Automatic elevator guide track gauge and perpendicularity measurer

An elevator guide rail and automatic measurement technology, applied in the field of measuring instruments, can solve the problems of affecting measurement accuracy, low efficiency, and high measurement labor intensity, and achieve the effect of fast and simple measurement process and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

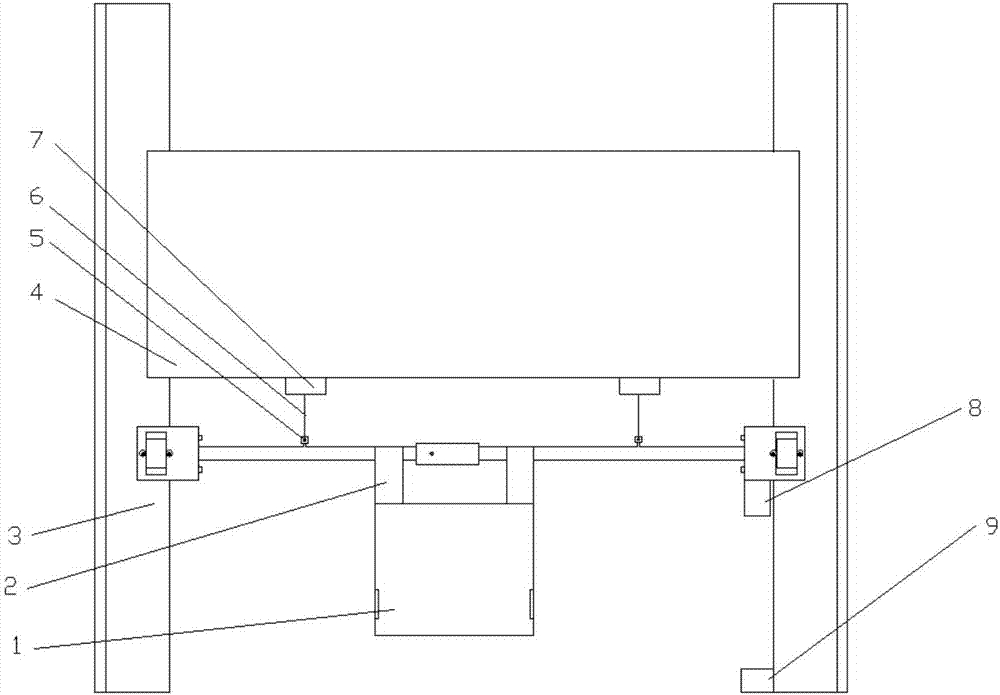

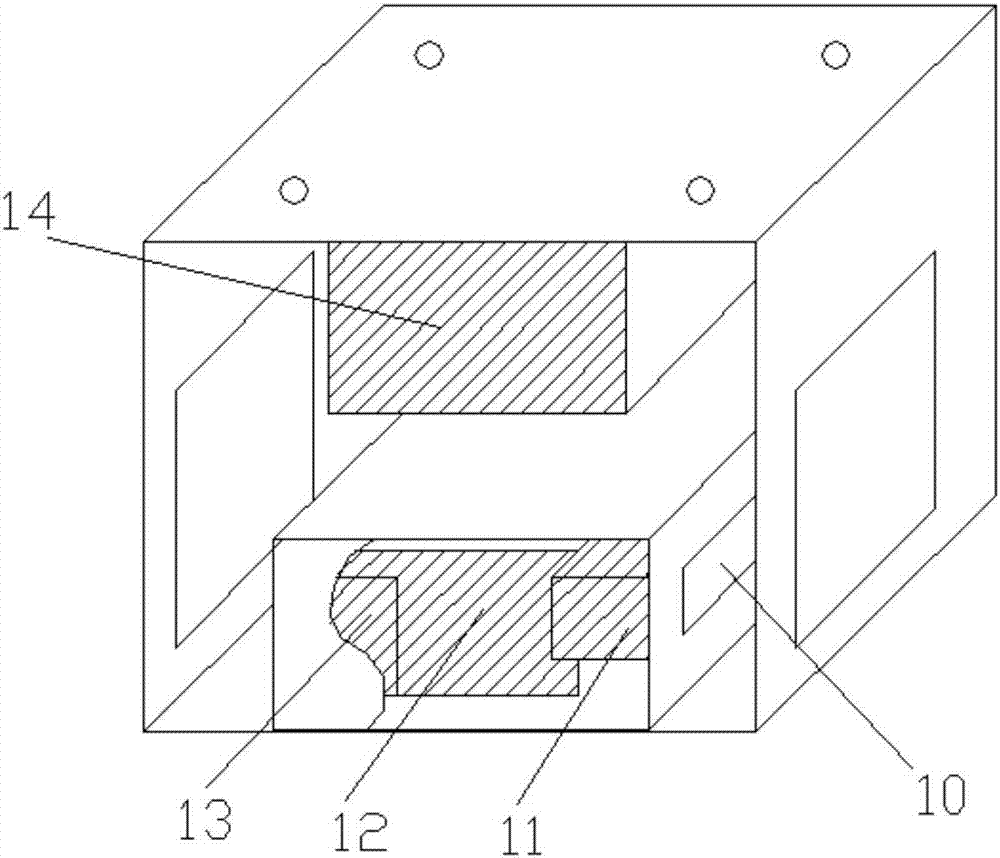

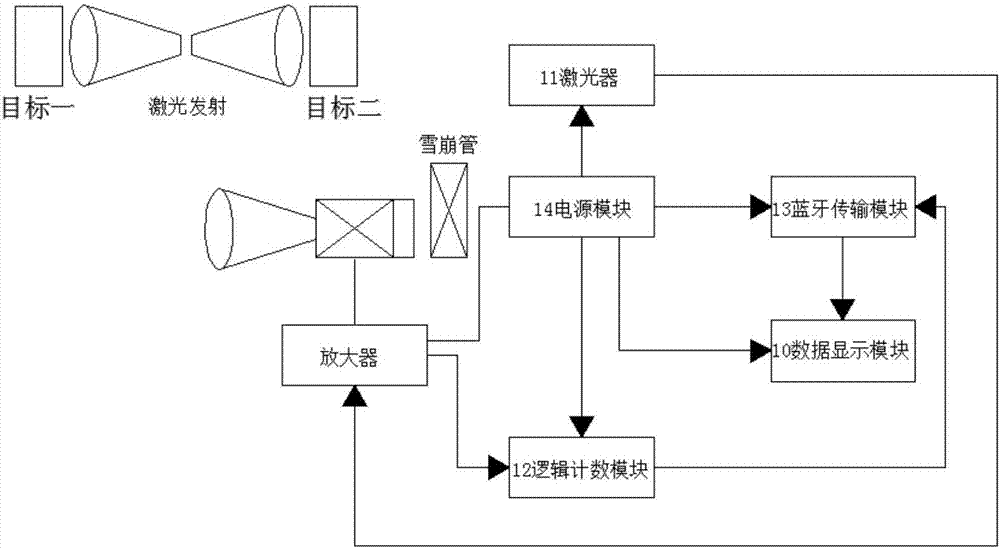

[0020] Such as Figure 1-Figure 7 As shown, the elevator guide rail gauge and verticality automatic measuring instrument includes a controller, a two-way laser gauge gauge 1, a moving bracket, an adjusting bolt 5, a steel wire rope 6, a magnet 7, a digital display target 8 and a laser light source 9, and the moving bracket The fixed plate 2 is fixedly installed at the bottom, and the fixed plate 2 is provided with a moving groove. The two-way laser gauge 1 is slidingly connected with the fixed plate 2, so as to ensure that the two laser beams of the two-way laser gauge 1 are shot on the top surface of the elevator guide rail 3 during measurement. , to measure the effective data of the guide rail gauge, the two ends of the moving bracket are slidingly connected with the elevator guide rail 3, and there are two adjusting bolts 5 threaded on the moving bracket, and the two adjusting bolts 5 are distributed on both sides of the two-way laser track gauge 1 , the adjusting bolt 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com