Continuous technological method for multi-stage circular reaction of catalytic ozonation

A technology of ozone catalytic oxidation and process method, which is applied in the field of continuous process of ozone catalytic oxidation multi-stage cycle reaction, can solve the problems of ozone waste, poor coordination, large equipment investment, etc., and achieve equipment investment cost reduction, equipment size reduction, The effect of enhancing the mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

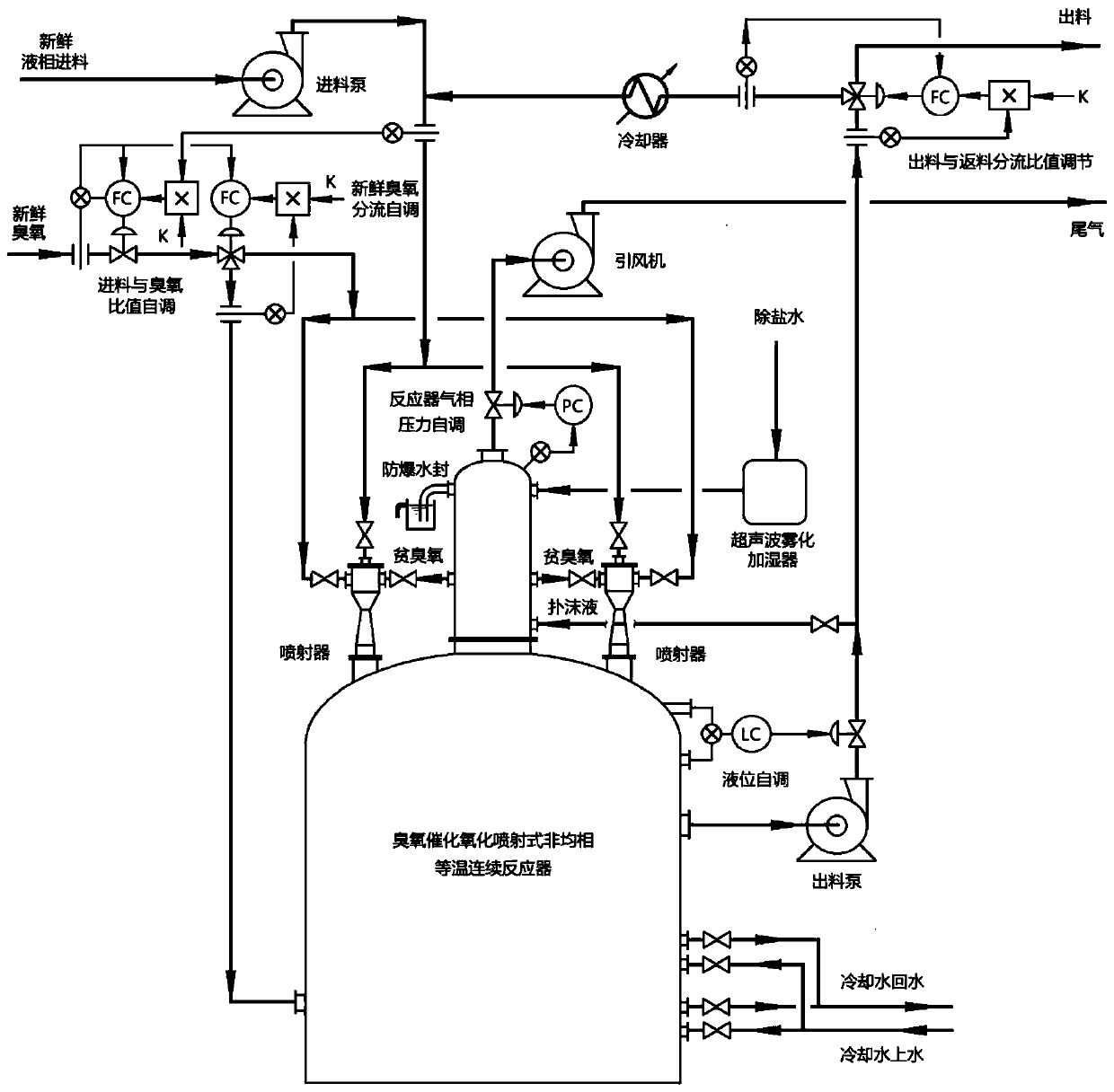

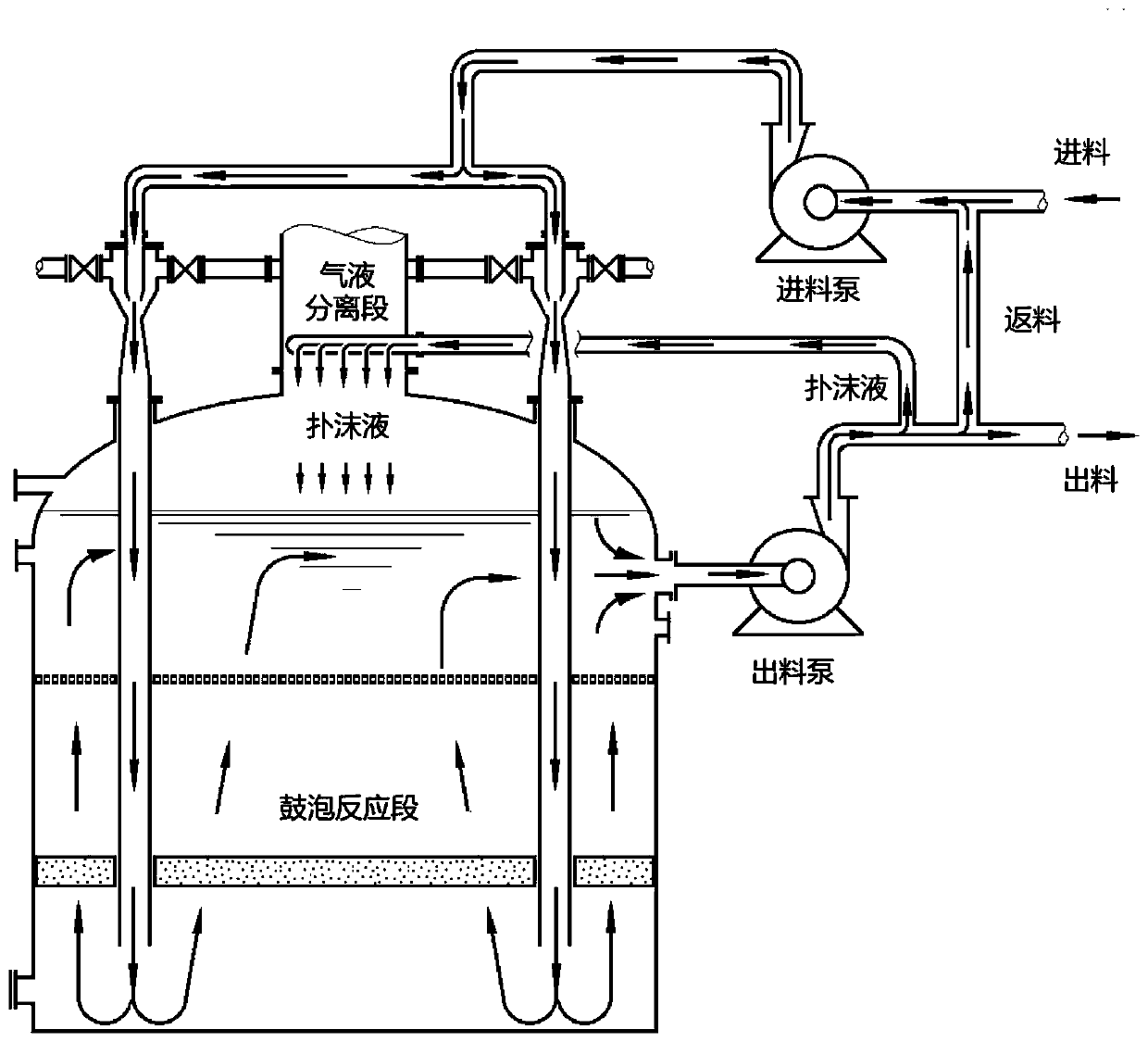

[0044] The technological process flow of the present invention conforms to the basic theory and basic principles involved in chemical reaction engineering. During the implementation process, according to the material characteristics and production requirements, the engineering design is carried out according to the relevant design regulations; the engineering construction is carried out according to the chemical equipment installation specifications; and formulating The corresponding production operation rules are organized and operated in compliance with the requirements of safety, environmental protection, occupational health and other relevant regulations.

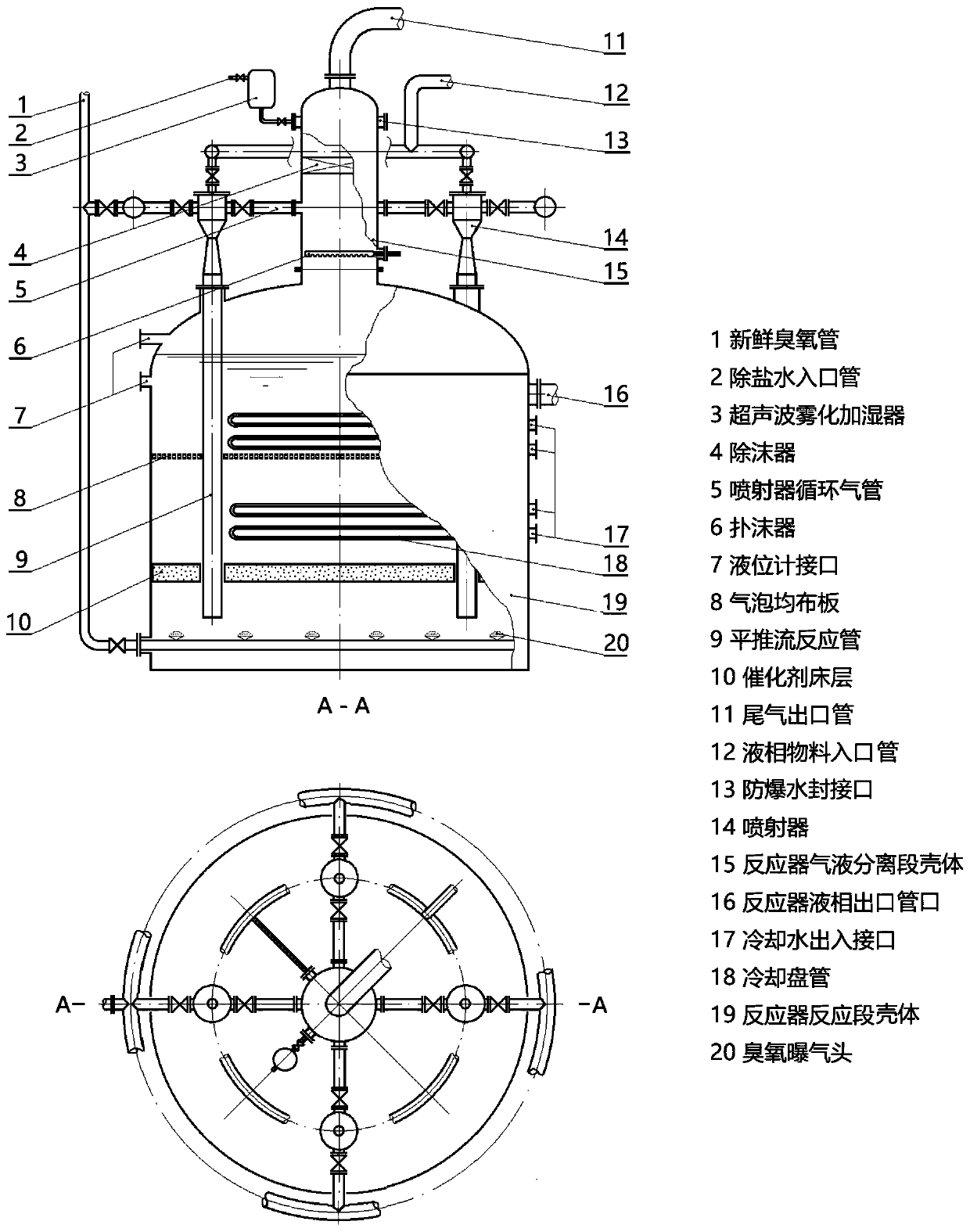

[0045] Among the related objects, the ozone catalytic oxidation injection heterogeneous isothermal continuous reactor assembly is a special conventional equipment. During implementation, materials are selected and manufactured according to mature chemical equipment manufacturing techniques; feed pumps, discharge pumps, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com