Method for purifying molybdenum sulfide in heavy metal waste water containing molybdenum, and the like

A purification method and heavy metal technology, applied in the direction of molybdenum sulfide, chemical instruments and methods, water/sewage treatment, etc., to achieve the effect of reducing content, high recycling rate, and reducing purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

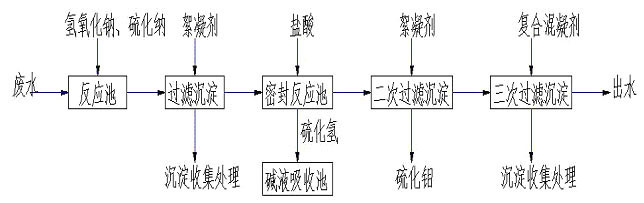

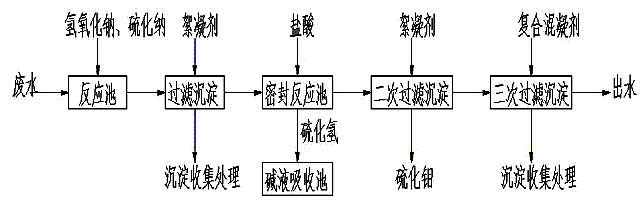

Image

Examples

Embodiment 1

[0020] Prepare a solution containing 100 mg / L molybdenum, 5 mg / L iron, 5 mg / L copper, and 5 mg / L zinc, adjust the pH of the solution to alkaline with a sodium hydroxide solution, and adjust the mass ratio of molybdenum to sodium sulfide at 1:3 Dosing sodium sulfide in the ratio of 1, reacting at room temperature for 1 hour, adding flocculant to the resulting solution and stirring rapidly, standing for 5 minutes, draining the clear liquid on the sediment and filtering. Adjust the pH value of the filtered solution to 2 with hydrochloric acid solution, react at room temperature for 2 hours, add flocculant polyacrylamide after precipitation occurs and stir rapidly, let stand for 5 minutes, discharge the clear liquid on the precipitate and filter. Adjust the pH value of the filtered solution to a neutral condition, add a mixed coagulant of polyaluminum chloride and ferrous sulfate and stir rapidly, let stand for 2 minutes, drain the supernatant on the sediment and filter. Detect th...

Embodiment 2

[0023] Prepare a solution containing 100 mg / L molybdenum, 5 mg / L iron, 5 mg / L copper, and 5 mg / L zinc, adjust the pH of the solution to alkaline with a sodium hydroxide solution, and adjust the molar ratio of molybdenum to sodium sulfide at 1:6 Dosing sodium sulfide in the ratio of 1, reacting at room temperature for 1 hour, adding flocculant to the resulting solution and stirring rapidly, standing for 5 minutes, draining the clear liquid on the sediment and filtering. Adjust the pH value of the filtered solution to 2 with hydrochloric acid solution, react at room temperature for 2 hours, add flocculant polyacrylamide after precipitation occurs and stir rapidly, let stand for 5 minutes, discharge the clear liquid on the precipitate and filter. Adjust the pH value of the filtered solution to a neutral condition, add a mixed coagulant of polyaluminum chloride and ferrous sulfate and stir rapidly, let stand for 2 minutes, drain the supernatant on the sediment and filter. Detect t...

Embodiment 3

[0026] Prepare a solution containing 100 mg / L molybdenum, 5 mg / L iron, 5 mg / L copper, and 5 mg / L zinc, adjust the pH of the solution to alkaline with a sodium hydroxide solution, and adjust the molar ratio of molybdenum to sodium sulfide at 1:6 Dosing sodium sulfide in the ratio of 1, reacting at room temperature for 1 hour, adding flocculant to the resulting solution and stirring rapidly, standing for 5 minutes, draining the clear liquid on the sediment and filtering. Use hydrochloric acid solution to adjust the pH value of the filtered solution to 1, react at room temperature for 2 hours, add flocculant polyacrylamide after precipitation occurs and stir rapidly, let stand for 5 minutes, discharge the clear liquid on the precipitate and filter. Adjust the pH value of the filtered solution to a neutral condition, add a mixed coagulant of polyaluminum chloride and ferrous sulfate and stir rapidly, let stand for 2 minutes, drain the supernatant on the sediment and filter. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com