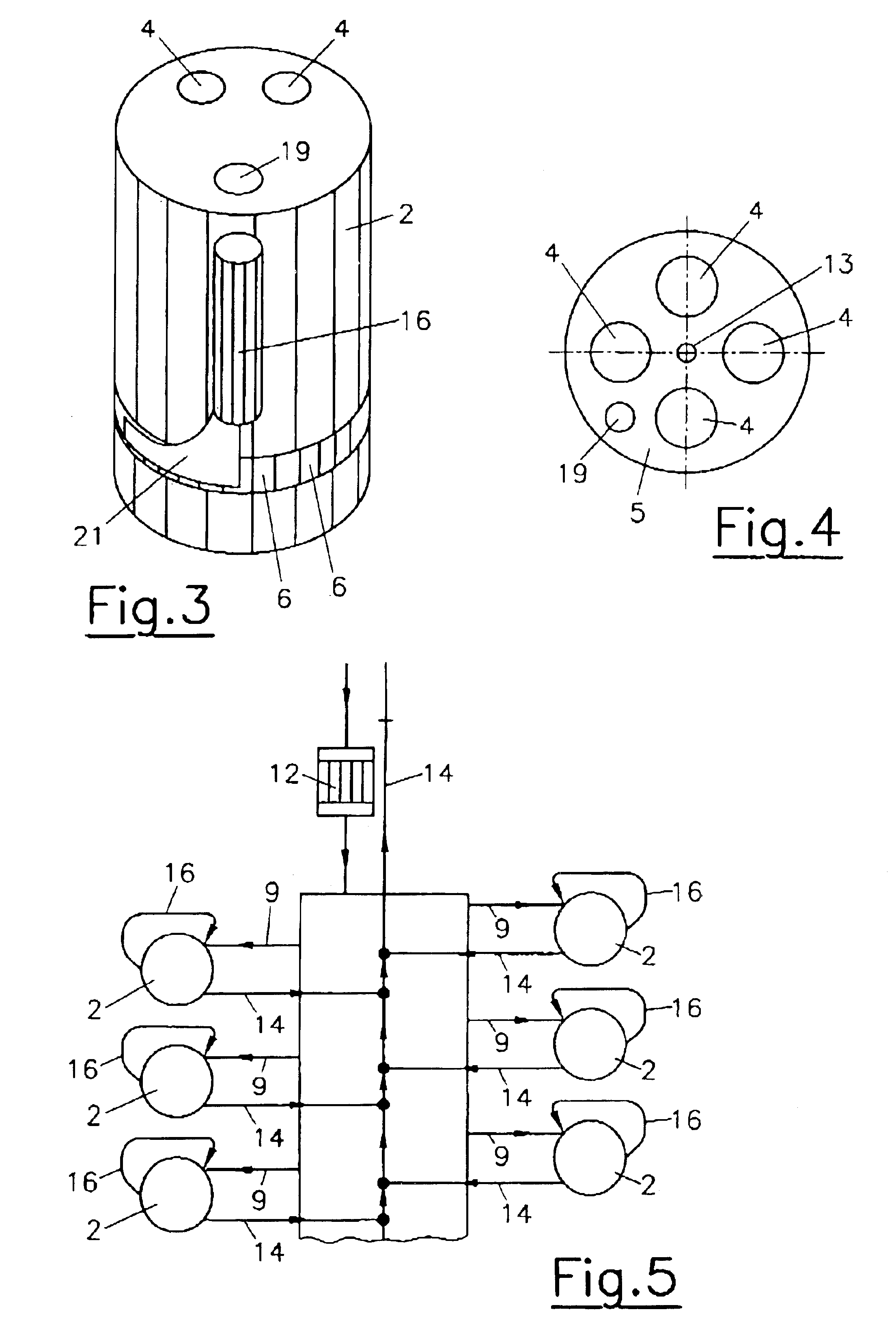

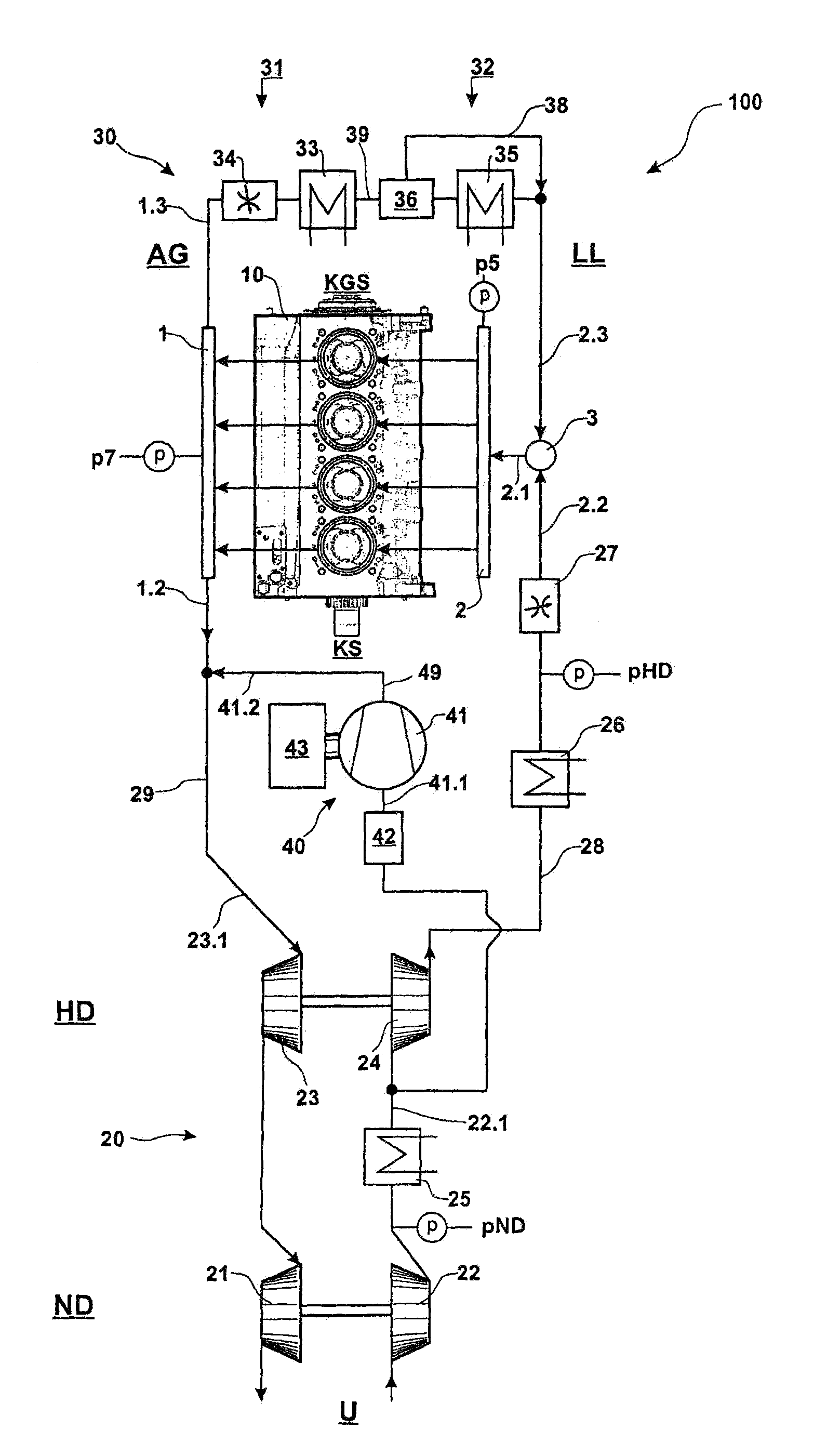

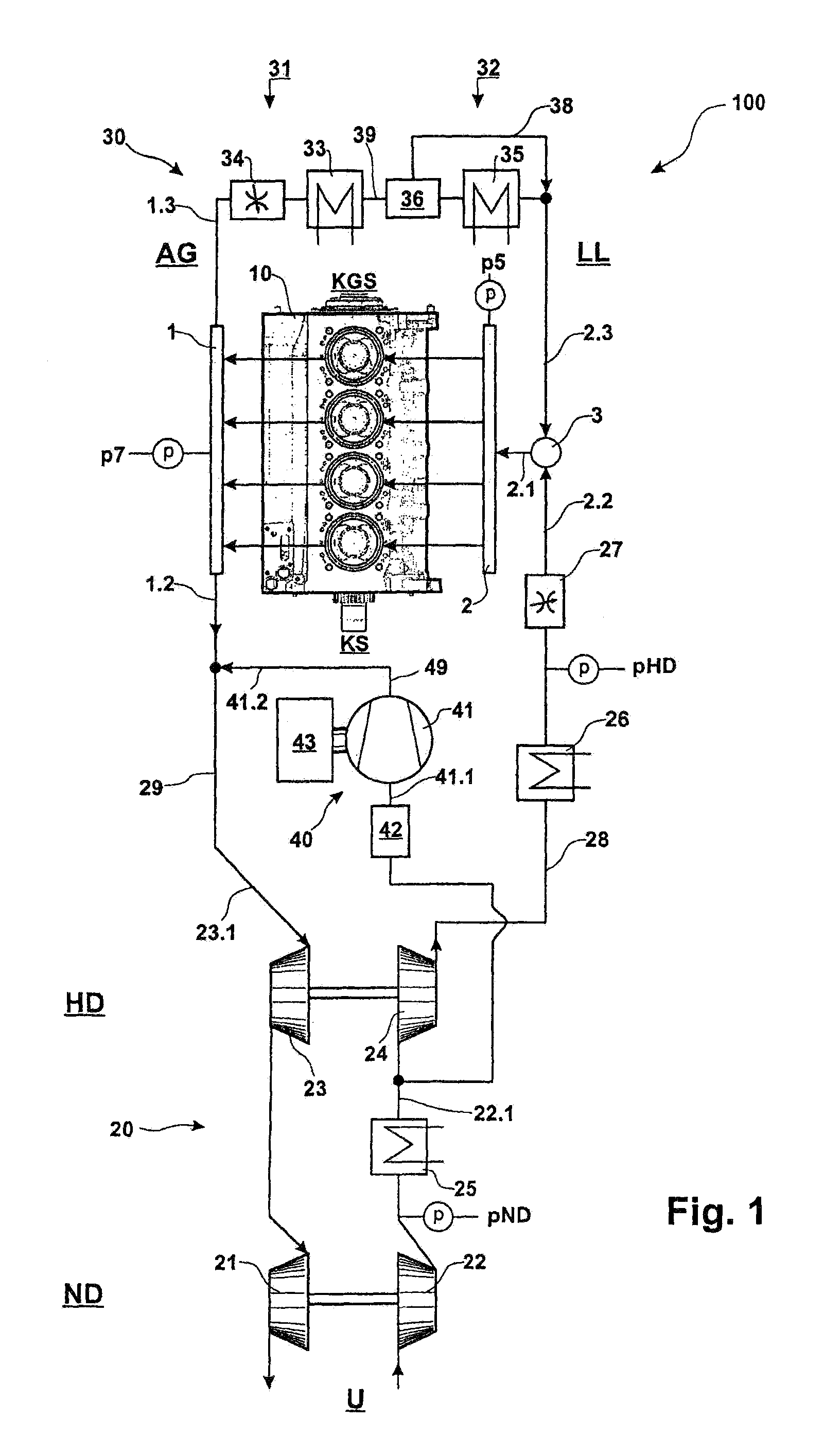

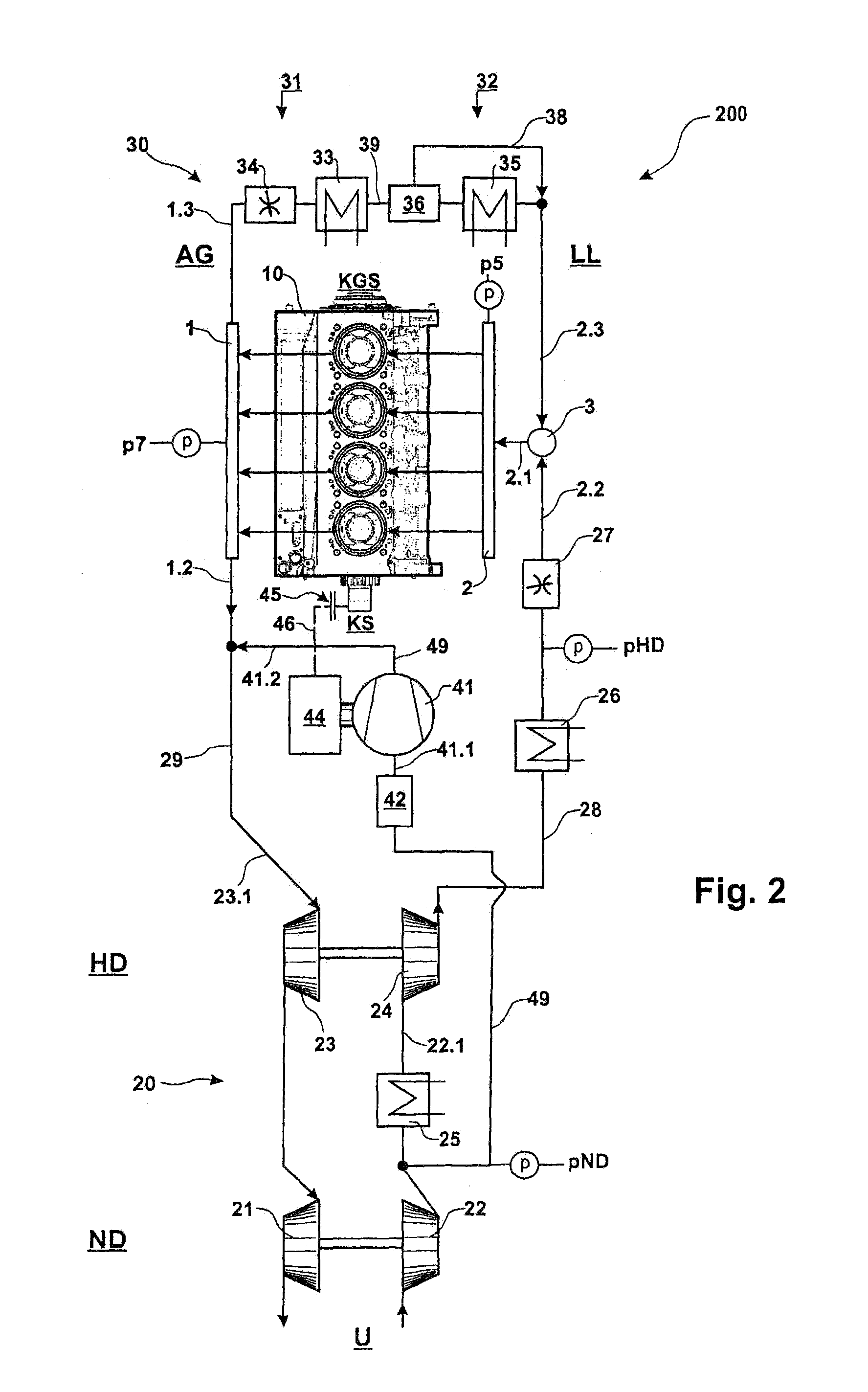

Method and system for influencing the quantity of exhaust gas recirculated in a pressure charged internal combustion engine

InactiveUS20060101819A1High recycling rateImprove pressure resistanceInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerExhaust fumes

The invention relates to a pressure charged internal combustion engine (1) having at least two cylinders (3), configured to form two groups (3′, 3″) each with a separate exhaust line (4′, 4″), and two exhaust-gas turbochargers connected in parallel (6, 7), a first turbine (6a) being arranged in the exhaust line (4′) of the first group (3′) and a second turbine (7a)) being arranged in the exhaust line (4″) of the second group (3 ″) and the compressors (6b, 7b) coupled to these turbines (6a, 7a) arranged in separate intake lines (2′, 2″), which converge to form an intake manifold (2) to supply the internal combustion engine (1) with fresh air. The invention relates to a method of influencing the quantity of exhaust gas recirculated by a pressure charged internal combustion engine (1). The pressure charged internal combustion engine is capable of achieving high exhaust gas recirculation rates and high boost pressures simultaneously.

Owner:FORD GLOBAL TECH LLC

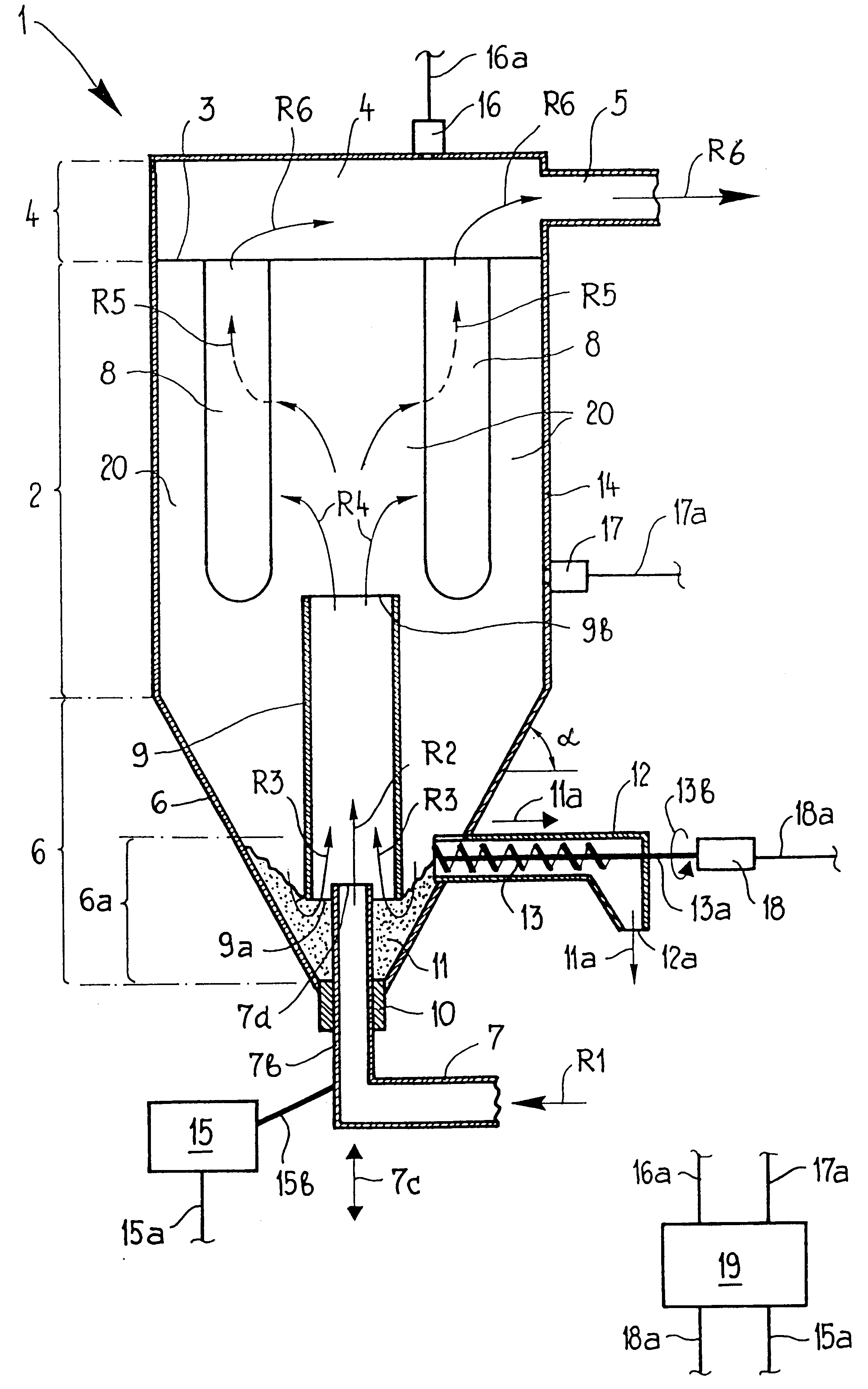

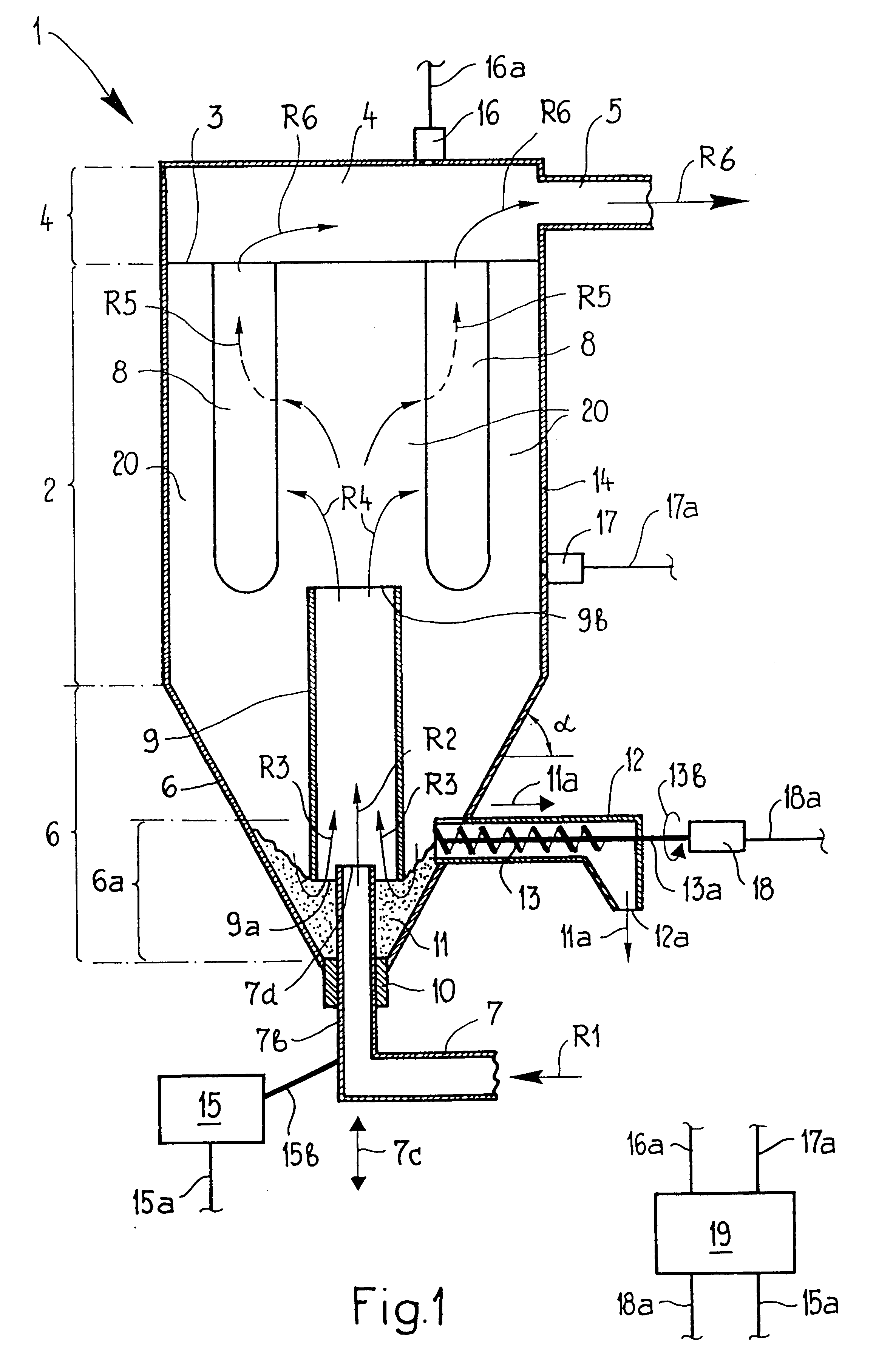

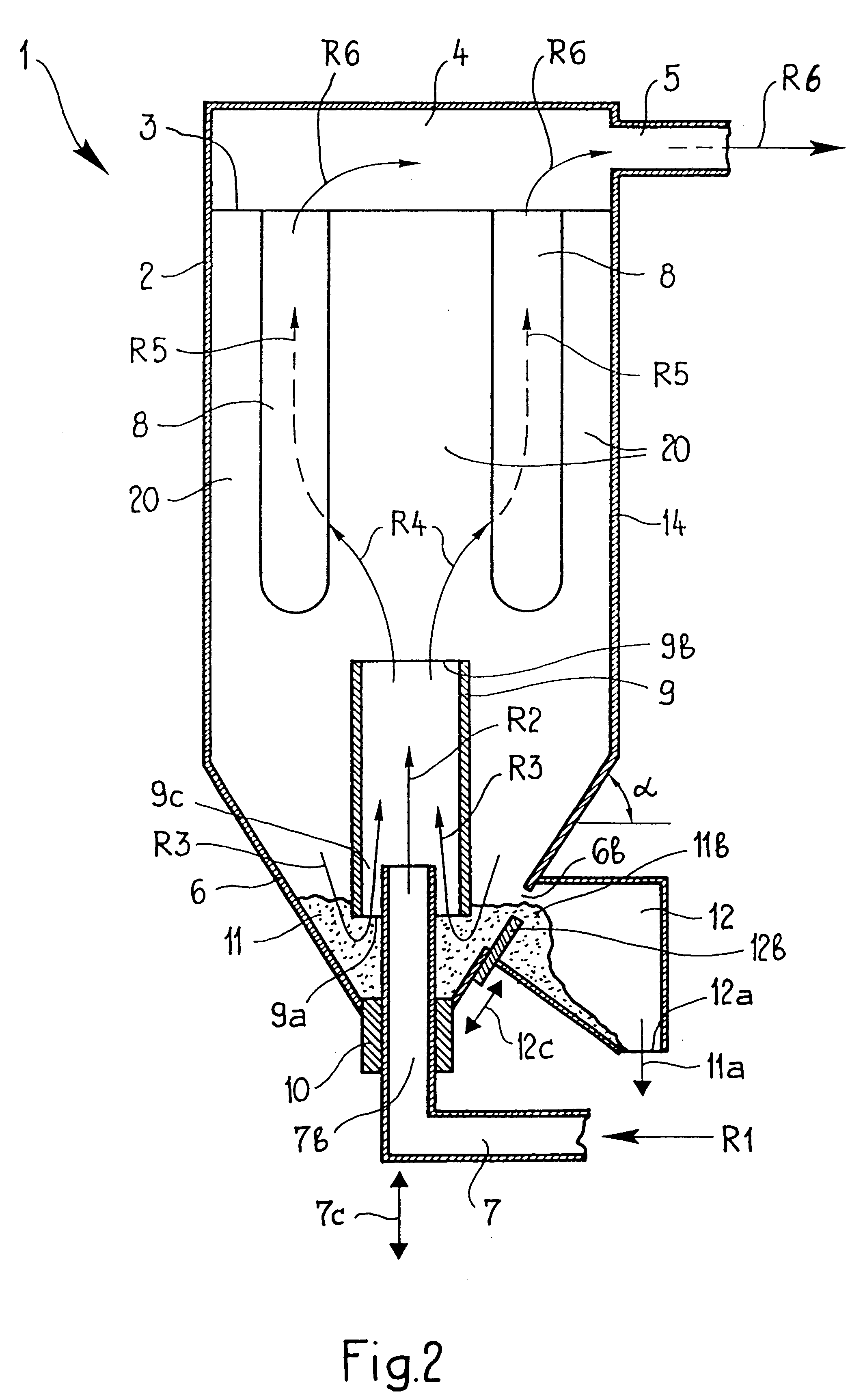

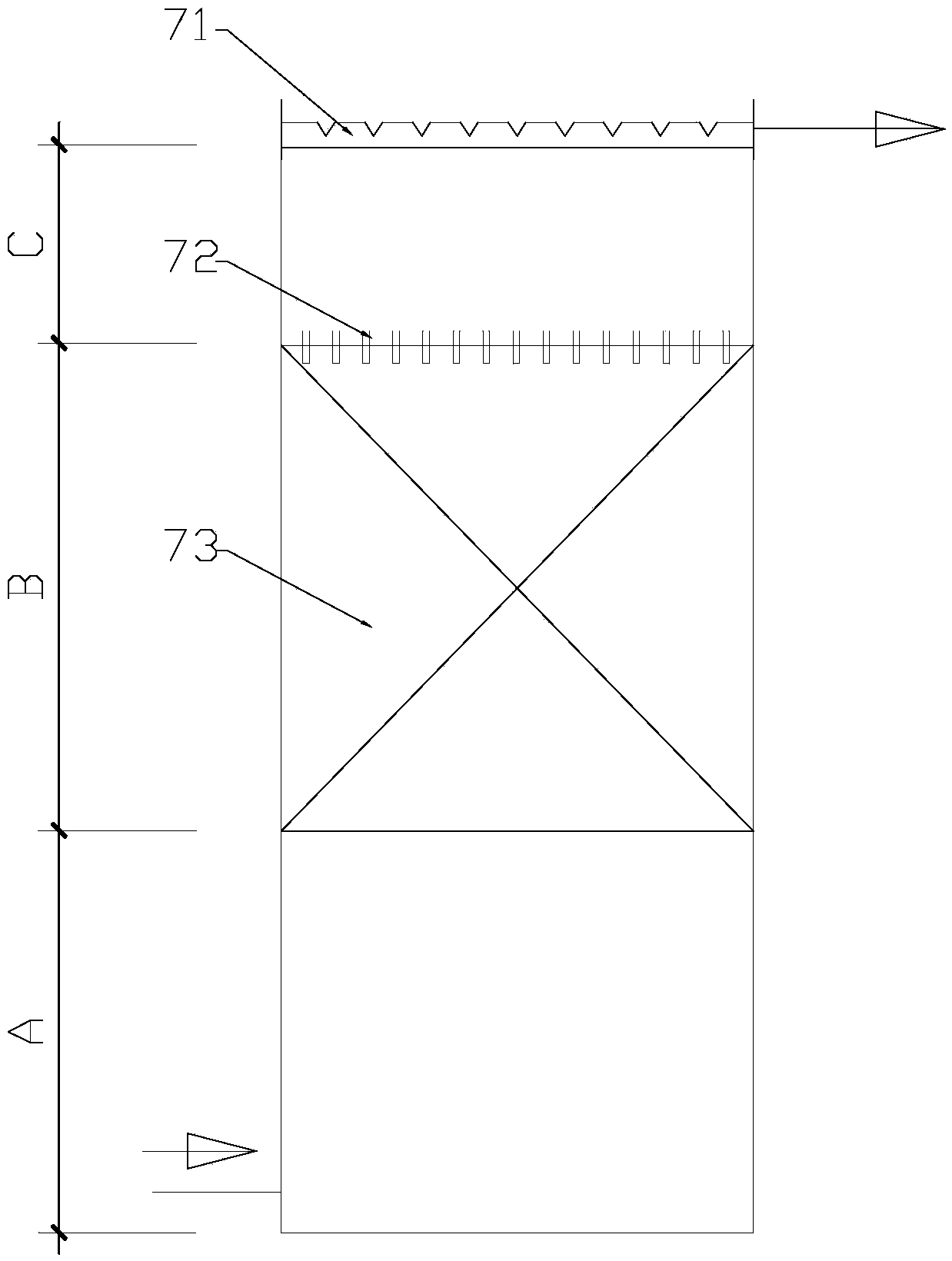

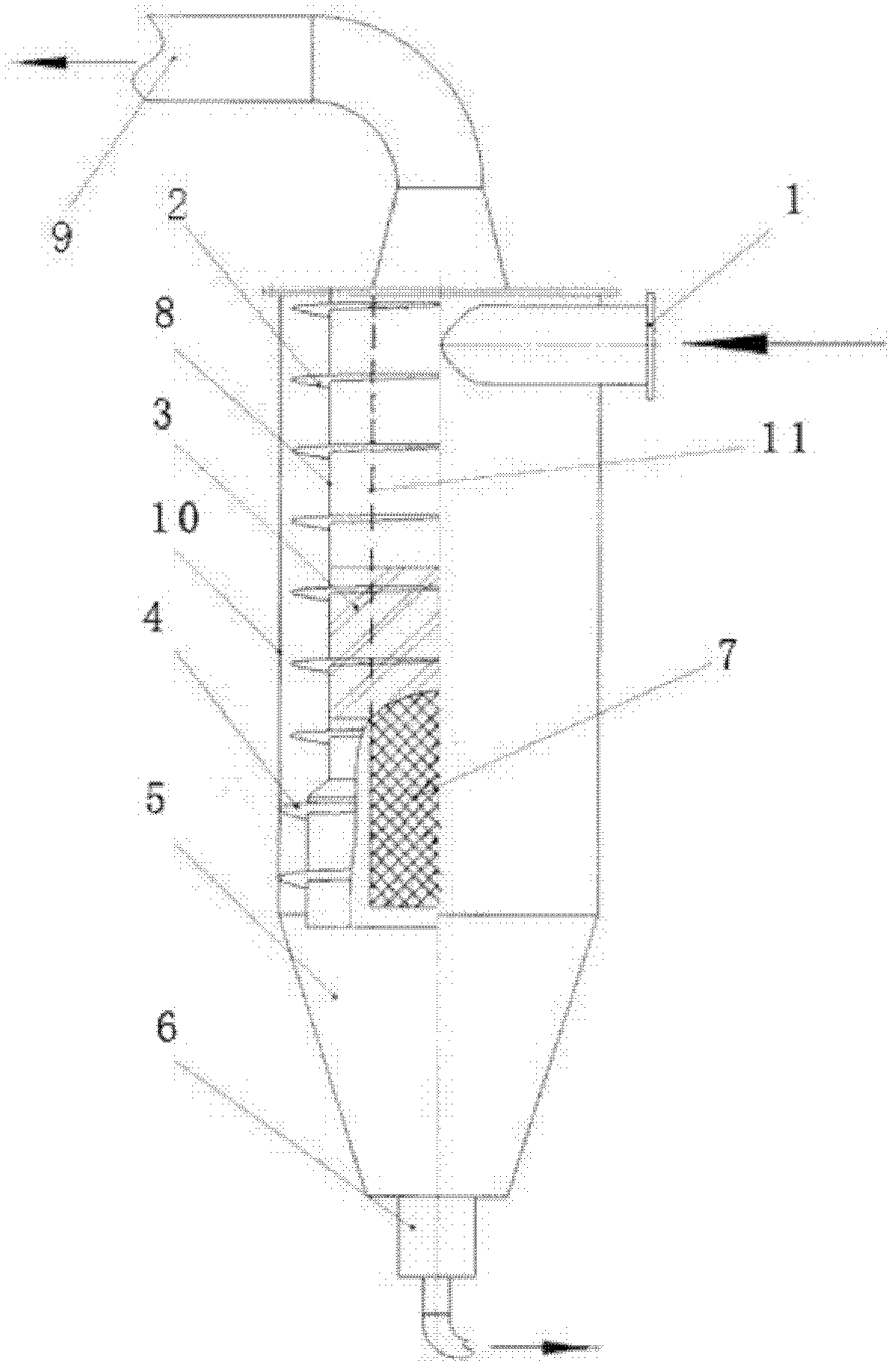

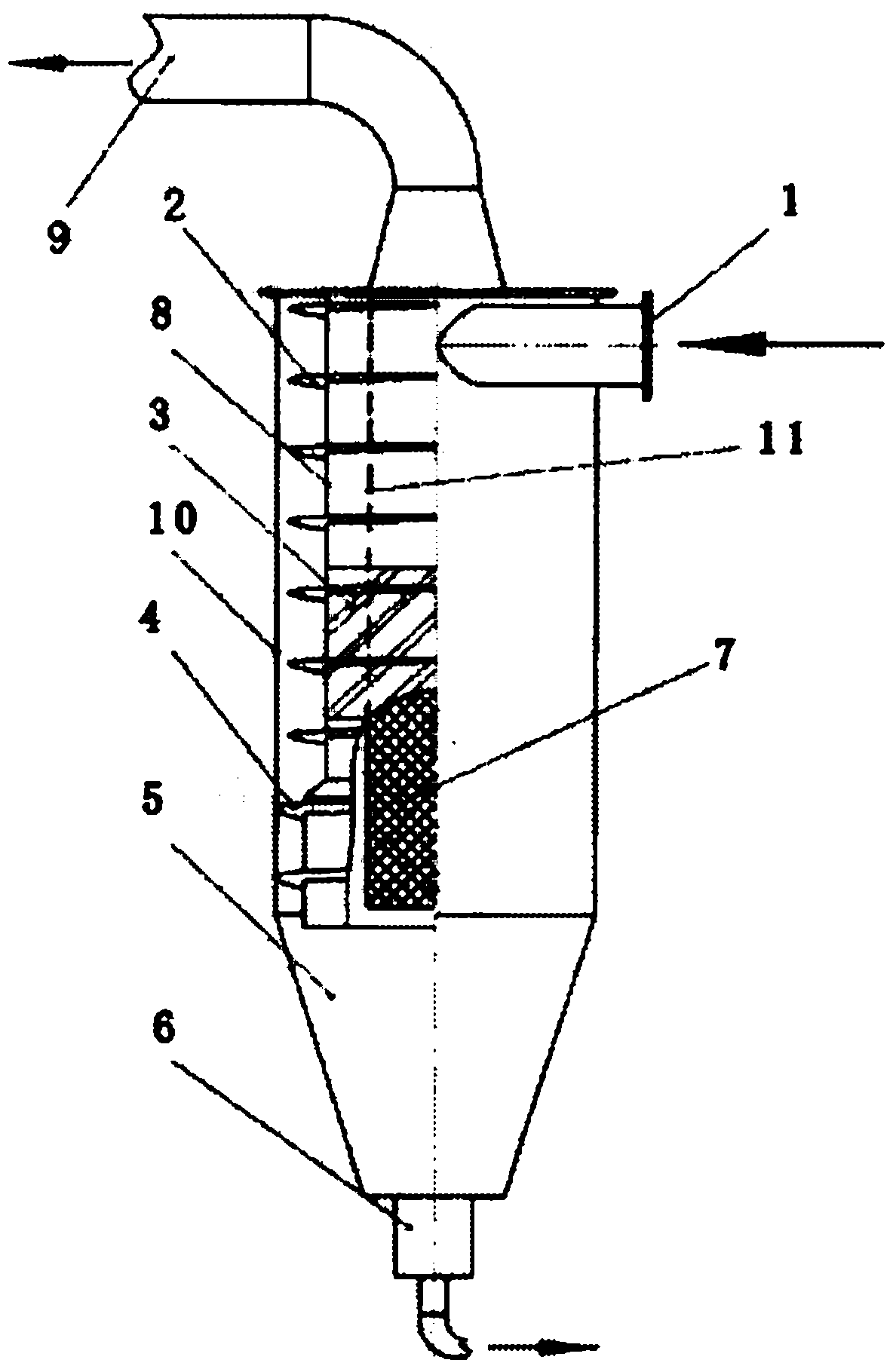

Device and process for adsorption or chemisorption of gaseous constituents from a gas flow

InactiveUS6290752B1High densityHigh recycling rateCombination devicesAuxillary pretreatmentChemisorptionProduct gas

A filter device for adsorption of gaseous constituents from a gas flow includes a filter chamber with filters arranged therein, a clean-gas chamber connected to the first chamber in a fluid-conducting manner via the filters, and a collection chamber arranged beneath the filter chamber, is open toward the filter chamber and has an interior which narrows toward the bottom. An unfiltered-gas duct which leads from the outside, is arranged in the lower area of the collection chamber in such a manner that it can be adjusted in the direction toward the filters. A dust-discharge device, which leads toward the outside, is arranged in the lower area.

Owner:VOL ROLL UMWELTTECHNIK AG

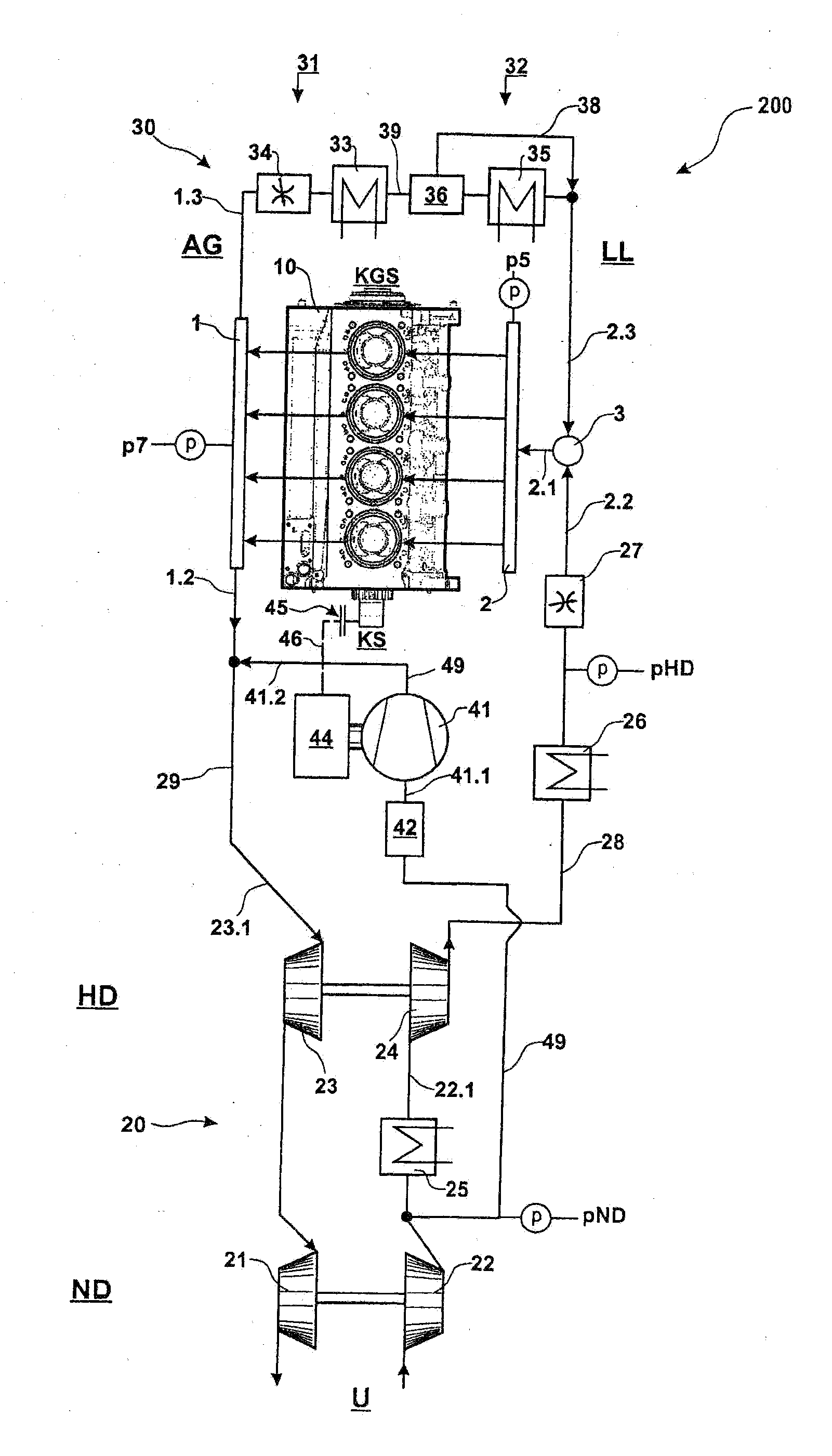

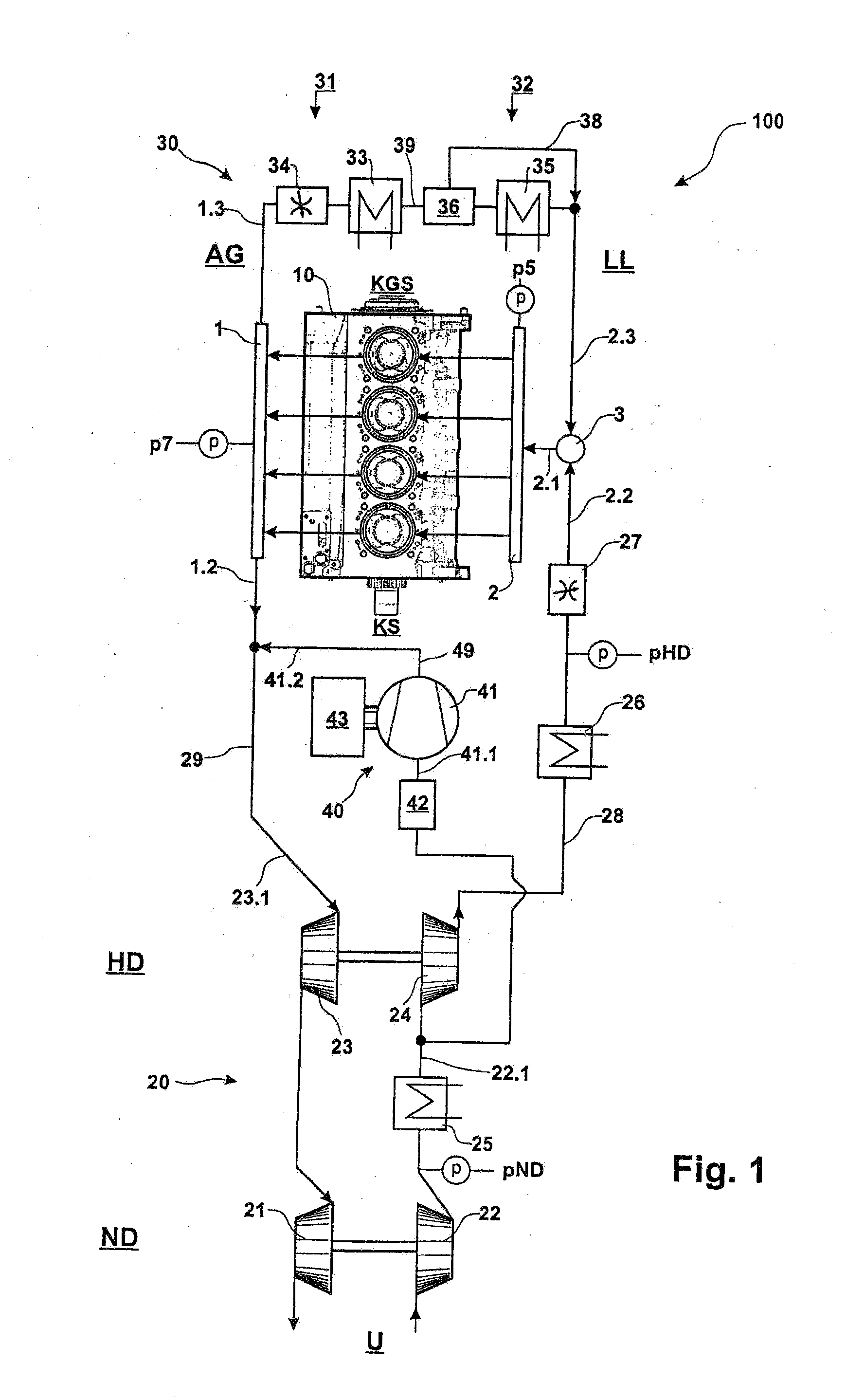

Internal combustion engine

ActiveUS20130232972A1Prevent scalingIncrease high pressureInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerControlled combustion engine

In an exhaust gas turbocharger system for charging an engine including a compressor arrangement at a charging fluid side LL and a turbine arrangement at an exhaust gas side AG, a further compressor which is driven by a separate controllable drive and whose primary side is connected to the charging fluid side LL while its secondary side is connected to the exhaust gas side is provided for compressing charge air taken from the charging fluid side and supply it to the exhaust gas side for assisting driving the exhaust gas turbines so as to maintain them at relatively high speeds in transition periods including engine idling.

Owner:MOTOREN & TURBINEN UNION FRIEDRICHSHAFEN GMBH

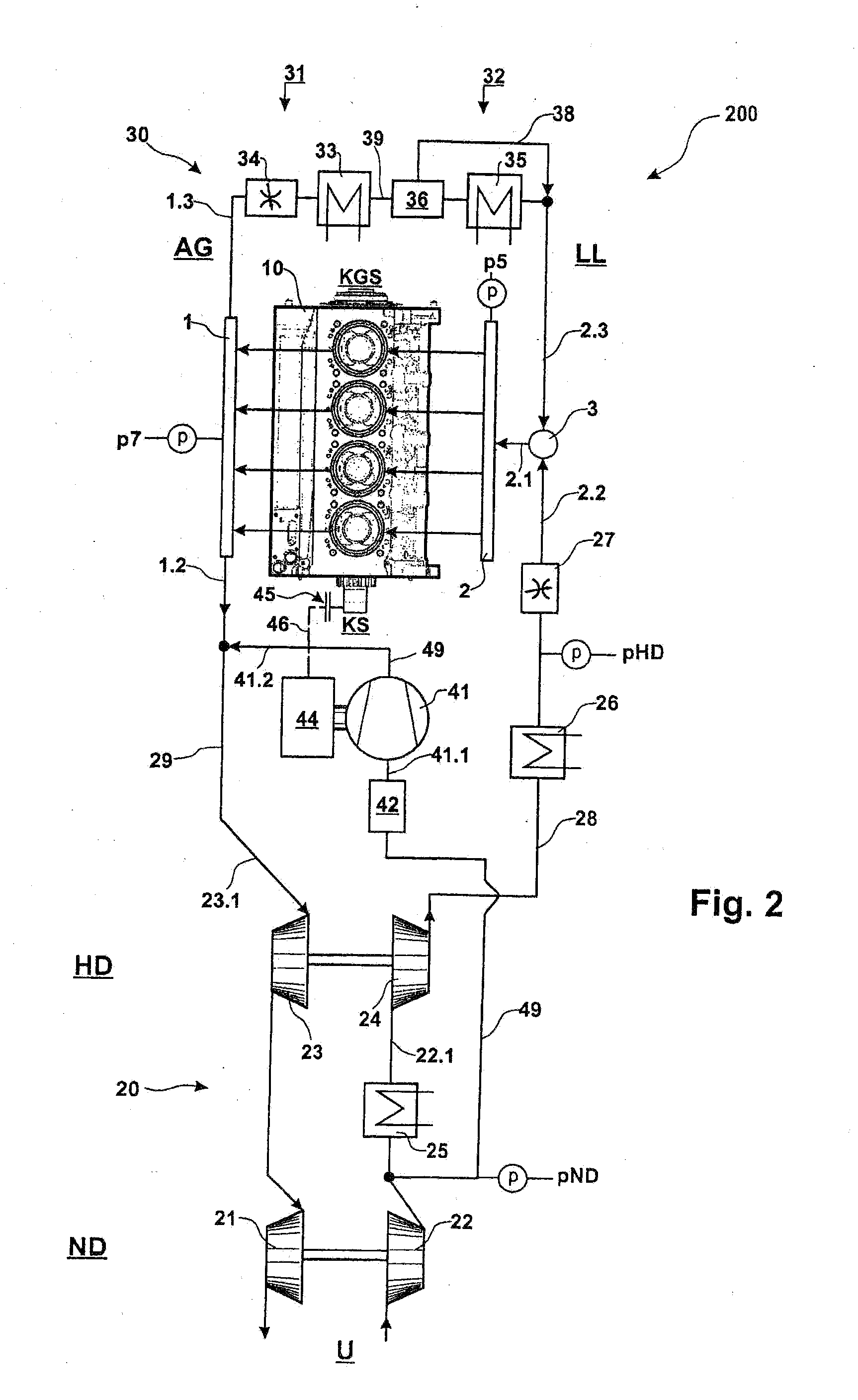

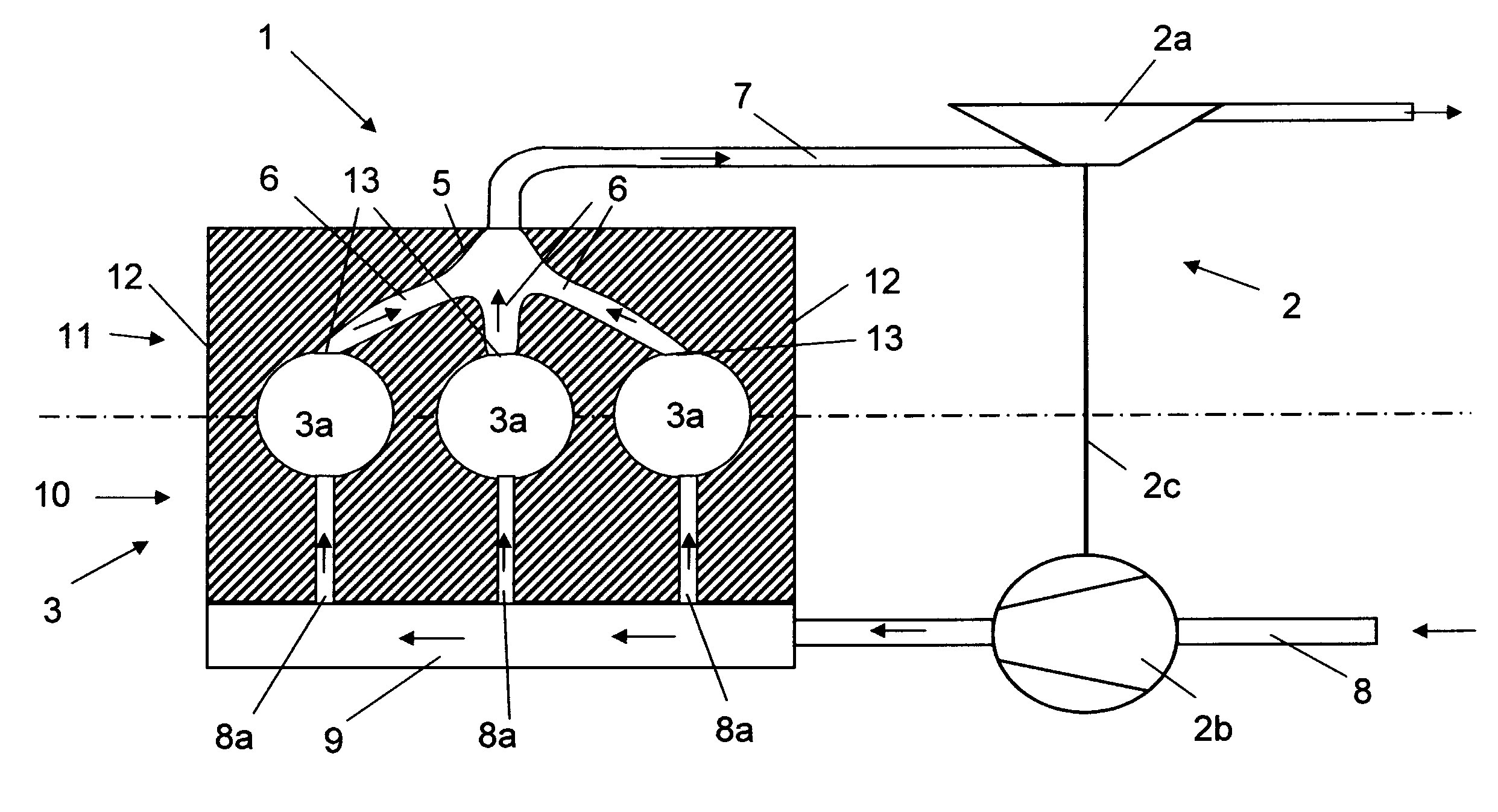

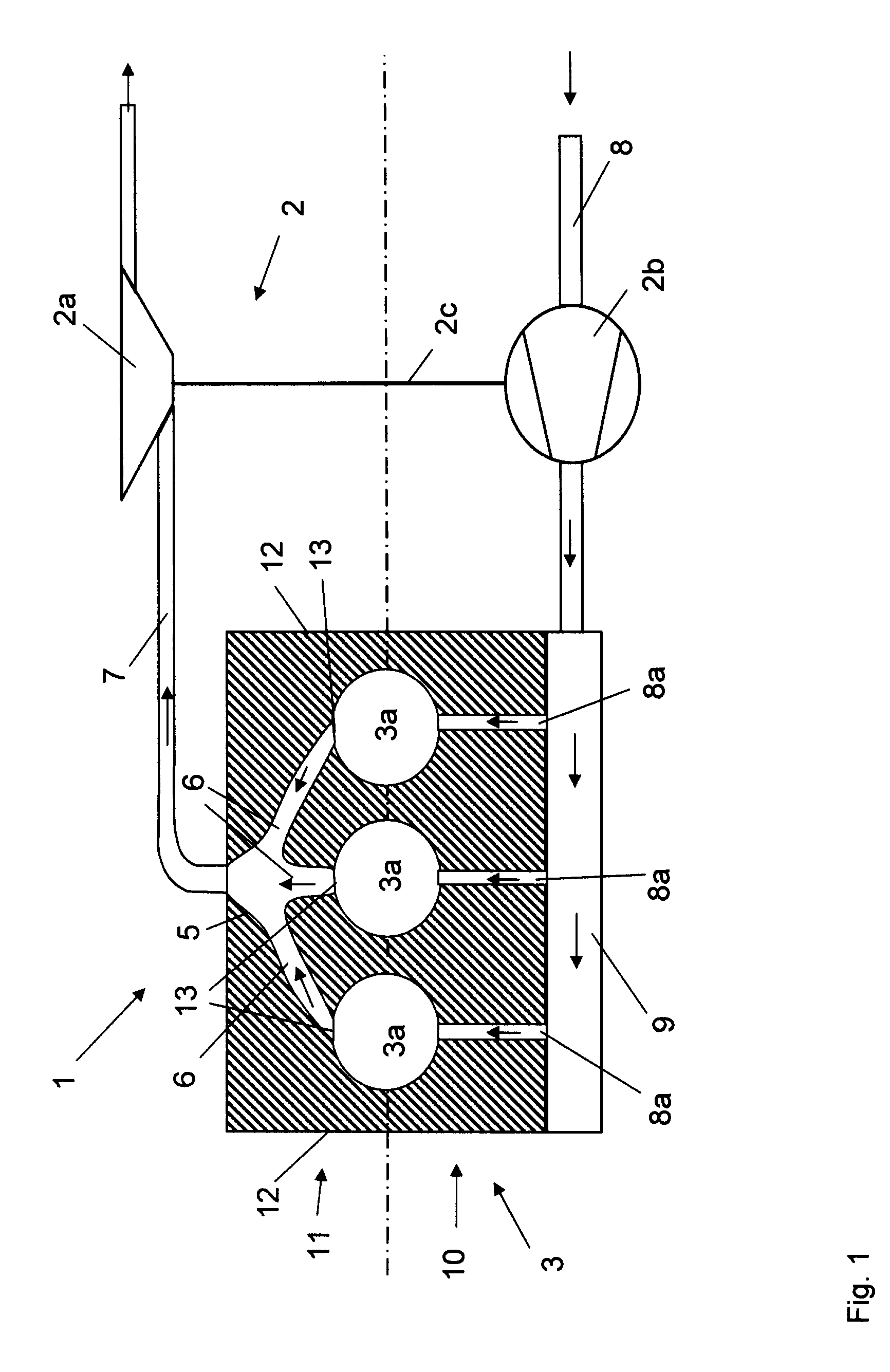

Internal combustion engine with exhaust-gas turbocharging

InactiveUS20100175374A1Reduce total powerLow efficiencyNon-fuel substance addition to fuelCylinder headsCombustionCylinder head

Disclosed is a turbocharged internal combustion engine (1) having at least one intake (8) for supplying the internal combustion engine (1) with fresh air or fresh mixture on an inlet side (10), a cylinder head (3) having at least two cylinders (3a) which are arranged along a cylinder head longitudinal axis (4) and each of which has at least one outlet opening (13) which is adjoined by an exhaust line (6) for discharging the exhaust gases out of the cylinder (3a), with the exhaust lines (6) of at least two cylinders (3a) being merged on an outlet side (11), so as to form an integrated exhaust manifold (5) within the cylinder head (3), to form an overall exhaust line (7), and at least one exhaust-gas turbocharger (2) which comprises a turbine (2a) arranged in the overall exhaust line (7) and a compressor (2b) arranged in the at least one intake (8), with the turbine (2a) having a turbine rotor, which is provided on a charger shaft (2c), and an inlet region for supplying the exhaust gas, and the compressor (2b) having a compressor rotor, which is arranged on the charger shaft (2c), and an outlet region for discharging the compressed combustion air.

Owner:FORD GLOBAL TECH LLC

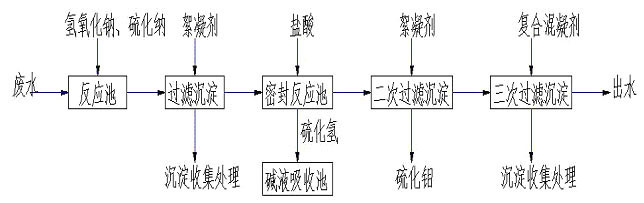

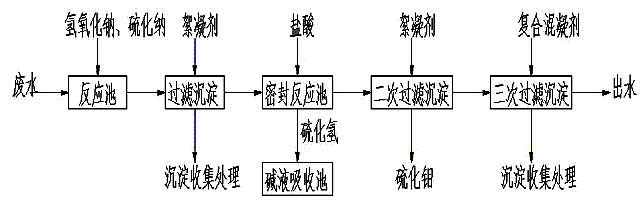

Method for purifying molybdenum sulfide in heavy metal waste water containing molybdenum, and the like

ActiveCN101973652AReduce purification costsReduce contentMultistage water/sewage treatmentWater/sewage treatment by neutralisationAluminium chlorideMolybdic acid

The invention belongs to the technical field of water treatment, in particular to a method for purifying molybdenum sulfide in heavy metal waste water containing molybdenum, and the like. The method comprises the following steps of: putting waste water containing the heavy metal molybdenum and other heavy metals to be purified in a reaction tank; regulating the waste water to alkalinity and adding sodium sulfide for reacting; filtering the waste water and putting filtered water in a sealing device; regulating the pH value of the waste water to 1-3 and reacting at normal temperature to guarantee that molybdenum acid radical ions are all converted into molybdenum sulfide to precipitate; absorbing gas generated by using an absorption tower, wherein sodium hydroxide is used as absorption liquid; adding polyacrylamide used as a flocculating agent to an obtained solution and quickly stirring for reacting; standing still; after the precipitate subsides, draining the supernate, filtering through a filtering device, and treating the precipitate for recycling; regulating the pH of the obtained acid solution to neutrality, adding a coagulant compounded by polymeric aluminum and ferrous sulphate and quickly stirring to remove redundant sulfur ions and further improve the quality of yield water; standing still; and after the precipitate subsides, filtering. The invention has the advantages of good treatment effect, simple and convenient treatment equipment, low treatment cost, higher purity of recovered molybdenum sulfide, and the like.

Owner:TONGJI UNIV

Compound Turbocharger System Having a Connectable Compressor

InactiveUS20110100339A1Considerable torque increasesImproves the initial-movement behaviorInternal combustion piston enginesOutput powerClutchExhaust gas

The invention relates to an internal combustion engine having a turbocompound system. The turbocompound system encompasses an exhaust-gas turbocharger, a turbo intercooler, and a power turbine. The power turbine is connectable, via a transmission with clutch, to the crankshaft of the internal combustion engine. A connectable compressor, which is couplable either to the power turbine or to the internal combustion engine, is received in a multiple-flow intake pipe.

Owner:ROBERT BOSCH GMBH

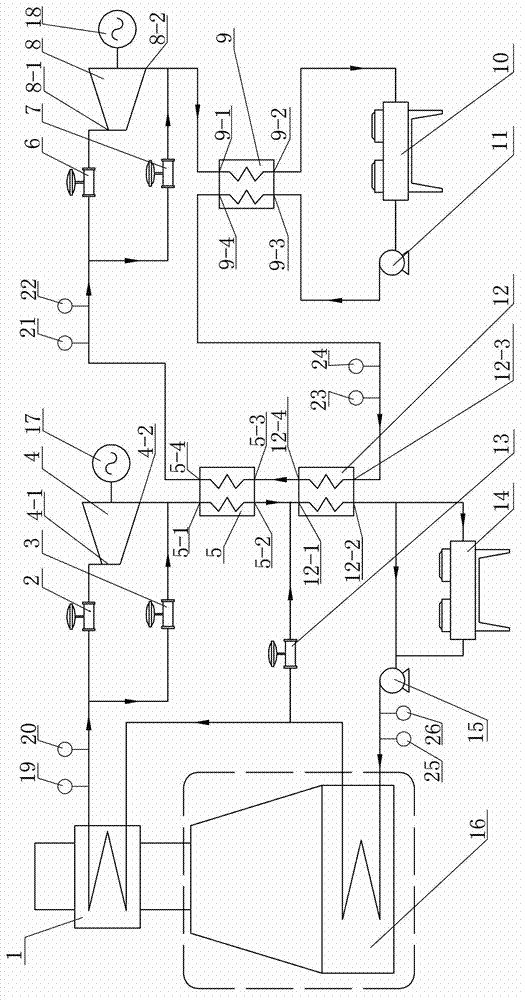

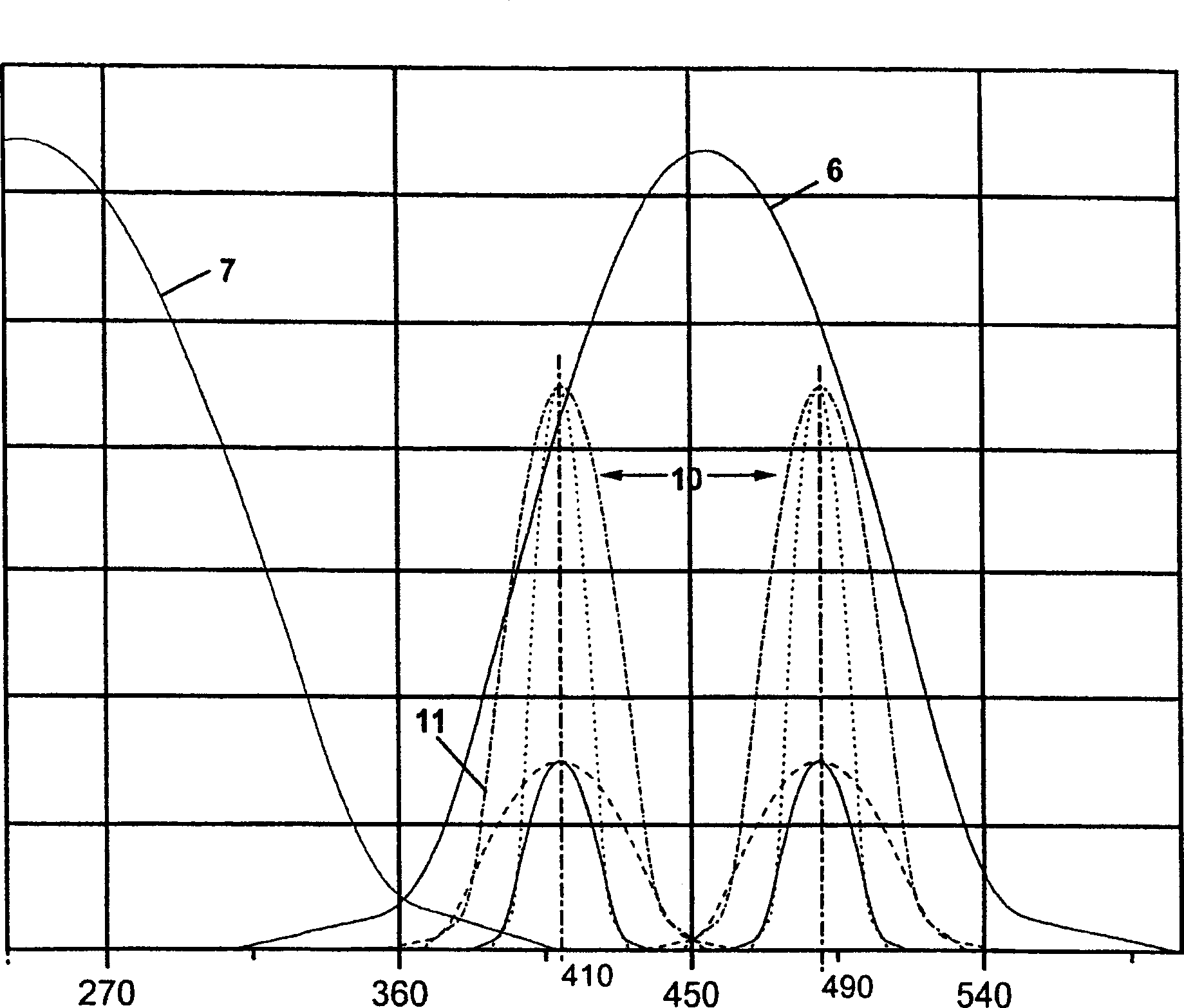

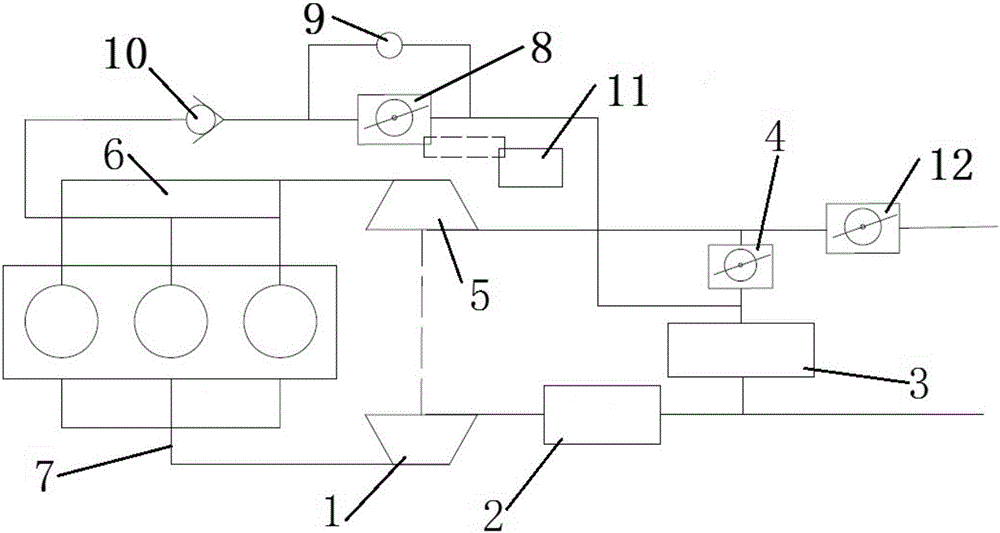

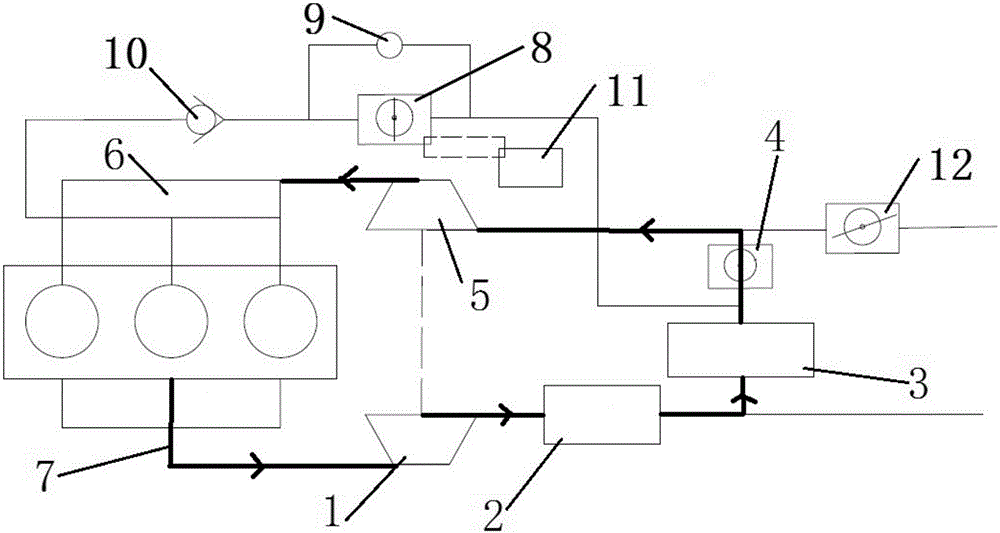

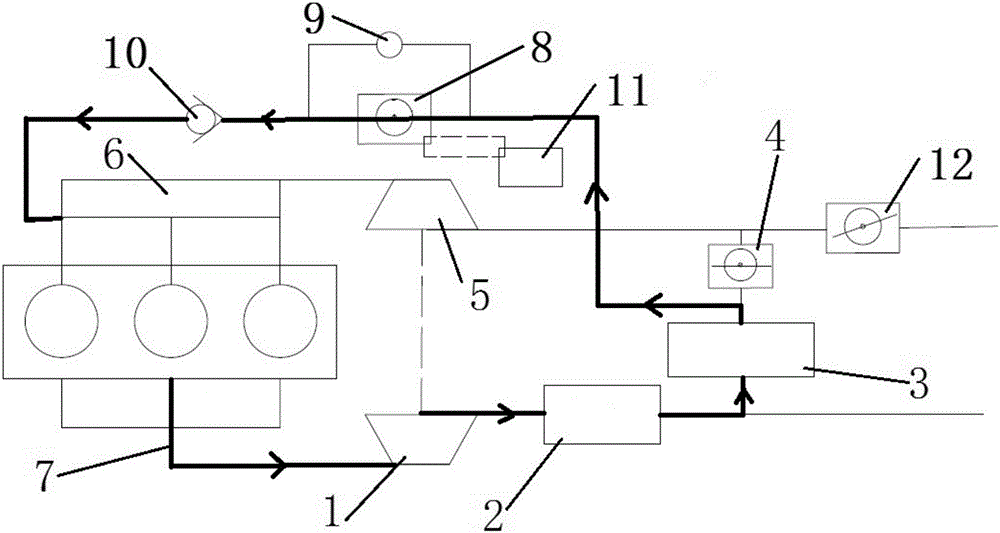

Cascaded recycling system for waste heat of internal combustion generating set

ActiveCN103206317AImprove recycling efficiencyLower exhaust gas temperatureInternal combustion piston enginesEngine componentsCombustionOrganic Rankine cycle

The invention provides a cascaded recycling system for waste heat of an internal combustion generating set and relates to a smoke waste heat recycling system of the internal combustion generating set, which solves the problems of high smoke temperature of the internal combustion generating set, low energy utilization efficiency and low generating efficiency as smoke waste heat of the existing internal combustion generating set is directly recycled by an organic Rankine cycle system. The cascaded recycling system for waste heat of the internal combustion generating set comprises a steam Rankine cycle subsystem and an organic Rankine cycle subsystem; the steam Rankine cycle subsystem comprises a waste heat boiler, a steam turbine, a first generator and a delivery pump; the organic Rankine cycle subsystem comprises an organic working medium evaporator, an organic working medium preheater, an organic turbine, a heat regenerator, an organic working medium condenser, an organic working medium pump and a second generator; a superheated steam outlet of the waste heat boiler is communicated with an acting cycle working medium inlet of the steam turbine, and the organic working medium condenser is communicated with a second inlet of the heat regenerator. The cascaded recycling system is used for smoke waste heat recycling of the internal combustion generating set.

Owner:GRAND NEW POWER

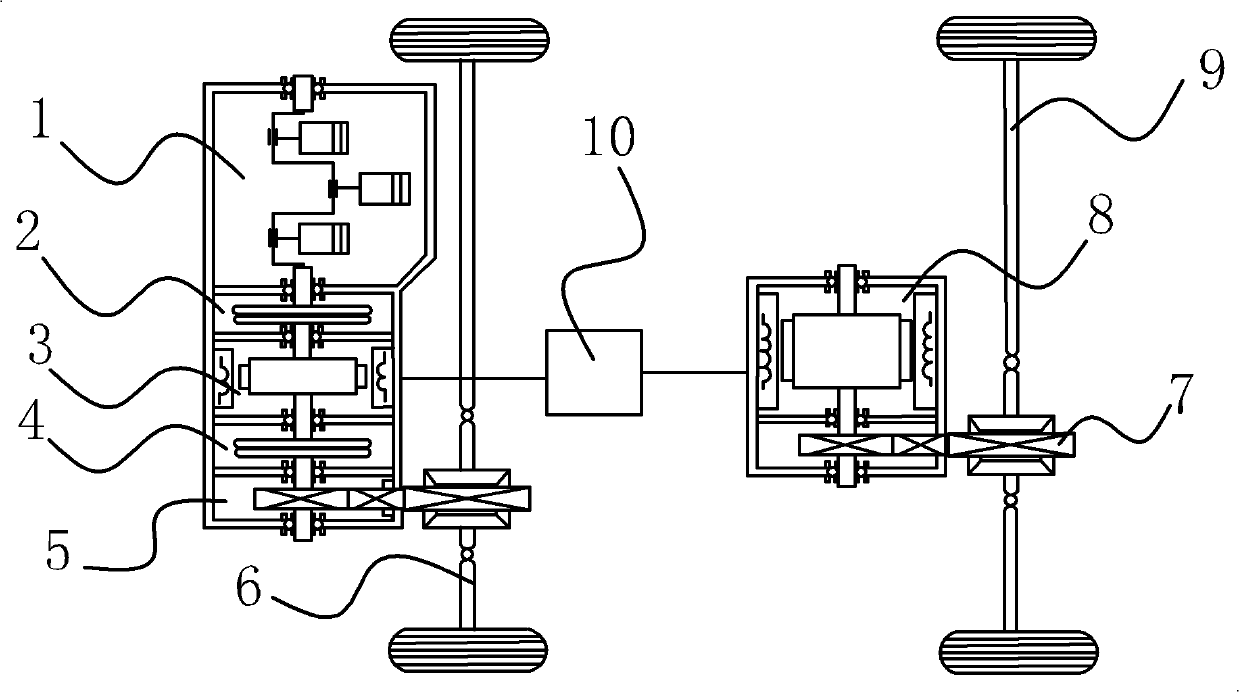

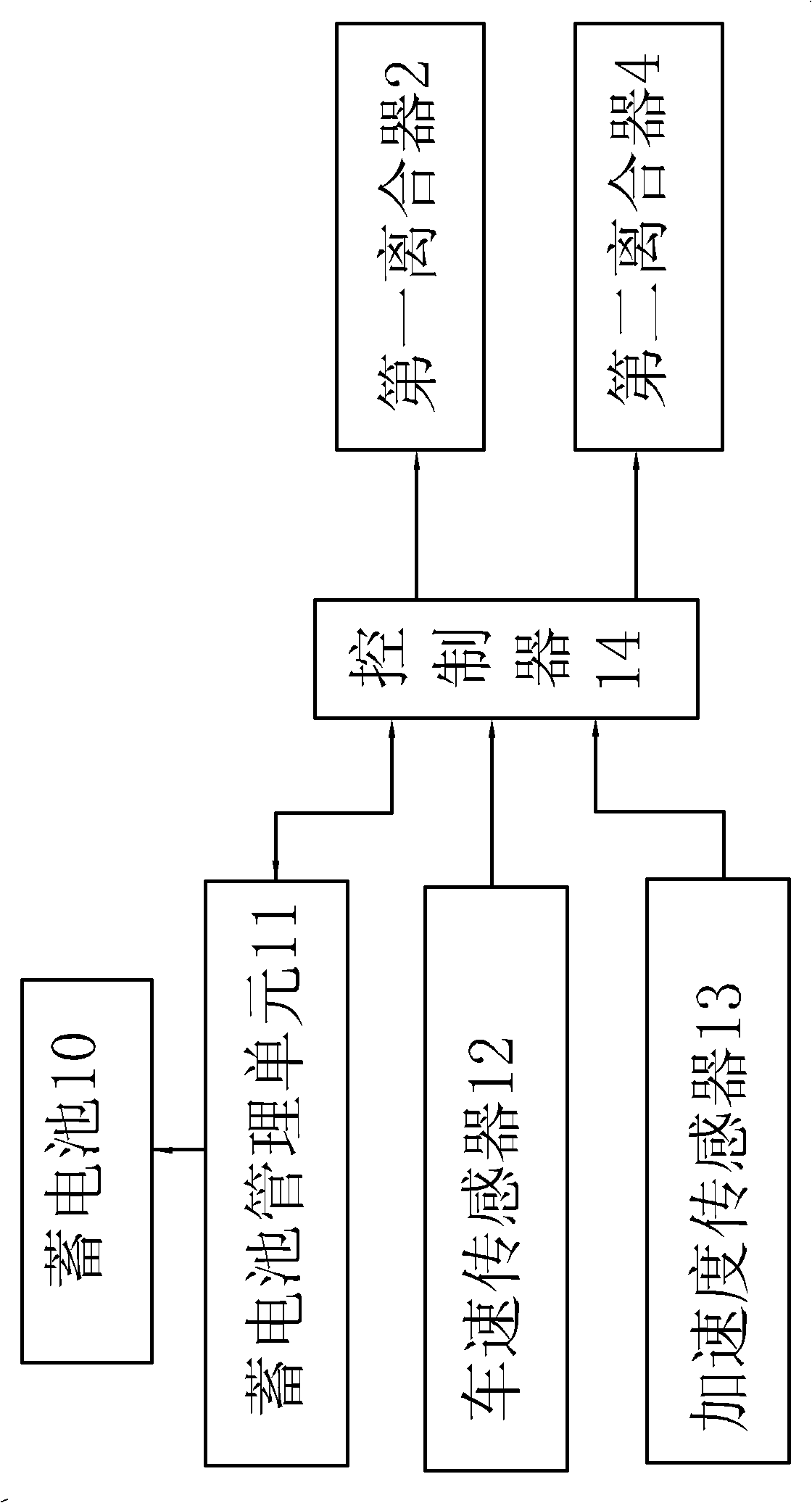

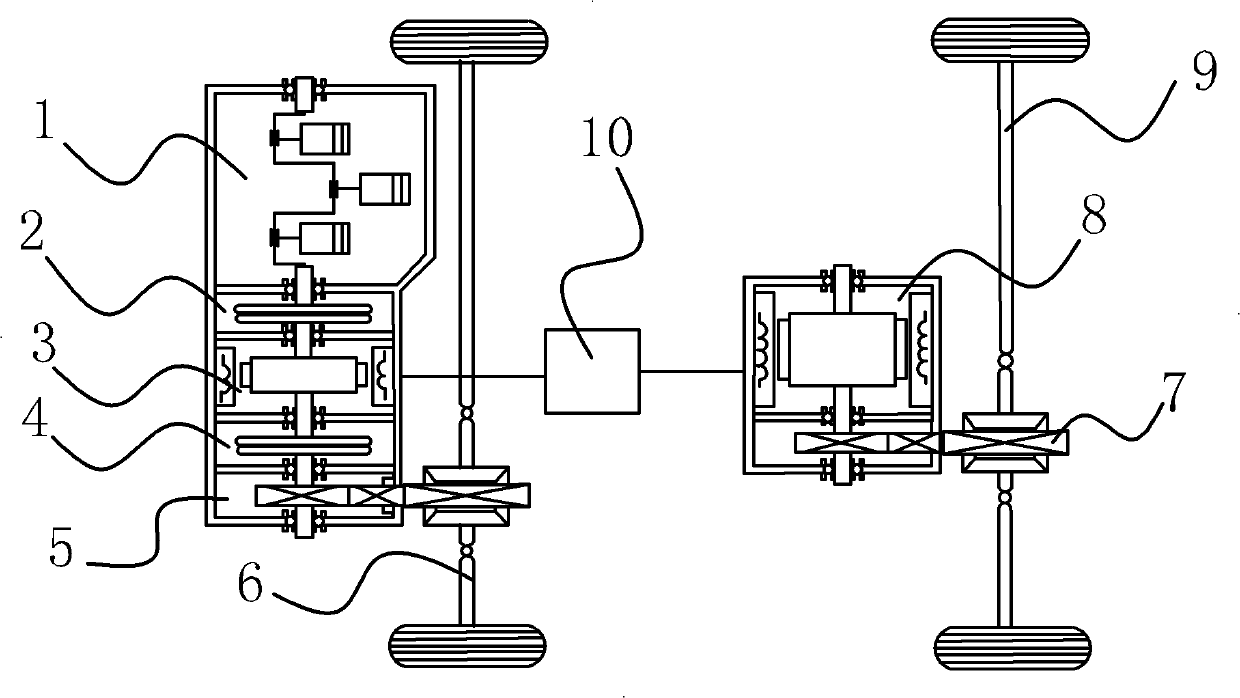

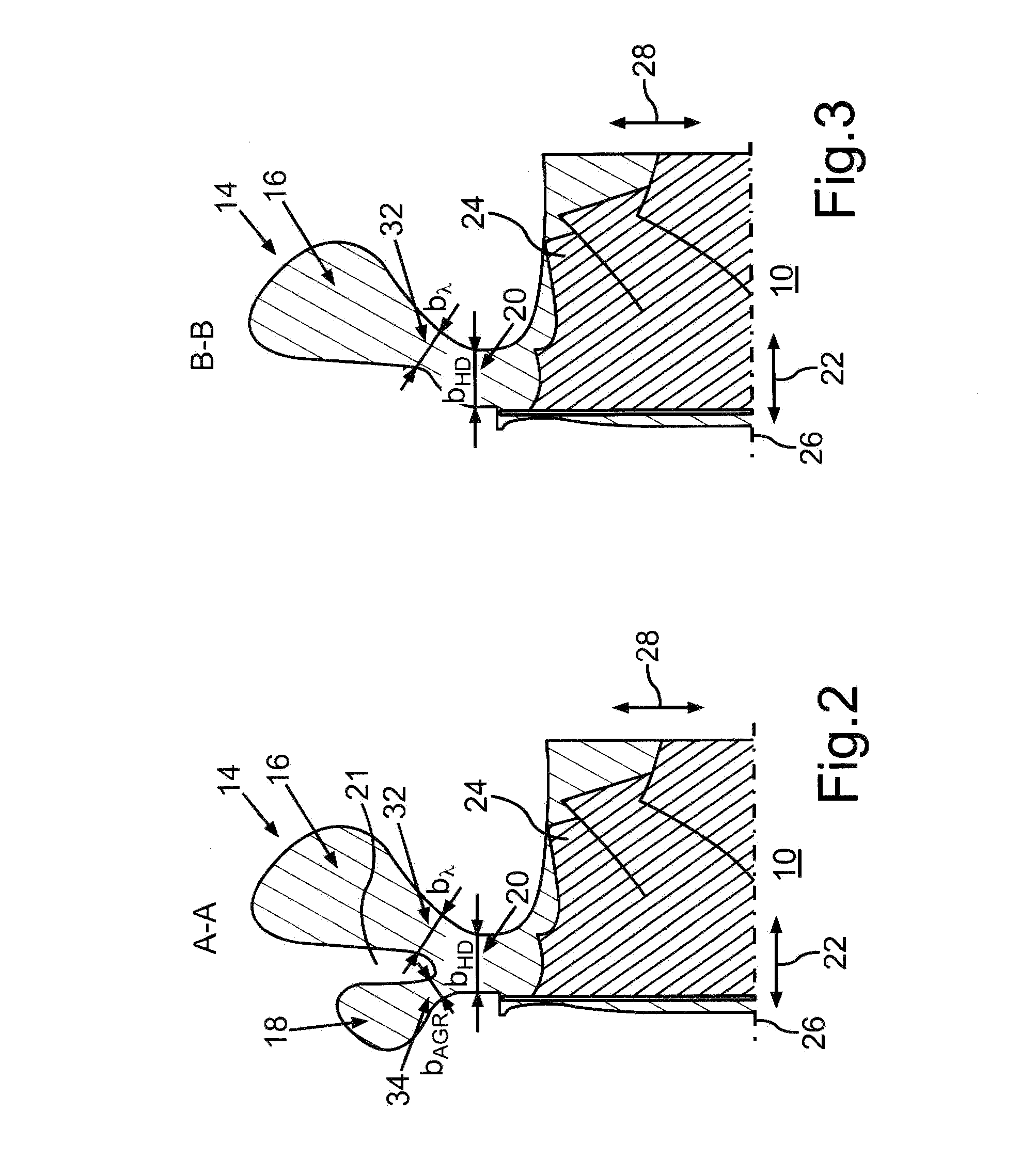

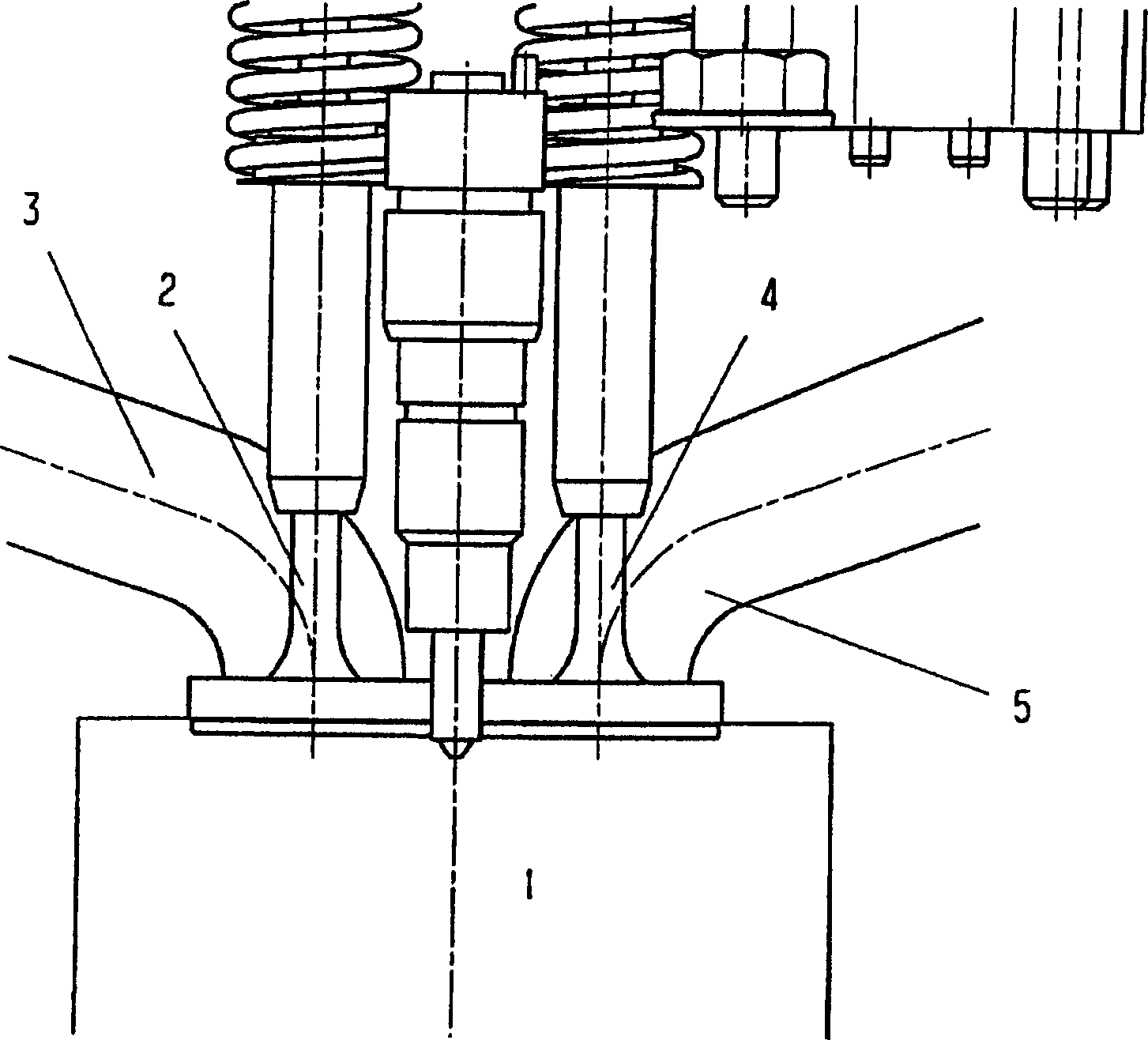

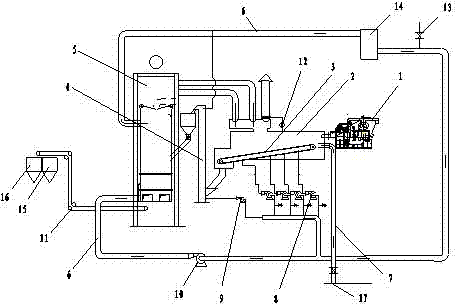

Automobile hybrid driving device and control method thereof

ActiveCN102555762AConducive to installation and layoutIncrease the rate of recyclingElectrodynamic brake systemsElectric propulsion mountingClutchDrive motor

The invention provides an automobile hybrid driving device and a control method thereof, which belong to the technical field of hybrid and solve the problem that the existing hybrid driving device is long in axial length and extremely difficult in layout. The hybrid driving device comprises an engine, a front driving motor, a back driving motor and a storage battery, the engine is connected with the front driving motor through a first clutch, the front driving motor is connected with a front driving shaft through a speed changer, a second clutch is arranged between a front speed changer and the front driving motor, the back driving motor is connected with a back driving shaft through a speed changer, and the front driving motor and the back driving motor are both connected with the storage battery. The control method achieves driving of the whole automobile under different models and recovery of braking energy by judging stored electric quantity of the storage battery, automobile speed signals and acceleration speed signals. The automobile hybrid driving device and the control method are easy to install and lay out, and improve recovery ratio of the braking energy and the whole automobile all-electric range.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Method of operating a spark-ignition internal combustion engine

InactiveUS20060011165A1Reduce exhaust emissionsIncrease fuel consumptionElectrical controlInternal combustion piston enginesCombustion chamberOperating point

In a method for operating a spark-ignition internal combustion engine, wherein fuel is metered into the cylinders by direct fuel injection into the combustion chambers and by the addition of fuel in an intake region of the engine and a control unit matches the quantity of fuel to be added in the intake region and the quantity of fuel to be injected directly into the combustion chamber to one another as a function of the operating point of the internal combustion engine so as to provide an ignitable fuel mixture in the combustion chamber, the control unit determines a recirculation rate for the re-circulated exhaust gas and adjusts a predetermined excess air ratio (λ) for the mixture composed of fresh air, re-circulated exhaust gas and fuel by means of the direct injection of fuel into the combustion chamber taking into account the recirculation rate in order to reduce the exhaust emissions of the internal combustion engine and improve fuel consumption.

Owner:DAIMLER AG

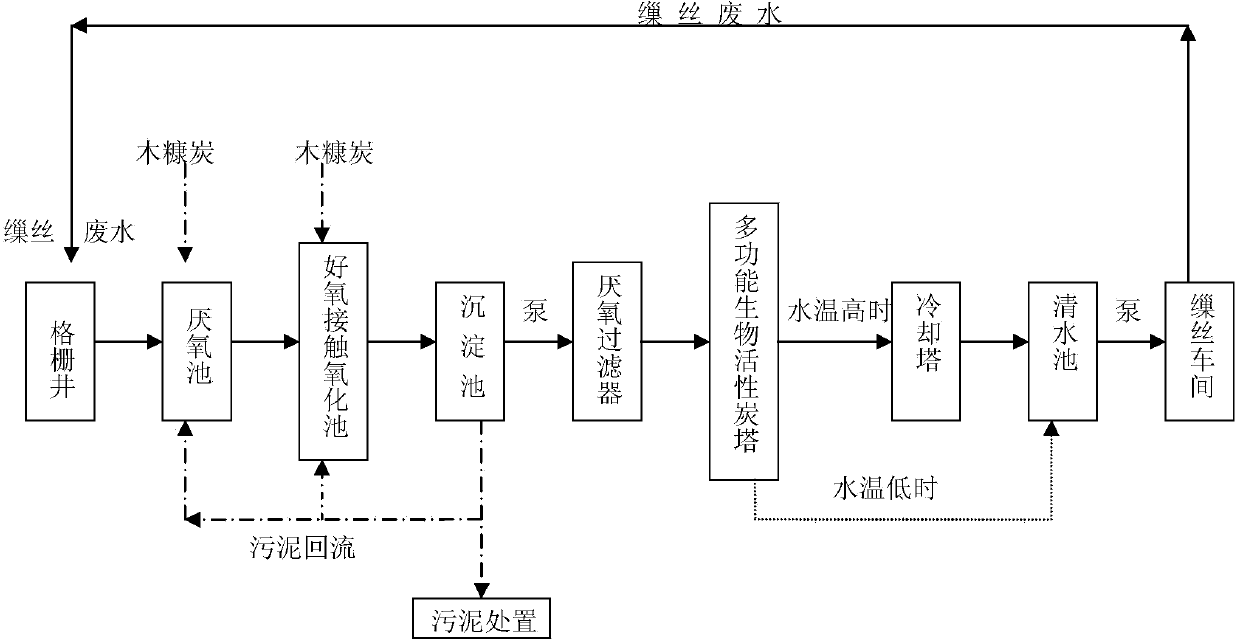

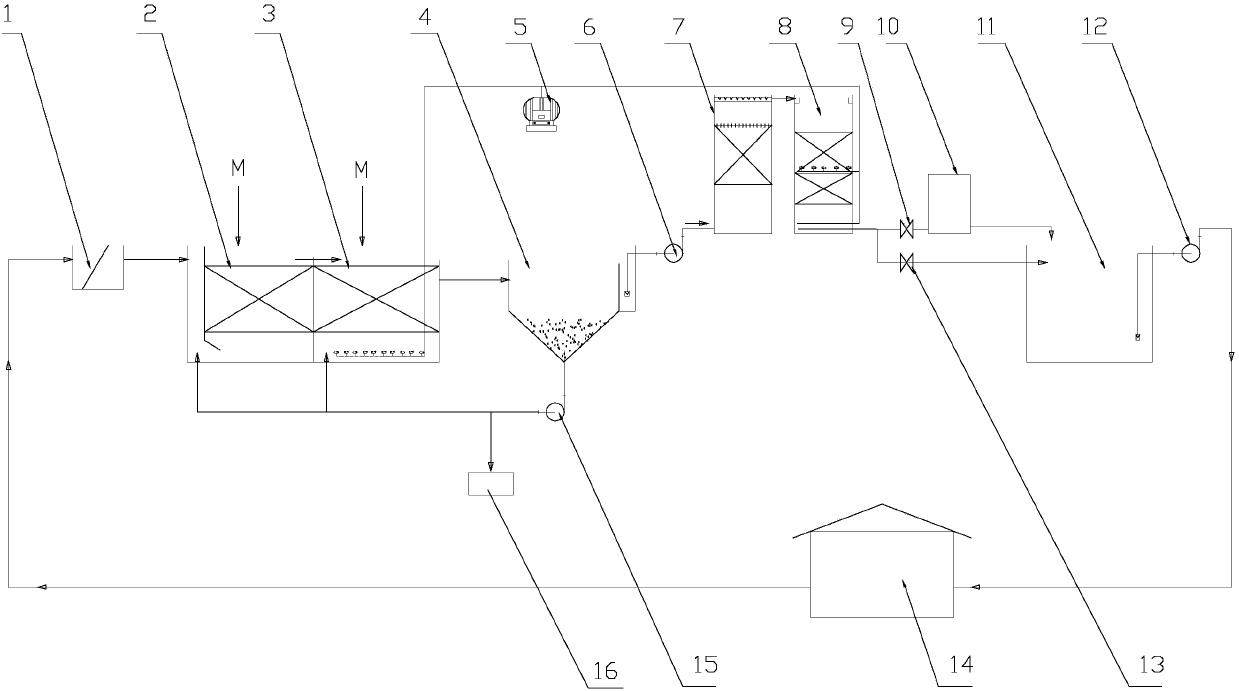

Reeling waste water deep treating method and apparatus

ActiveCN103588363AImprove removal efficiencyExtended service lifeMultistage water/sewage treatmentChemistryBackflow

The invention relates to a reeling waste water deep treating method and an apparatus, the method comprises the following steps: A) the reeling waste water is passed through a grating well, then enters into an anaerobic pond, sawdust carbon is put into the anaerobic pond; B) effluent from the anaerobic pond enters into an aerobic contacting oxidation pond, the sawdust carbon is put into the anaerobic contacting oxidation pond; C) effluent from the anaerobic contacting oxidation pond enters into a sedimentation pond; naturally deposited activated sludge containing sawdust carbon is directly discharged or performed with backflow to the above anaerobic pond or / and aerobic contacting oxidation pond, a supernatant is lifted in the sedimentation pond to an anaerobic filter for treating; D) effluent from the anaerobic filter enters into a multifunctional biological active carbon tower; and E) effluent from the multifunctional biological active carbon tower enters into a clean water pond for recycling or directly discharging in a silk reeling workshop. The method and the apparatus have the advantages of low operation cost, high circular reuse rate, good water quality, simple operation management and the like, utilization rate of water resource can be increased, pollution of reeling waste water on environment can be mitigated, and the silkworm industry has a good and fast development.

Owner:GUANGXI CHUNHUI ENVIRONMENTAL PROTECTION ENG

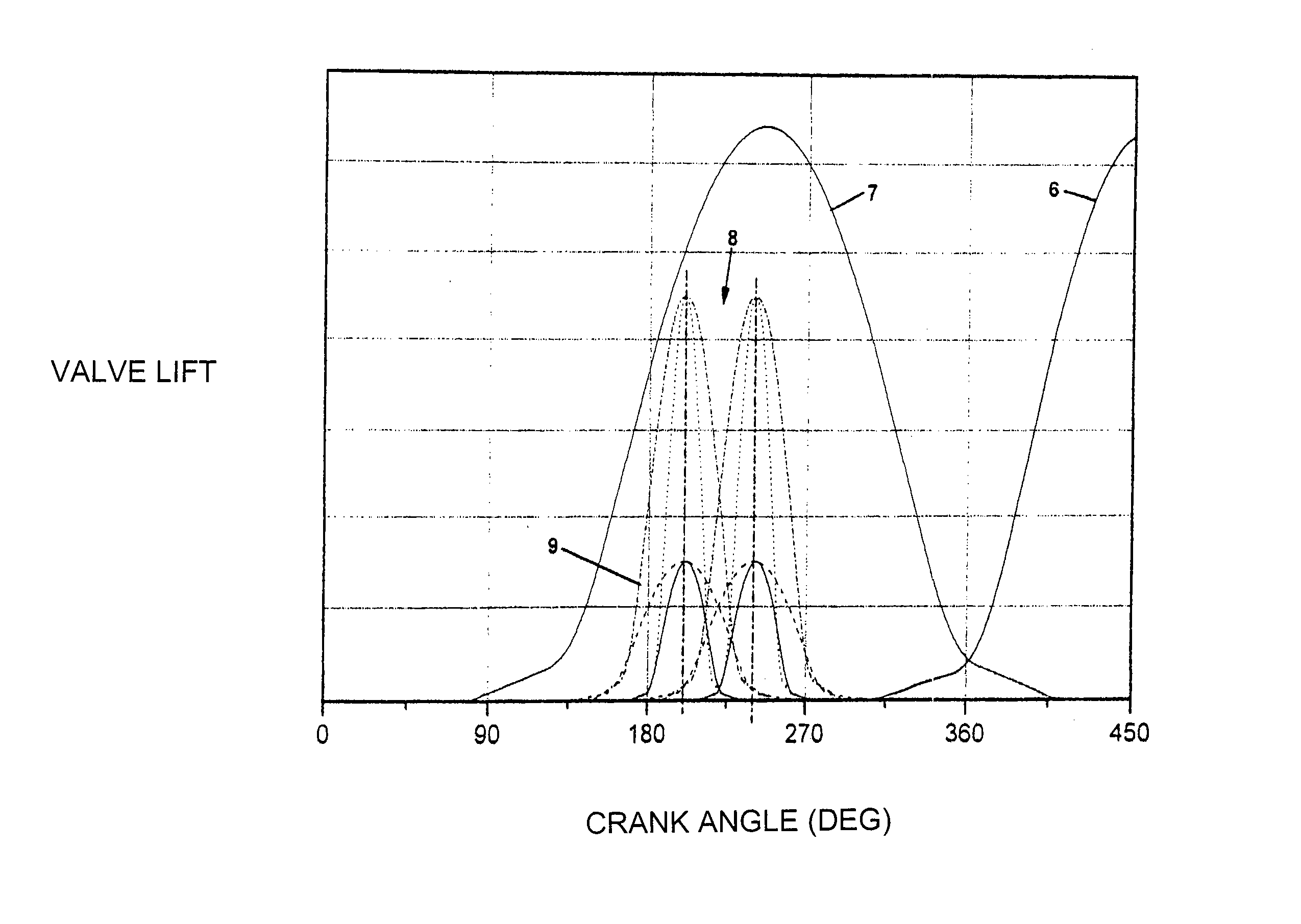

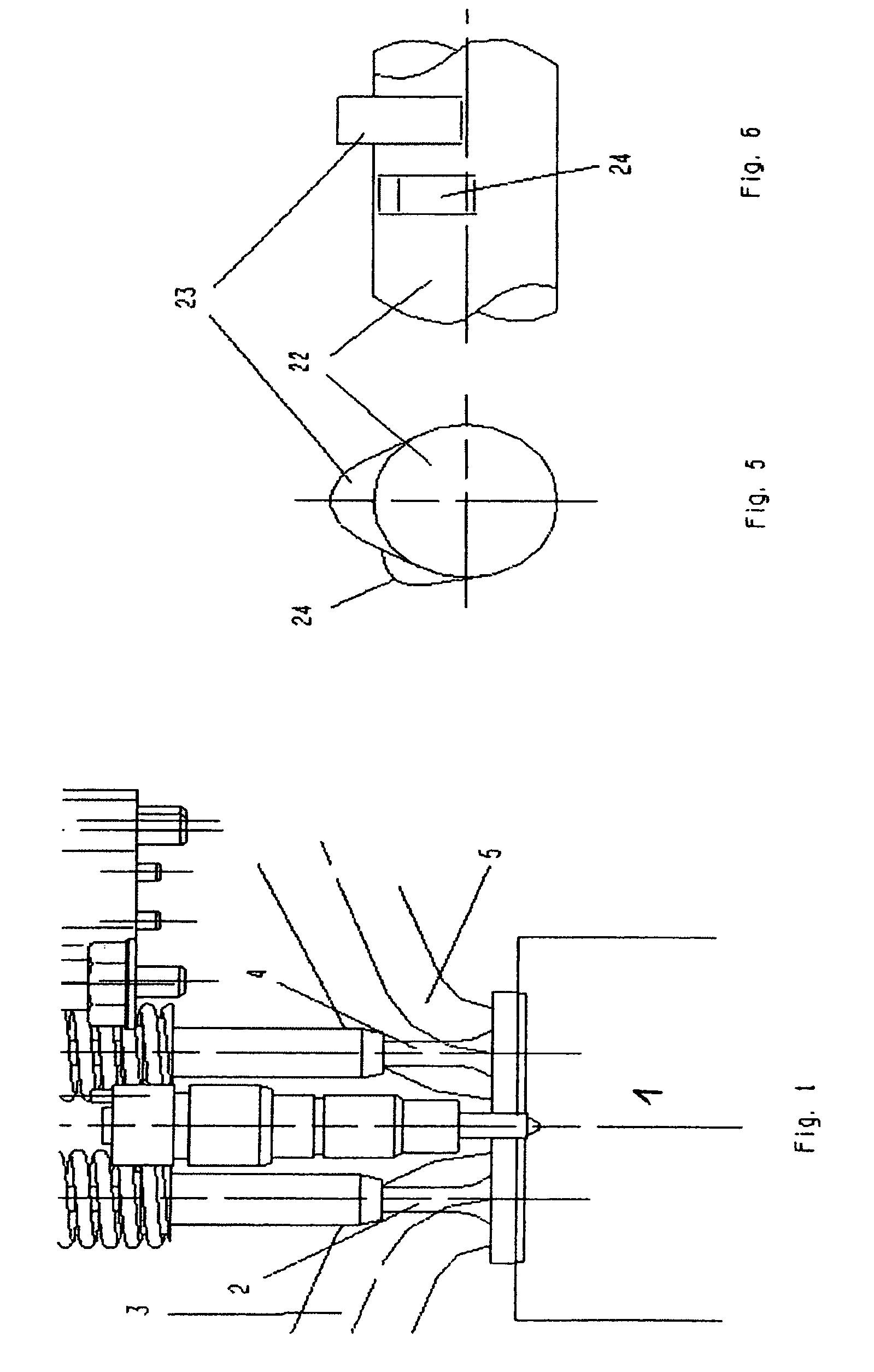

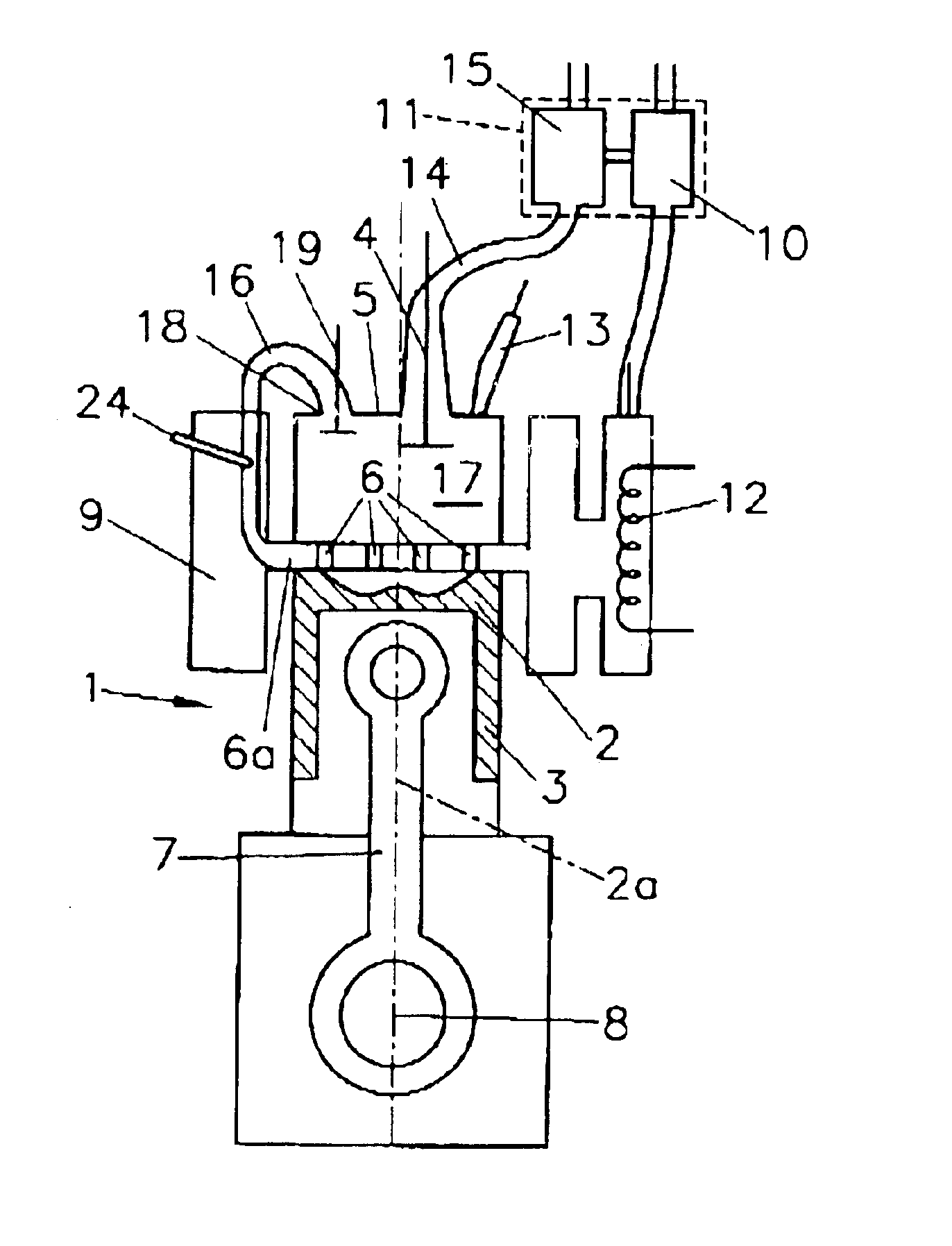

Internal exhaust recirculation method for an internal combustion engine

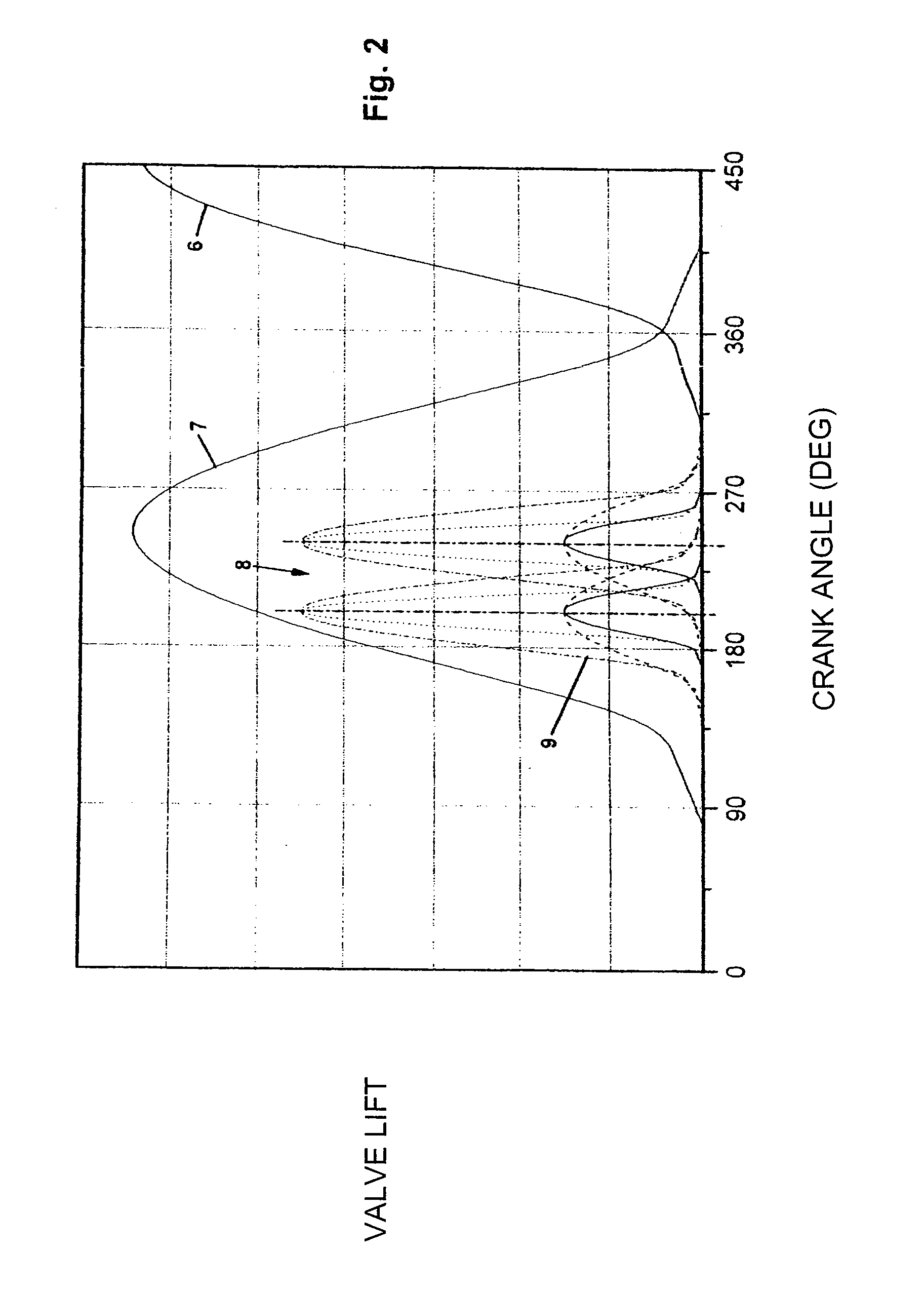

InactiveUS7249597B2Simple designHigh actuate forceValve arrangementsInternal combustion piston enginesTop dead centerExhaust valve

The invention relates to the internal exhaust-gas recirculation in an internal combustion engine with gas exchange valves periodically controlled by a camshaft (22) in accordance with the four-stroke principle, in which, during the gas exchange exhausting of exhaust gas from the respective cylinder (1) into the exhaust duct (5), an intake valve (2) associated with the respective cylinder (1) is open in a crank angle range after top dead center of the ignition of the gas mixture present in the cylinder (1), in order to exhaust part of the exhaust gas into an intake duct (3), so that during the next gas exchange intake both fresh gas and exhaust gas are taken in from the intake duct (3), the respective intake valve (2) being actuated during the gas exchange exhausting independently of the periodic gas exchange intake, and the additional opening of the respective intake valve (2) being carried out in the range from 110 to 150% of the opening angle of the start of opening of the exhaust duct (5) by the exhaust valve (4).

Owner:FEV MOTORENTECHN

Compound turbocharger system having a connectable compressor

InactiveUS8495877B2Considerable torque increasesImproves the initial-movement behaviorInternal combustion piston enginesOutput powerTurbochargerIntercooler

The invention relates to an internal combustion engine having a turbocompound system. The turbocompound system encompasses an exhaust-gas turbocharger, a turbo intercooler, and a power turbine. The power turbine is connectable, via a transmission with clutch, to the crankshaft of the internal combustion engine. A connectable compressor, which is couplable either to the power turbine or to the internal combustion engine, is received in a multiple-flow intake pipe.

Owner:ROBERT BOSCH GMBH

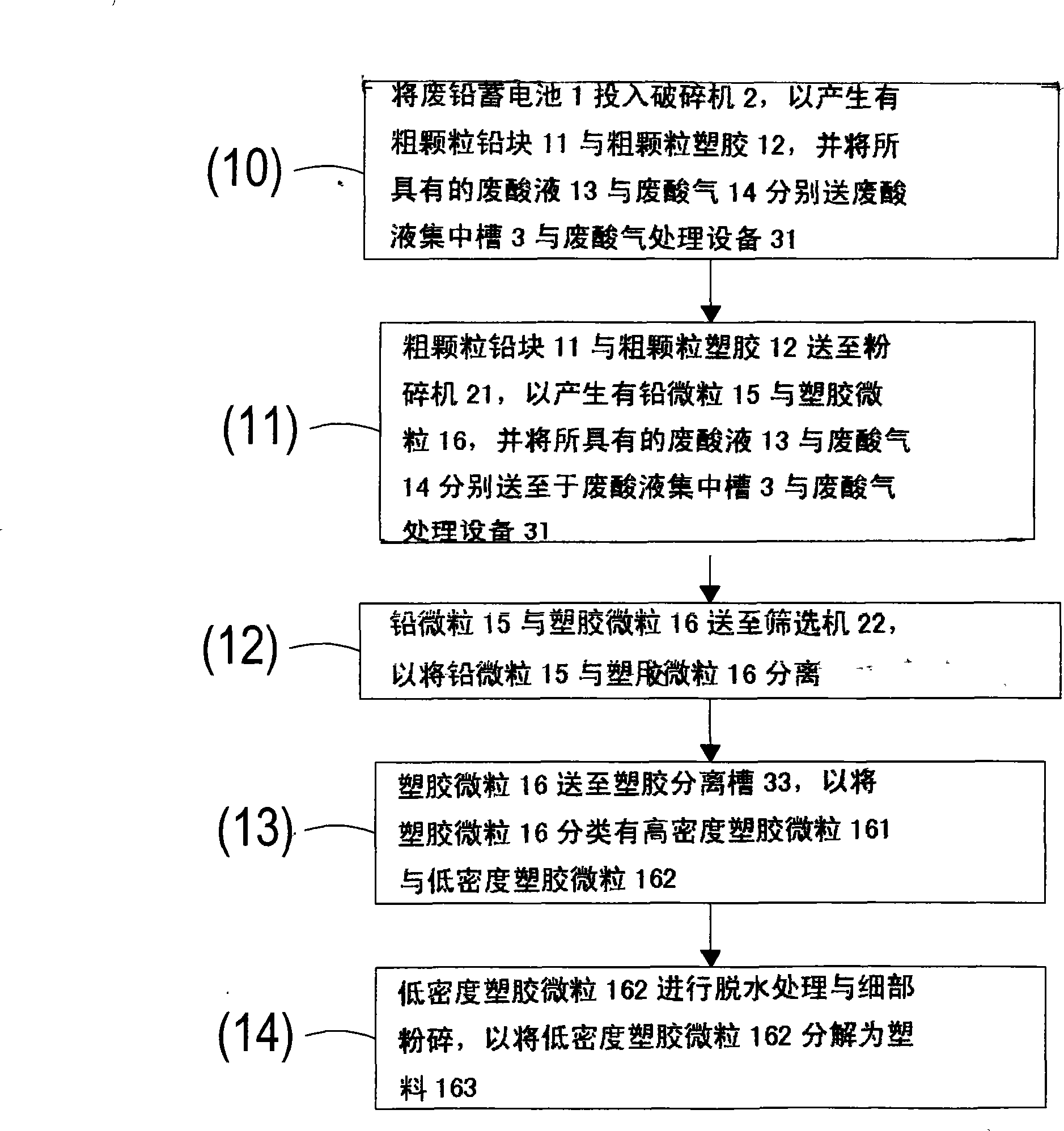

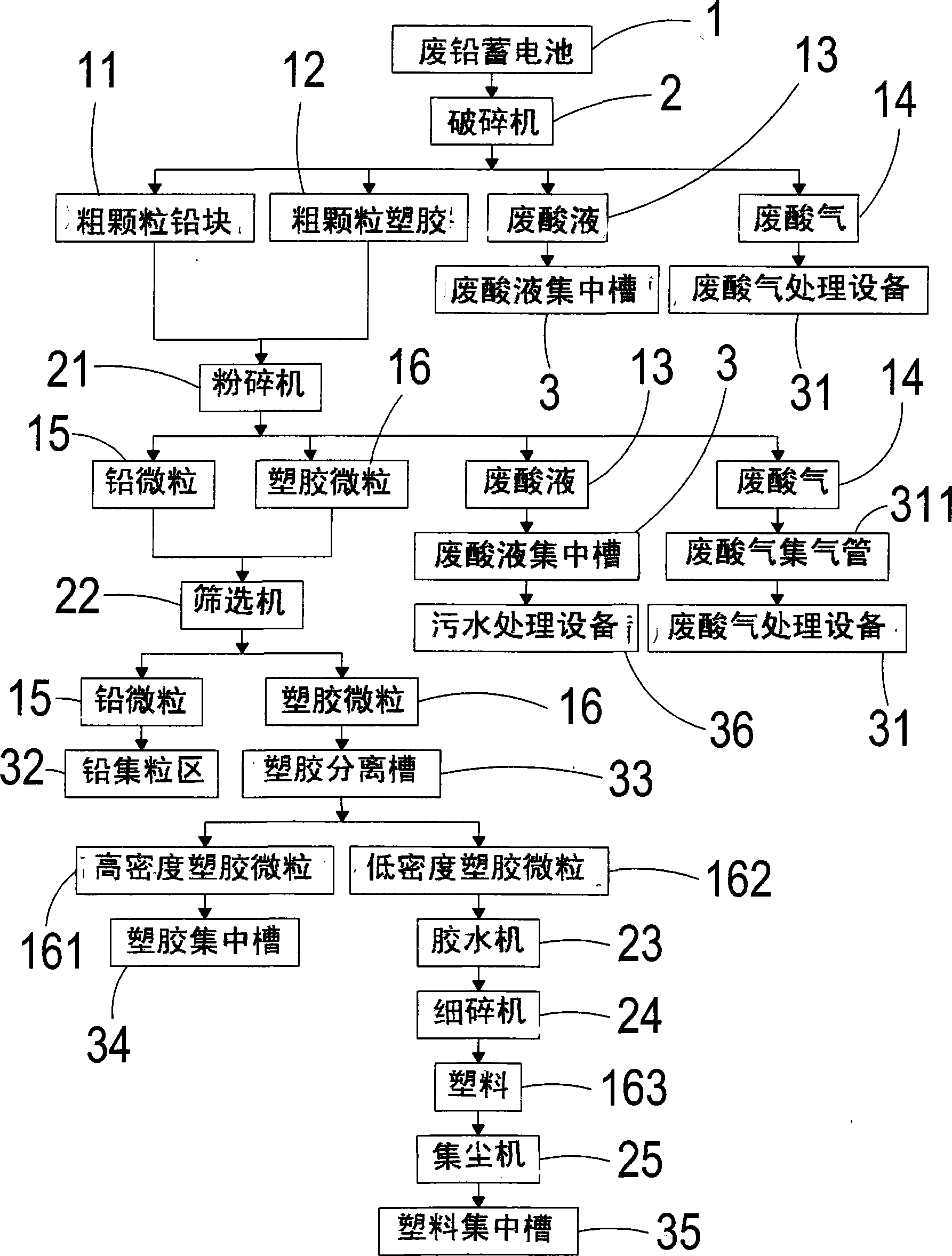

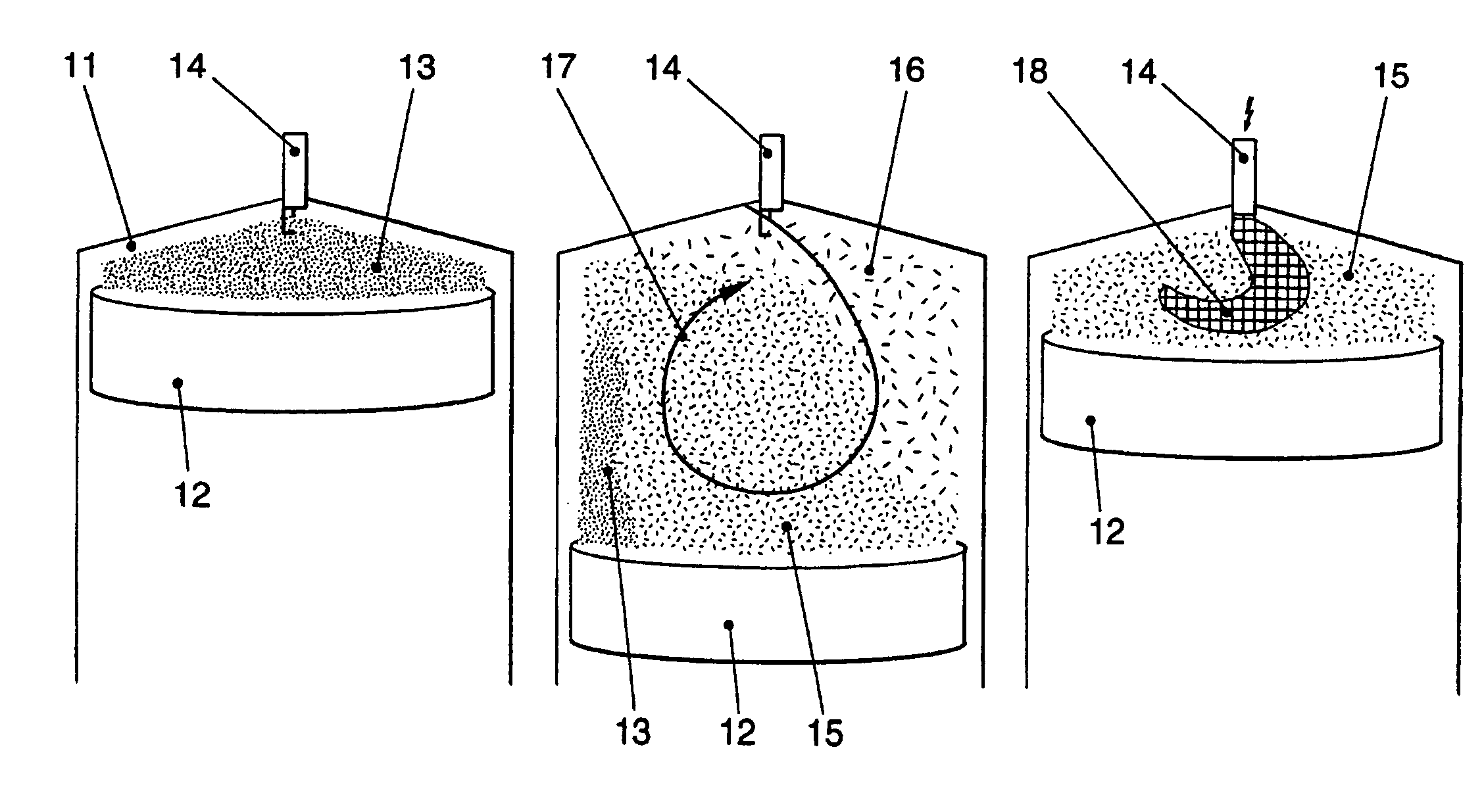

Method for processing waste lead accumulator

InactiveCN101246979AHigh recycling ratePracticalWaste accumulators reclaimingBattery recyclingPrillBrick

The present invention relates to a method for processing a waste lead accumulator which belongs to filed of circumstance protection. The method comprises of steps of: casting waste lead accumulator to crusher, sending coarse particle lead brick and coarse particle plastic to crusher, seeding lead granules and plastic granules to screening machine, sending plastic granules to plastic separate groove, dehydrating and crushing low-density plastic granules. The present invention can reclaim waste lead accumulator by high reclaiming rate, as the same time avoids circumstance pollution, sanitation pollution caused by waste acid liquid and waste acid gas of waste lead accumulator, the practicability is high.

Owner:陈永松

Direct injection internal combustion engine with NOx-reduced emissions

InactiveUS7021279B1Low pollutant emissionHigh engine loadValve arrangementsElectrical controlNitrogen oxideEngineering

A direct injection internal combustion engine, especially an Otto engine, is provided with layered lean operation and internal exhaust-gas recirculation. An exhaust-gas aftertreatment for reducing Nox using an Nox storage catalyst is also provided. This combination is to achieve the highest possible exhaust-gas recirculation rates with the lowest HC and Nox emission values. A tumble flow is provided for the incoming fresh gases, which may contain recirculated exhaust gas from external exhaust-gas recirculation. The swirl axis of the incoming fresh gases therefore extends substantially crosswise to the piston movement. This results in an emissions-reducing, optimal mixture inside the cylinder during the layered lean operation.

Owner:VOLKSWAGEN AG

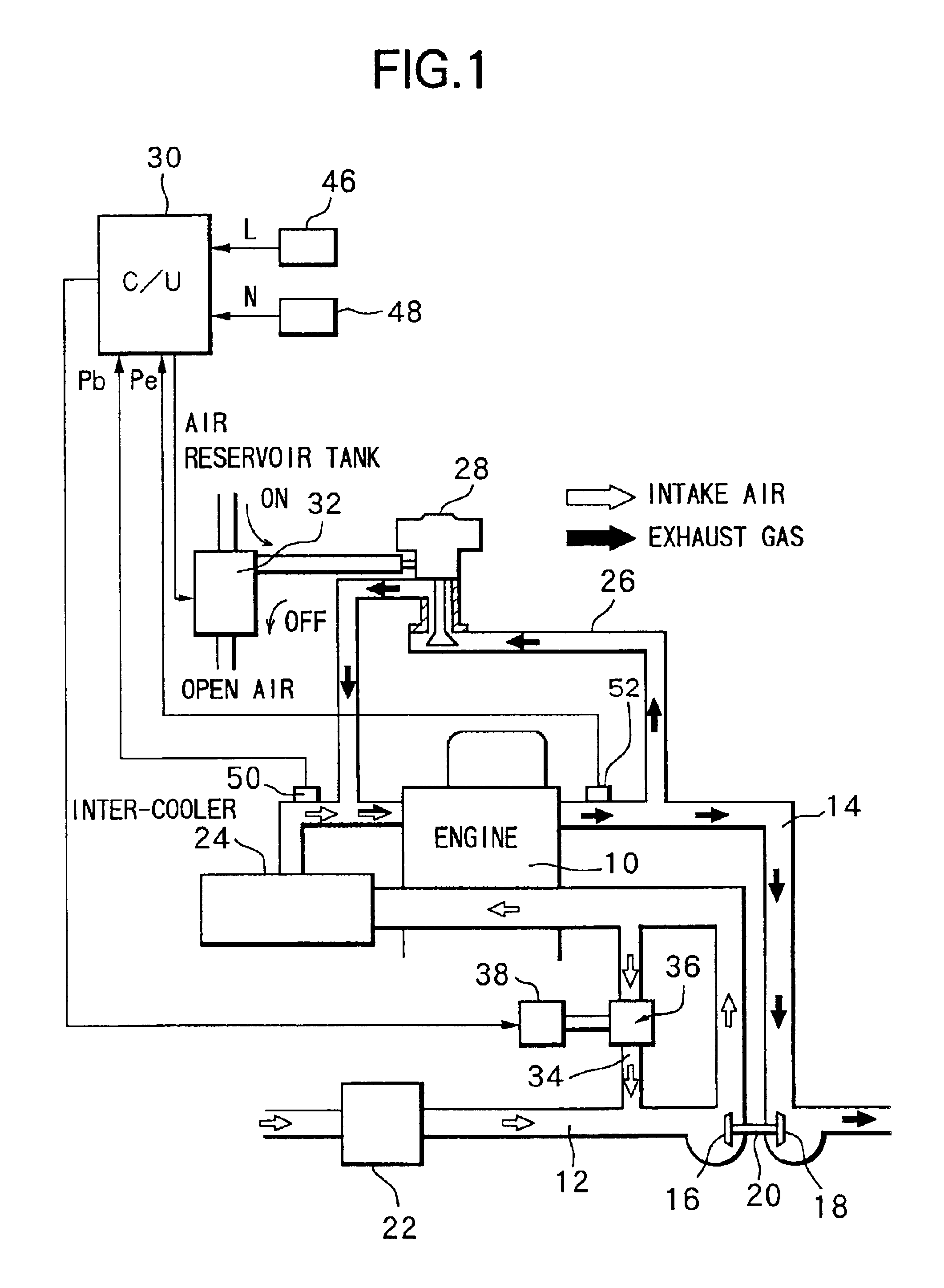

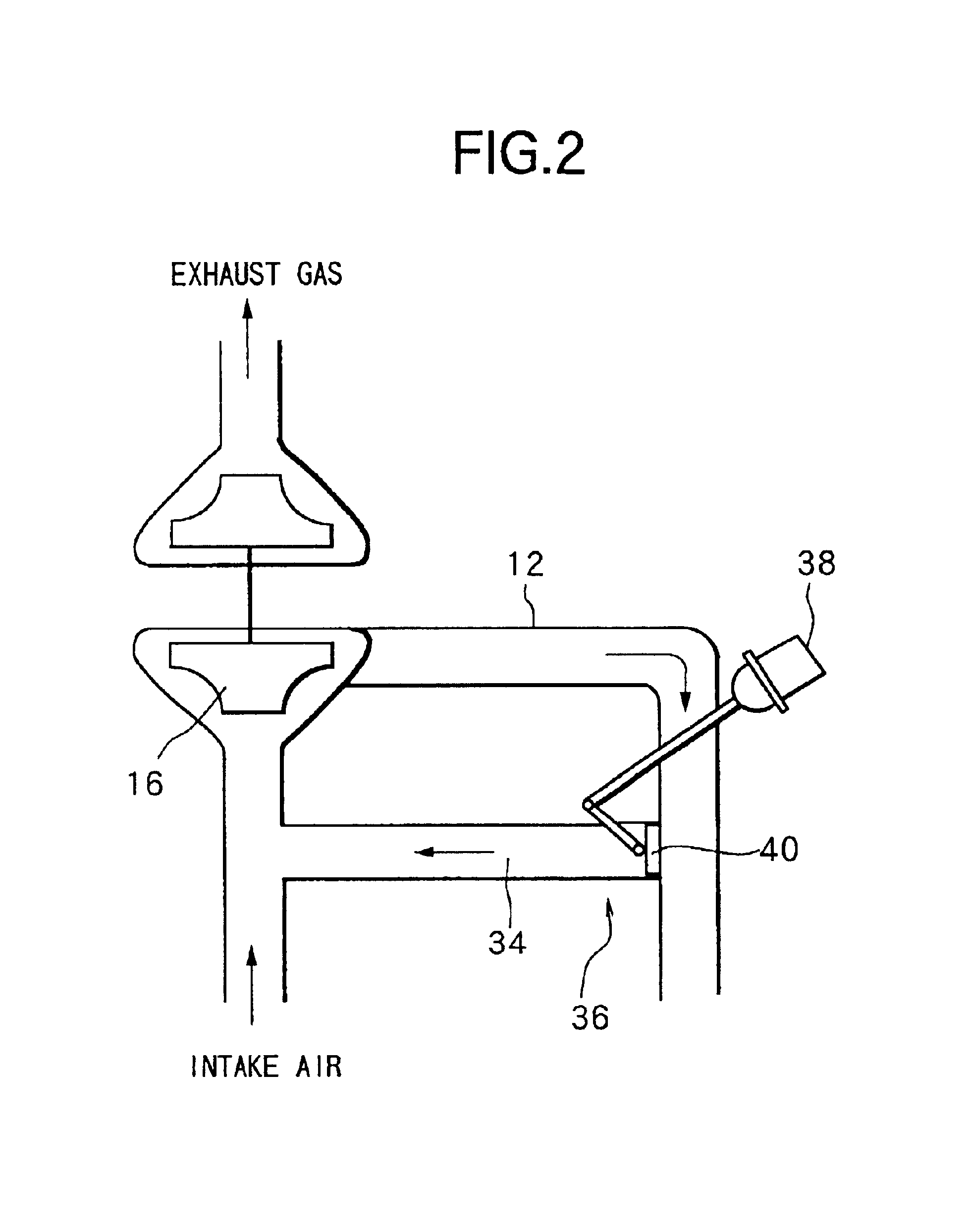

Device and method for exhaust gas circulation of internal combustion engine

InactiveUS6945240B2Reduce negative pressureIncrease negative pressureElectrical controlNon-fuel substance addition to fuelTurbochargerDifferential pressure

In an exhaust gas recirculation apparatus for an internal combustion engine mounted with a turbocharger in which a turbine is disposed in an exhaust passage and a compressor is disposed in an intake passage, when the exhaust gas recirculation is carried out, a port formed at the intake passage on the downstream side of the compressor is opened. As a result, since an intake air on the downstream side of the compressor is released to the atmosphere and a negative pressure in the exhaust passage is lowered, a differential pressure between an exhaust pressure in the intake passage and the negative pressure in the intake passage is increased, to improve an exhaust gas recirculation rate, so that a NOx discharge amount can be reduced.

Owner:NISSAN DIESEL MOTOR CO

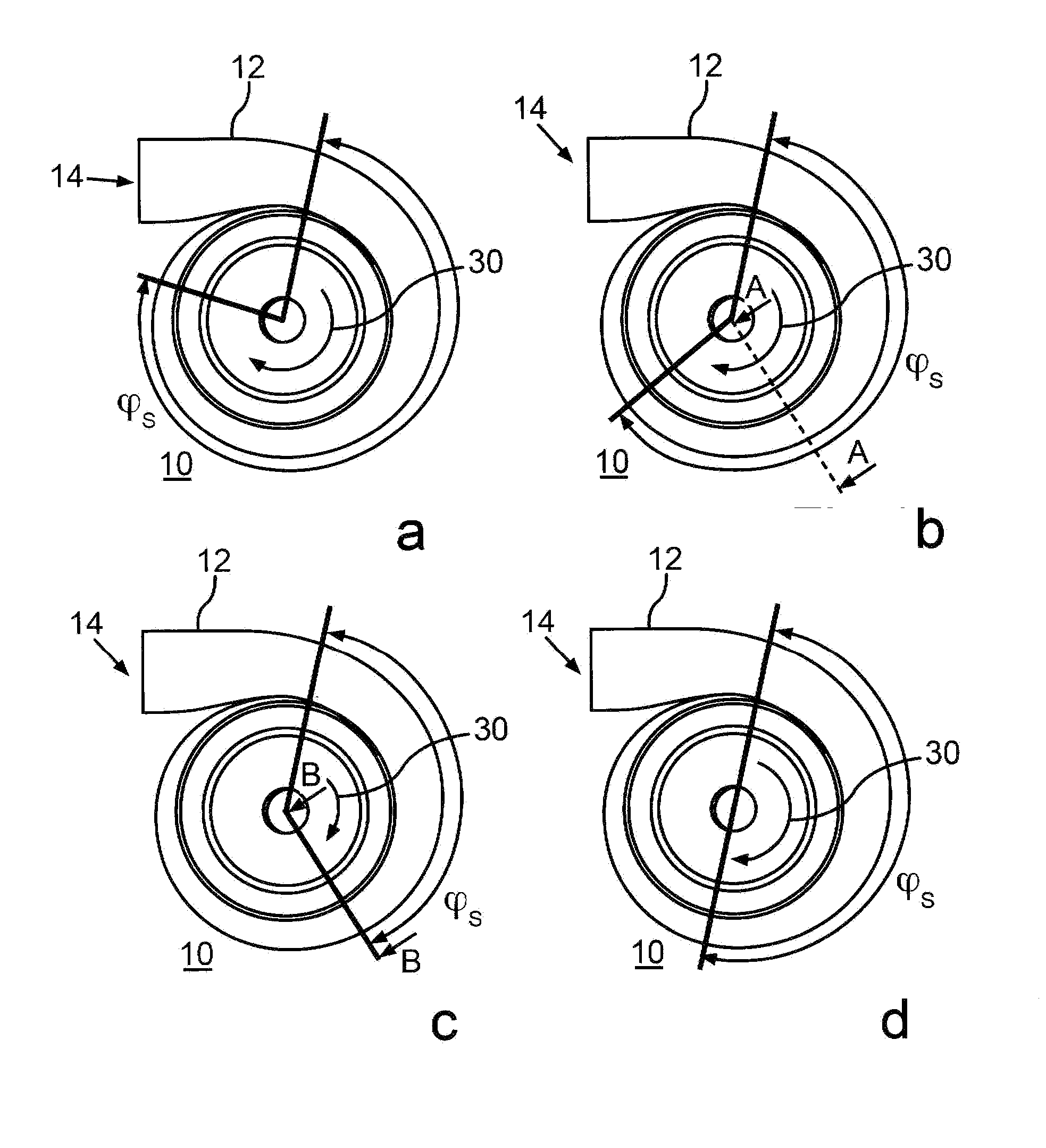

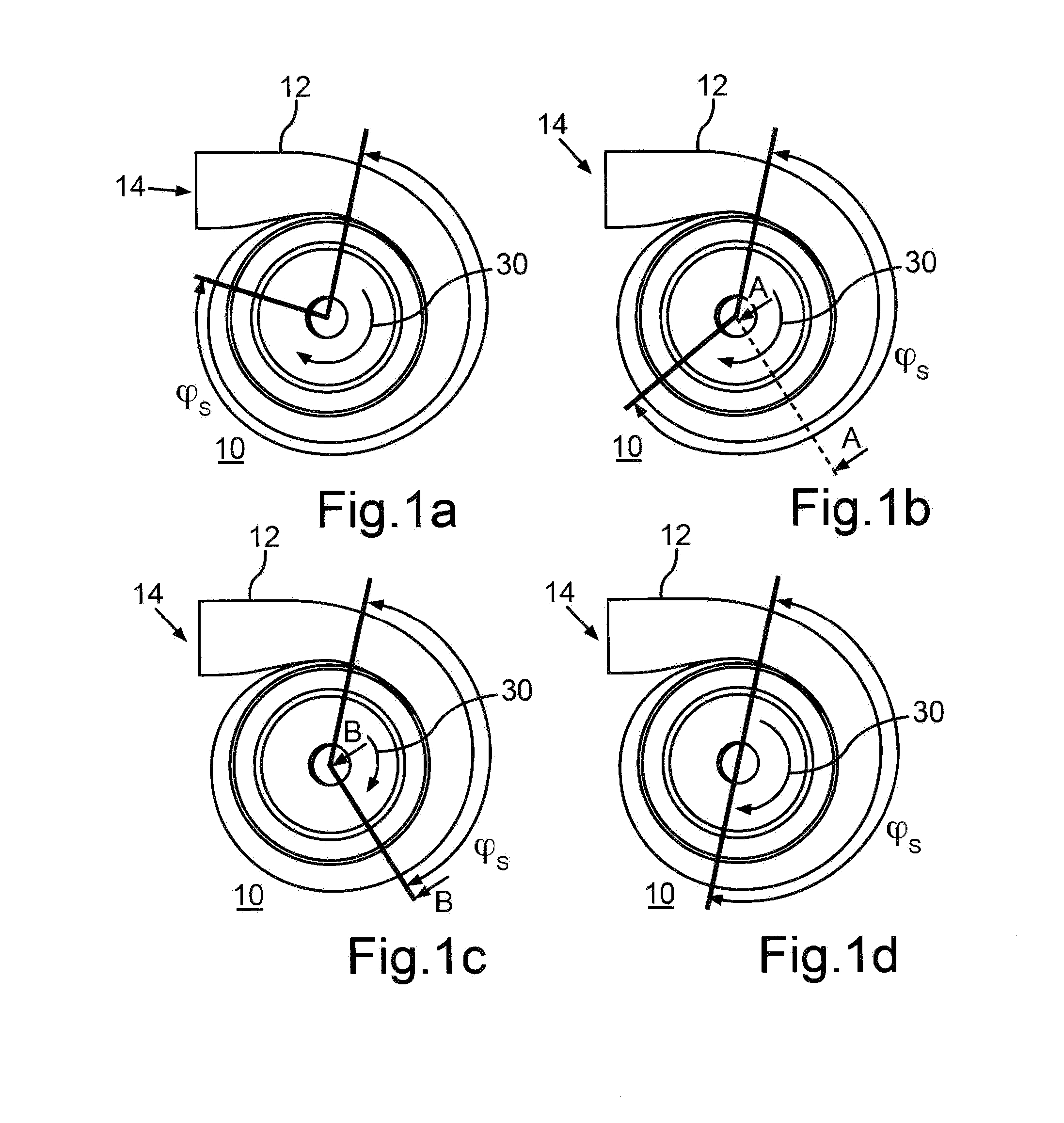

Turbine for an exhaust gas turbocharger

ActiveUS20140003910A1Easy to operateImprove efficiencyInternal combustion piston enginesPump componentsImpellerTurbine wheel

In a turbine for an exhaust gas turbocharger having a turbine housing which has a first and a second spiral channel with the second spiral channel extending over a wrap angle range of less than 360 degrees of a turbine wheel of the turbine, and the first spiral channel having a larger wrap angle range than the second spiral channel and the spiral channels being arranged adjacent each other in at least one angular range which includes the wrap angle ranges, the nozzle has an overall nozzle width via which exhaust gas is admitted to the turbine wheel over a respective partial nozzle width of the spiral channels wherein the partial nozzle width of the first spiral channel is greater than the partial nozzle width of the first spiral channel in the first angular range, at least in a further angular range of the wrap angle range which is different from the at least one angular range.

Owner:IHI CHARGING SYST INT

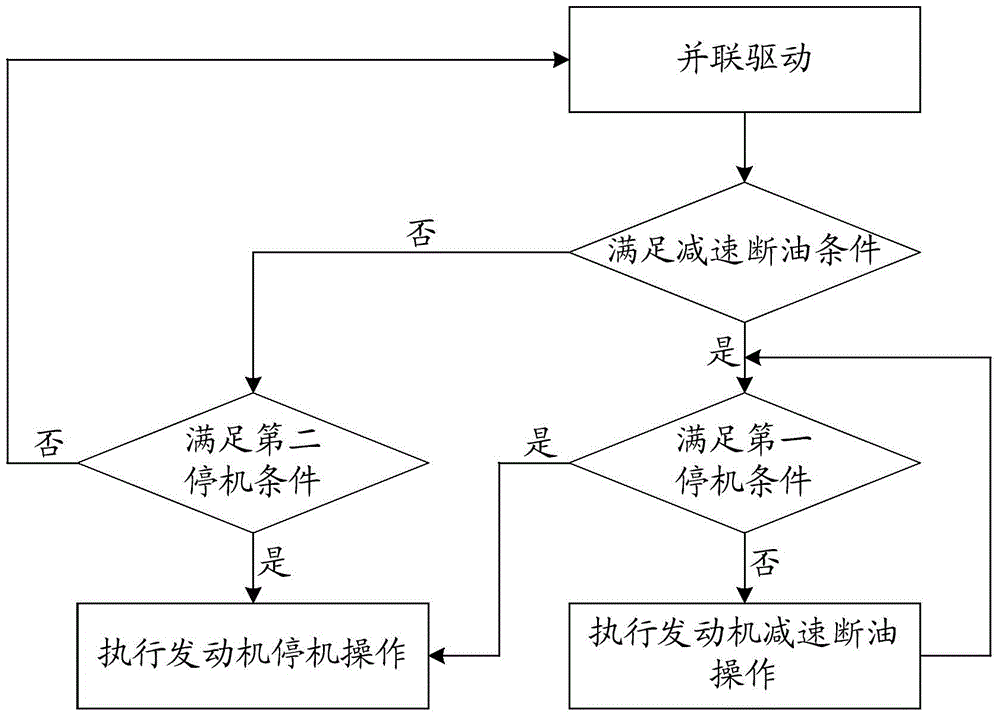

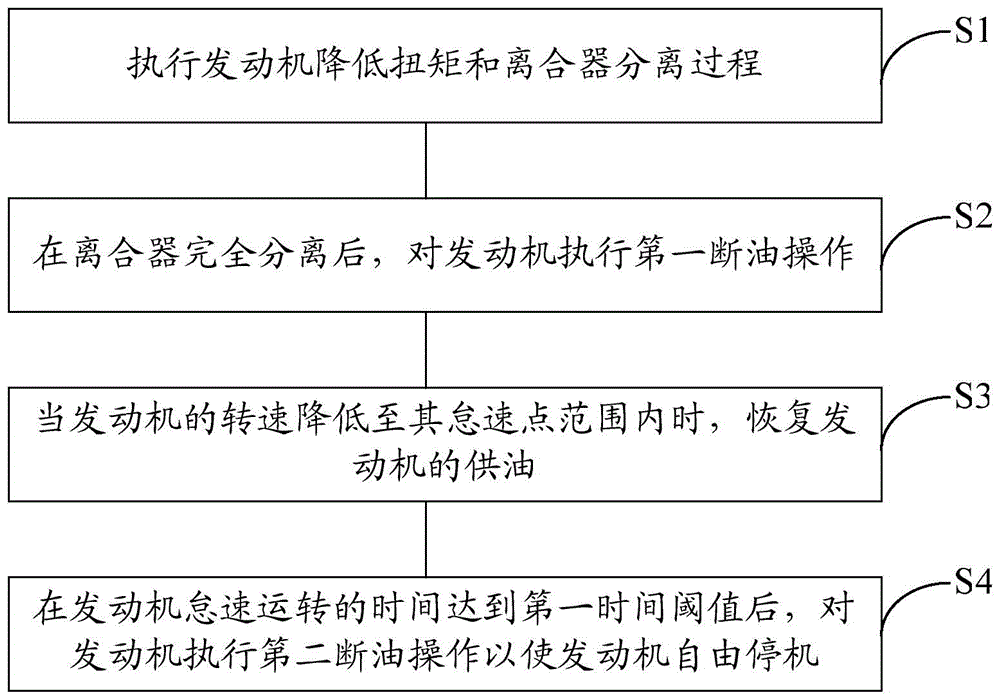

Method and apparatus for shutdown control of vehicle engine

ActiveCN105235679AImprove economyReduce shockHybrid vehiclesInternal combustion piston enginesFuel efficiencyIdle speed

The invention discloses a method and an apparatus for shutdown control of a vehicle engine, wherein the method comprises: carrying out shutdown operations to the engine when successively meeting the decelerating oil-cut condition and a first shutdown condition or when not meeting the decelerating oil-cut condition but the second shutdown condition; the shutdown operations to the engine that are carried out comprises: reducing the torque of the engine and separating a clutch; carrying out a first oil-cut operation to the engine when the clutch is completely separated; recovering oil supply for the engine when the rotation speed of the engine is reduced to within the idle speed point range; and carrying out a second oil-cut operation to the engine after the running time of the engine idle speed reaches the first time threshold value, so as to make the engine freely shutdown. According to the technical solution of the invention, during the process that the engine is shut down at high vehicle speed, the fuel efficiency is improved and the impact of the shutdown of the engine at the high rotation speed to the whole vehicle transmission system is reduced.

Owner:SAIC MOTOR

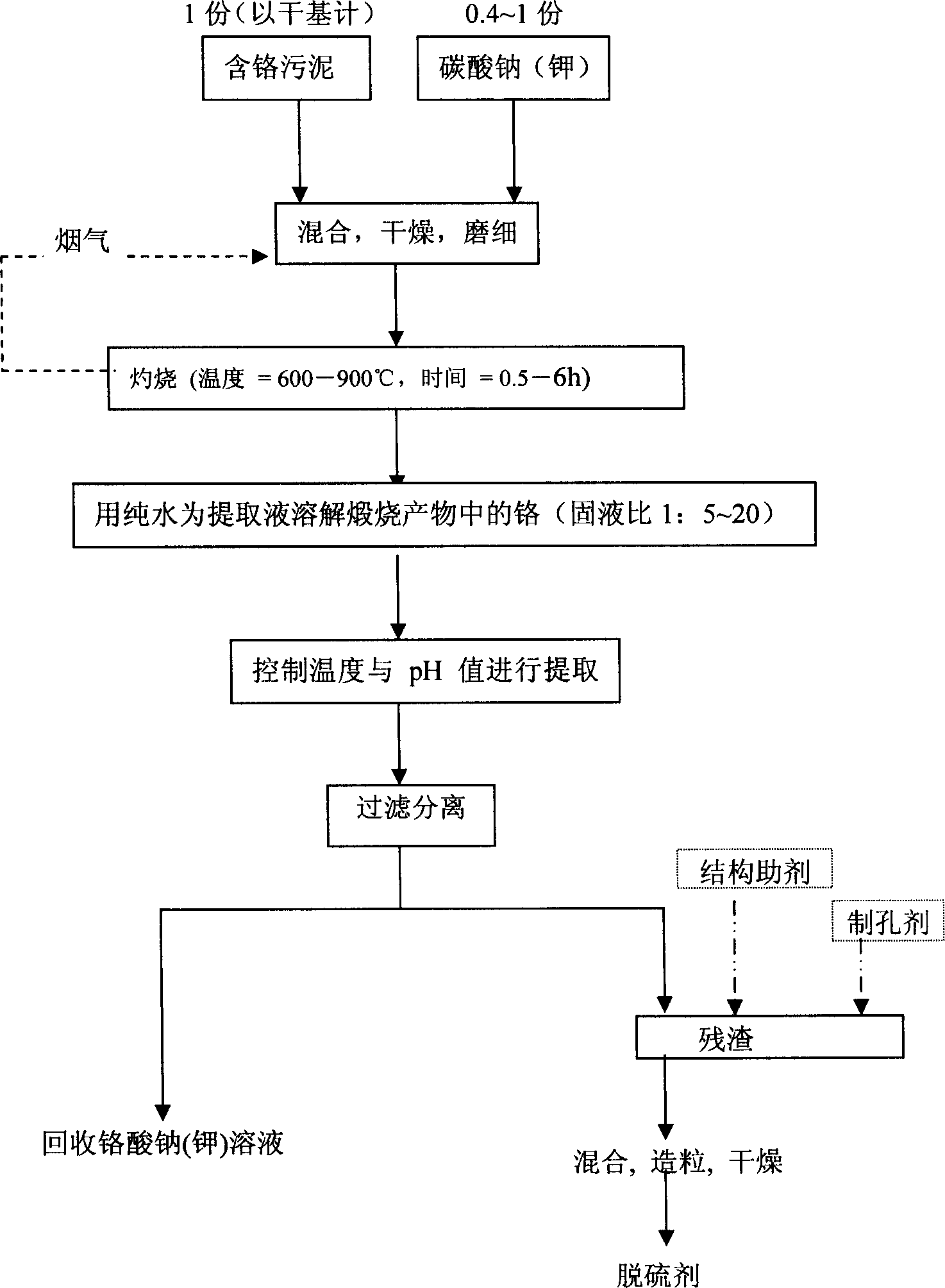

Method for recovering chromium from iron and steel plant waste water and sludge, and its resource utilization method

ActiveCN1807291AAchieve recyclingSimple processSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeResource utilization

The invention relates to a method to recover the Cr element and make proper use to the residue in sewage and sludge from steel plant. Wherein, drying the sludge to mix with Na2CO3 or K2CO3 by ratio as 1: 0. 4~1 and roast for 0. 5~6h at 600-900Deg; leaching with water by ratio as 1: 5~10 for 0. 2~12h to recover Cr element; and adding necessary auxiliary agent to prepare biogas desulfurizer with the separated residue as well material. The whole process produces no pollutent.

Owner:徐州美利圆环保科技有限公司

Internal exhaust recirculation method for an internal combustion engine

InactiveCN1774568AAvoid increased smokingGood effectInternal combustion piston enginesNon-fuel substance addition to fuelExhaust valveExhaust gas emissions

The invention relates to the internal exhaust-gas recirculation in an internal combustion engine with gas exchange valves periodically controlled by a camshaft ( 22 ) in accordance with the four-stroke principle, in which, during the gas exchange exhausting of exhaust gas from the respective cylinder ( 1 ) into the exhaust duct ( 5 ), an intake valve ( 2 ) associated with the respective cylinder ( 1 ) is open in a crank angle range after top dead center of the ignition of the gas mixture present in the cylinder ( 1 ), in order to exhaust part of the exhaust gas into an intake duct ( 3 ), so that during the next gas exchange intake both fresh gas and exhaust gas are taken in from the intake duct ( 3 ), the respective intake valve ( 2 ) being actuated during the gas exchange exhausting independently of the periodic gas exchange intake, and the additional opening of the respective intake valve ( 2 ) being carried out in the range from 110 to 150% of the opening angle of the start of opening of the exhaust duct ( 5 ) by the exhaust valve ( 4 ).

Owner:FEV MOTORENTECHN GMBH

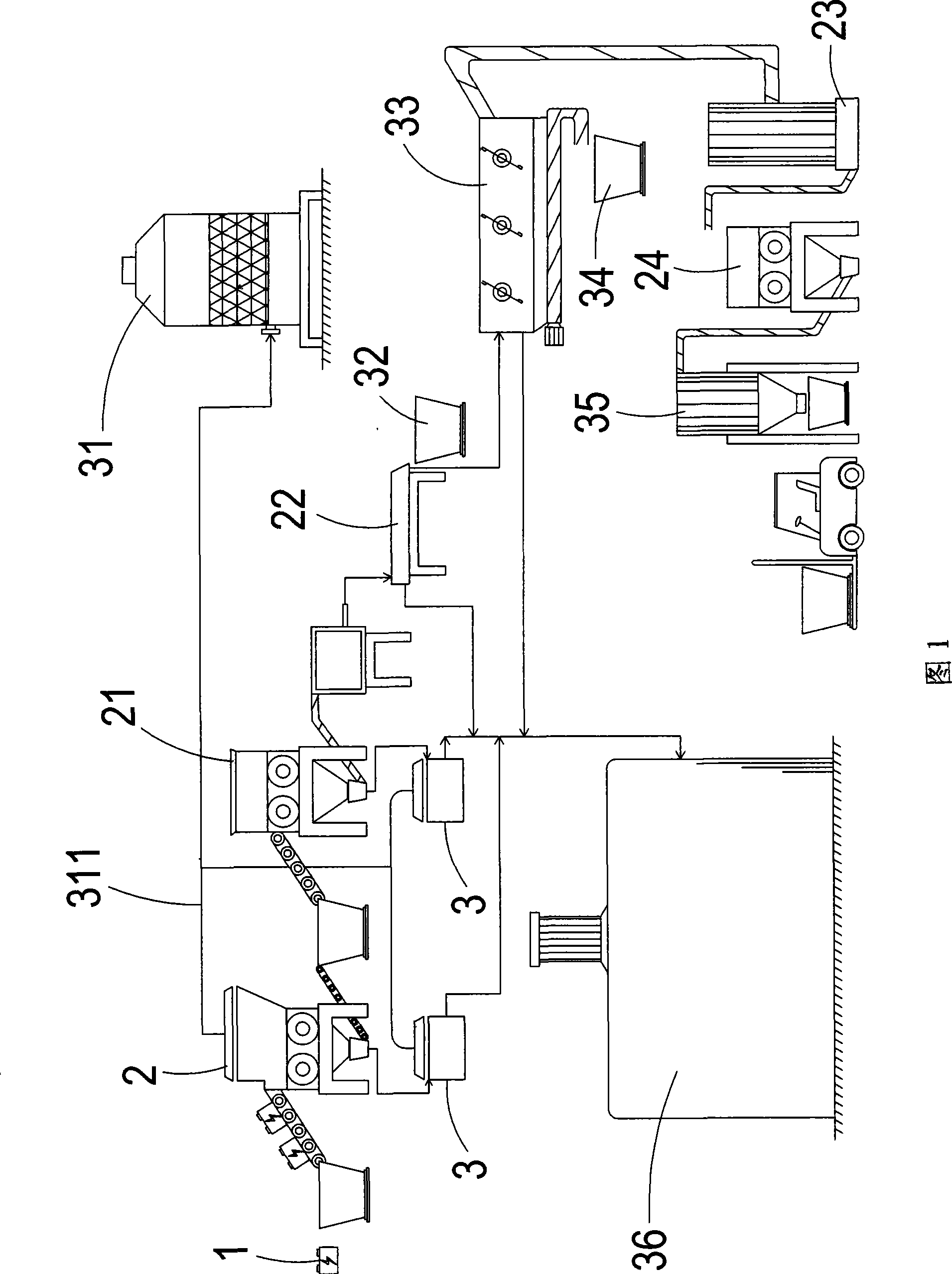

Equipment for steel slag air quenching and waste heat recycling

ActiveCN102952908AExpand the scope of processingImprove mobilityIncreasing energy efficiencyManufacturing convertersQuenchingSlag

Equipment for steel slag air quenching and waste heat recycling belongs to the technical field of the steel slag processing equipment and method. Steel slag air quenching and waste heat recycling processes are utilized to treat high-temperature steel slags and recovering heat; and the technical scheme is as follows: in the equipment, an air quenching slag pot is connected with a pelletization air tunnel which is connected with a grate cooling conveyor; the grate cooling conveyor is connected with a high-temperature-resistant bucket elevator; the high-temperature-resistant bucket elevator is connected with a circulating fluidized bed heat recovery boiler; an external nitrogen pipeline is connected with the pelletization air tunnel and the grate cooling conveyor, respectively; and a nitrogen circulating pipeline is connected with the high-temperature-resistant bucket elevator and the circulating fluidized bed heat recovery boiler, respectively. The process flow comprises hardening and cracking liquid-state steel slags into even particles by using low-temperature nitrogen, and then feeding the steel slag particles to the circulating fluidized bed heat recovery boiler through pneumatic transmission so as to collect waste heat and zero-valent iron. The integrated steel slag air quenching process provided by the invention is in a world leading level and is innovation of liquid-state steel slag treatment and heat recovery, thereby having wide prospect.

Owner:唐钢国际工程技术有限公司

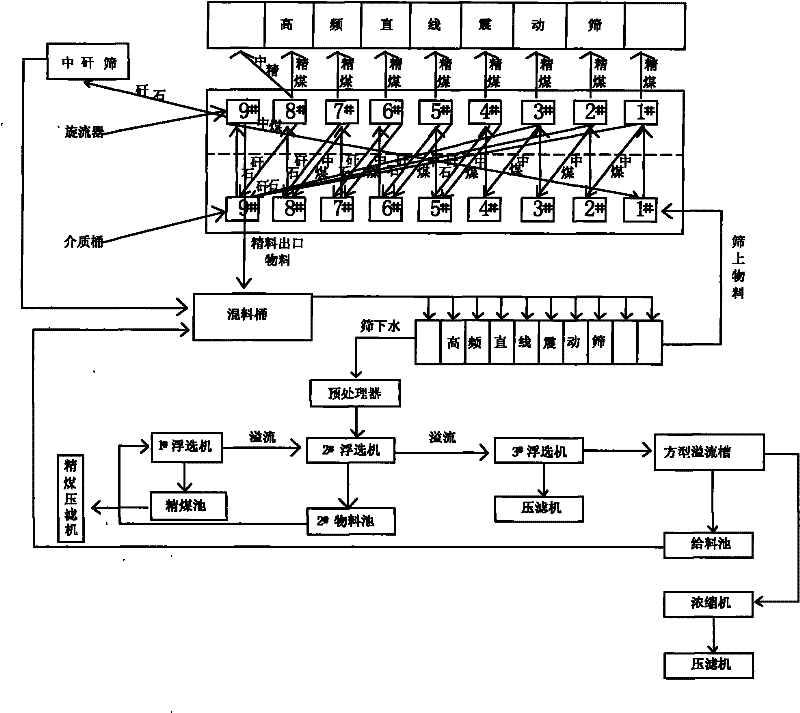

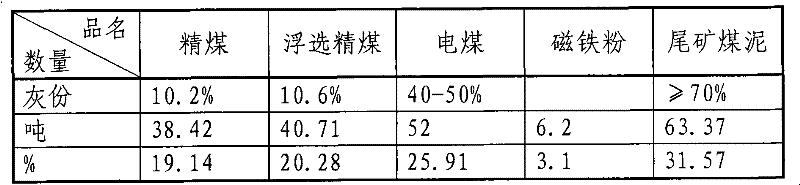

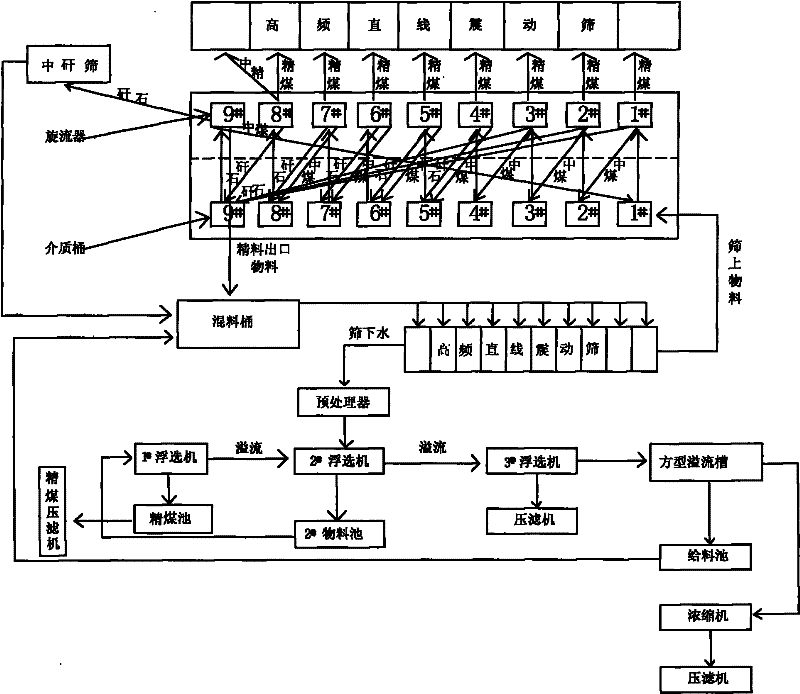

Method for recycling clean coal from high-ash coal slurry tailings

The invention relates to a method for recycling clean coal from high-ash coal slurry tailings, which belongs to the method for recycling the clean coal from the coal slurry tailings. The method is mainly used for solving the technical problem that the existing coal cleaning method can not perform separation on high-ash coal slurry by utilizing the differences in density and particle size. The technical scheme of the invention is as follows: the method for recycling the clean coal from the high-ash coal slurry tailings comprises the following steps: firstly regulating water in the coal slurry to the concentration which is below 30%, using a pump to pump the coal slurry into a material mixing barrel, and enabling the coal slurry to automatically flow into a high-frequency linear vibrating screen for screening so as to realize desliming and coarse cutting-off and separation of the coal slurry, wherein the mesh size of the high-frequency linear vibrating screen is 200-260 meshes; enabling material below the screen after screening and separation by the high-frequency linear vibrating screen to pass through multiple stages of flotation machines connected in series for recycling the clean coal; and adopting nine stages of cyclones connected in series to recycle the clean coal from the material above the screen after screening and separation by the high-frequency linear vibrating screen.

Owner:杨灵奎

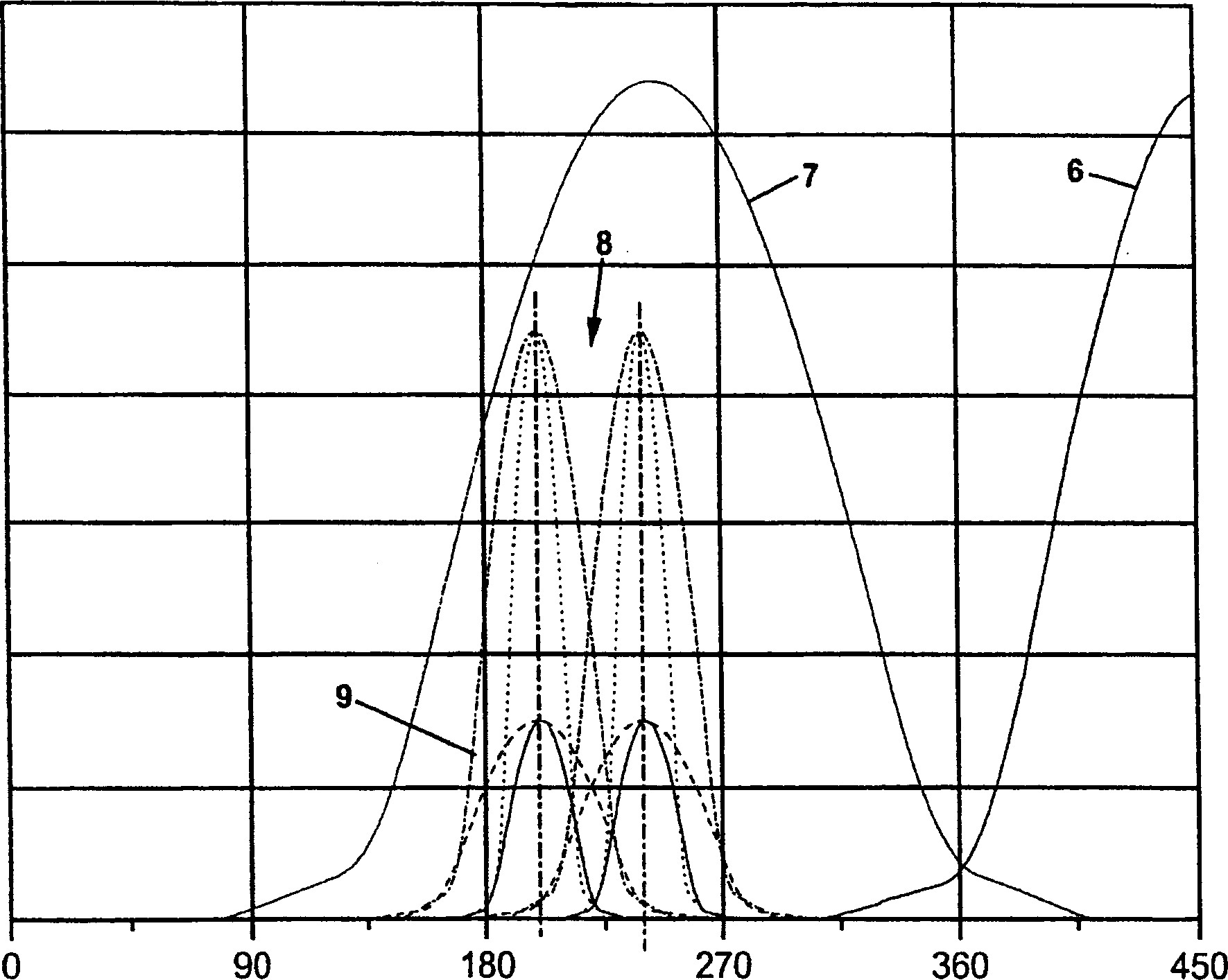

Low-pressure waste gas recirculating system based on supercharged engine

InactiveCN106762238AHigh recycling rateIncrease temperatureElectrical controlInternal combustion piston enginesProcess engineeringAtkinson cycle

The invention provides a low-pressure waste gas recirculating system based on a supercharged engine. The supercharged engine comprises a gas inlet side and a gas compressor arranged on the gas inlet side. The low-pressure waste gas recirculating system comprises a waste gas recirculating loop, an auxiliary waste gas recirculating loop and a controller; the waste gas recirculating loop is used for introducing part of waste gas exhausted out of a Miller and / or Atkinson circulating engine into the gas inlet side through the gas compressor for reburning; the auxiliary waste gas recirculating loop is used for introducing part of the waste gas exhausted out of the Miller and / or Atkinson circulating engine into the gas inlet side for reburning on the condition that the gas compressor is not used; the controller is used for controlling the waste gas to selectively flow through the waste gas recirculating loop and the auxiliary waste gas recirculating loop according to the vehicle driving speed. According to the low-pressure waste gas recirculating system based on the supercharged engine, part of the waste gas exhausted out of the engine can enter an air cylinder for reburning through the gas compressor or not through the gas compressor under the different conditions, therefore, the gas temperature in the air cylinder before stroke compressing and the gas temperature at the beginning of burning can be increased, then the engine efficiency is improved, and the waste gas recirculating rate is increased.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD

Two-stroke internal combustion engine with internal scavenging

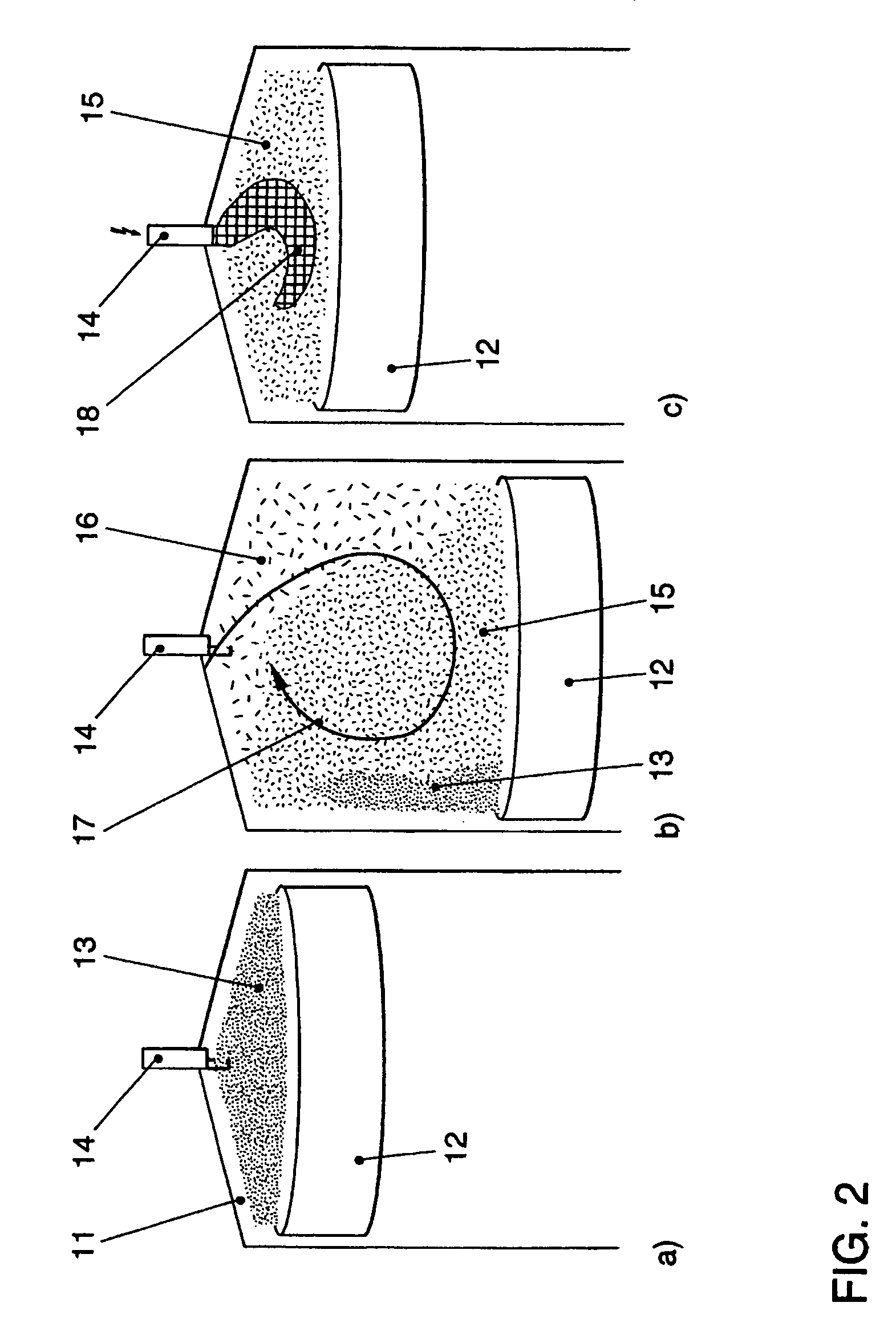

InactiveUS6892682B2Avoid fireHigh recycling rateNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberExhaust valve

The invention relates to a two-stroke internal combustion engine with longitudinal scavenging, with at least one piston reciprocating in a cylinder, with at least one exhaust valve disposed in the cylinder head floor and with at least one intake slot per cylinder which can be passed by a control edge of the piston, with at least one exhaust gas recirculation conduit for the recirculation of exhaust gas into the combustion chamber and at least one exhaust gas recirculation valve for controlling the recirculated exhaust gas quantity. In order to enable exhaust gas recirculation in the simplest possible way, it is provided that the exhaust gas recirculation conduit starts out directly from the combustion chamber and the exhaust gas recirculation valve is arranged as a stroke valve which is disposed in the region of the entrance of the exhaust gas recirculation conduit into the cylinder head floor.

Owner:AVL LIST GMBH

Dual-swirl water purifier

InactiveCN102614711AReach the standard of recyclingRealize the function of filtration and purificationFiltration circuitsWater resourcesOblique cutting

The invention belongs to the field of water treatment equipment and discloses a dual-swirl water purifier, which can perform tertiary sewage treatment without extra power. The dual-swirl water purifier is formed by sleeving three layers of pipe sleeves with different diameters, wherein the upper part of an outer sleeve is provided with a water inlet which is communicated with a primary swirl cavity; a sewage collecting and settling area and a sewage outlet are formed on the lower part in the outer sleeve; a water inlet oblique cut is formed on the surface of a middle section of a middle sleeve along the tangential direction; the outer surface is wound with spiral swirl vanes and spiral swirl lower vanes; gaps are reserved between the vanes and the outer sleeve; a gap is not reserved between the lower vanes and the outer sleeve; and a filtering net is arranged on an outer surface of an inner meshed pipe framework and is communicated with a purified water outlet. Three filtering and purifying functions, namely primary filtering, middle precision filtering and final filtering are realized, and the invention has the characteristics that the water purifier is small in size, compact in structure and high in sewage treatment amount, a recycling ratio of water is improved, and the water resources are saved.

Owner:北京五一环保科技股份有限公司

Internal combustion engine

ActiveUS9316180B2Increase high pressureLarge volumeInternal combustion piston enginesExhaust apparatusTurbochargerEngineering

In an exhaust gas turbocharger system for charging an engine including a compressor arrangement at a charging fluid side LL and a turbine arrangement at an exhaust gas side AG, a further compressor which is driven by a separate controllable drive and whose primary side is connected to the charging fluid side LL while its secondary side is connected to the exhaust gas side is provided for compressing charge air taken from the charging fluid side and supply it to the exhaust gas side for assisting driving the exhaust gas turbines so as to maintain them at relatively high speeds in transition periods including engine idling.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

Manufacturing process for porous opening metal pipe

InactiveCN101011791AReduce manufacturing costIncrease productivityExtrusion diesOther manufacturing equipments/toolsPunch pressEngineering

The multi perforated metal tube is made by crushing the metal blank, cold rolling and strap opening to form the metal plate, punching holes on the metal plate, welding perforated round tubes through mold locating, grinding the round tube to get the final product, and finally compressing the got round tube to multi perforated square tube, rectangular tube or shape tube through molds. It is easy in process, low in cost, high in efficiency, good in material quality, strong in structure, less in welding joint, high in material recovery rate, low in mold scrap and strong in repairing.

Owner:青静

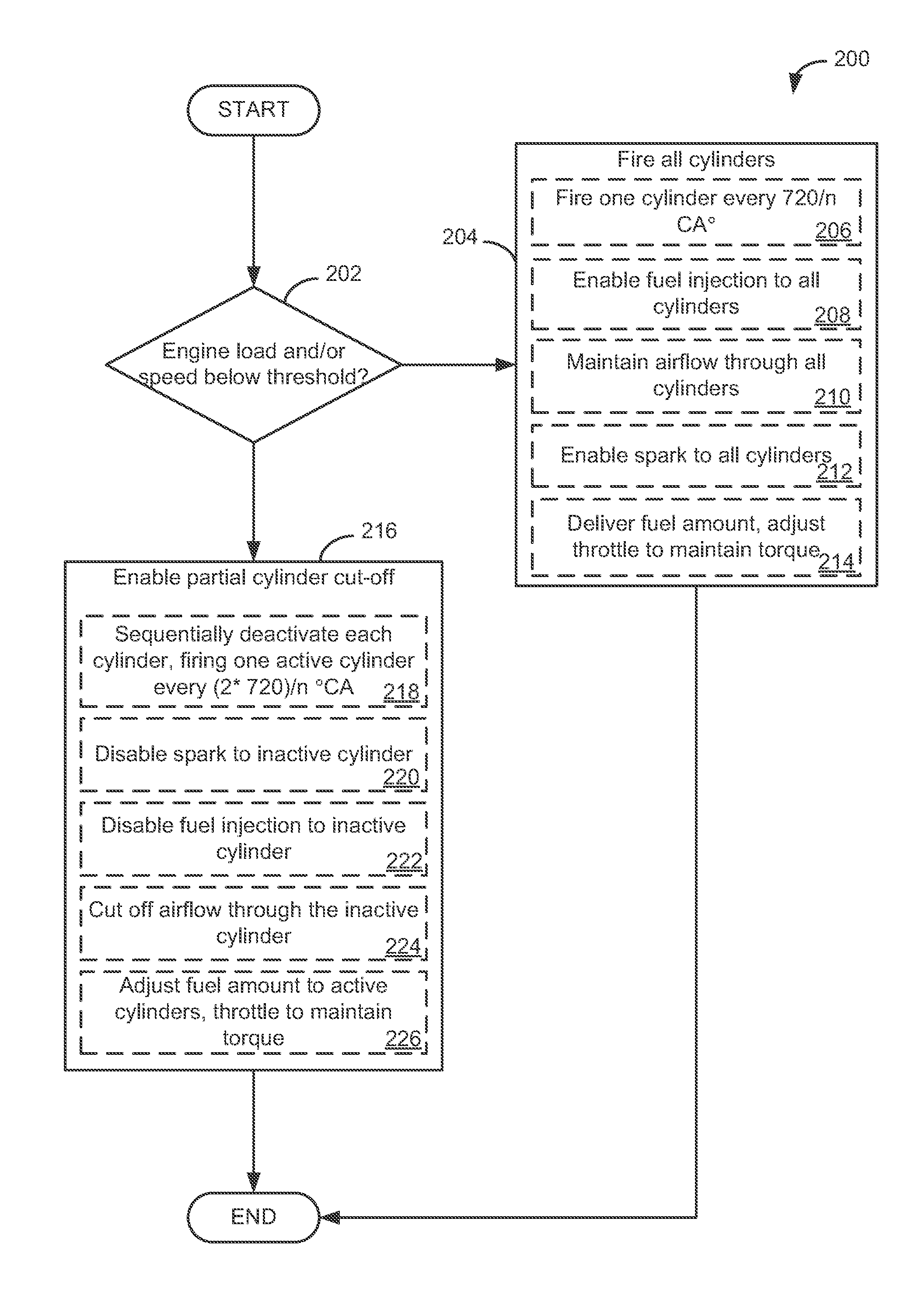

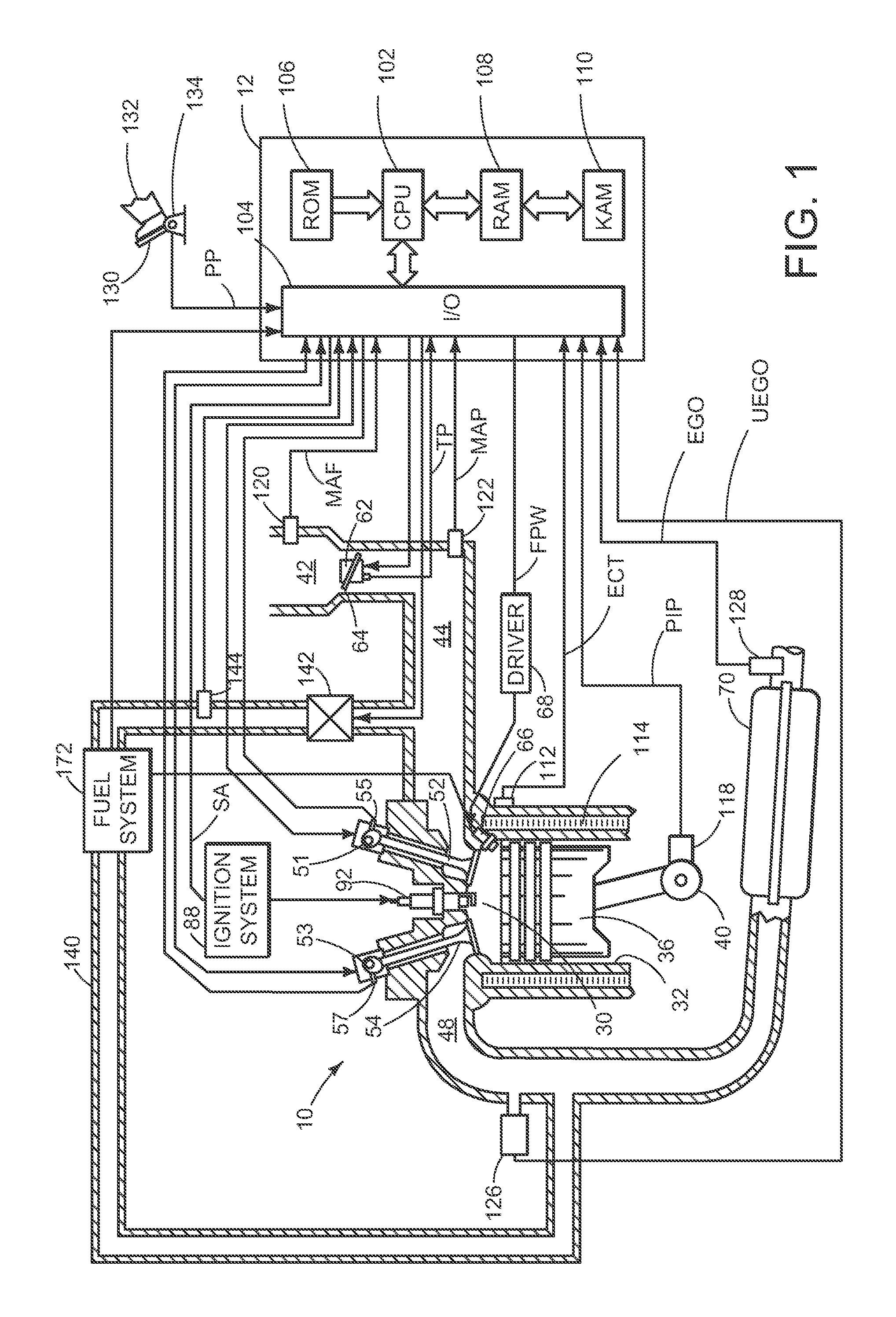

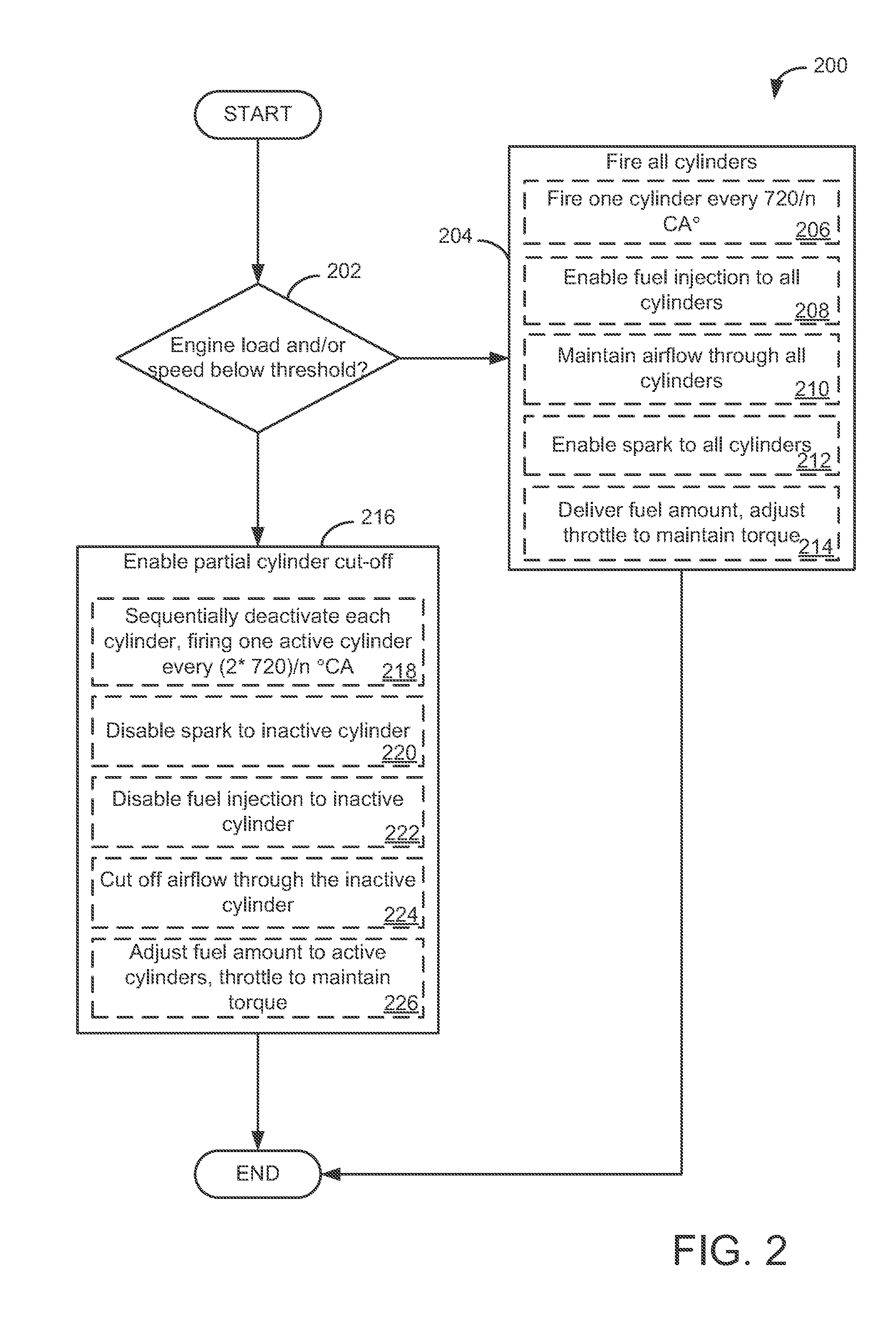

Multi-cylinder internal combustion engine and method for operating a multi-cylinder internal combustion engine

ActiveUS20150142296A1No lossLarge air massAnalogue computers for vehiclesElectrical controlInternal combustion engine

A method for partial cylinder cutoff is provided. The method comprises operating a multi-cylinder internal combustion engine with applied ignition, in which an odd number n of cylinders is arranged in line, and during partial-load operation when engine load is below threshold, enabling a partial cutoff of the cylinders, the partial cutoff comprising operating each cylinder only intermittently such that each cylinder is fired and cut off in turn at an interval of (2*720° CA) / n.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com