Method for processing waste lead accumulator

A technology for waste lead-acid batteries and processing equipment, which is applied in the field of environmental protection and can solve problems such as waste liquid overflow, environmental pollution, environmental pollution and sanitation by waste lead-acid batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

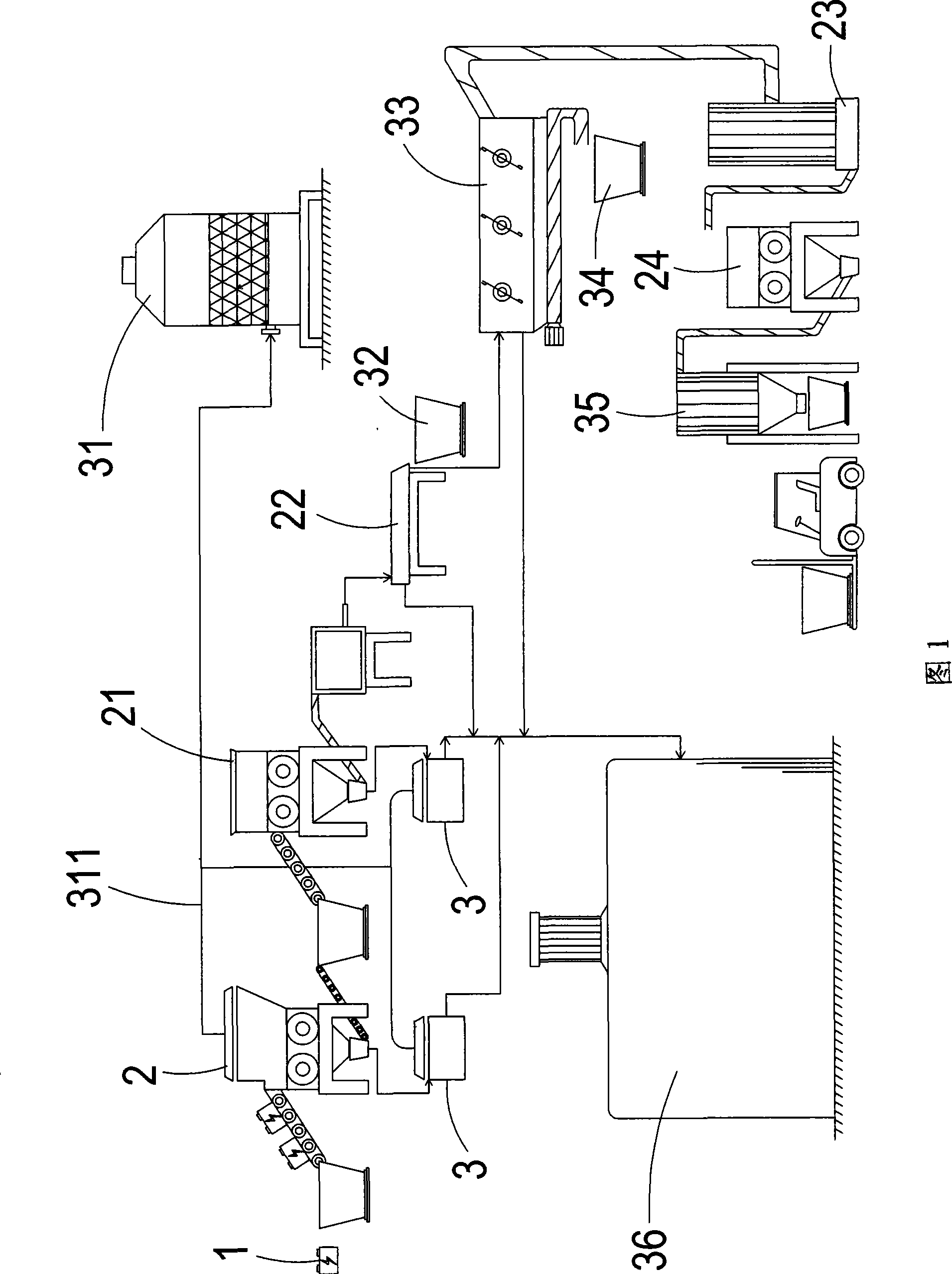

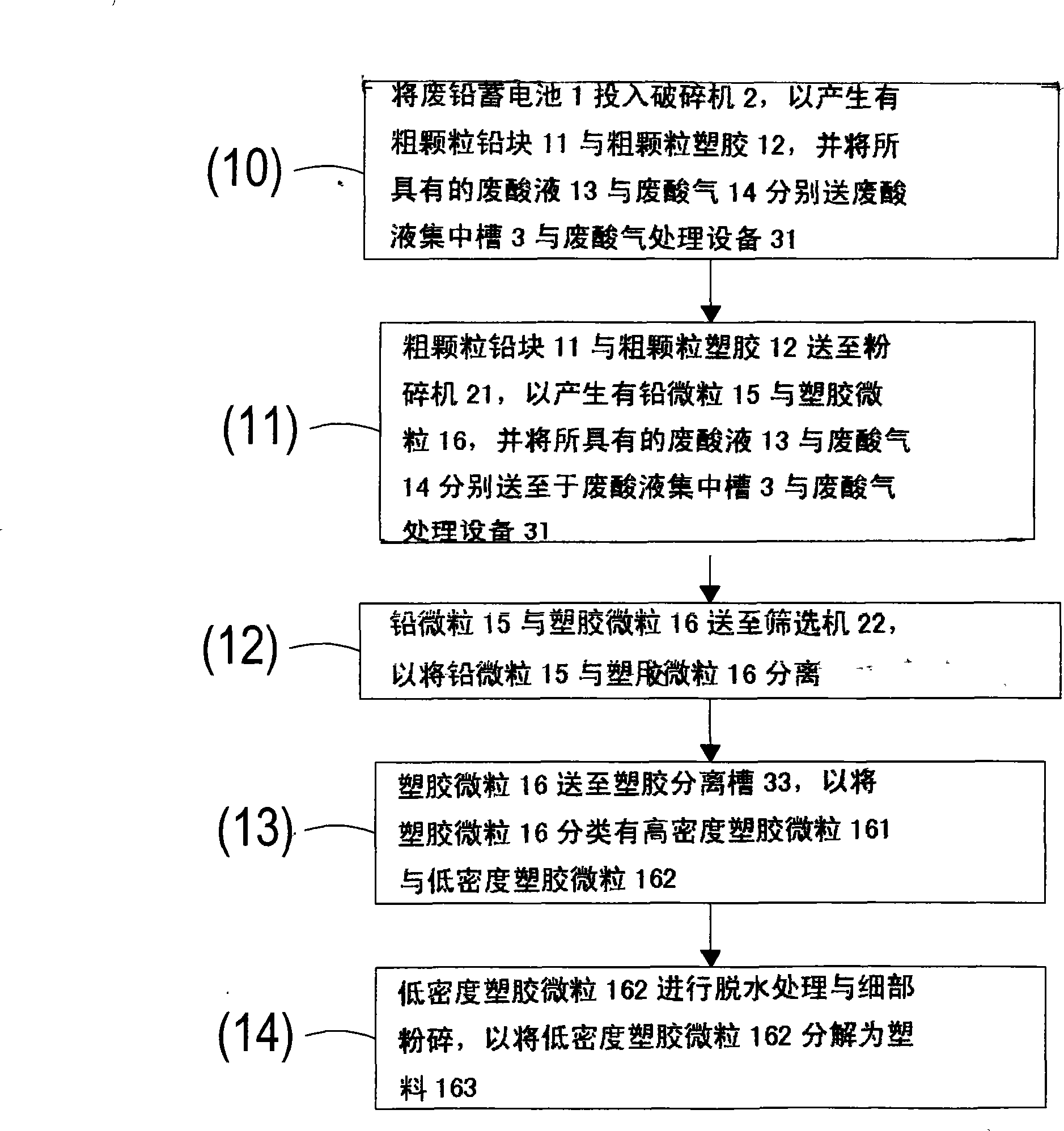

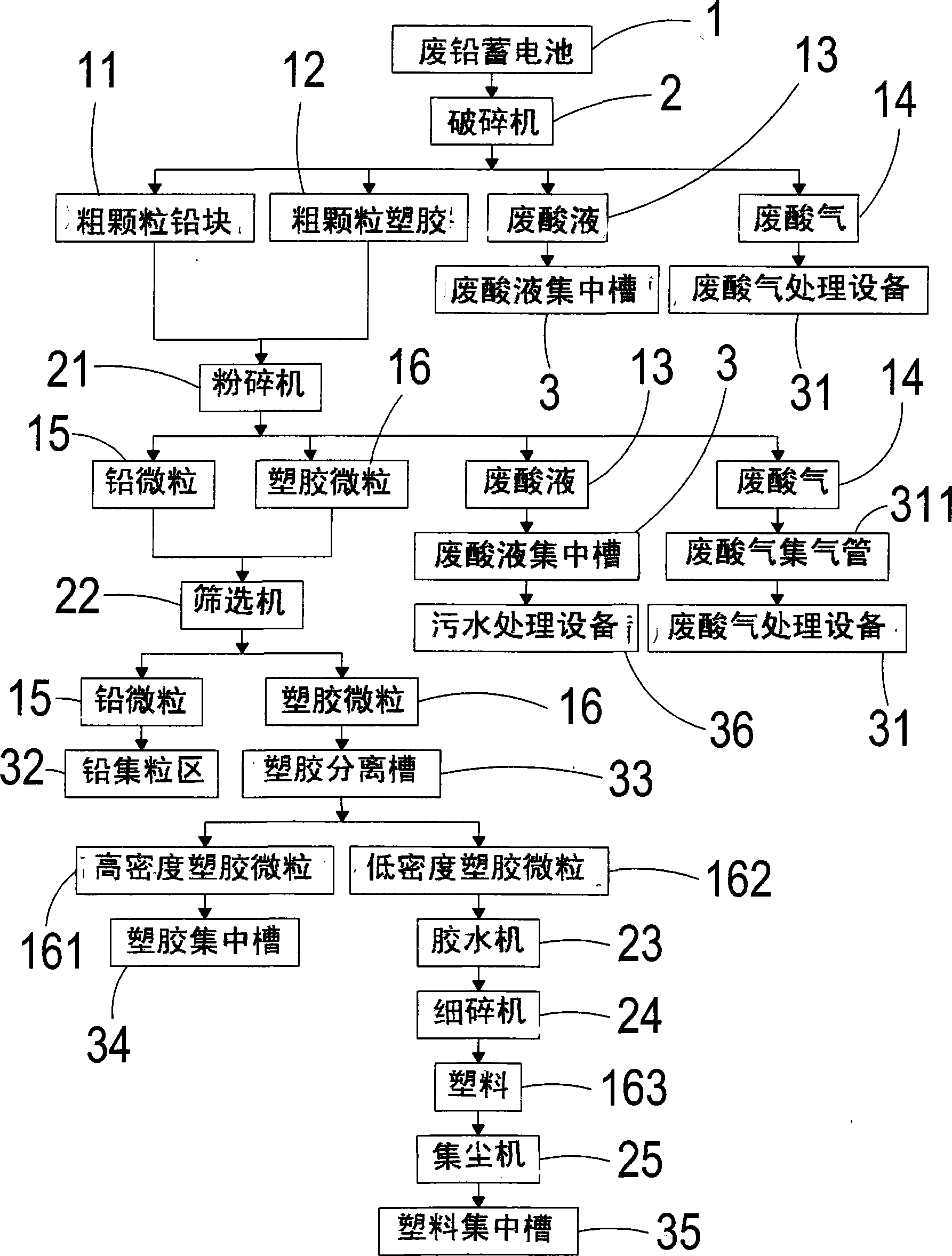

[0024] Attached Figure 1 to Attached image 3 Shown, the present invention carries out according to the following steps:

[0025] 10. Put the waste lead storage battery 1 into the crusher 2 to produce coarse-grained lead block 11 and coarse-grained plastic 12, and send the waste acid liquid 13 and waste acid gas 14 to the waste acid liquid concentration tank 3 and Waste acid gas treatment equipment 31;

[0026] 11. Send the coarse-grained lead block 11 and the coarse-grained plastic 12 to the pulverizer 21 to produce lead particles 15 and plastic particles 16, and send the waste acid liquid 13 and waste acid gas 14 to the waste acid liquid concentration Tank 3 and waste acid gas treatment equipment 31;

[0027] 12. The lead particles 15 and the plastic particles 16 are sent to the screening machine 22 to separate the lead particles 15 from the plastic particles 16;

[0028] 13. The plastic particles 16 are sent to the plastic separation tank 33 to classify the plastic parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com