Method for recycling clean coal from high-ash coal slurry tailings

A high-ash coal recycling technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high-ash coal slime separation and unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

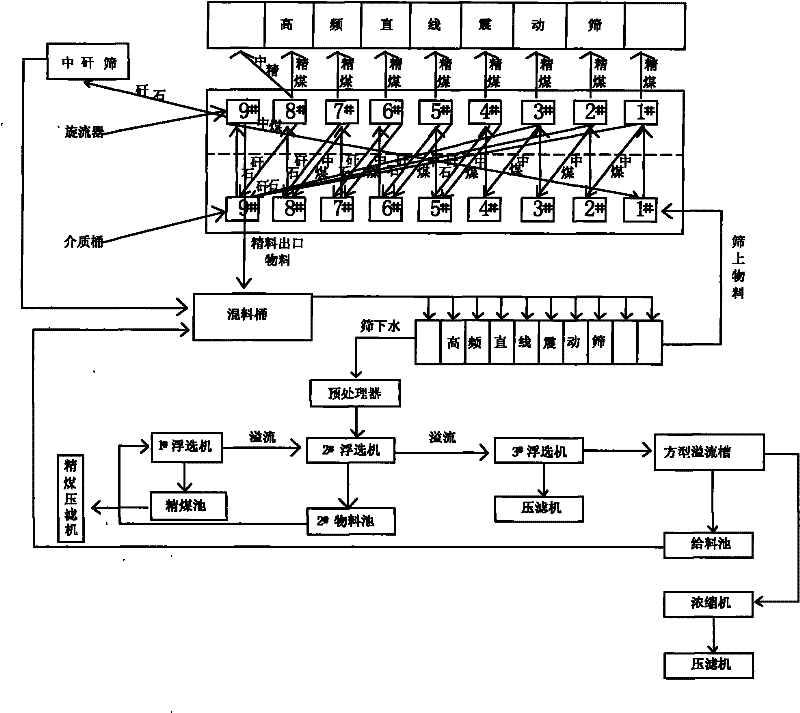

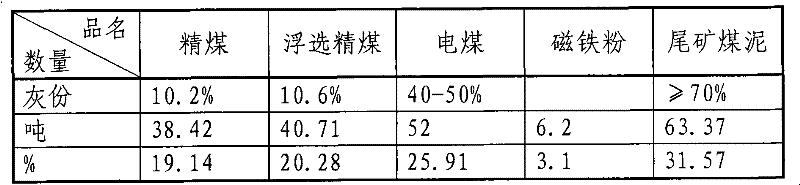

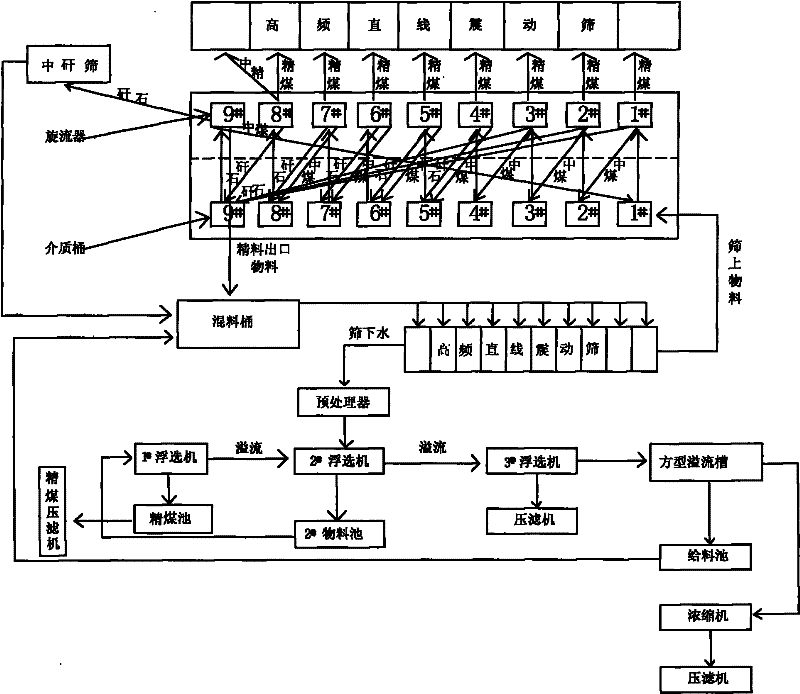

[0023] As shown in the accompanying drawings, a method for reclaiming clean coal from high-ash slime tailings in this embodiment includes the following steps: firstly adjust the slime water to a concentration below 30%, and drive it into the mixed coal with a pump. The material barrel flows into the high-frequency linear vibrating screen for screening to realize desliming and coal slime coarse separation. The mesh number of the high-frequency linear vibrating screen is 200 mesh;

[0024] The under-screen material screened and separated by the high-frequency linear vibrating sieve passes through the multi-stage flotation machine in series to recover clean coal. The steps are: the under-screen material under the high-frequency linear vibrating screen is sent to the preprocessor by water pump for drug mixing: drug foaming Collecting agent and collector are added according to the weight ratio of 1:2, and then flow into 2# flotation machine for rough selection, the scraped material ...

Embodiment 2

[0037] The mesh number of the high-frequency linear vibrating screen in this embodiment is 260 mesh, and the drug foaming agent and collector are added in a ratio of 1:8 by weight, and the rest are the same as those in Embodiment 1.

Embodiment 3

[0039] The mesh number of the high-frequency linear vibrating screen in this embodiment is 240 mesh, and the drug foaming agent and collector are added in a ratio of 1:6 by weight, and the rest are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com