Internal exhaust recirculation method for an internal combustion engine

A technology of internal combustion engine and exhaust gas emission, which is applied in the direction of exhaust gas recirculation, internal combustion piston engine, combustion engine, etc., to achieve the effects of reduced fuel consumption rate, high exhaust gas recirculation rate and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

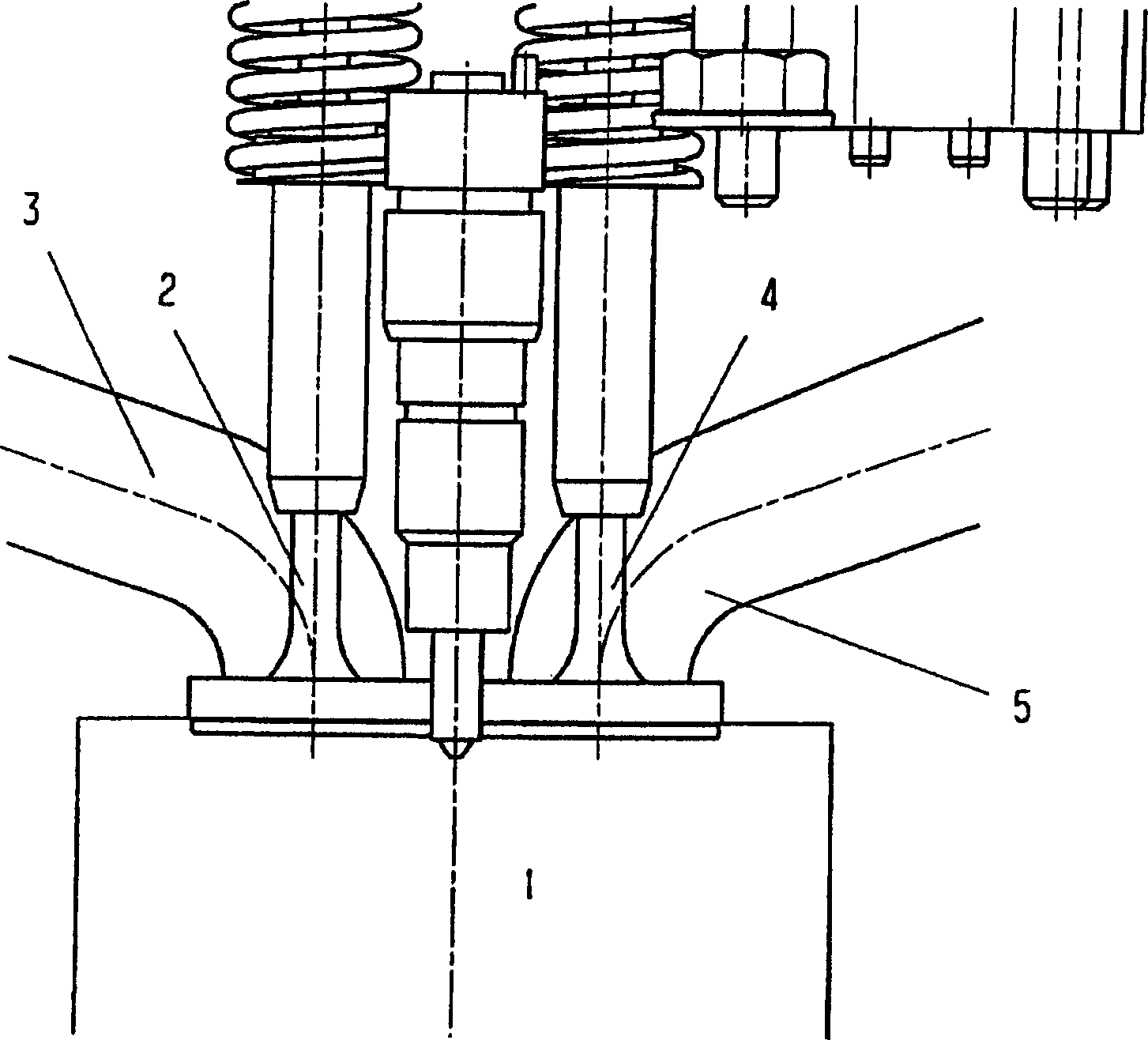

[0032] figure 1 It shows that the cylinder 1 among the multiple cylinders of the four-stroke internal combustion engine can be connected with the intake pipe 3 through the intake valve 2 for inhaling fresh air, and connected with the exhaust pipe 5 through the exhaust valve 4 for exhaust gas discharge.

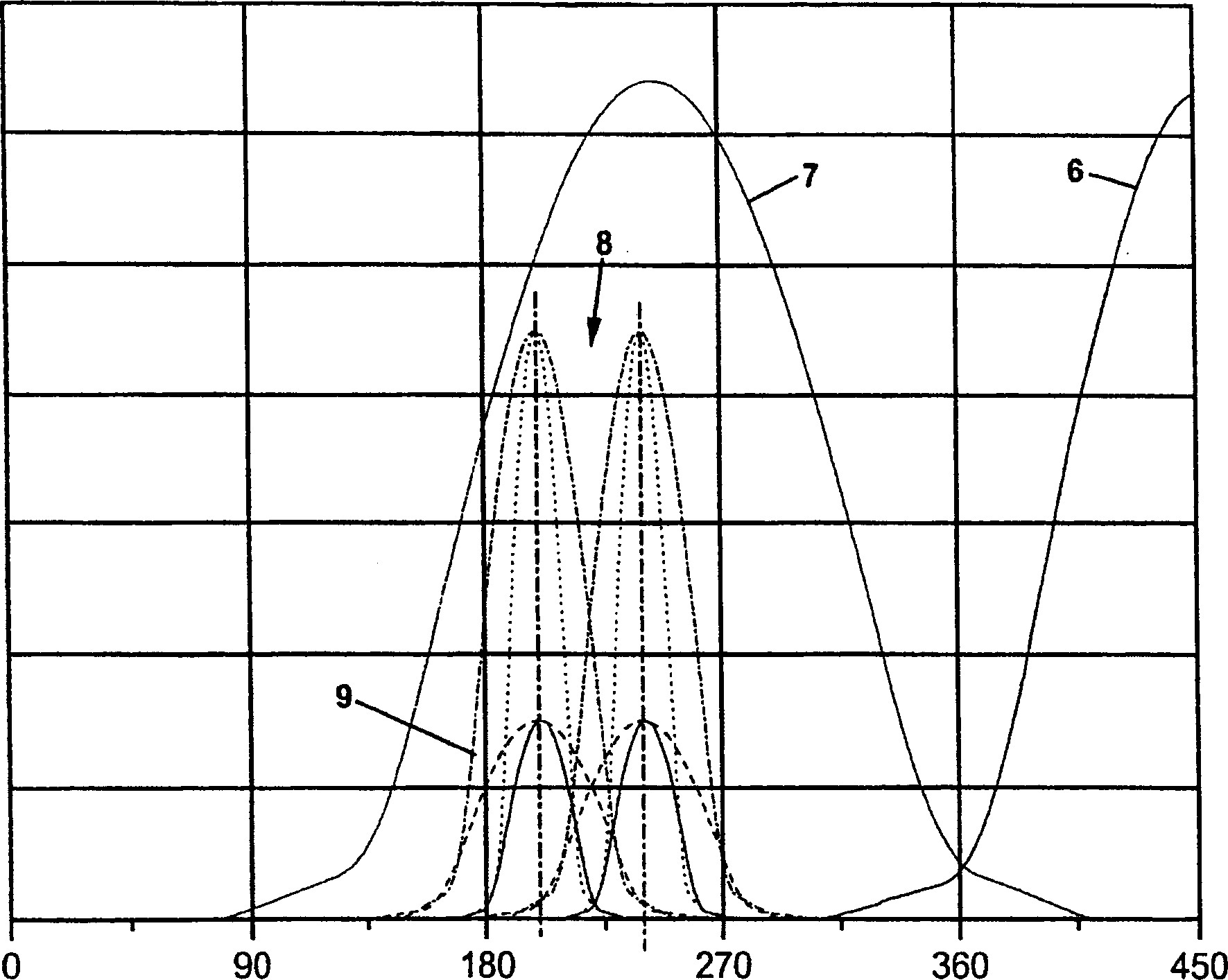

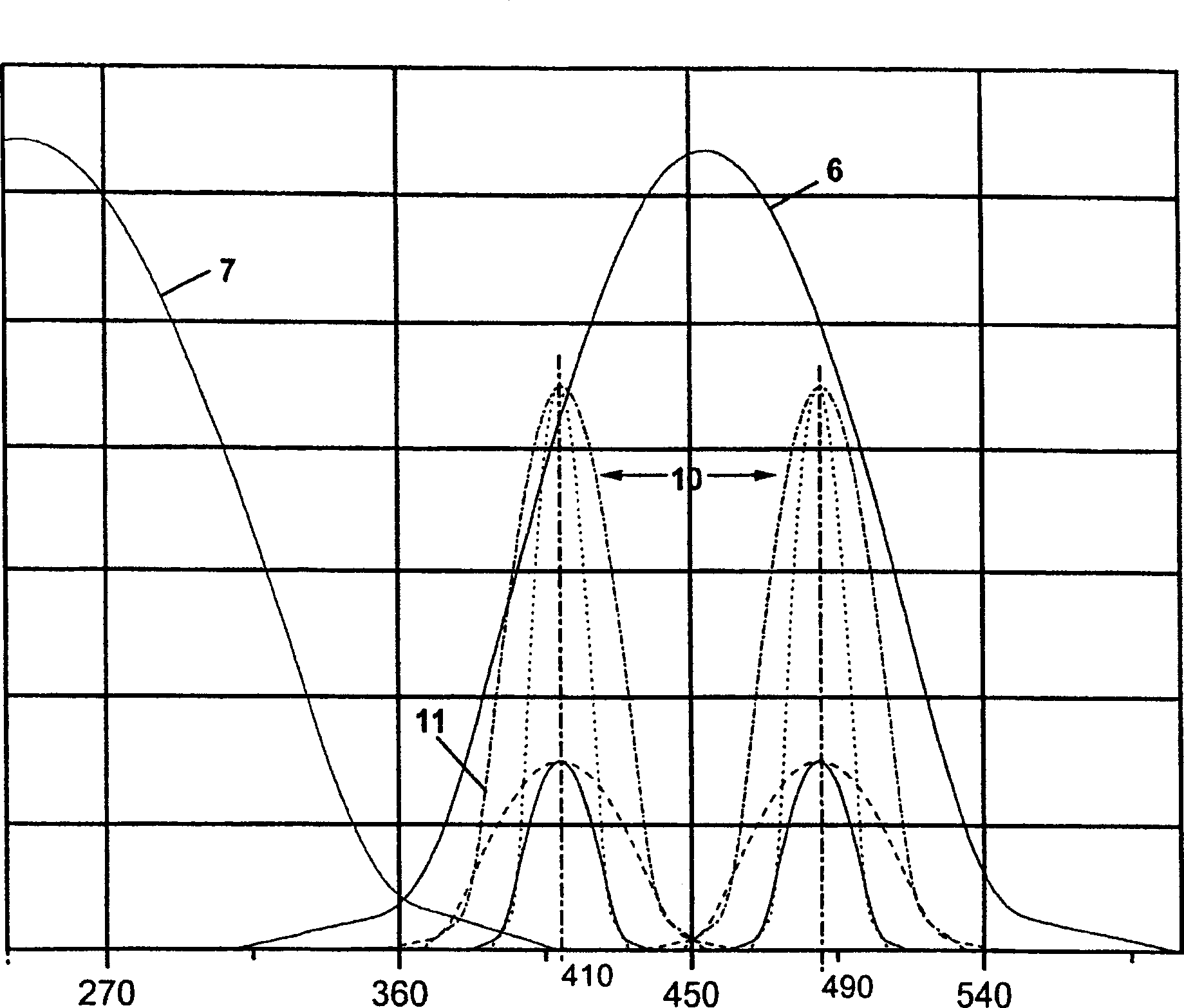

[0033] An internal combustion engine sequentially undergoes an intake stroke, a compression stroke, a combustion stroke, and an exhaust stroke, where the exhaust and intake strokes represent gas exchange. For this purpose, the valves 2, 4 are periodically actuated in known manner, in particular under camshaft control. During intake, figure 2 The partially shown valve lift curve 6 represents the intake valve 2, during exhaust the valve lift curve 7 represents the exhaust valve 4; the two valve lift curves 6, 7 can be superimposed on each other in a known manner, so that Exhaust gases are completely expelled from cylinder 1.

[0034] For internal exhaust gas recirculation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com