High-precision automatic measurement device for batch equipment attitude angle matrix on satellite

A technology of measuring devices and mobile devices, which is applied in the direction of using feedback control, theodolite, etc., and can solve the problems of inability to realize automatic measurement and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following introduces the specific implementation mode as the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

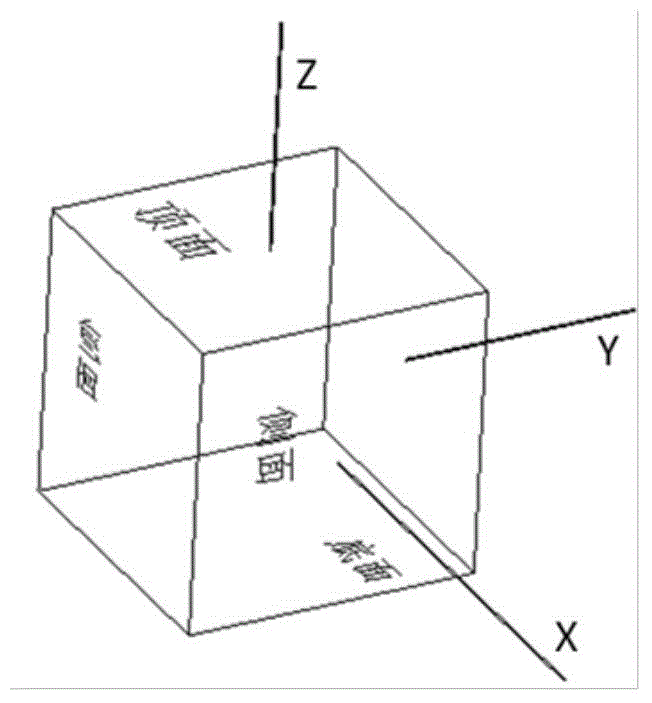

[0023] In this paper, the term "reference cube" refers to an orthorhomb made of optical glass, such as figure 1 As shown, including the top surface, bottom surface and four sides, each surface is coated with a reflective film, the normals of each adjacent two reflective surfaces are orthogonal to each other, and the three mutually orthogonal mirror normals represent the coordinate system of the device body The coordinate axes x, y, z point to.

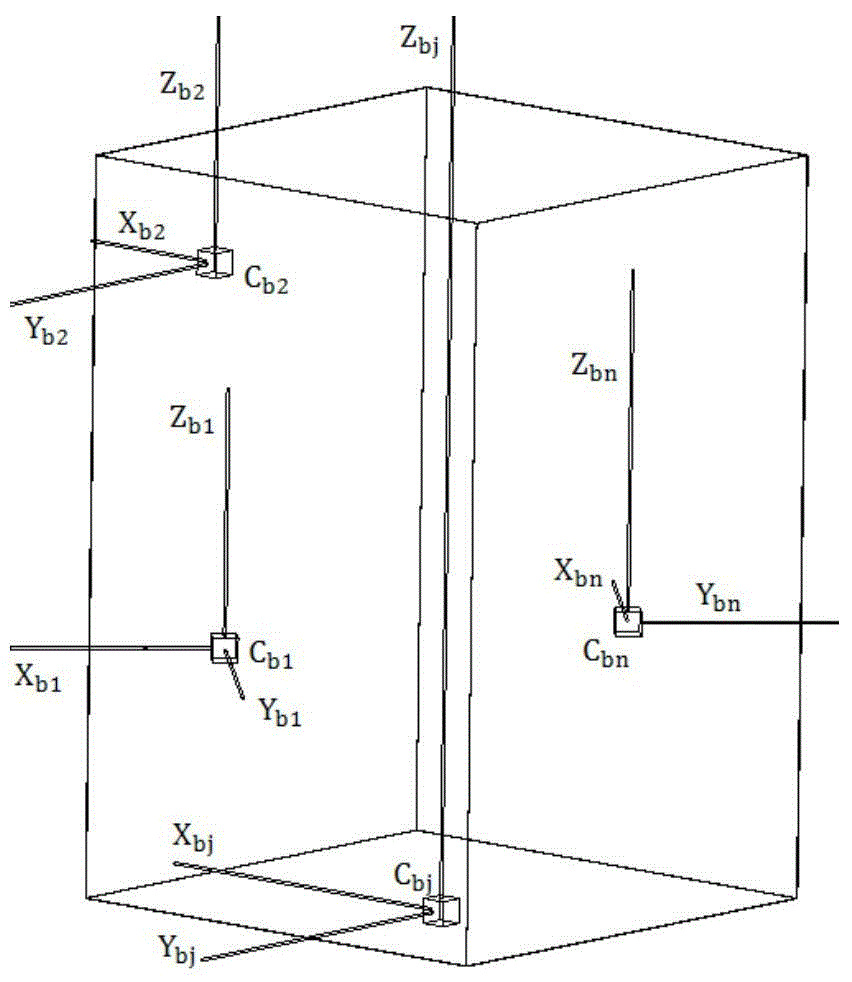

[0024] Different reference cube mirrors can be used on the satellite to be tested to represent different equipment set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com