Cascaded recycling system for waste heat of internal combustion generating set

A technology for waste heat and cascade recovery of generator sets, which is applied to internal combustion piston engines, combustion engines, engine components, etc., can solve the problems of low power generation efficiency and low energy utilization efficiency, increase power generation, improve total recycling efficiency, reduce Effect of exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

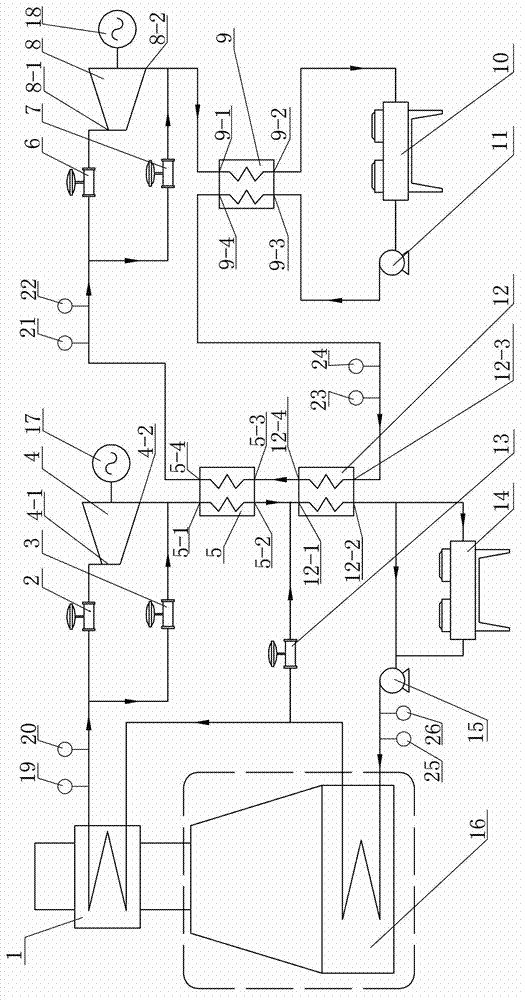

[0010] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a cascade waste heat recovery and utilization system of an internal combustion generator set in this embodiment includes a water vapor Rankine cycle subsystem and an organic Rankine cycle subsystem;

[0011] The steam Rankine cycle subsystem includes a waste heat boiler 1, a steam turbine 4, a first generator 17 and a transfer pump 15; the organic Rankine cycle subsystem includes an organic working fluid evaporator 5, an organic working fluid preheating device 12, organic turbine 8, regenerator 9, organic working medium condenser 10, organic working medium pump 11 and second generator 18;

[0012] The superheated steam outlet of the waste heat boiler 1 is connected with the working medium inlet port 4-1 of the steam turbine 4, and the working medium outlet port 4-2 of the steam turbine 4 is connected with the first inlet 5 of the organic working medium evaporator 5 -1 port is connected, t...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the recycling system in this embodiment also includes a first regulating valve 2, and a first regulating valve is installed on the pipeline connecting the superheated steam outlet of the waste heat boiler 1 and the working medium inlet port of the steam turbine 4. Regulating valve 2, the first regulating valve 2 is an electric regulating valve or a pneumatic regulating valve. With this setting, the control is convenient and timely, meeting the needs of steam parameters. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the recycling system described in this embodiment also includes a second regulating valve 3, and a second regulating valve is installed on the pipeline connecting the superheated steam outlet of the waste heat boiler 1 and the working medium outlet port 4-2 of the steam turbine 4. Two regulating valves 3, the second regulating valve 3 is an electric regulating valve or a pneumatic regulating valve. With such setting, the control is convenient and timely, which can ensure the start-up and emergency shutdown of the unit. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com