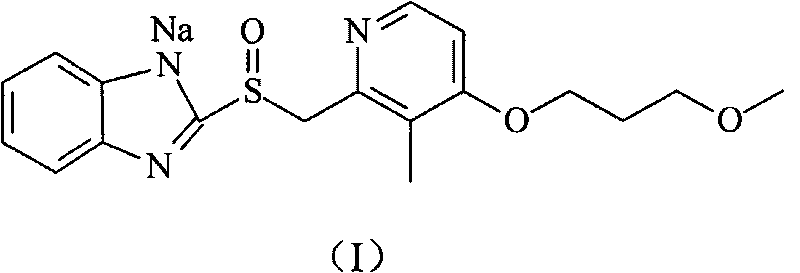

High-purity sodium rabeprazole compound

A technology of rabeprazole sodium and rabeprazole, which is applied in the field of medicine, can solve the problems of rabeprazole sodium purification cost, low yield and purity, difficulty in purification, low purity, etc., and achieve the improvement of clinical drug effect and simple method , high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The refining of embodiment 1 rabeprazole sodium

[0039] (1) 100g rabeprazole and 12.5g sodium hydroxide were stirred and reacted in water for 2 hours, spray-dried to generate 104.3g rabeprazole sodium;

[0040](2) Dissolve 100 g of rabeprazole sodium crude product in 2000 ml of water, add 20% sodium dihydrogen phosphate solution to adjust the pH value to 5.5, stir to precipitate insoluble matter, filter, and wash with 200 ml of purified water to obtain a solid;

[0041] (3) Dissolving the solid obtained in step (2) with a mixture of 1500ml dichloromethane and ethanol (1: 4), adsorbed by D101 macroporous adsorption resin, and eluted and purified with a mixture of 500ml chloroform and acetone (3: 2), Collect the eluate;

[0042] (4) The eluent obtained in step (3) is adjusted to a pH value of 9.0 with 5% sodium bicarbonate solution, and a solid is precipitated, centrifuged for 10 min, washed with 200 ml of ethanol, and vacuum-dried at 40° C. for 8 hours to obtain rabep...

Embodiment 2

[0043] The refining of embodiment 2 rabeprazole sodium

[0044] (1) 100g rabeprazole and 12.8g sodium hydroxide were stirred and reacted in water for 2 hours, freeze-dried to generate 103.8g rabeprazole sodium;

[0045] (2) Dissolve 100 g of rabeprazole sodium crude product in 2000 ml of water, add 5% sodium bisulfate solution to adjust the pH to 7.5, stir to precipitate insoluble matter, filter, and wash with 200 ml of purified water to obtain a solid;

[0046] (3) Dissolve the solid obtained in step (2) with a mixture of 1500ml of dichloromethane and ethanol (1:4), absorb through AB-8 macroporous resin, and elute and purify with a mixture of 500ml of chloroform and acetone (3:2) , to collect the eluate;

[0047] (4) The eluate obtained in step (3) is adjusted to a pH value of 11.0 with 10% potassium bicarbonate solution, and a solid is precipitated, centrifuged for 10 min, washed with 200 ml of ethanol, and vacuum-dried at 50° C. for 5 hours to obtain rabeprazole The pur...

Embodiment 3

[0048] The refining of embodiment 3 rabeprazole sodium

[0049] (1) 100g rabeprazole and 13.2g sodium hydroxide were stirred and reacted in water for 2 hours, spray-dried to generate 105.1g rabeprazole sodium;

[0050] (2) Dissolve 100g of rabeprazole sodium crude product in 2000ml of water, add 5% potassium hydrogen tartrate solution to adjust the pH to 6.8, stir to precipitate insoluble matter, filter, and wash with 200ml of purified water to obtain a solid;

[0051] (3) Dissolve the solid obtained in step (2) with a mixture of 1500ml of dichloromethane and ethanol (1:4), absorb through AB-8 macroporous resin, and elute and purify with a mixture of 500ml of chloroform and acetone (3:2) , to collect the eluate;

[0052] (4) The eluent obtained in step (3) is adjusted to a pH value of 10.0 with 5% potassium carbonate solution, and a solid is precipitated, centrifuged for 10 min, washed with 200 ml of ethanol, and vacuum-dried at 45° C. for 6 hours to obtain rabeprazole sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com