Integral combined-type heat absorber of solar thermomotor

A heat absorber and heat engine technology, which is applied in the field of integral combined heat absorbers, can solve the problems of absorbing solar radiation energy loss, high technical difficulty of processing technology, and influence of heat absorption effect, and achieve reliable processing technology and gas heat exchange Good effect, convenient for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

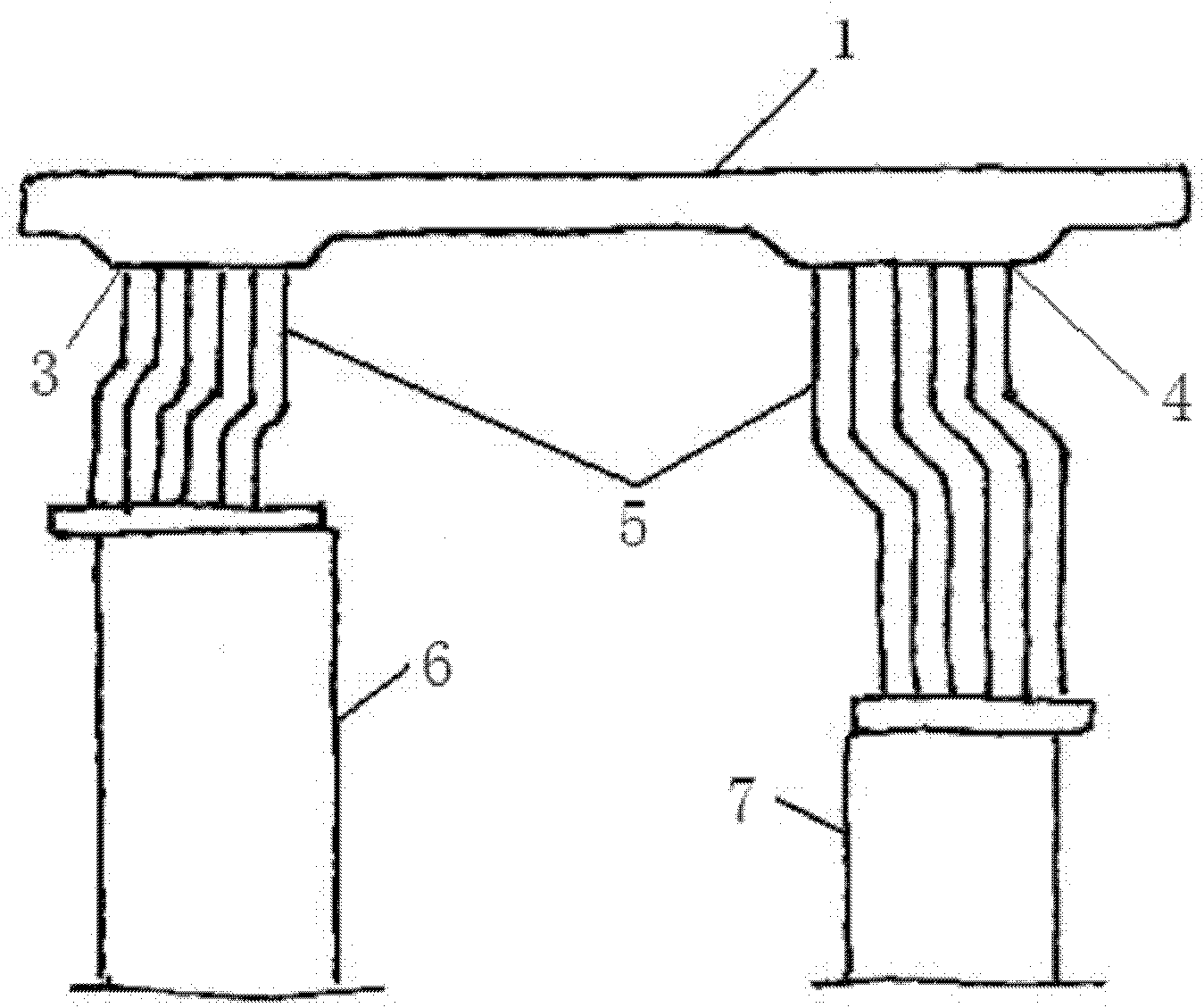

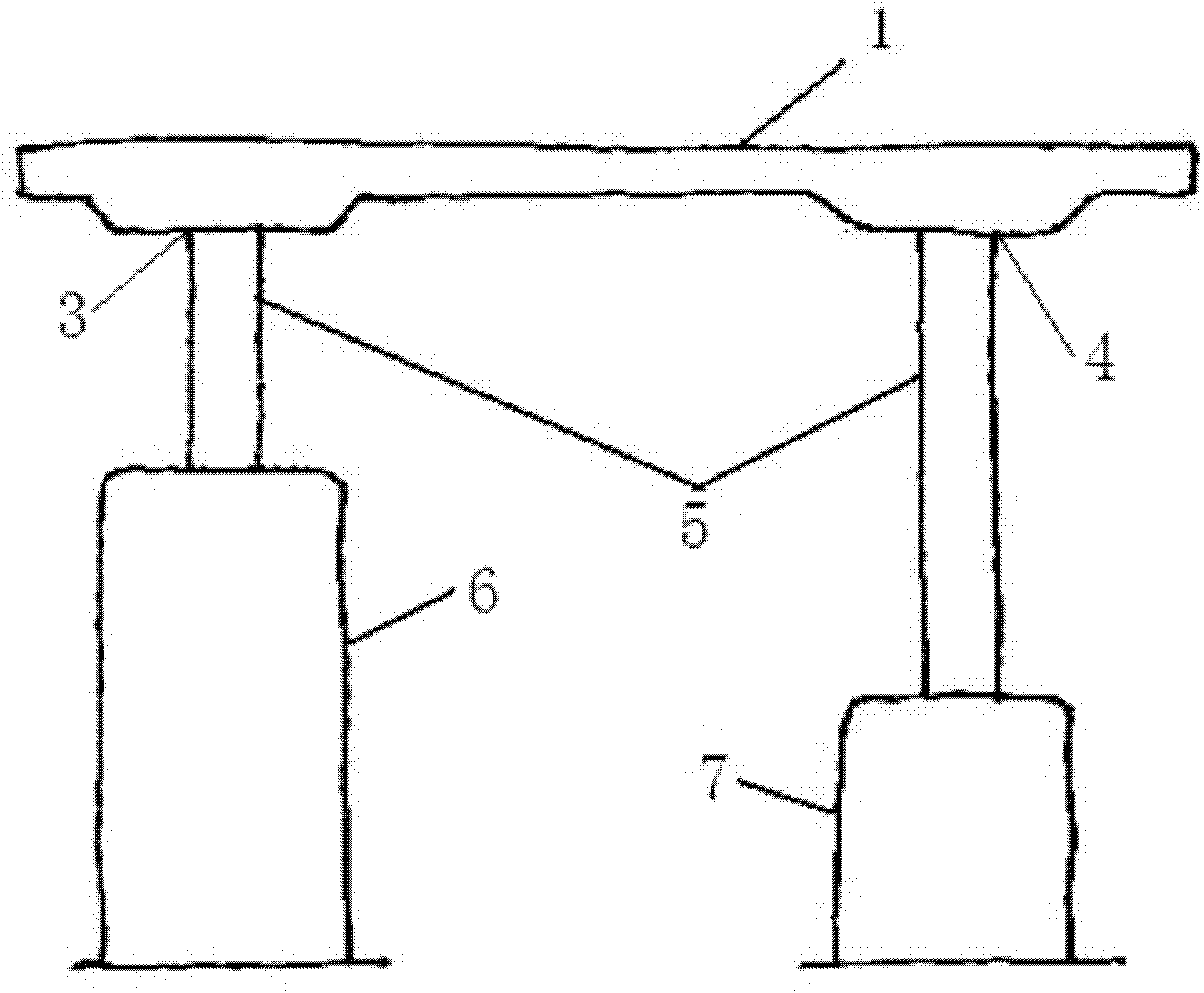

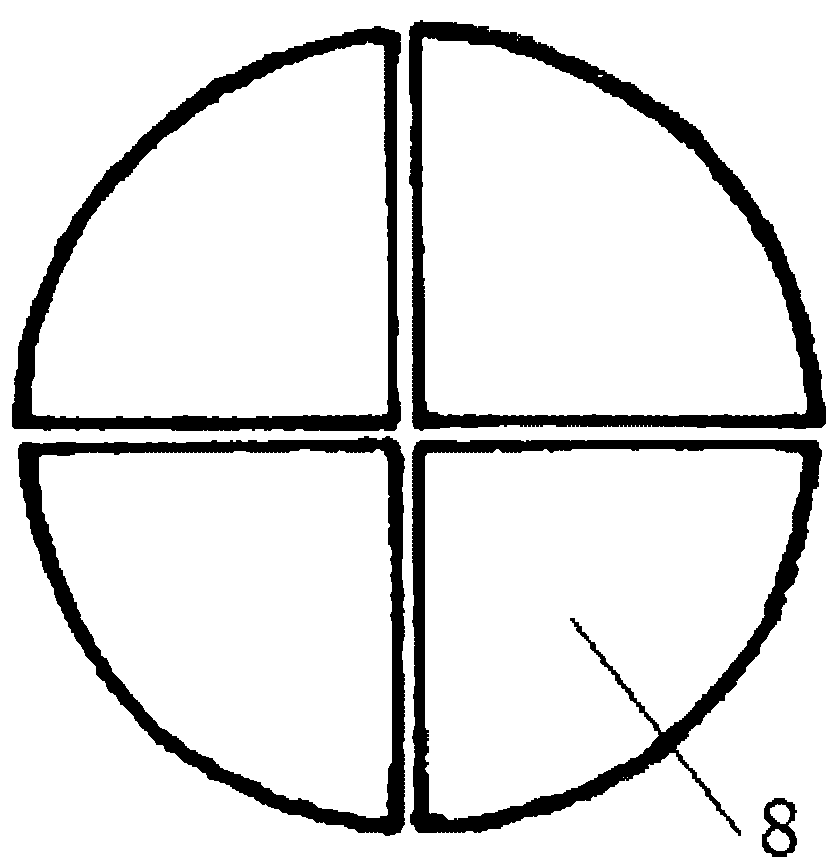

[0032] The integral combined heat absorber of the solar energy heater of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0033] The heat absorber device involved in the present invention is generally located at the front of the solar heat engine, that is, near the focus of the solar concentrator, and it essentially belongs to a gas heat exchanger that absorbs solar radiant heat.

[0034] The front side of the combined overall heat absorber faces the solar concentrating mirror and absorbs the radiant heat reflected by the mirror. In order to reduce the heat dissipation loss of the heat absorber, it is necessary to set an outer cover with heat preservation function around it, also called a heat collecting chamber. At the same time, the back of the heat absorber is also provided with thermal insulation material, which not only serves as heat protection for the rear parts, but also plays a role of heat insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com