Measuring device and method for height of melt of aluminum electrolytic cell and pressure drop of furnace bottom

A technology of aluminum electrolytic cell and melt height, applied in the field of aluminum electrolysis, can solve the problems of reduced probe sensitivity, high labor intensity, and decreased measurement accuracy, so as to improve measurement accuracy and reliability, reduce labor intensity, and improve control level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

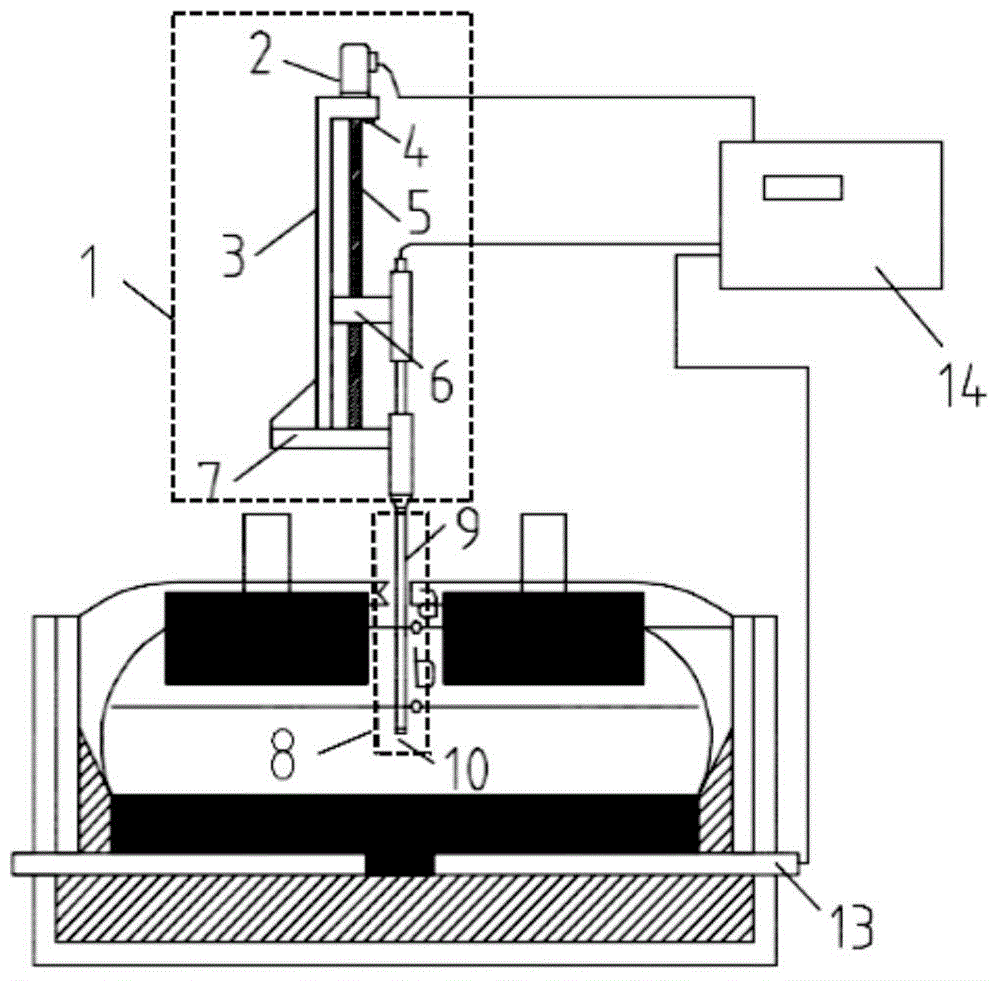

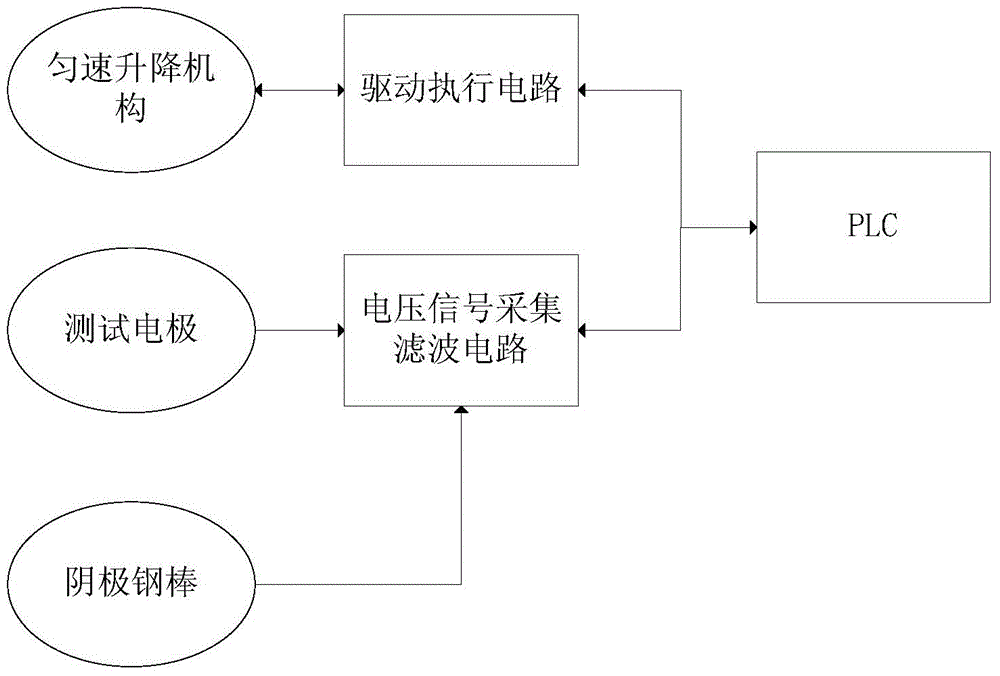

Method used

Image

Examples

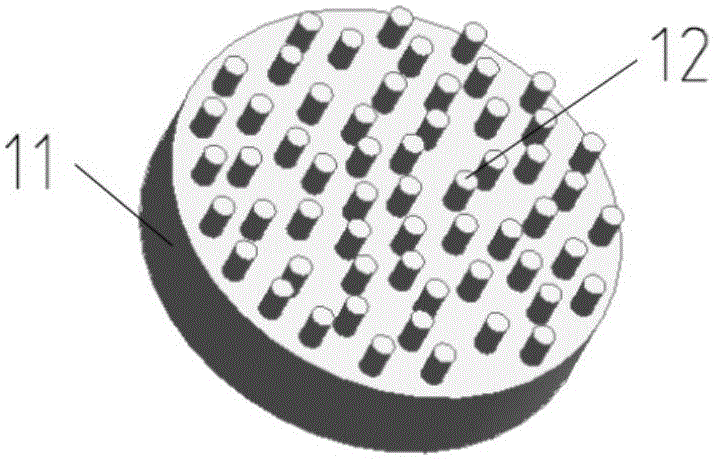

Embodiment Construction

[0024] The method of automatic measurement of melt height and furnace bottom pressure drop proposed by the present invention is based on the fact that there is a huge difference in the resistivity of air, molten aluminum and electrolyte, especially the difference of nearly 15,000 times between molten aluminum and electrolyte. This method specifically proposes to conduct derivative processing on the potential data, by analyzing the potential-displacement Curves and Potential Rate-Displacement The curve is used to determine the air-electrolyte interface a and the electrolyte-aluminum liquid interface b, and then calculate the melt height and furnace bottom pressure drop. The electrolyte-air interface a is or The electrode probe position S corresponding to the maximum value of the curve a . During the operation of the electrolytic cell, the interface b of the electrolyte-aluminum liquid is in a fluctuating state and there is a fuzzy diffusion layer at the interface, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com