Cathode roller machine

A cathode roller and roller shaft technology, applied in the direction of electrodes, electrolytic coatings, phosphating, etc., can solve problems such as insufficient conductive capacity, impact on bearing life, poor conduction performance, etc., to reduce heat generation, meet continuous production, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical features and technical effects of the technical solution of the present invention more clear, the exemplary solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention.

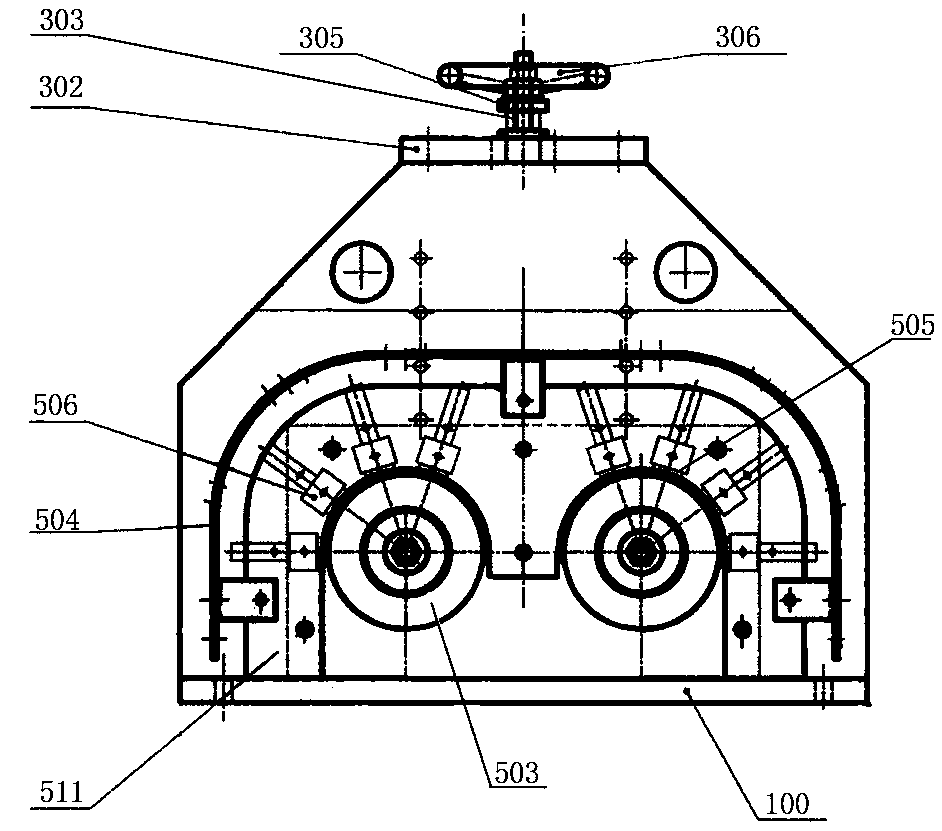

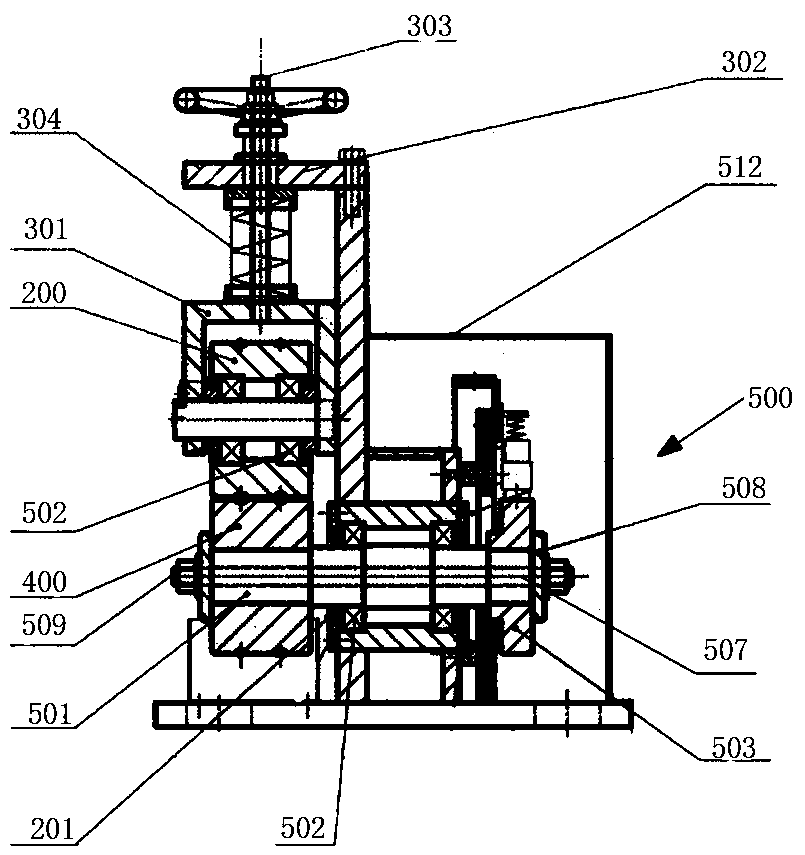

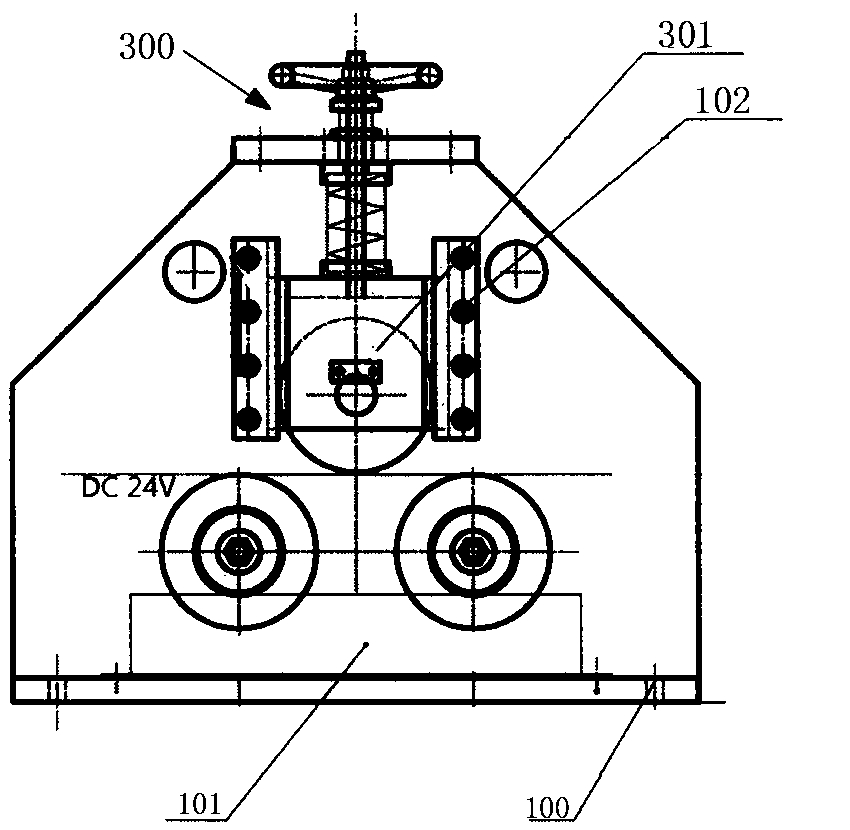

[0029] see Figure 1-Figure 3 , a cathode roller machine of the present invention, comprising a headstock 100, an upper roller 200, a lower roller 400 and a carbon brush assembly 500, the upper roller 200 is arranged on the headstock 100, and the upper roller 200 and the machine An adjustment assembly 300 is arranged between the headstocks 100, and the adjustment assembly 300 drives the upper roller 200 to move; the two lower rollers 400 are arranged on the headstock 100, and the two lower rollers 400 are connected to the The upper roller 200 is arranged in a triangle; the carbon brush assembly 500 is arranged corresponding to the lower rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com