Method for recovering chromium from iron and steel plant waste water and sludge, and its resource utilization method

A technology for recycling wastewater sludge and chromium, applied in the field of solid waste treatment and recycling, can solve the problems of high recovery cost, acid consumption, insufficient chromium content, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

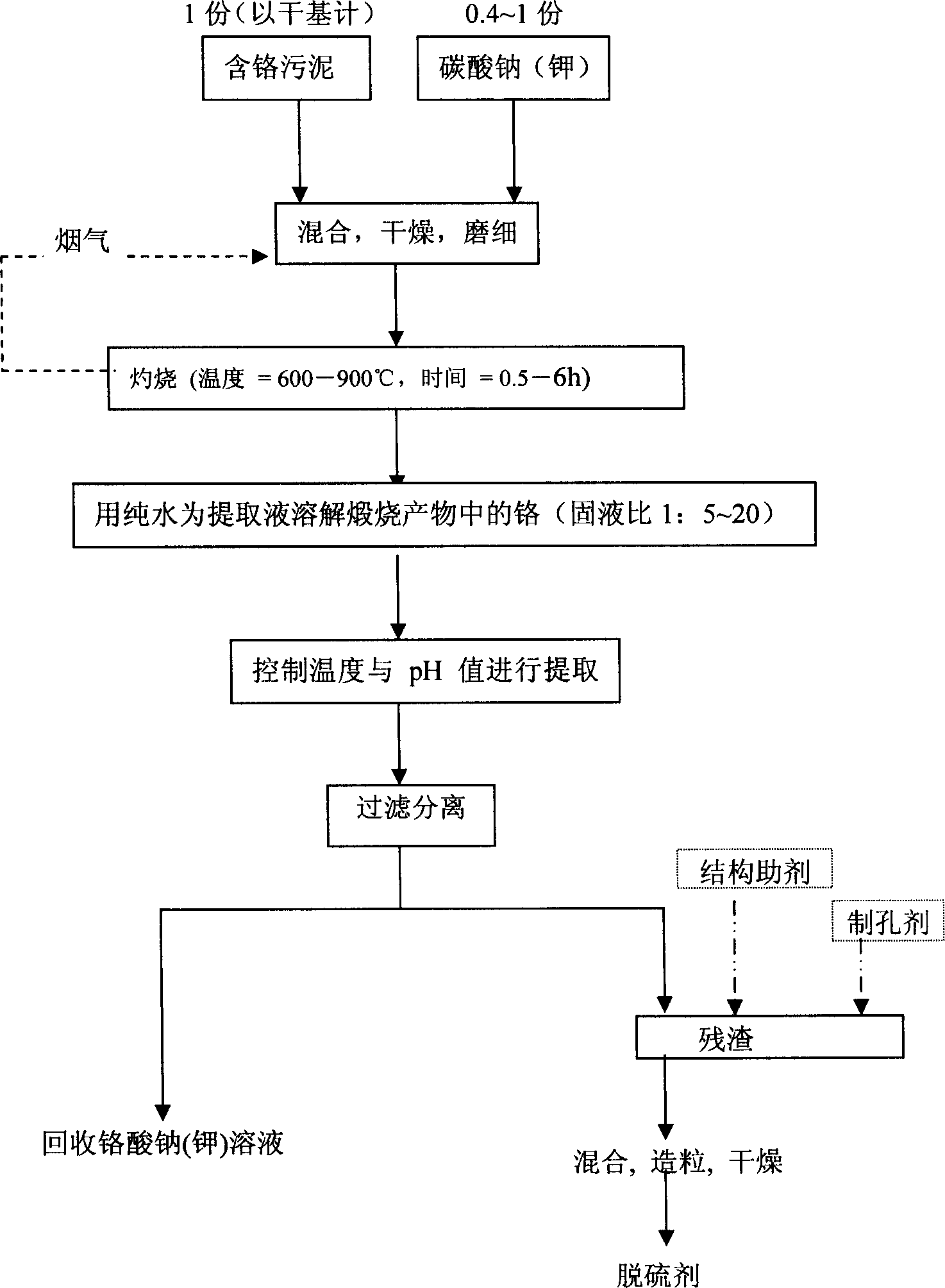

Method used

Image

Examples

example 1

[0029] The composition of a batch of wastewater sludge from a steel company in Shanghai is shown in Table 1:

[0030] elements and ingredients

[0031] The "non-volatile other solid impurities" listed in Table 1 refer to SiO 2 , CaSO 4 And Mn, Mg compounds. "Volatile solid impurities" refer to the weight loss when calcined above 600°C. Mix the sludge (calculated on a dry basis, the same below) with sodium carbonate at a mass ratio of 1:0.6, dry the sludge in a rotary kiln heater to a granular form, grind it finely, and roast it at 700°C for 4 hours. The high-temperature flue gas generated during the roasting process can be used as a heat source for sludge drying. Then add pure water at the ratio of solid-to-liquid mass ratio of 1:5 to leach chromium from the roasted product for 2 consecutive times, each leaching time is 0.5h, and add extremely dilute NaOH at the ratio of solid-to-liquid mass ratio of 1:2.5 for the third time Solution leaching, and supplemented by...

example 2

[0033] The composition of a batch of wastewater sludge from a steel company in Shanghai is shown in Table 2:

[0034] elements and ingredients

[0035] The sludge and sodium carbonate were mixed in a mass ratio of 1:0.8, and the sludge was dried to granular form in the rotary kiln heater (due to CaSO 4 The dried sludge is naturally granulated), ground into fine powder, and roasted at 800°C for 2 hours. The high-temperature flue gas generated during the roasting process can be used as a heat source for sludge drying. Then add pure water in the ratio of solid-liquid mass ratio 1:10 to extract chromium from the roasted product at 50°C. During the extraction process, air is introduced for 1h. Finally, the natural pH=11.95, and the concentration of chromium in the leaching solution is 8.97g / L, while the concentrations of iron and zinc were around 180ug / L and 200ug / L, respectively. The recovery rate of chromium is more than 80%. After adding structural aids and pore-for...

example 3

[0037] The iron and steel mill sludge in Example 1 was mixed with potassium carbonate at a mass ratio of 1:0.6, and the sludge was dried in a rotary kiln heater to a granular form, then ground, and then calcined at 900° C. for 1 hour. The high-temperature flue gas generated during the roasting process can be used as a heat source for sludge drying. Then add pure water at a solid-liquid ratio of 1:10 to extract chromium from the roasted product at 120°C. The extraction time is 2 hours, the natural pH=12.01, and the concentration of chromium in the extract is about 9.2g / L, while iron and zinc The concentrations are around 100ug / L and 120ug / L respectively. Then add a very dilute KOH solution with a solid-to-liquid mass ratio of 1:8, and leaching with air for 10 hours. The concentration of chromium in the leaching solution is about 1.87g / L, while the concentrations of iron and zinc are both below 100ug / L. The recovery rate of chromium is over 90%. After adding structural aids an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com