Device and method for automatically measuring parameters of taper thread of graphite electrode body

A graphite electrode and measuring device technology, applied in the field of automatic measuring equipment, can solve the problems of large manual measurement error and low precision, and achieve the effects of good usability, high precision, and avoiding human operation error and reading error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

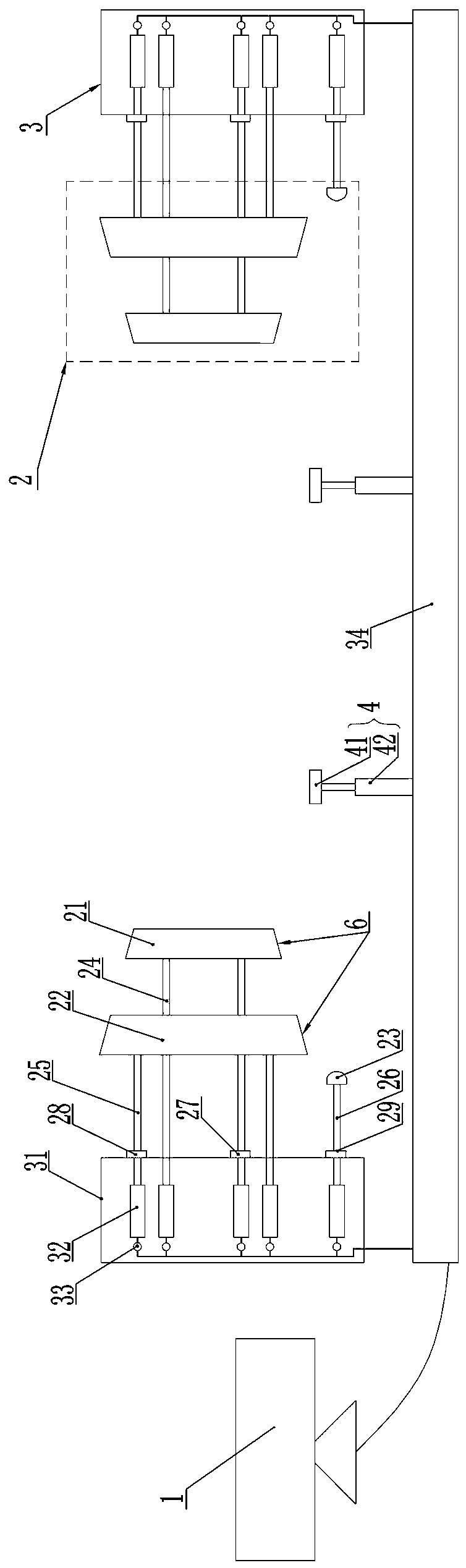

[0030] Embodiment 1: as Figure 1-Figure 2 As shown, an automatic measurement device for taper thread parameters of a graphite electrode body, including a drive assembly 3 symmetrically arranged on both sides, a plug gauge assembly 2 with a standard taper, and a computer control system 1;

[0031] The driving assembly 3 includes a box body 31, a plurality of first hydraulic cylinders 32 arranged in parallel in the box body 31, each first hydraulic cylinder 32 is connected to a hydraulic station 34 respectively, and each first hydraulic cylinder 32 is connected to the hydraulic station 34. There is a pressure sensor 33 for detecting the hydraulic oil pressure of each first hydraulic cylinder 32 .

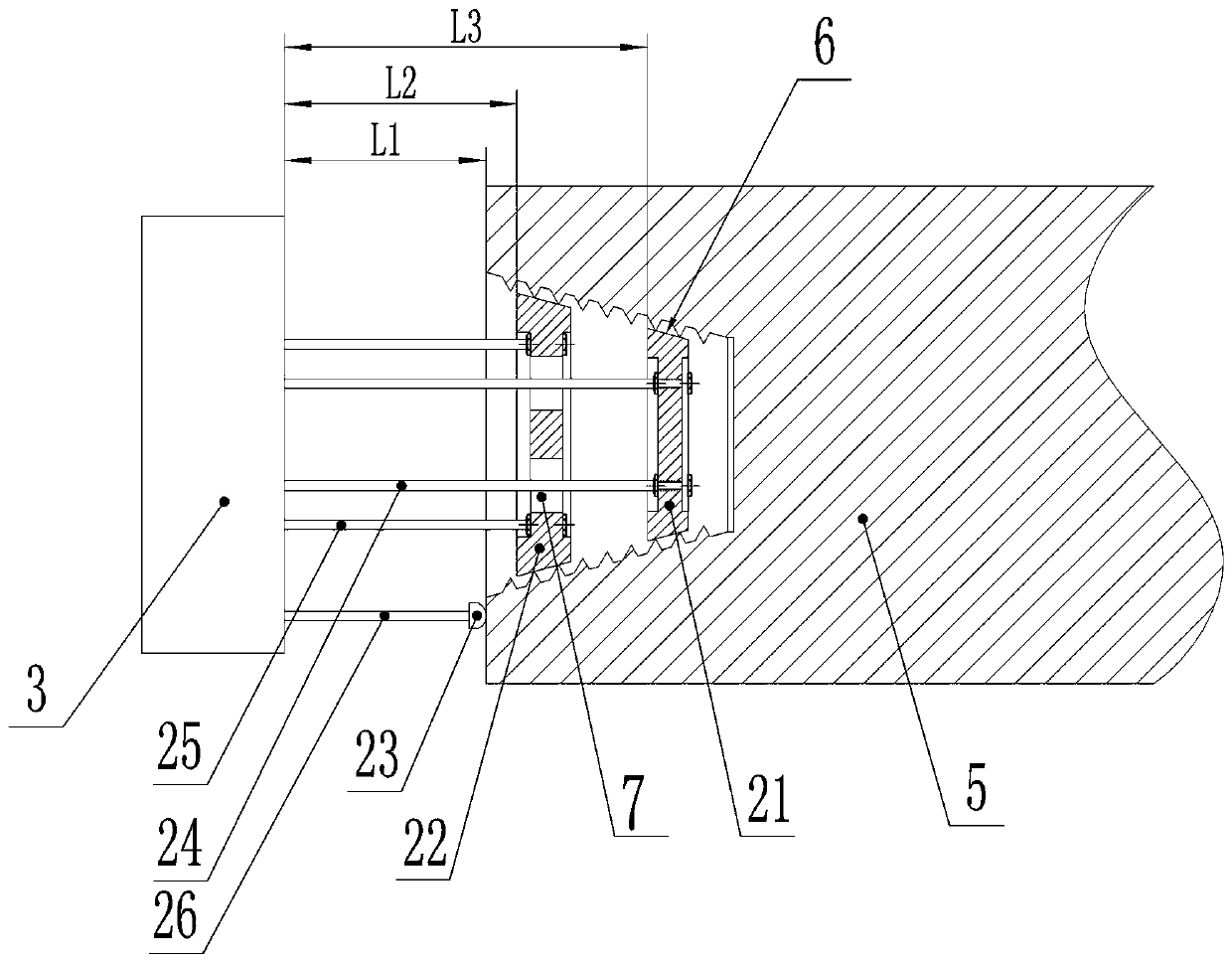

[0032] The plug gauge assembly 2 includes a large plug gauge 22 with a standard taper and a smooth outer conical surface 6, a small plug gauge 21, and an end surface measuring device 23. The rod 25 is fixedly connected, and the second digital display length meter 28 for measuring th...

Embodiment 2

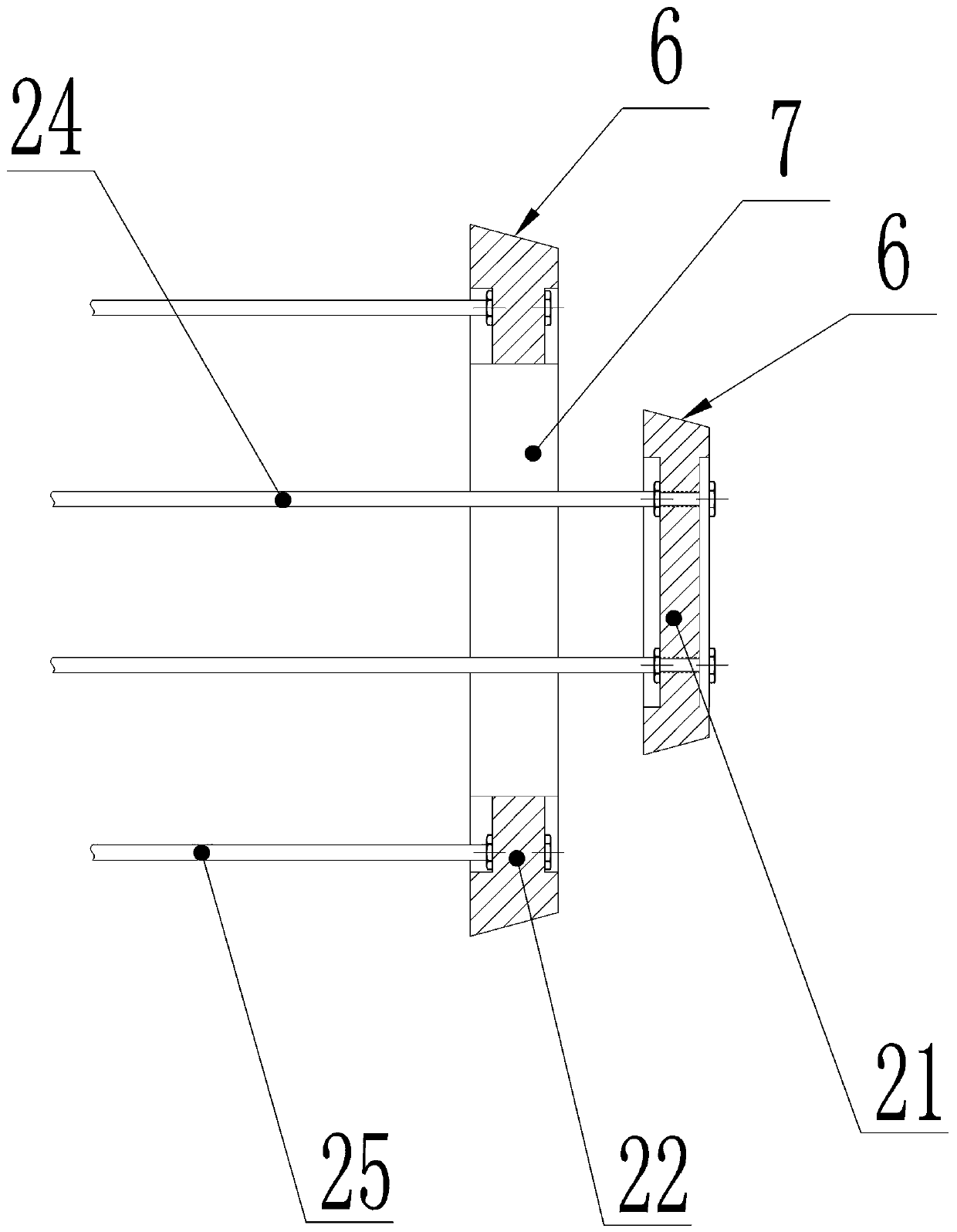

[0045] Example 2, such as image 3 As shown, an automatic measuring device and method for taper thread parameters of a graphite electrode body, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the through hole 7 is coaxial with the large plug gauge 22, and the diameter is larger than the small plug gauge 21 so that the small plug gauge 21 reciprocates through the through hole 7 driven by the first connecting rod 24 .

[0046]The computer control system 1 receives the measurement data L3, L2, L1, L3', L2', L1' (( L1, L2, L3 are the data correspondingly displayed by each digital display length meter at the left end, L1′, L2′, L3′ are the data correspondingly displayed by each digital display length meter at the right end), and then calculated according to the trigonometric function relationship or look up the table Parameters such as the taper of the taper thread at the left and right ends of the graphite electrode body 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com