Low-pressure waste gas recirculating system based on supercharged engine

A technology of exhaust gas recirculation and recirculation system, applied in the direction of exhaust gas recirculation, engine components, engine control, etc., can solve problems such as reduction, slow combustion speed, unfavorable engine thermal efficiency, etc., to increase gas temperature, increase temperature, improve Effects on Engine Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

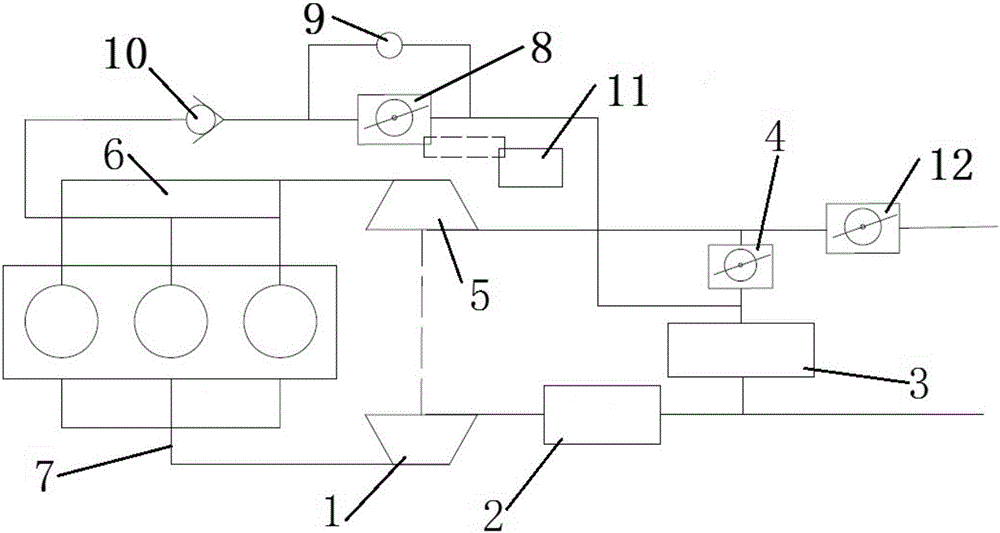

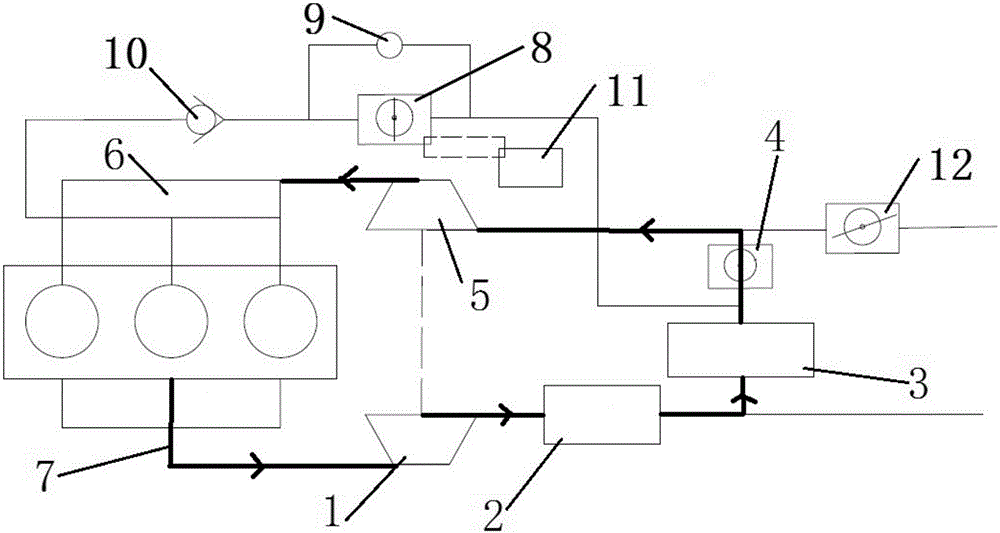

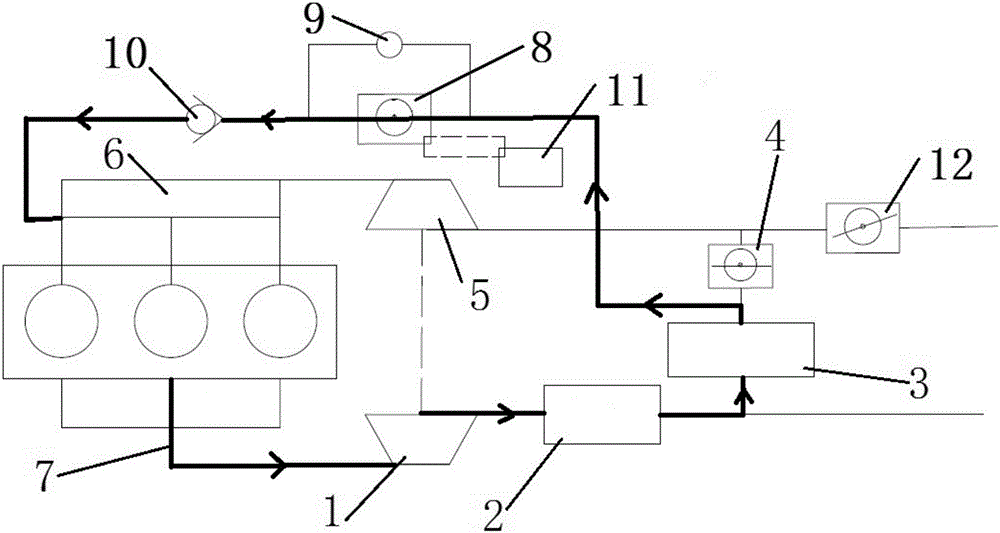

[0024] Such as figure 1 As shown, the approximate flow path of fresh air in the engine system is (some engine system conventional components are not marked in the figure): fresh air enters the engine intake pipe 6 through the mixing valve 12, the compressor 5, and then passes through the intake manifold The distribution of the fuel enters the engine and burns in the engine to do work. The combusted gases leave the engine exhaust pipe 7 and pass through the turbine 1 . The turbine 1 and the compressor 5 are components of a turbocharger. Turbine 1 uses the inertial momentum of the exhaust gas discharged from the engine to drive the turbine in the turbine chamber, and the turbine drives the coaxial impeller, which presses and sends fresh air, which is pressurized by the compressor 5 and enters the engine cylinder. The exhaust gas, having performed work in the turbine 1 , leaves the turbine 1 and enters the downstream catalytic converter 2 . The catalytic converter 2 can conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com